Patents

Literature

160 results about "Downhole safety valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A downhole safety valve refers to a component on an oil and gas well, which acts as a failsafe to prevent the uncontrolled release of reservoir fluids in the event of a worst-case-scenario surface disaster. It is almost always installed as a vital component on the completion.

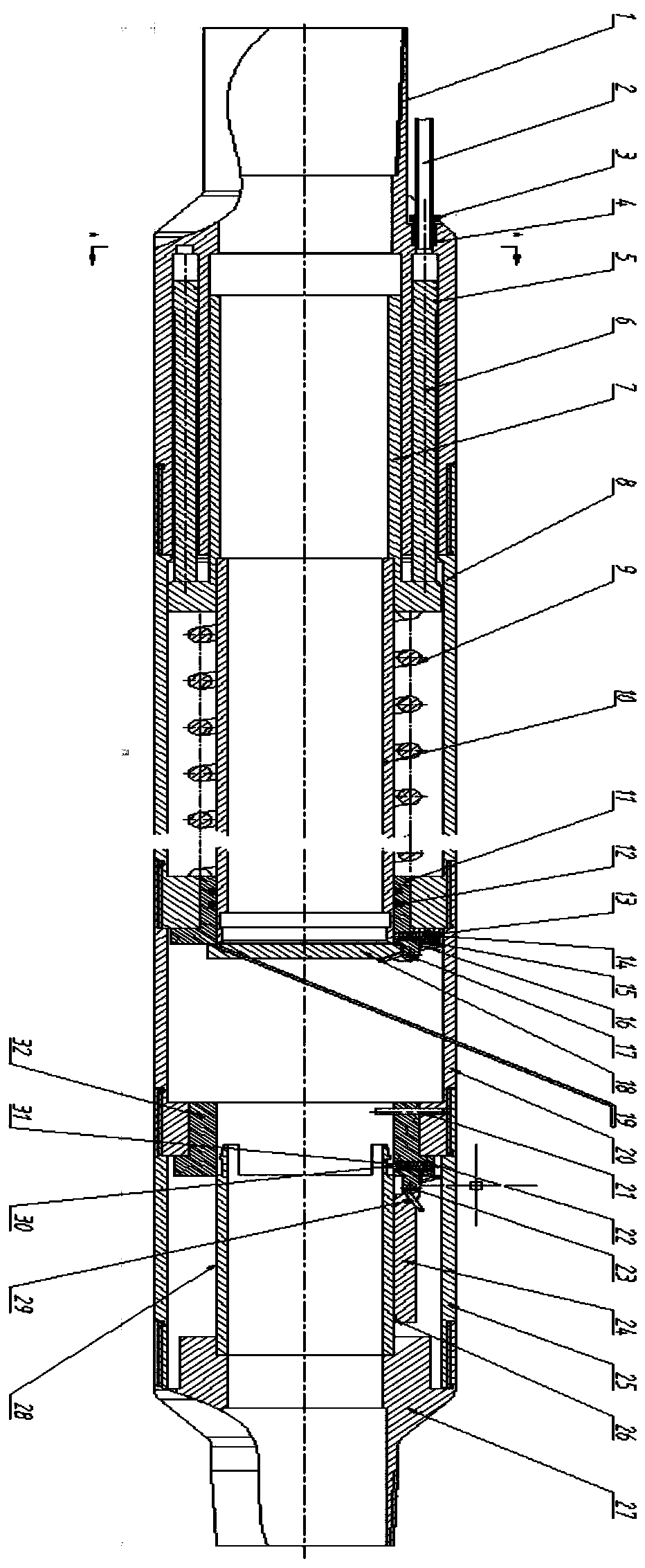

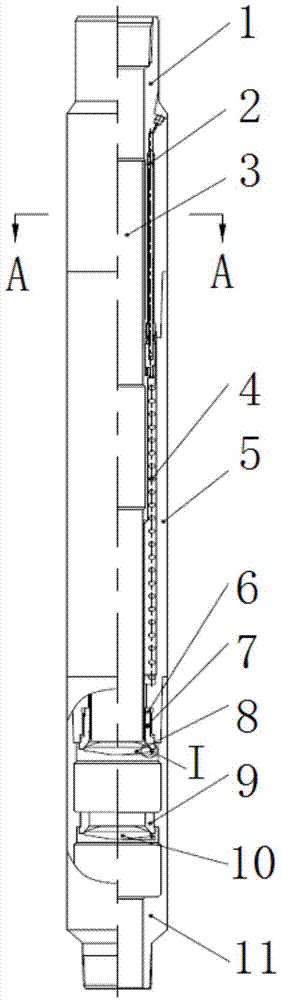

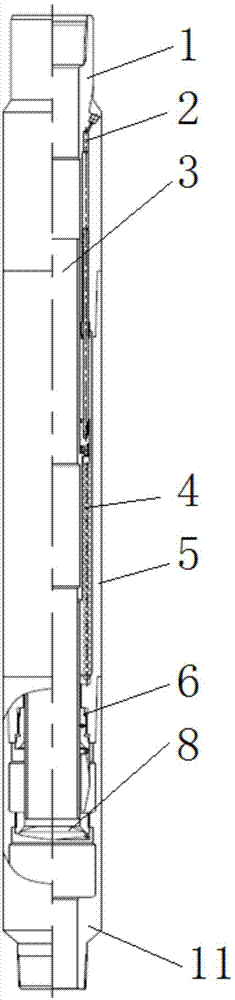

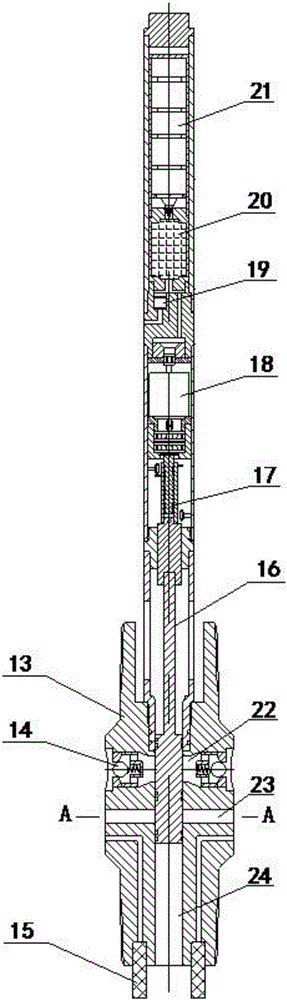

Fully-electrically driven downhole safety valve

ActiveUS10989019B2Improve response speedImprove working conditionsOperating means/releasing devices for valvesConstructionsControl systemMotronic

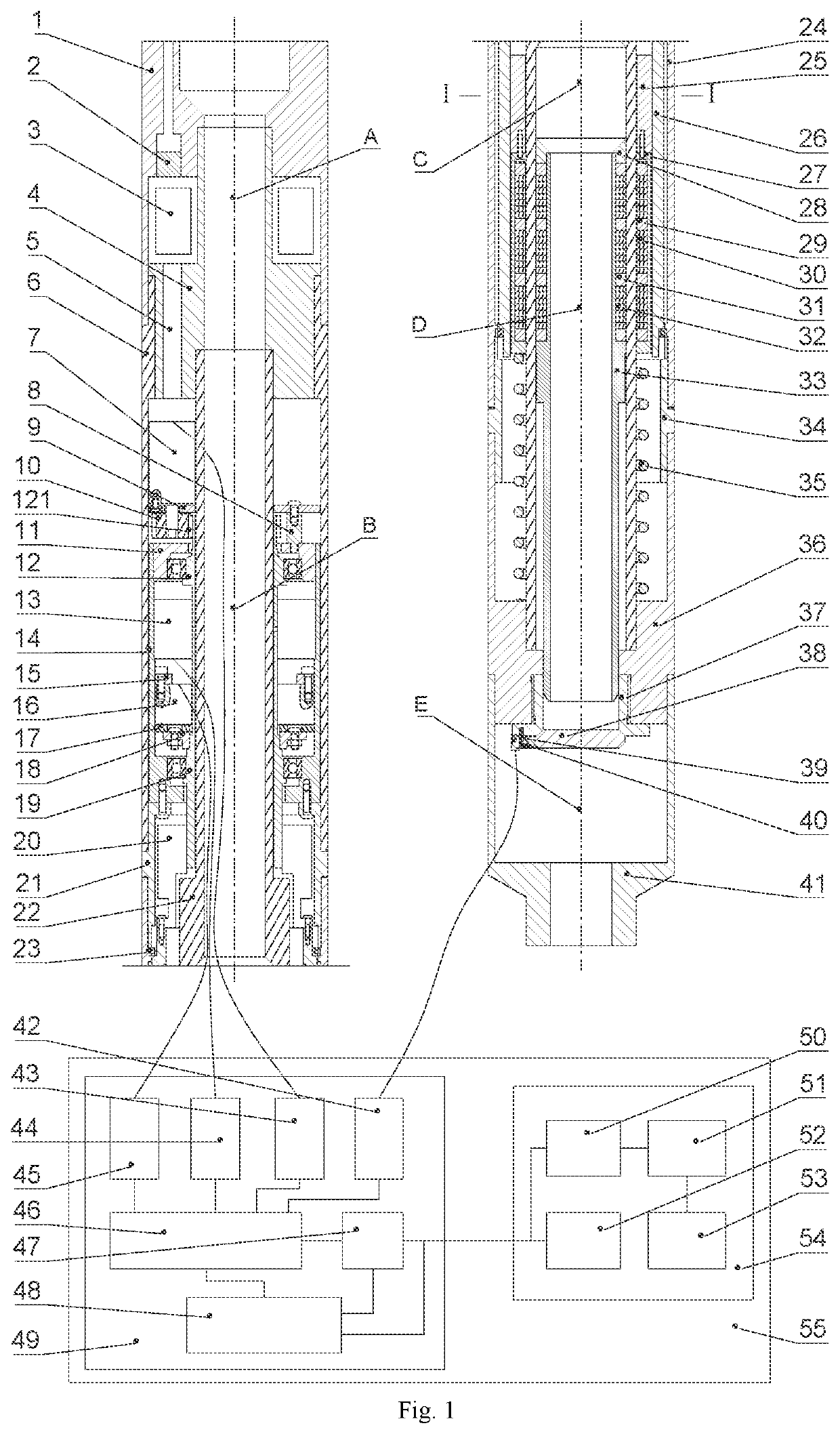

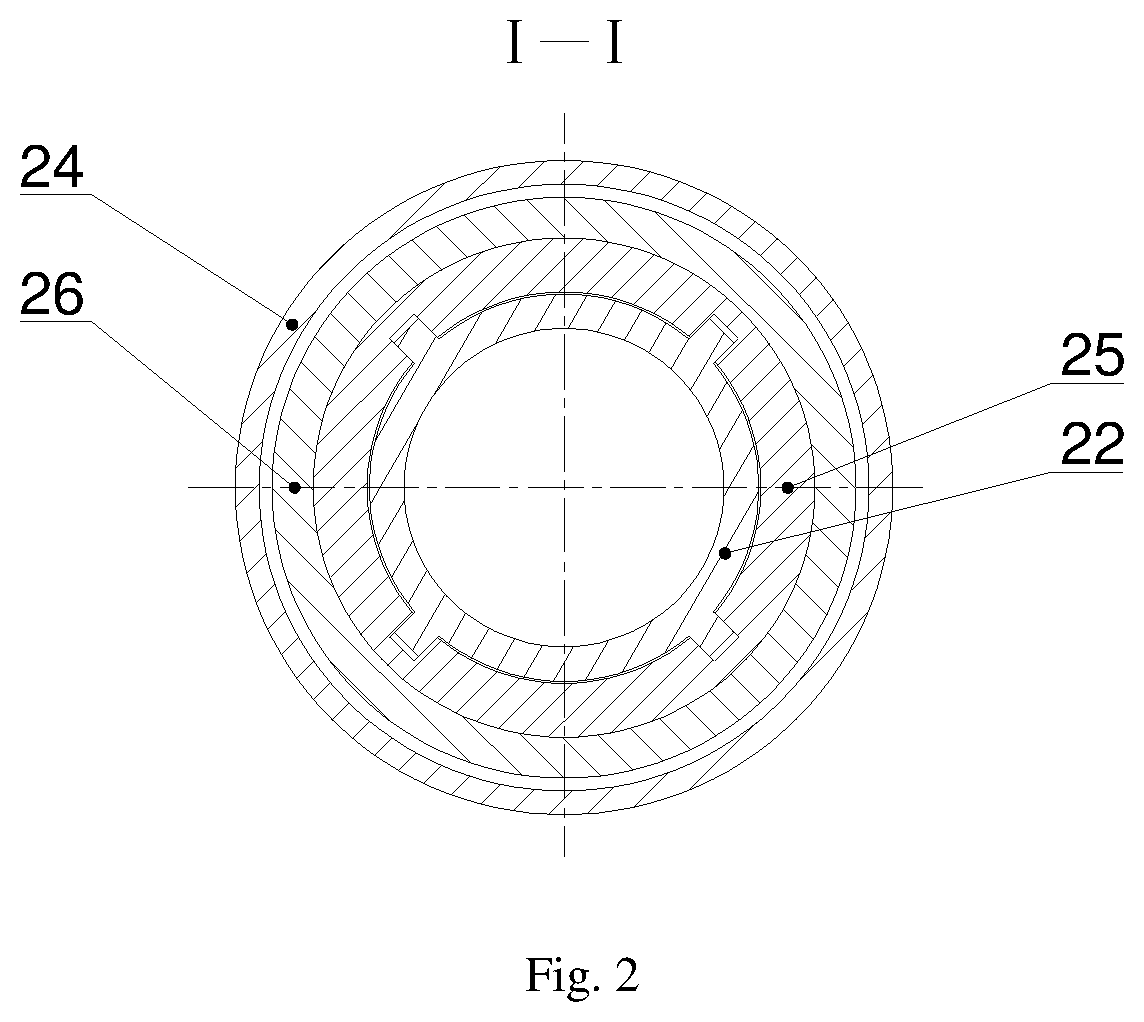

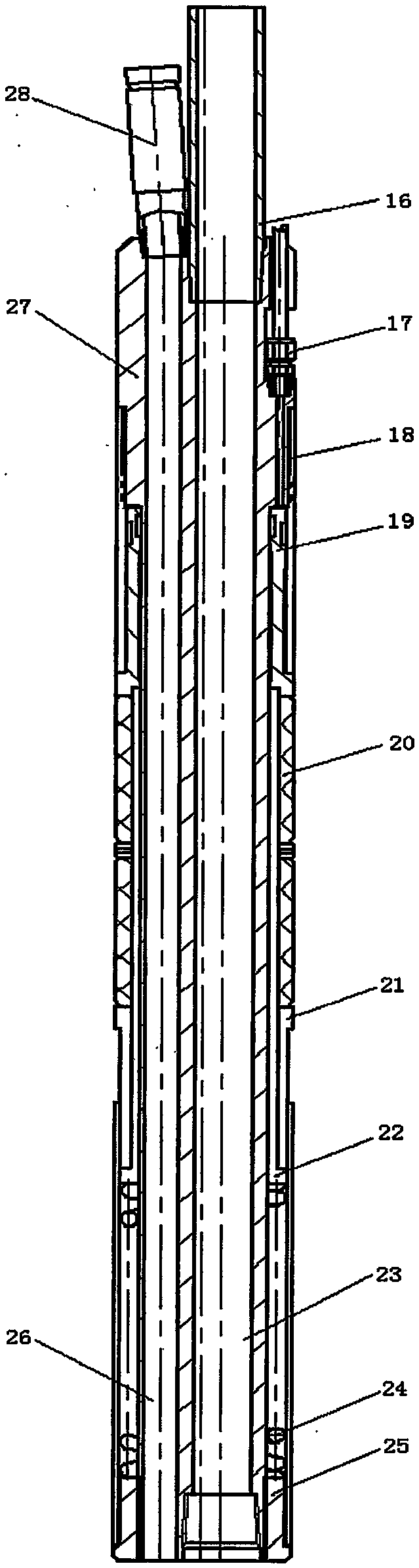

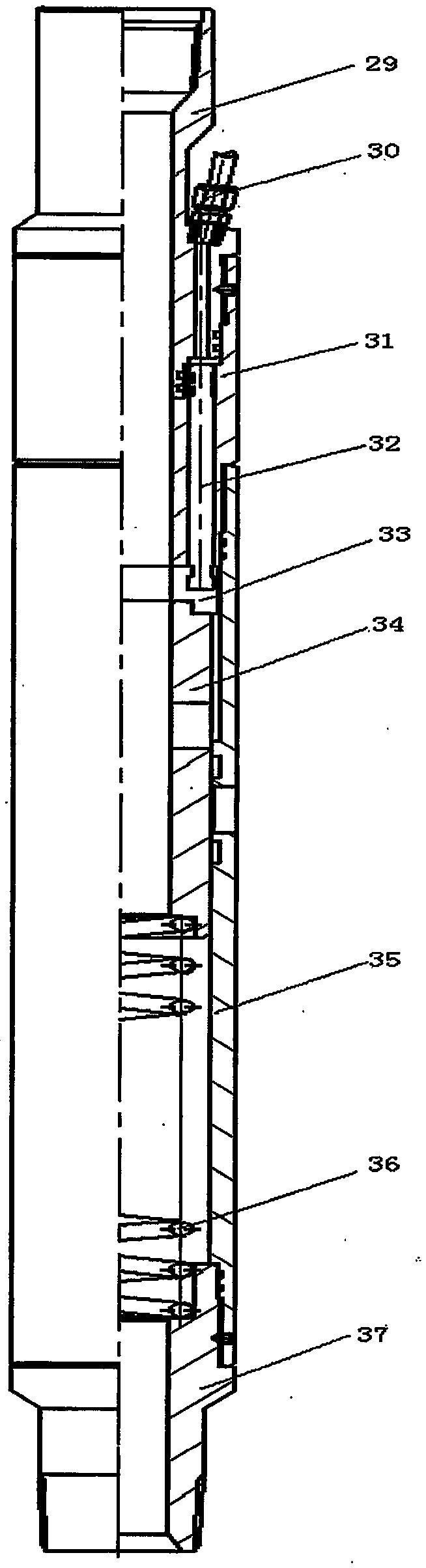

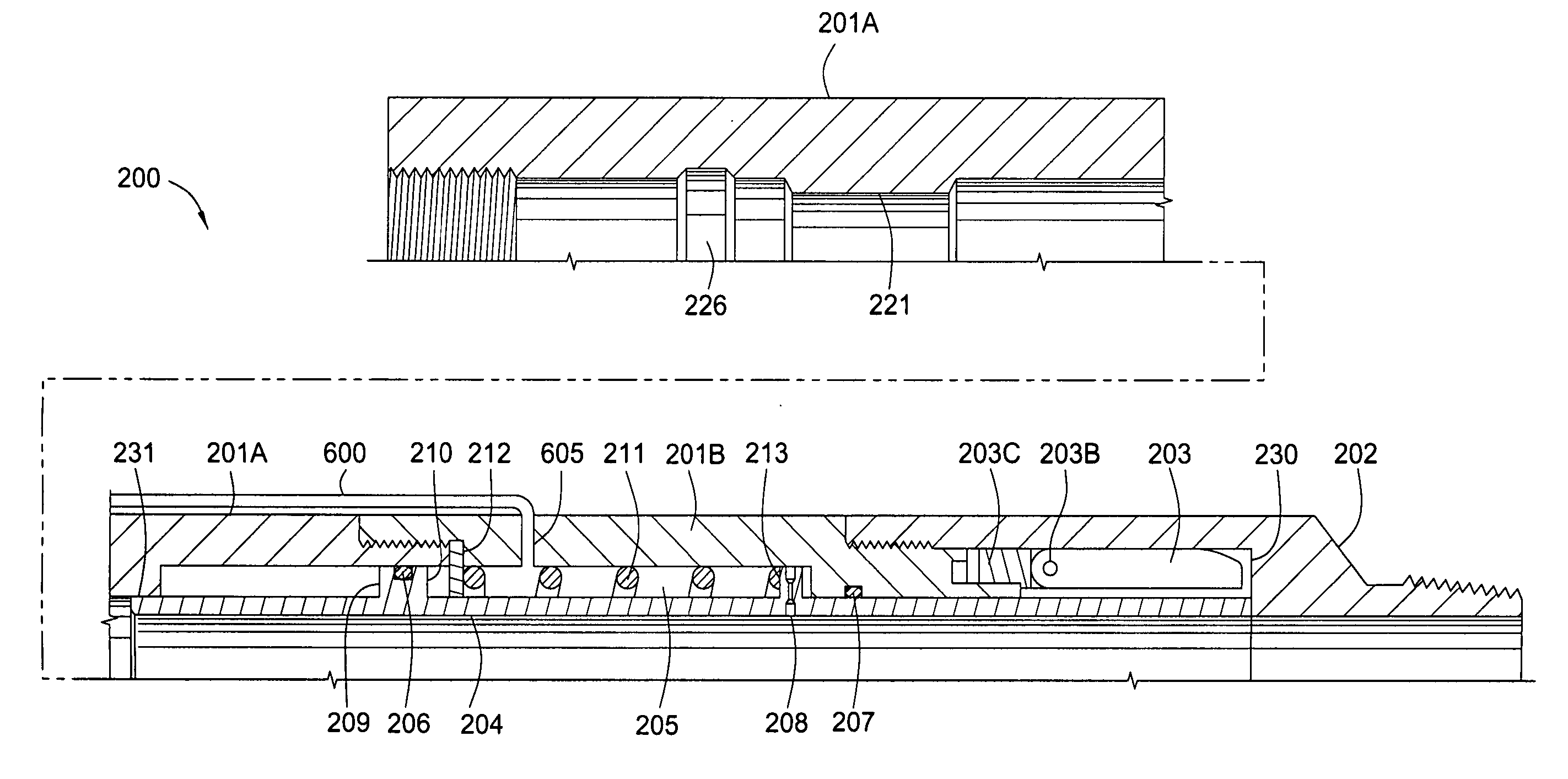

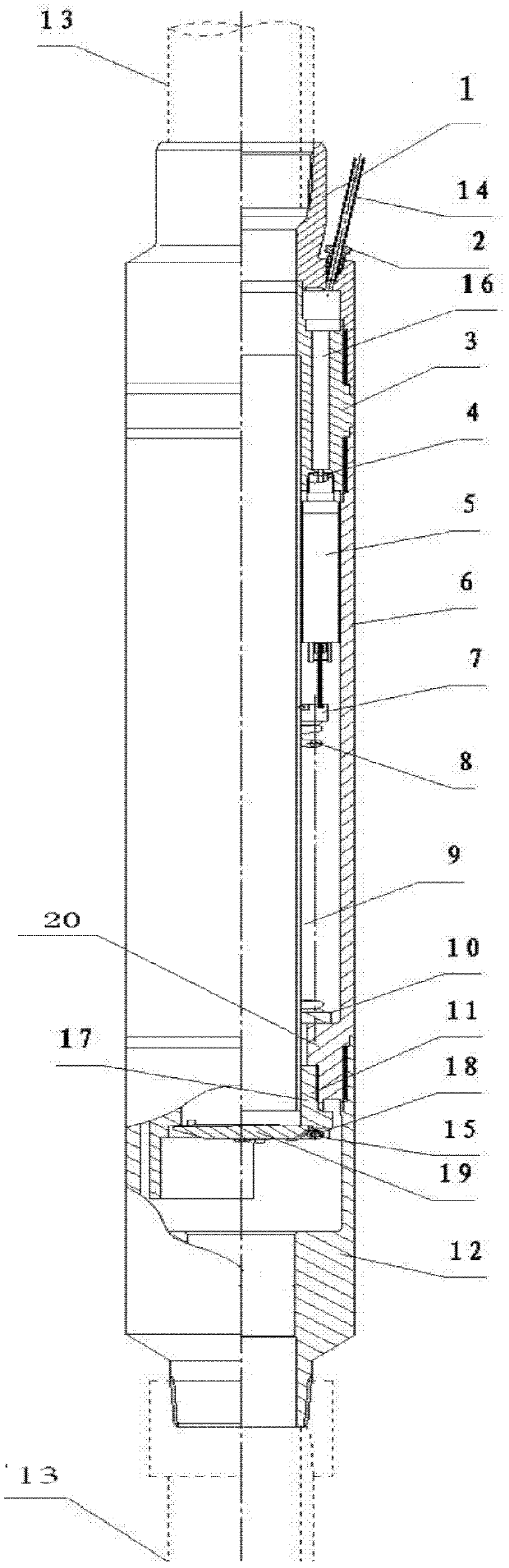

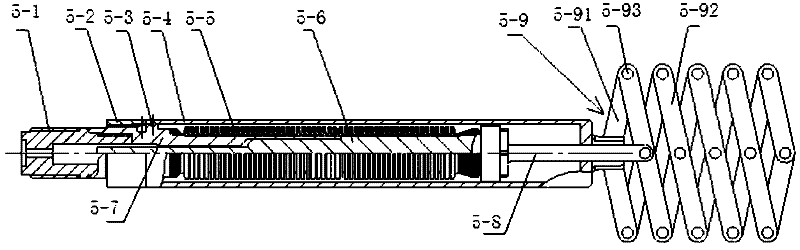

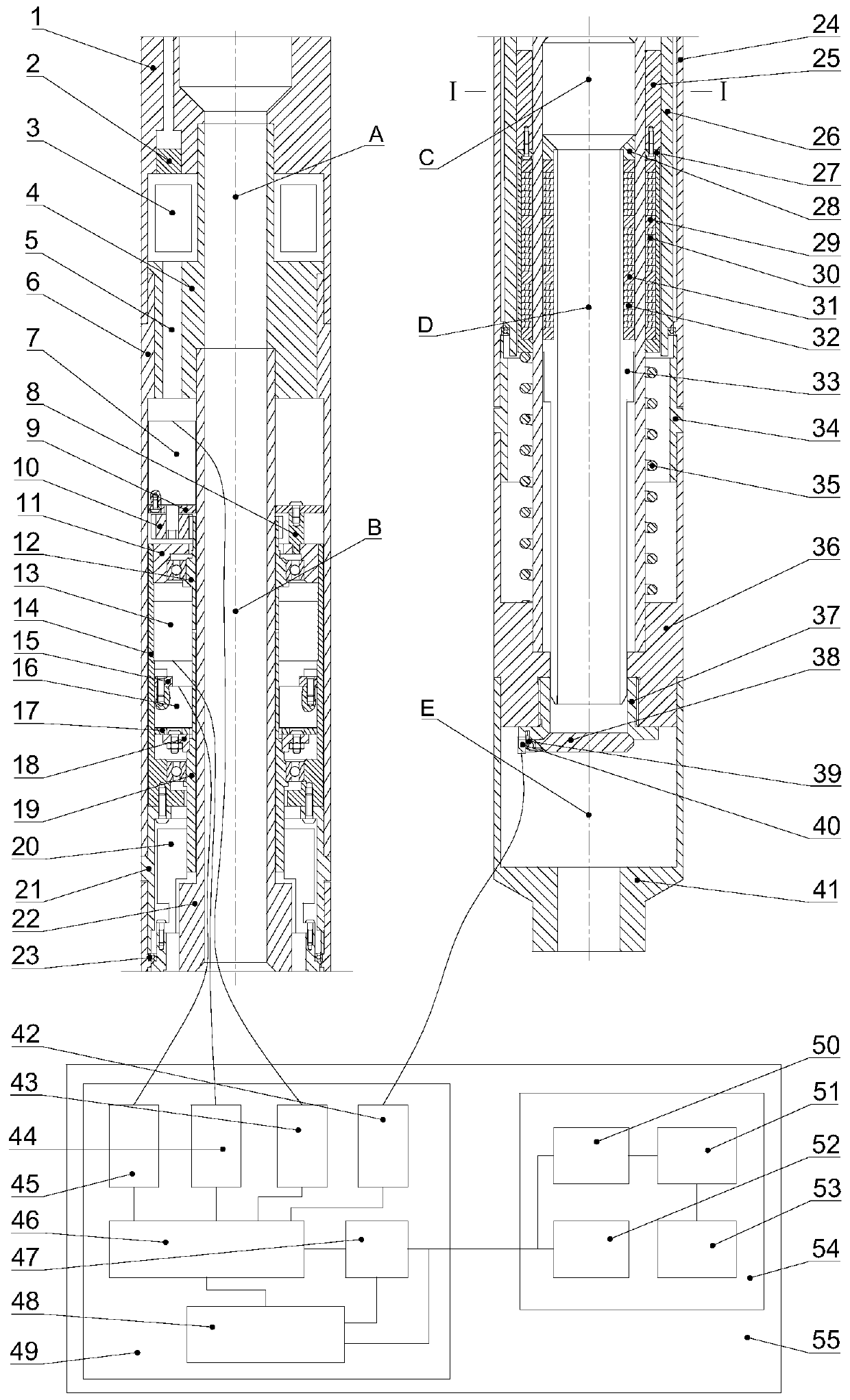

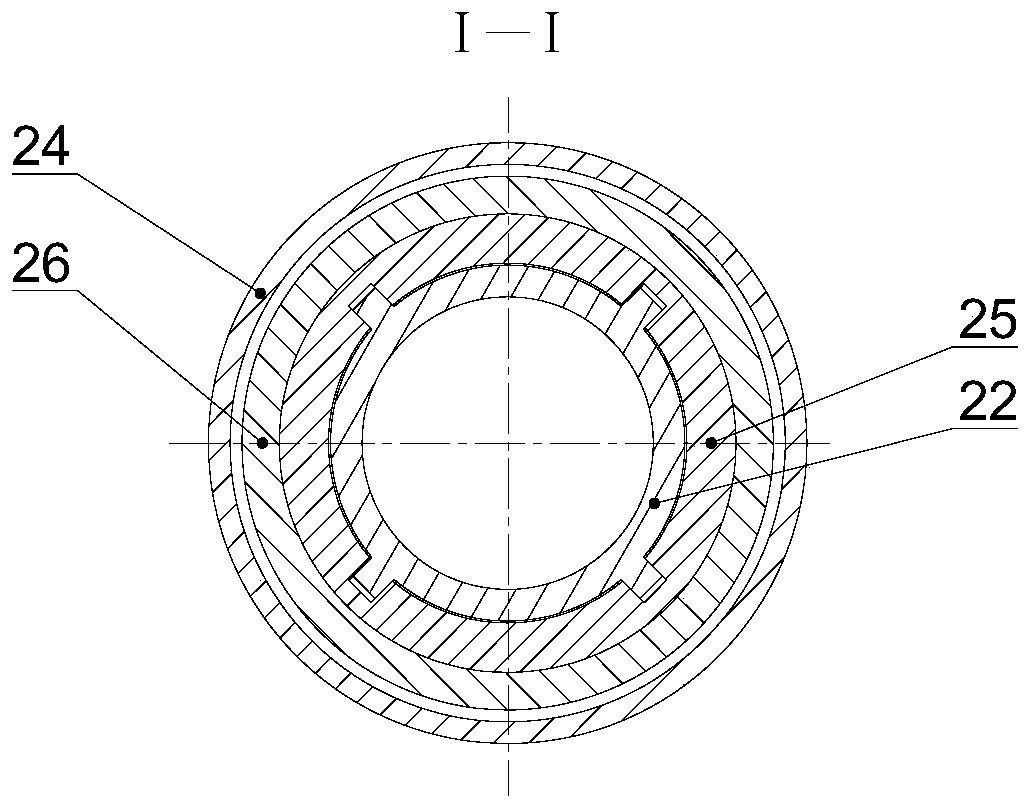

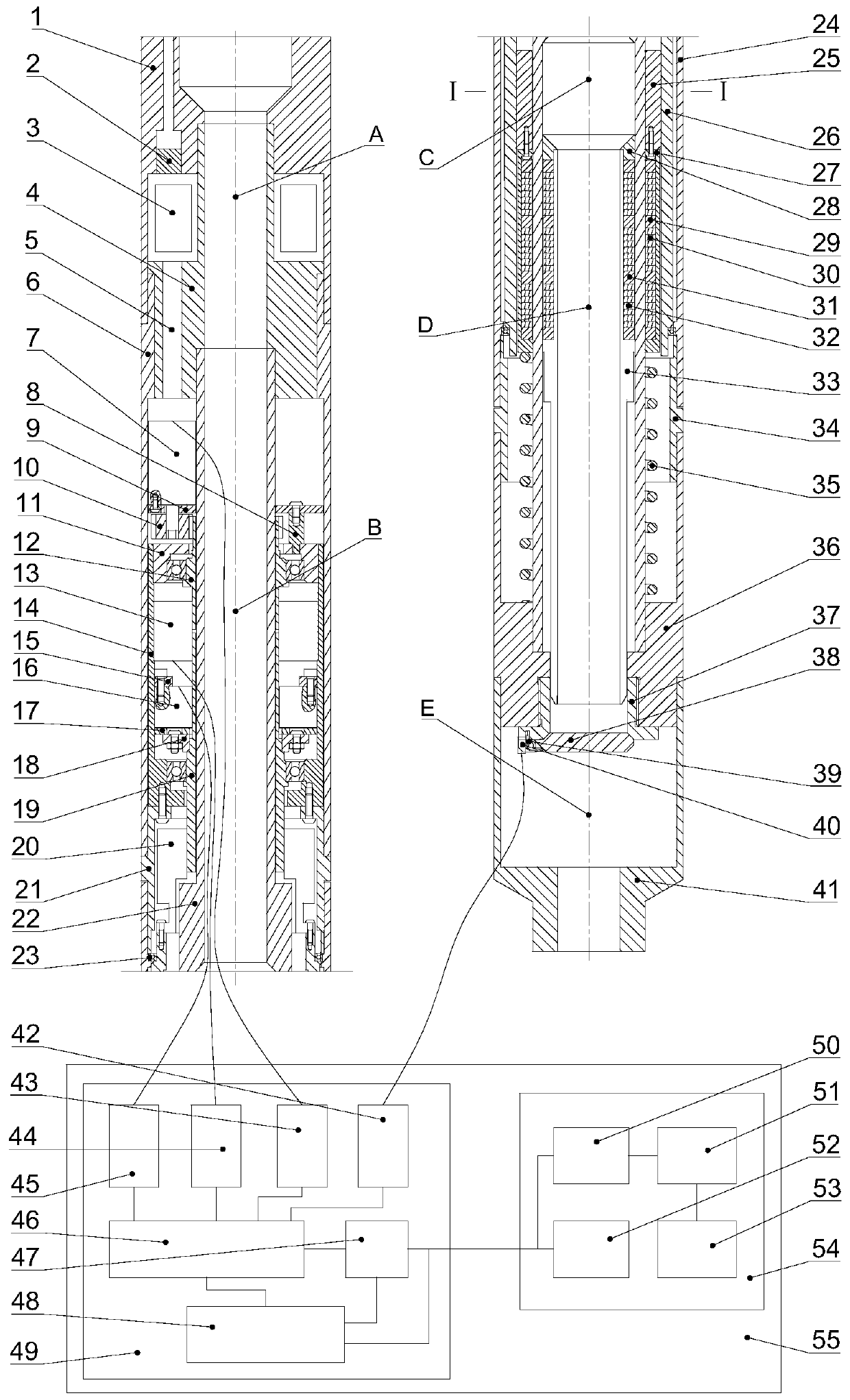

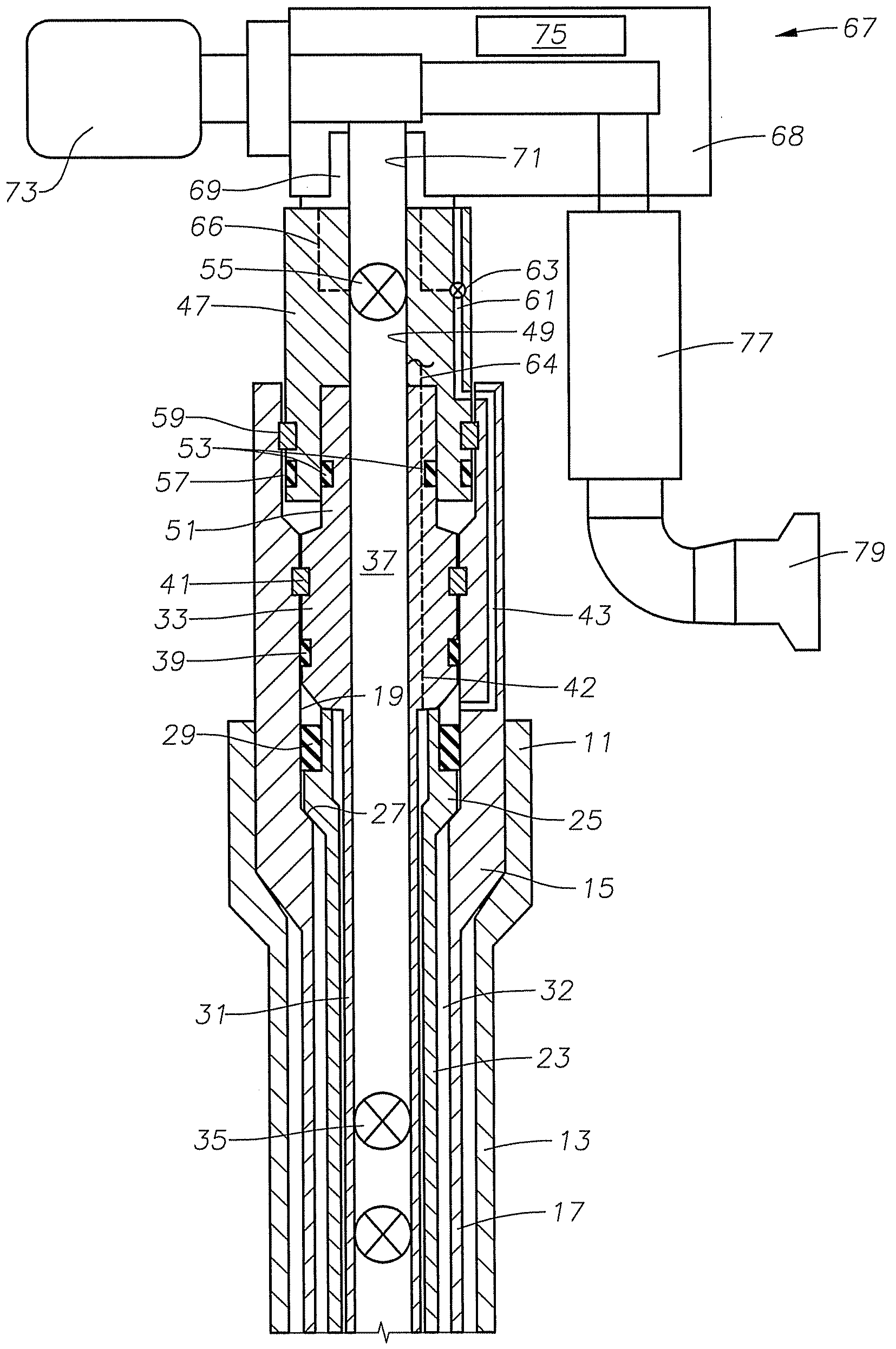

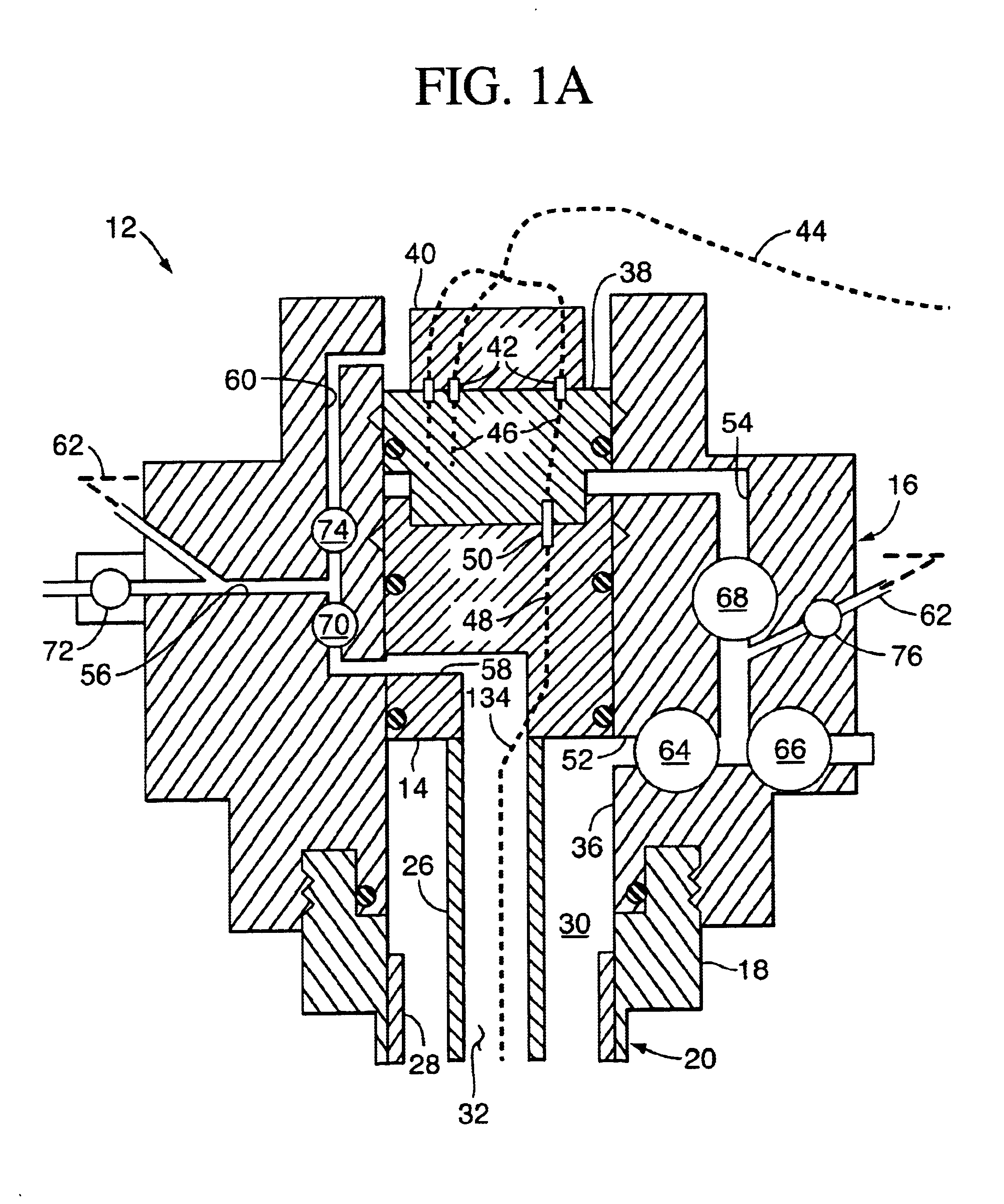

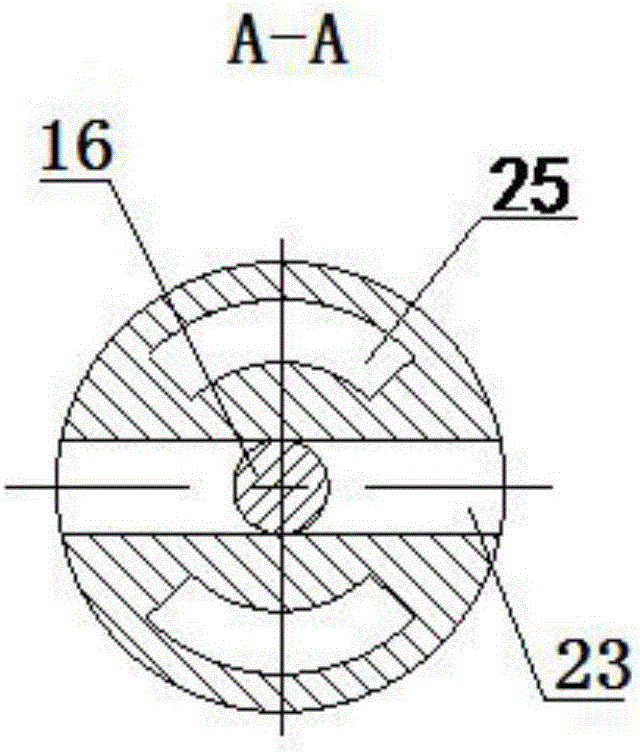

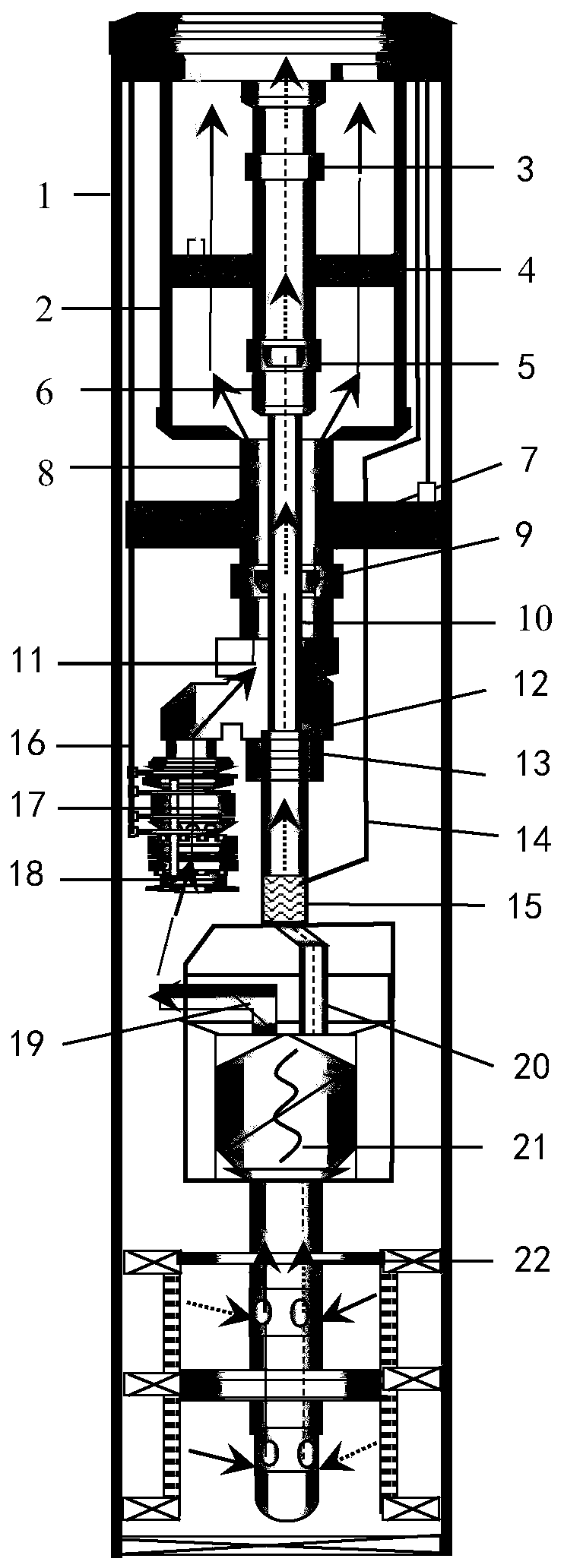

The present disclosure belongs to the field of petroleum engineering, in particular to a fully-electrically driven downhole safety valve. The fully-electrically driven downhole safety valve comprises a downhole safety valve mechanism and a downhole safety valve control system; wherein the downhole safety valve mechanism includes an electronic cabin module, a transmission control module, a motion conversion module, a magnetic coupling and spring module. and a valve module; the downhole safety valve control system includes a downhole comprehensive unit and an uphole comprehensive unit.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

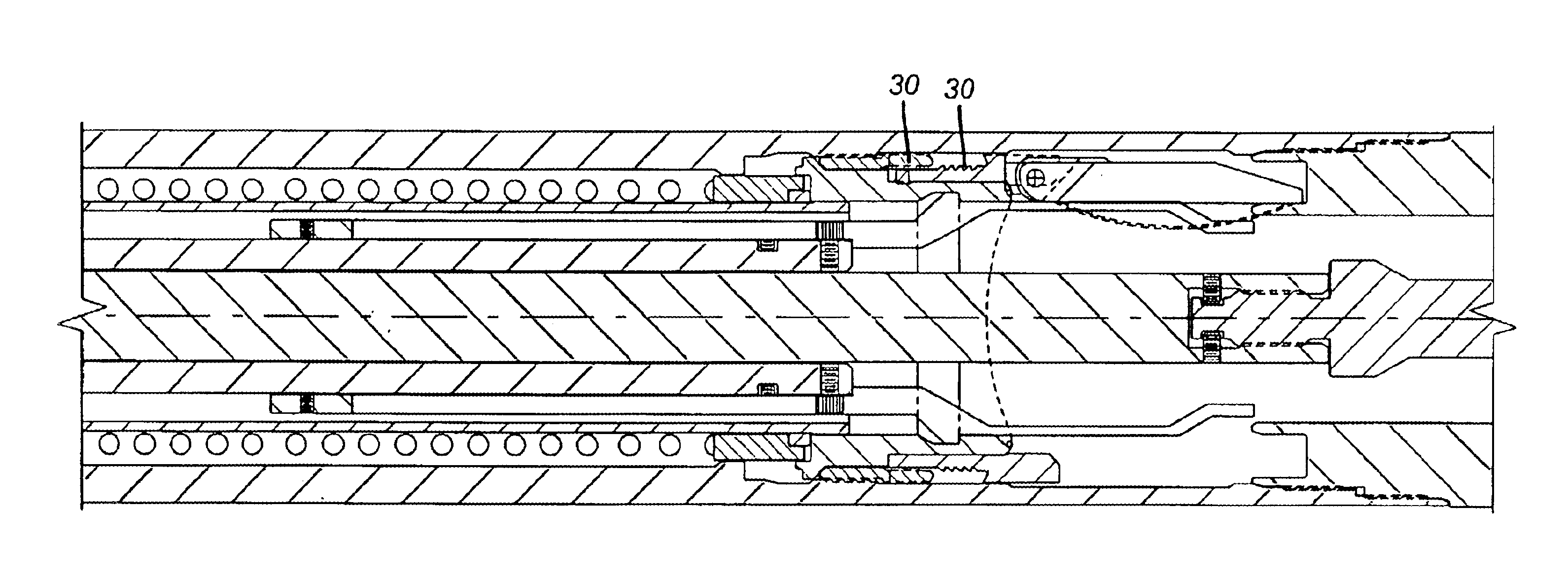

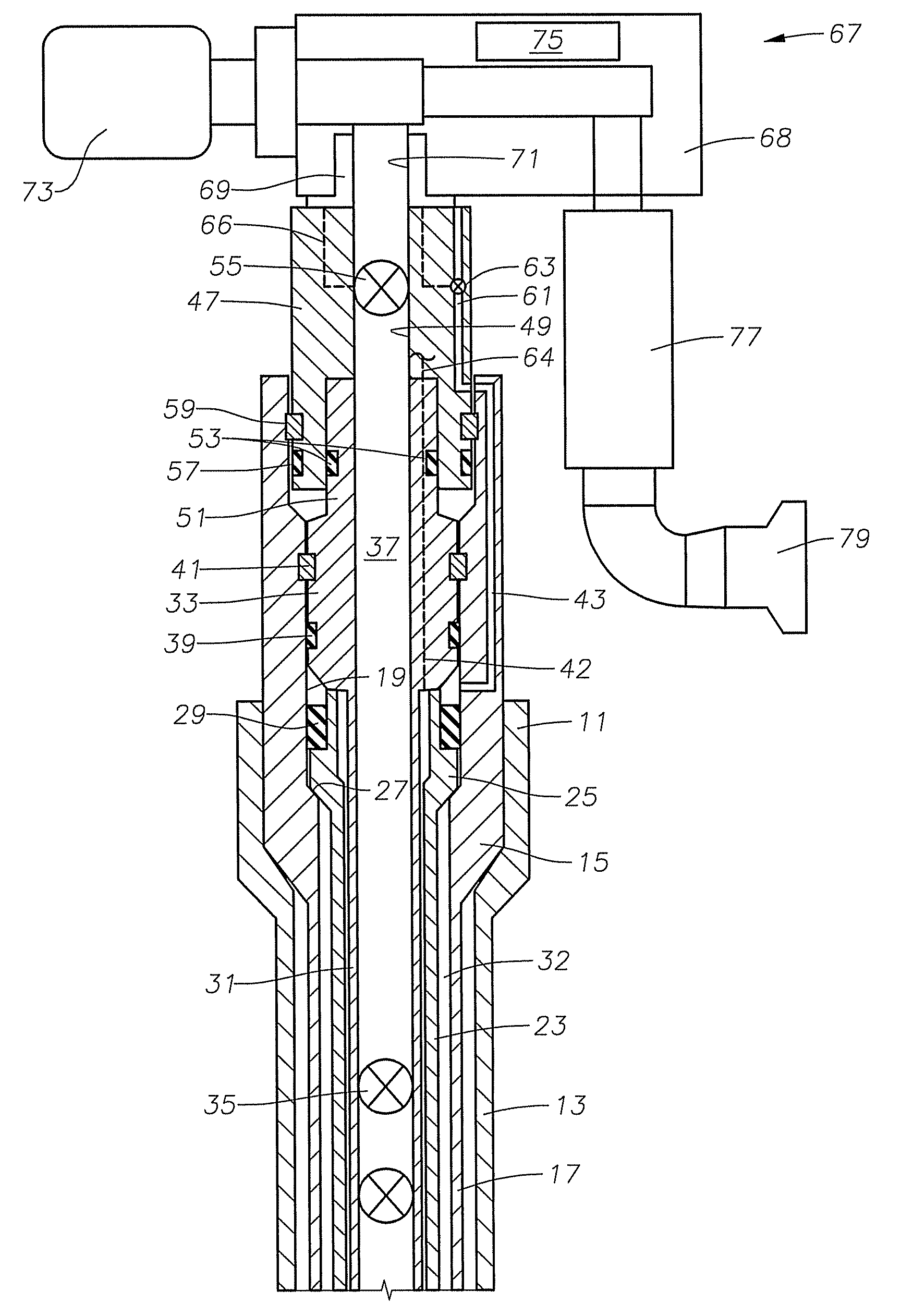

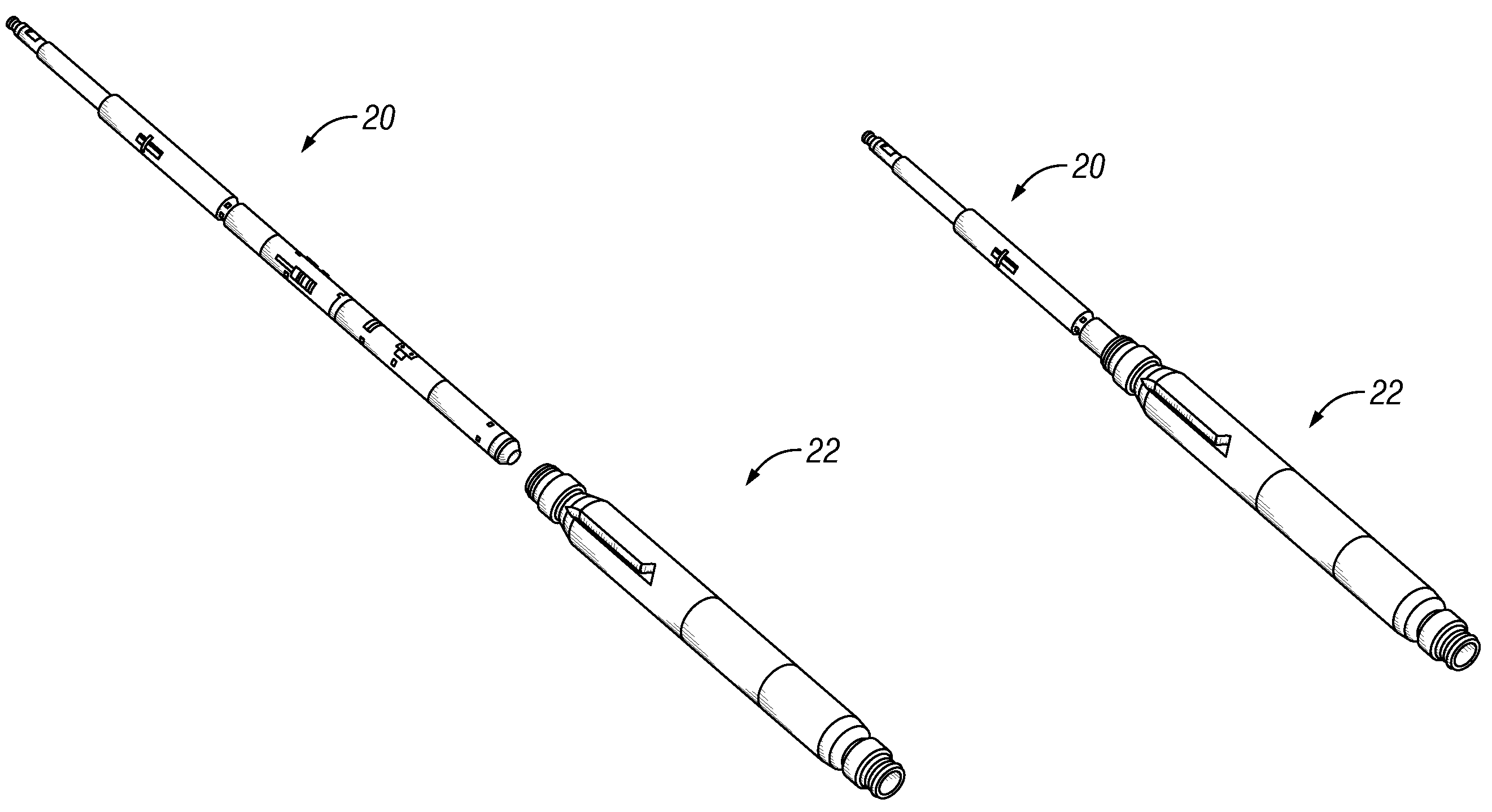

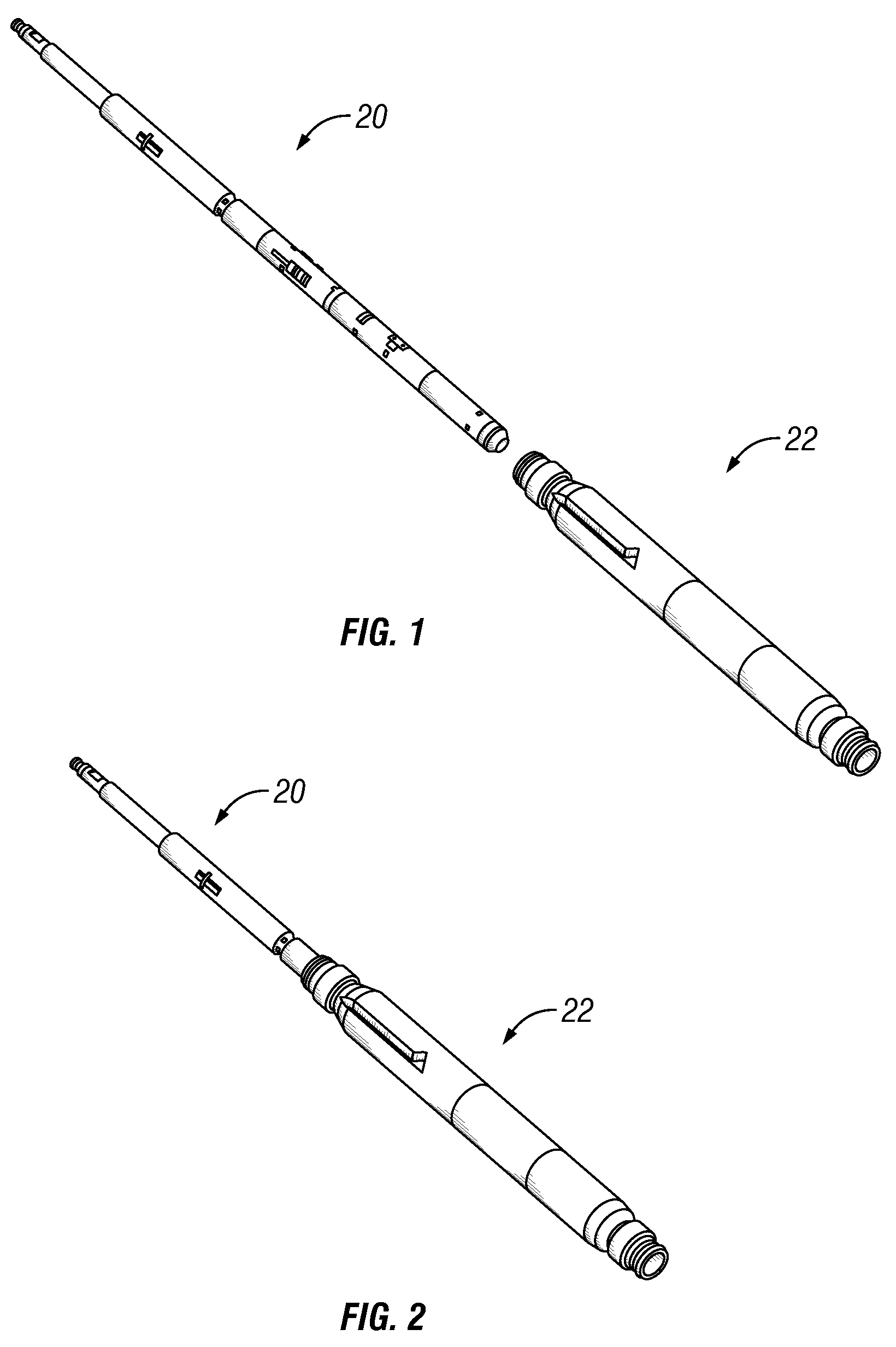

Lock open and control system access apparatus and method for a downhole safety valve

A lock open device for a flapper is disclosed. The tool engages in the sub-surface safety valve (SSSV) body and rotates the flapper to the open position, without shifting the flow tube. The flapper base is preferably held by a shearable thread and has a groove for engagement by the tool. The tool jars down on the flapper base to shear the thread and force the held open flapper into a retaining groove. Optionally, a penetrating tool can be connected so that, in a single trip, the flapper can be locked open and the pressurized control system can be accessed. Shearing the thread allows the flow tube spring to bias the held open flapper into its retaining groove.

Owner:BAKER HUGHES INC

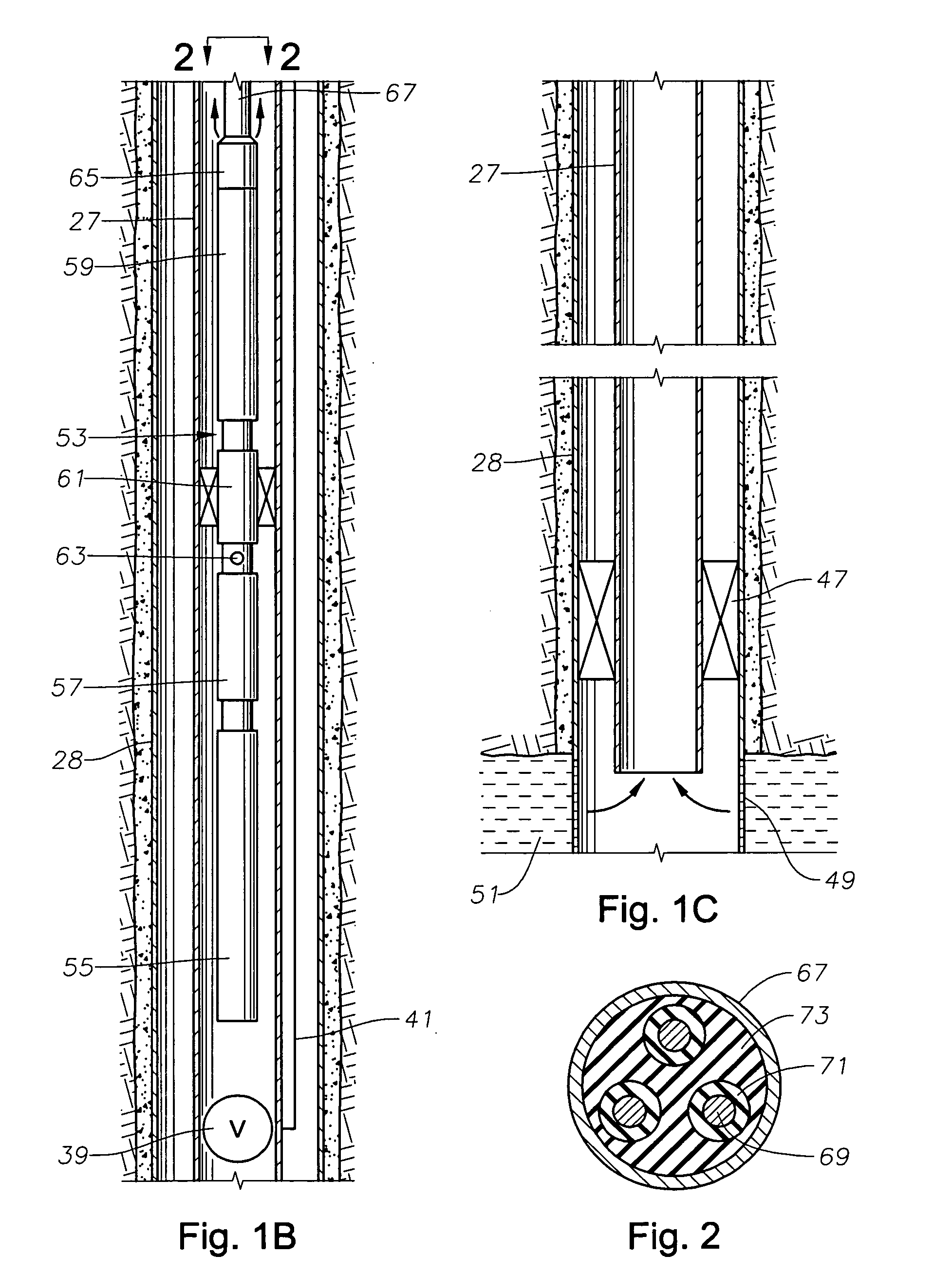

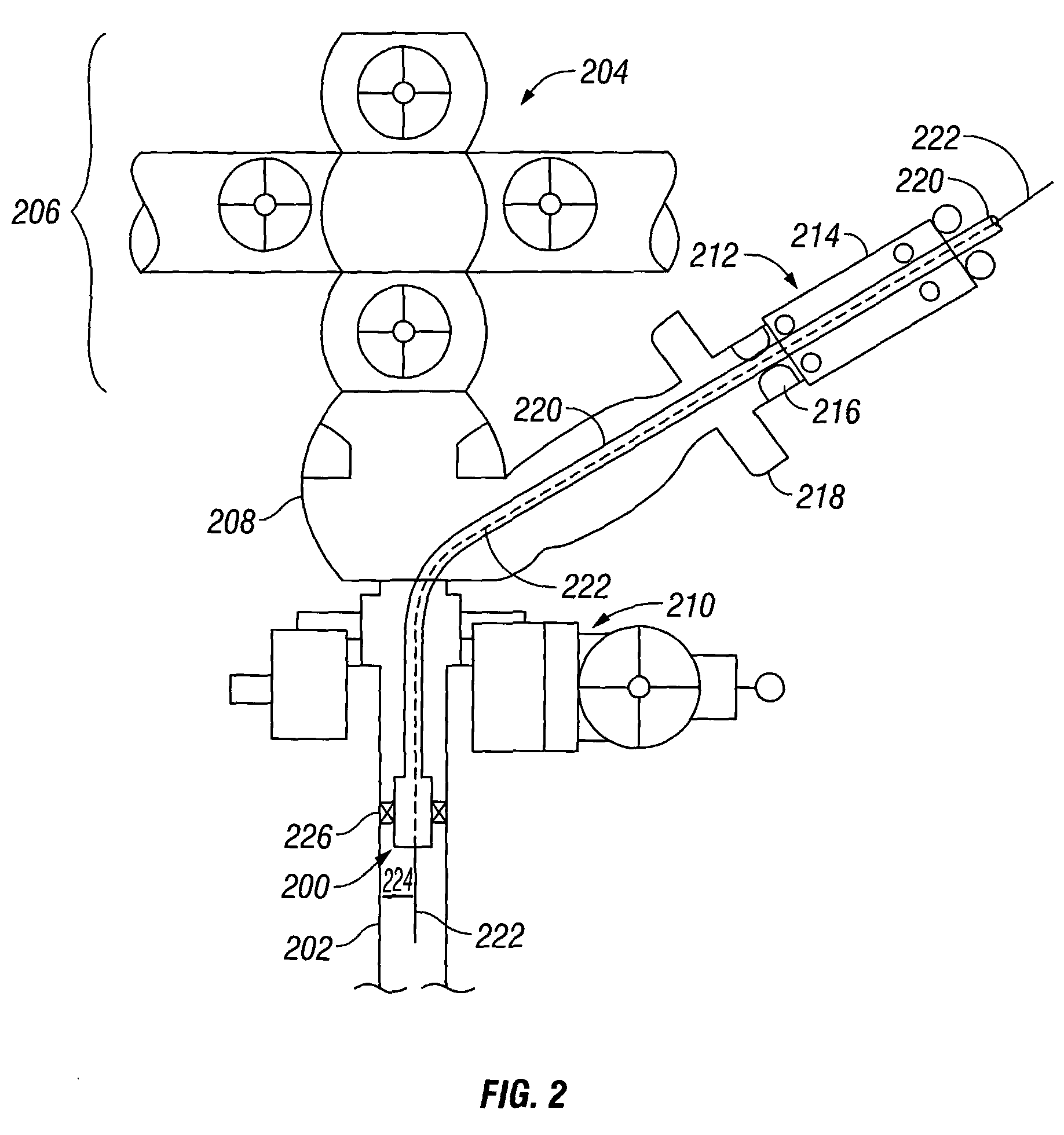

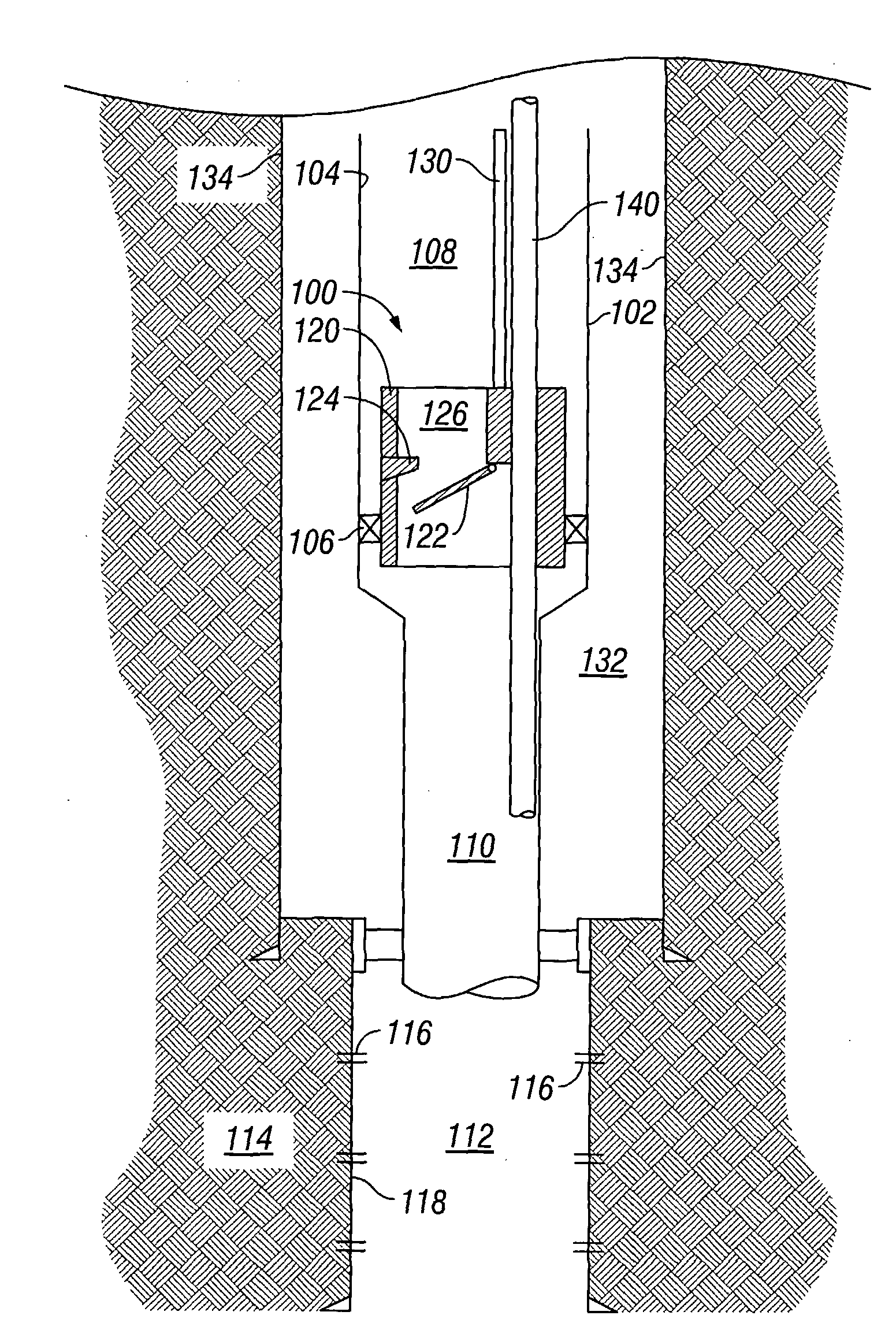

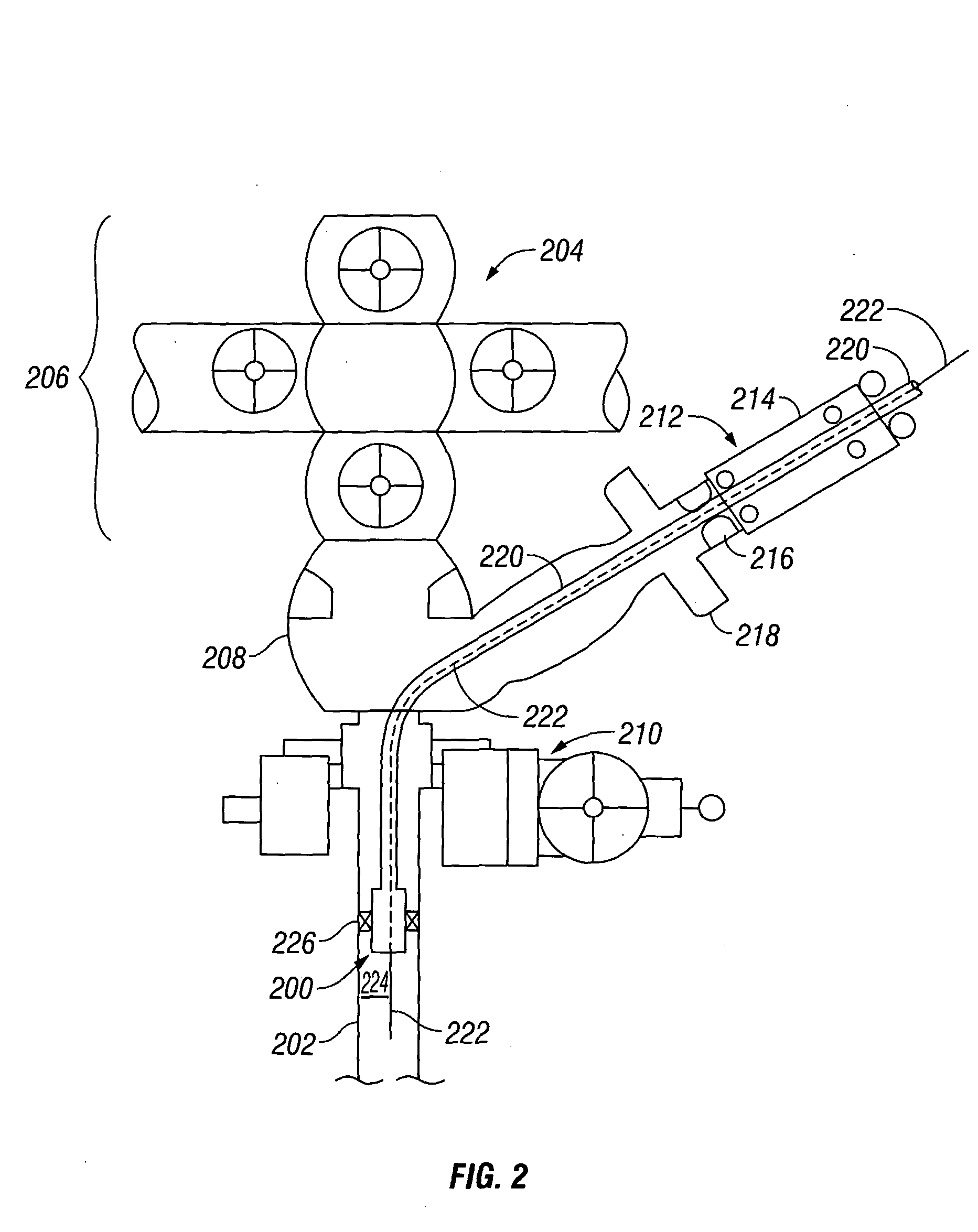

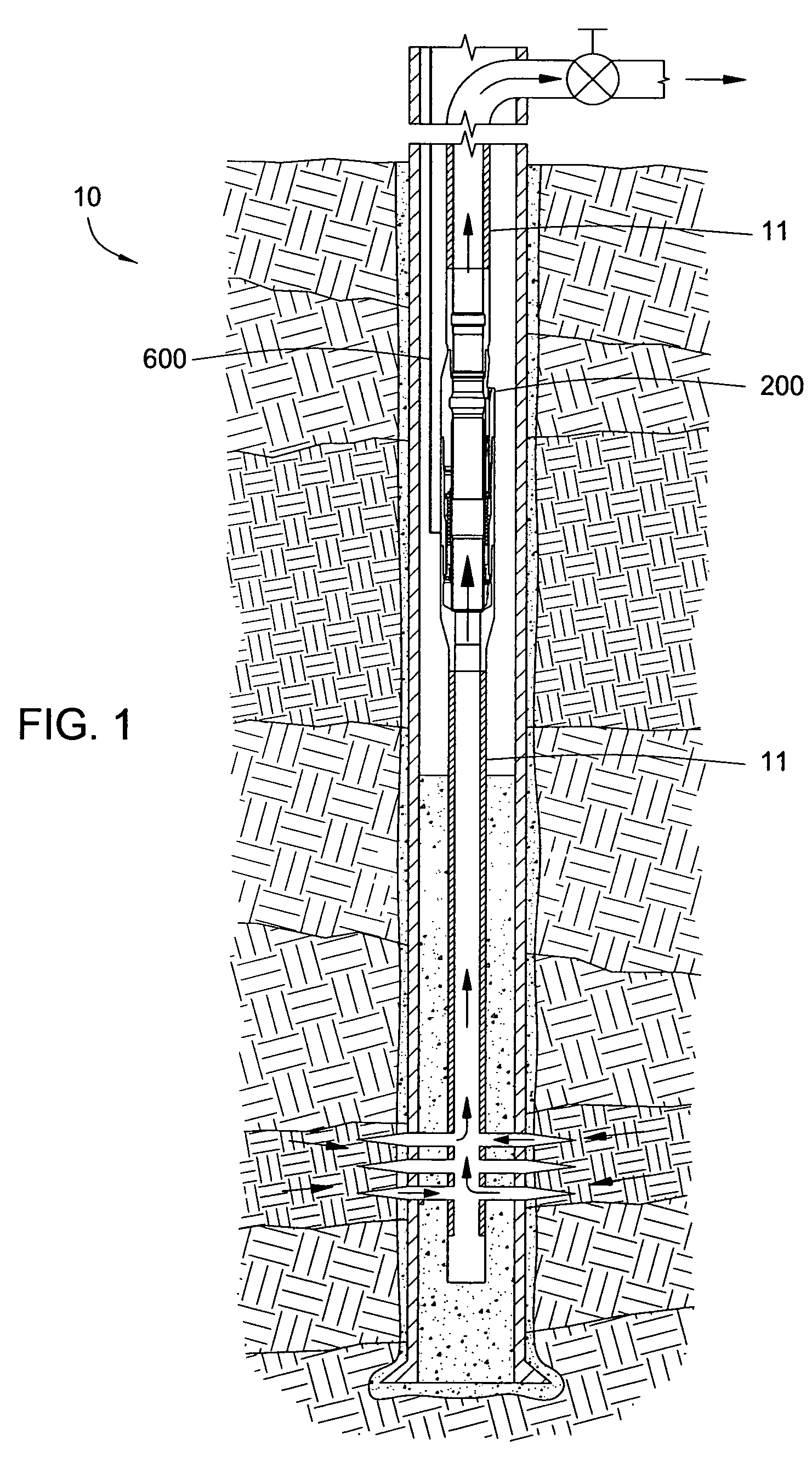

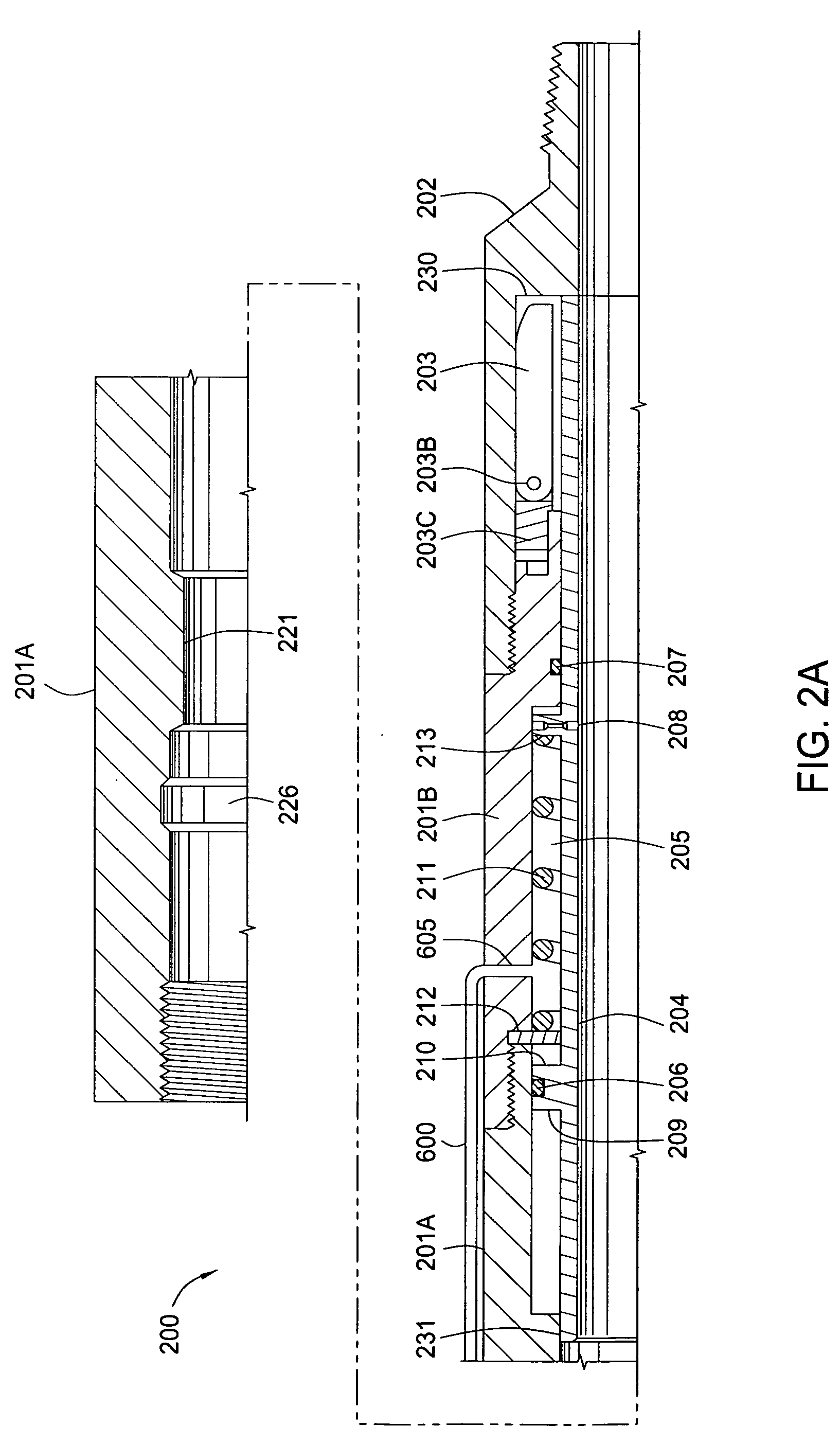

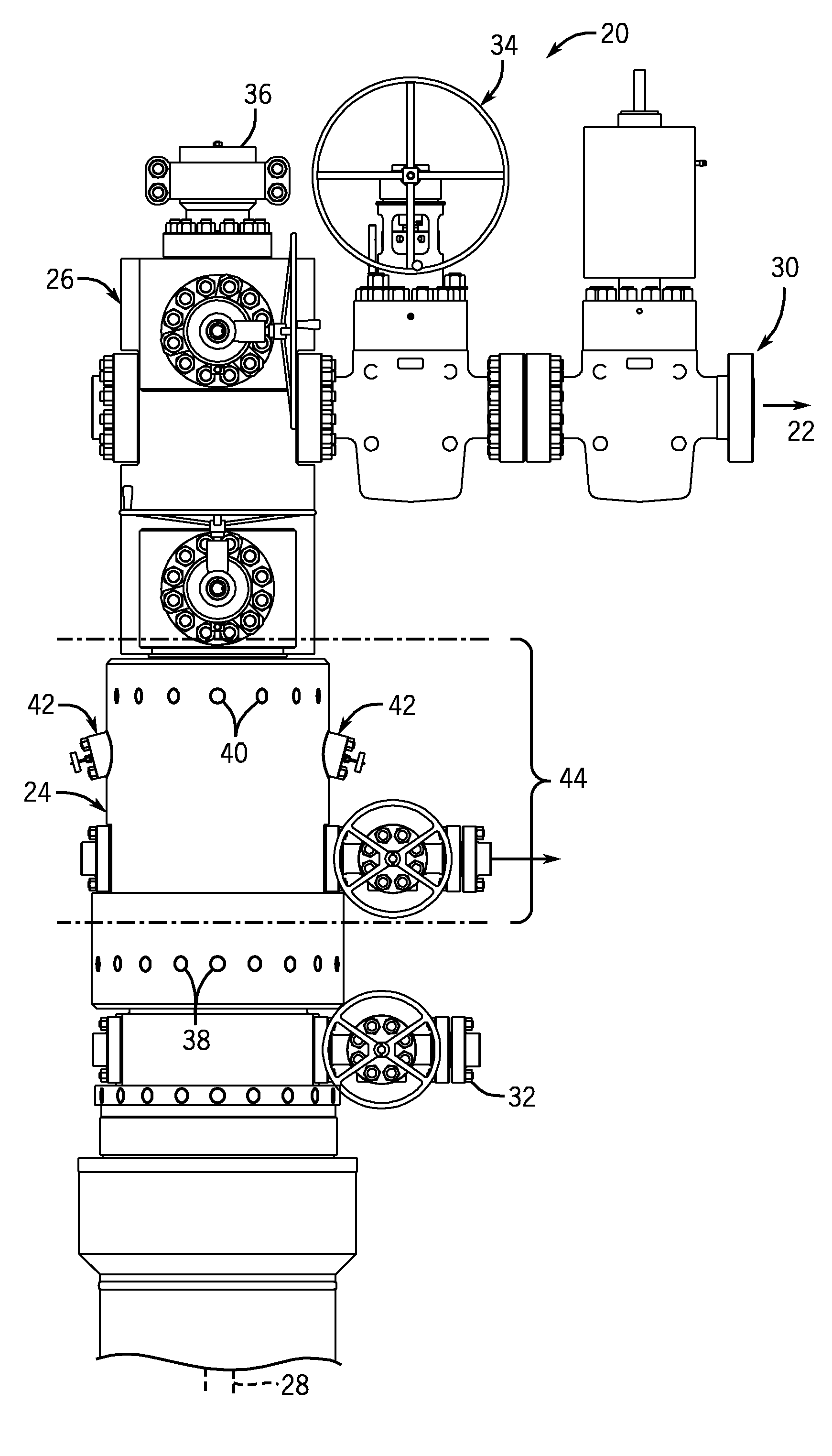

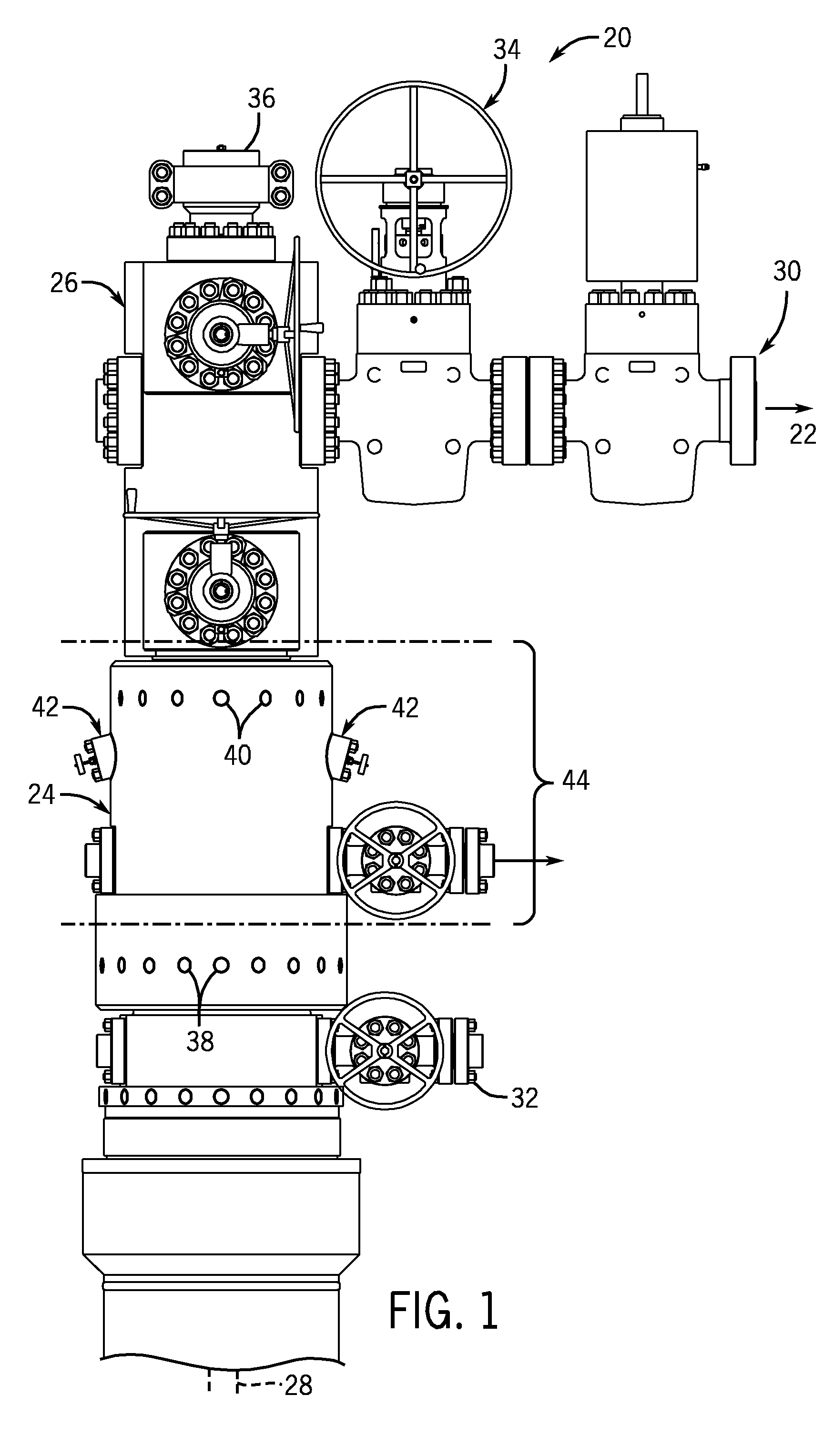

Subsea well with electrical submersible pump above downhole safety valve

A subsea well production system has a natural drive mode and a lift-assist mode using a submersible pump. The submersible pump can be installed while the well is live. The well system has a downhole safety valve in the production tubing. The operator closes the downhole safety valve and lowers an electrical submersible pump assembly into the production tubing. Once landed, the valve is opened and the pump assembly placed in operation.

Owner:BAKER HUGHES INC

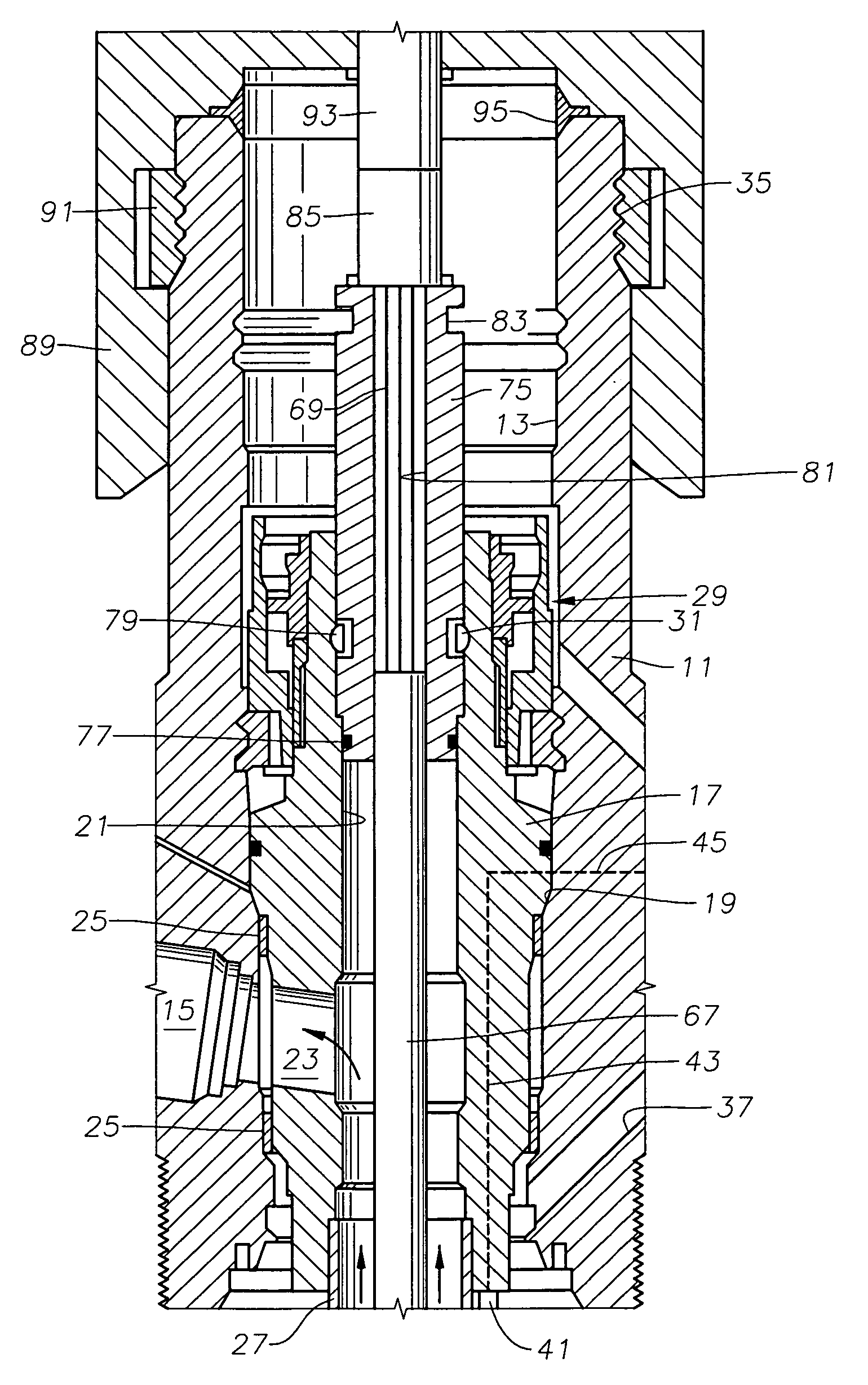

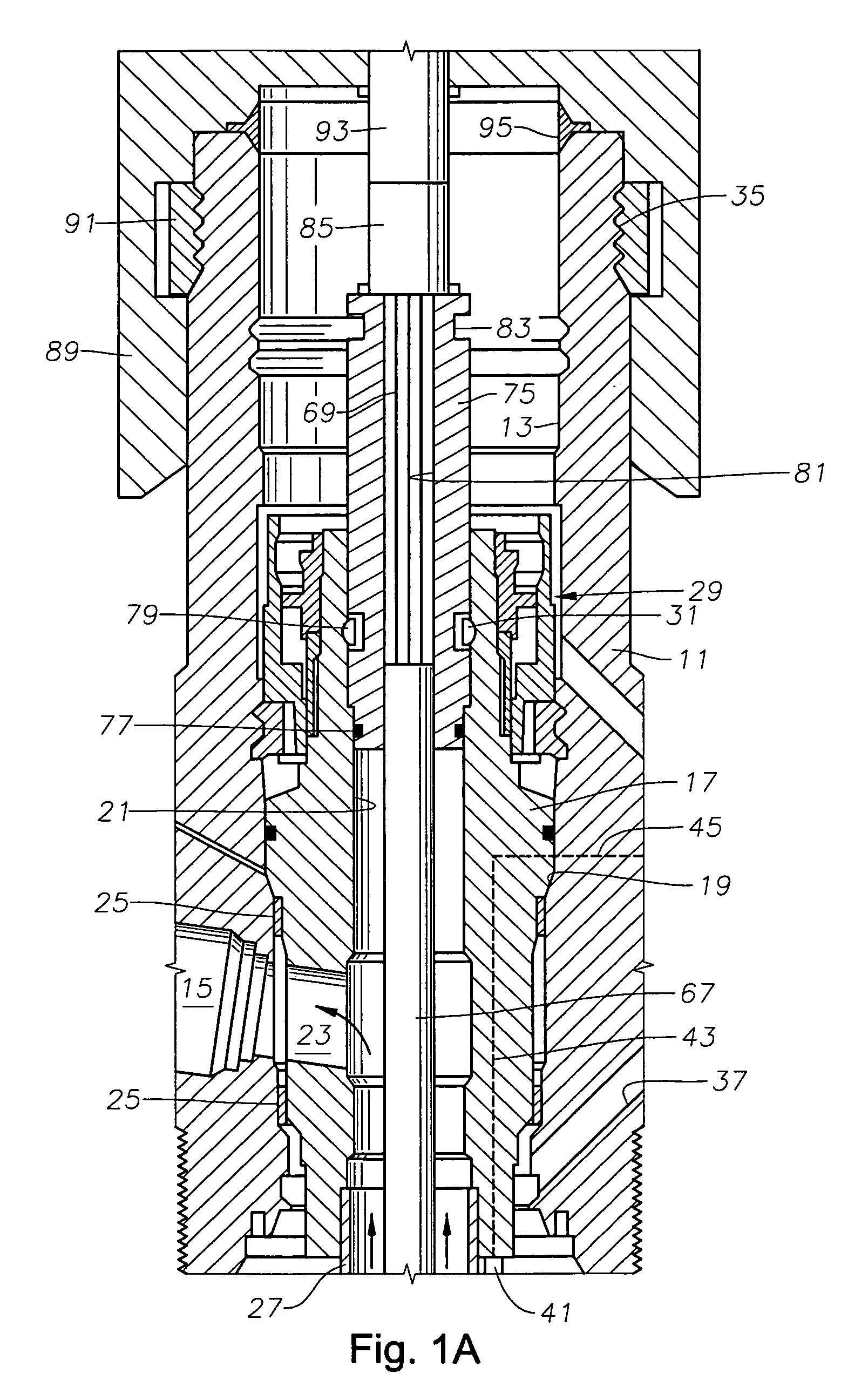

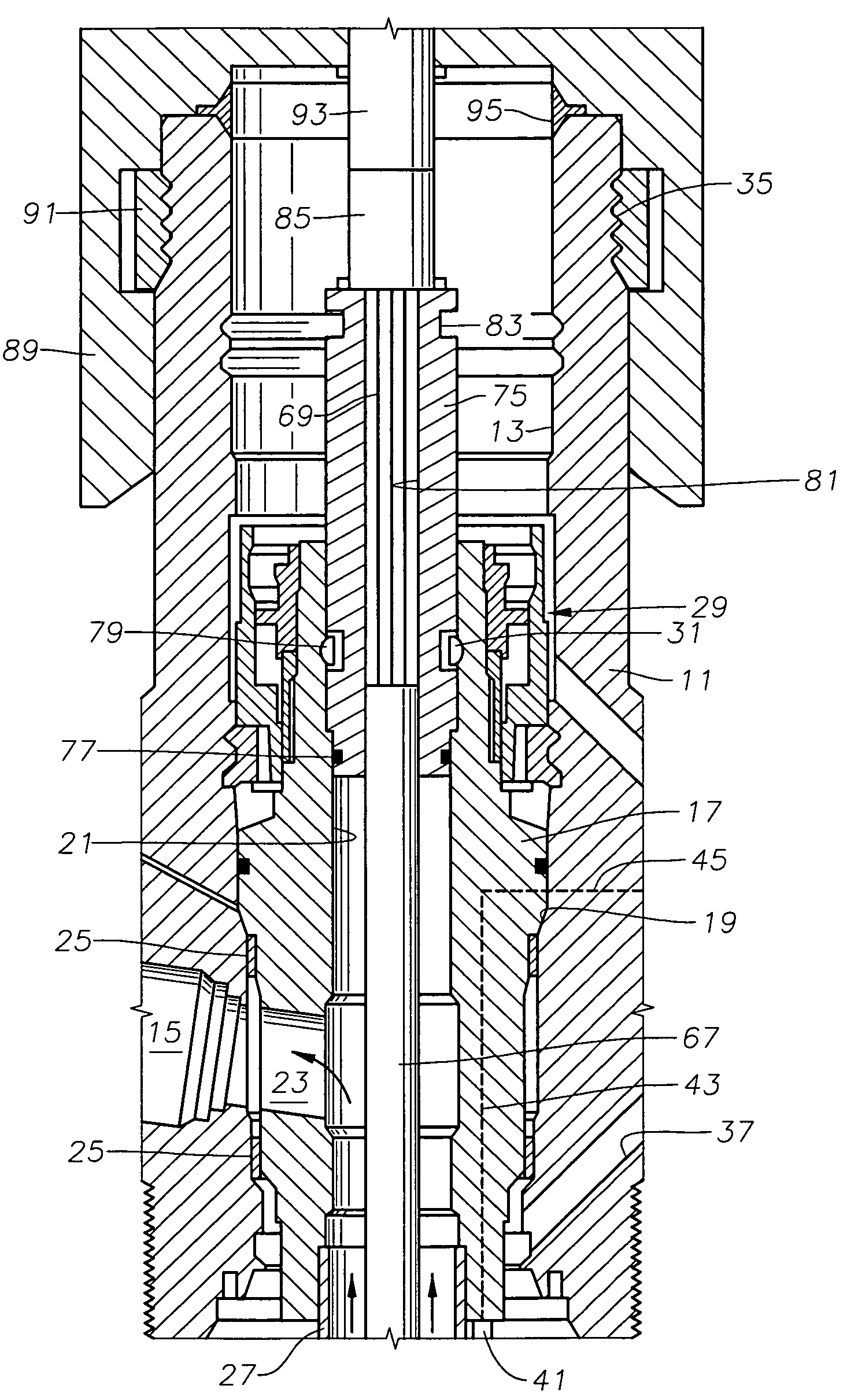

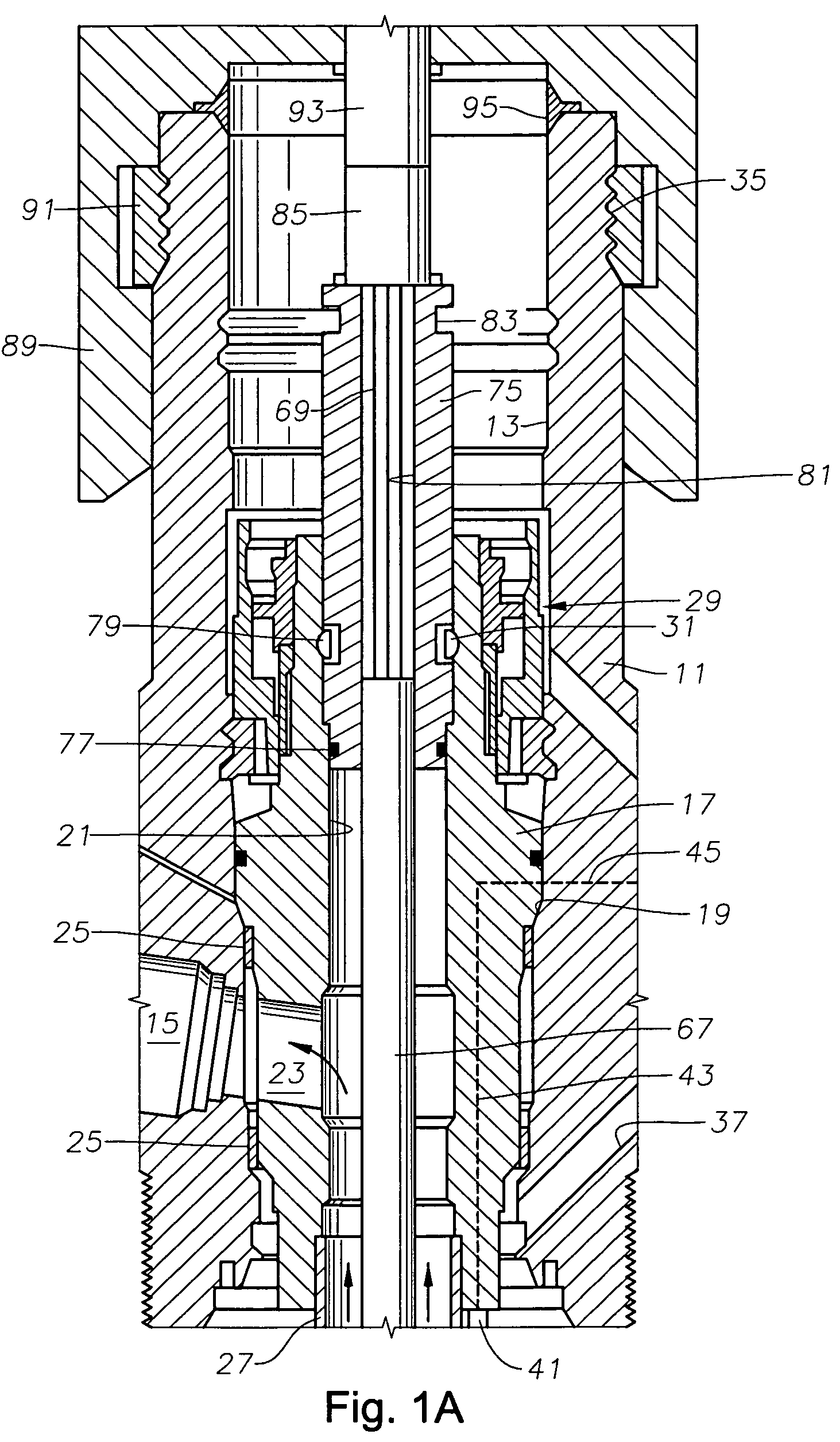

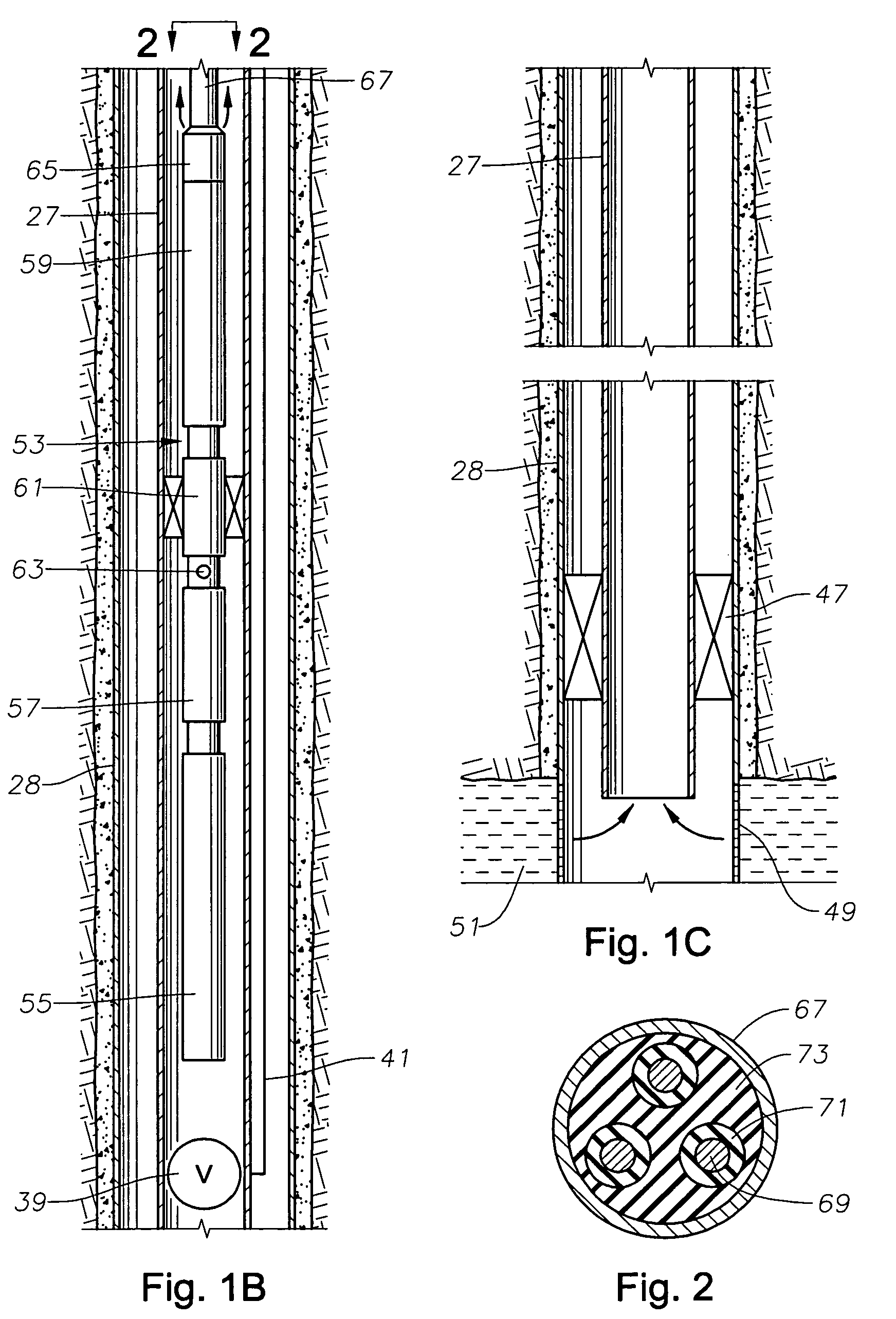

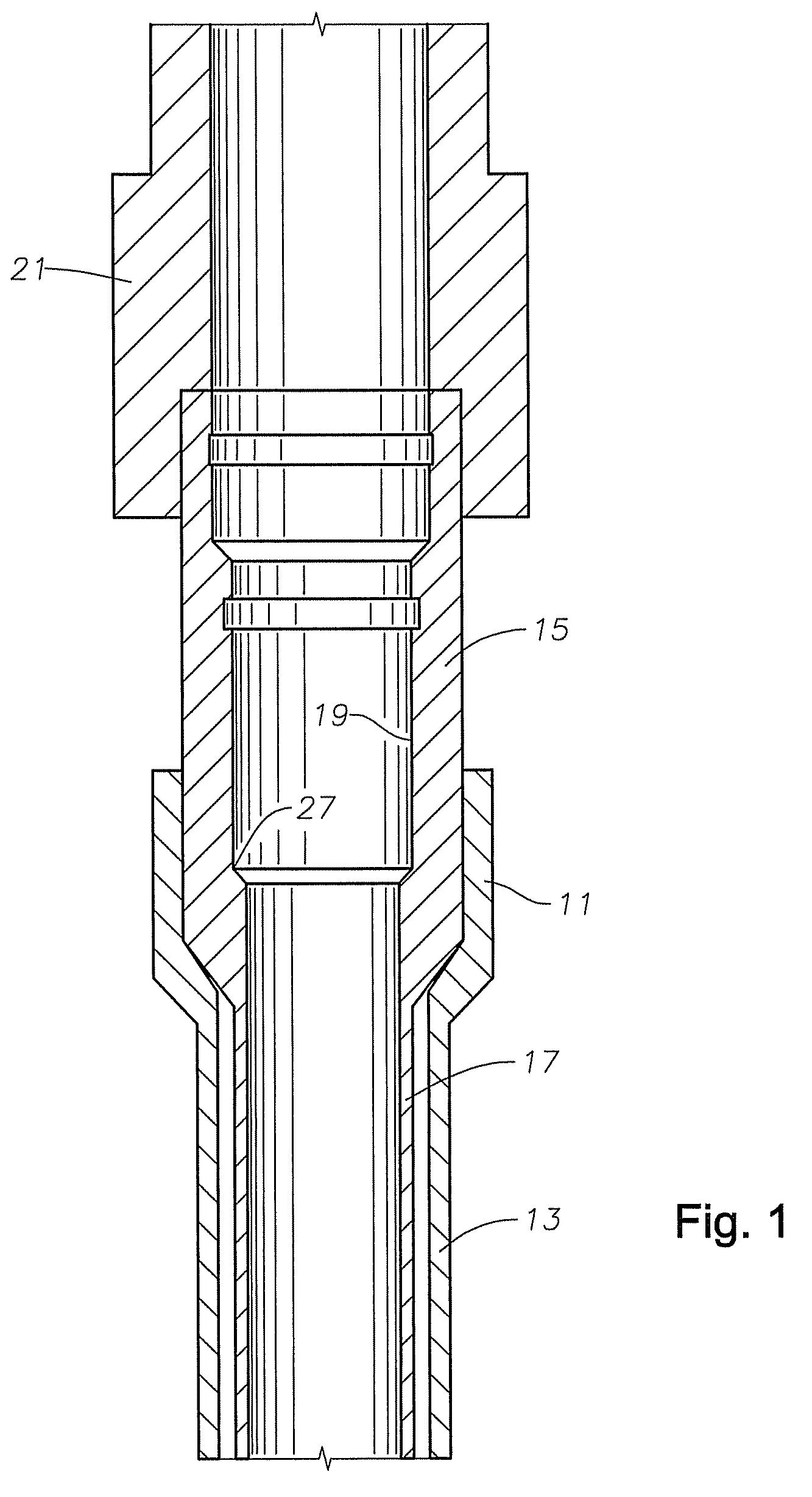

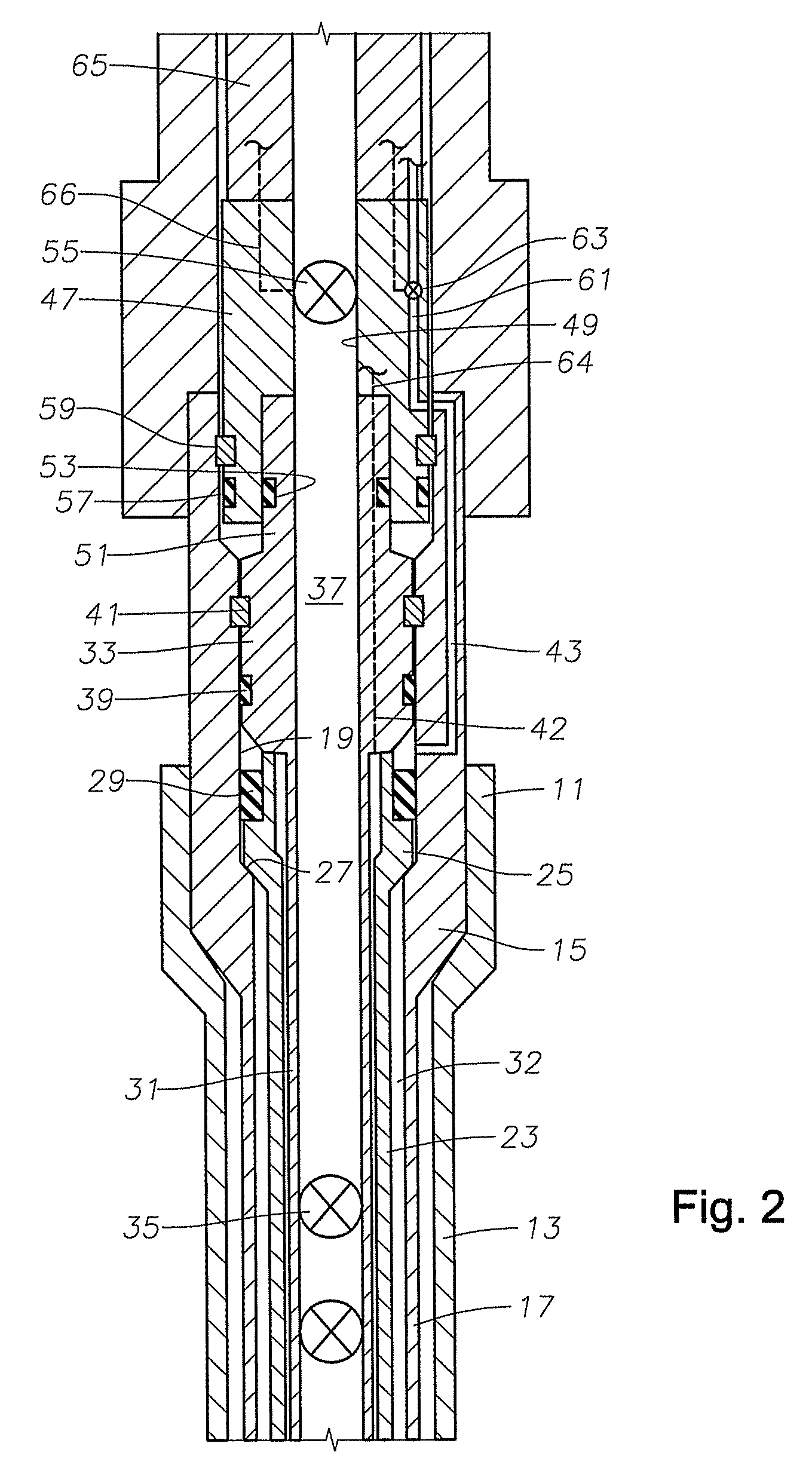

Downhole safety valve apparatus and method

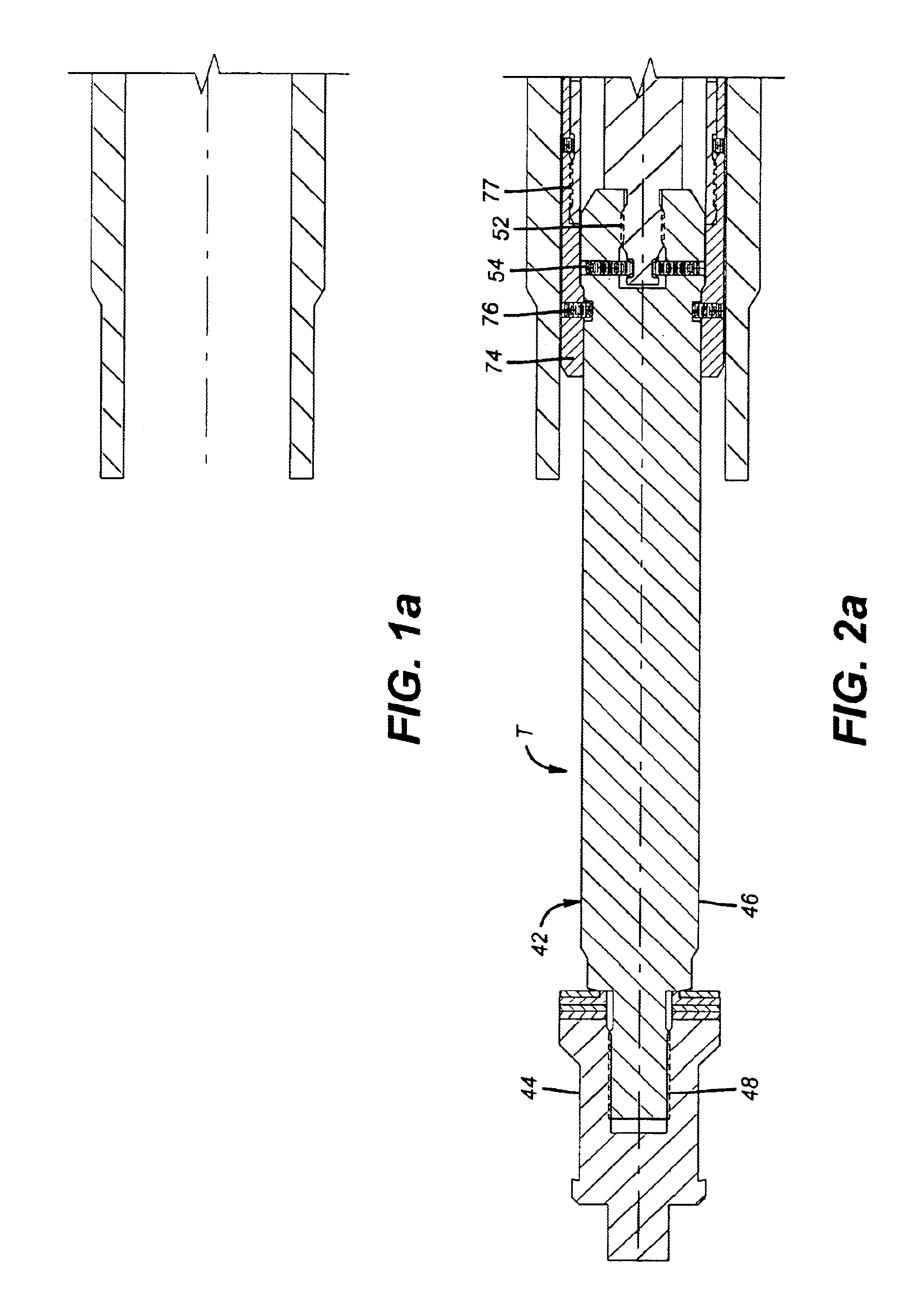

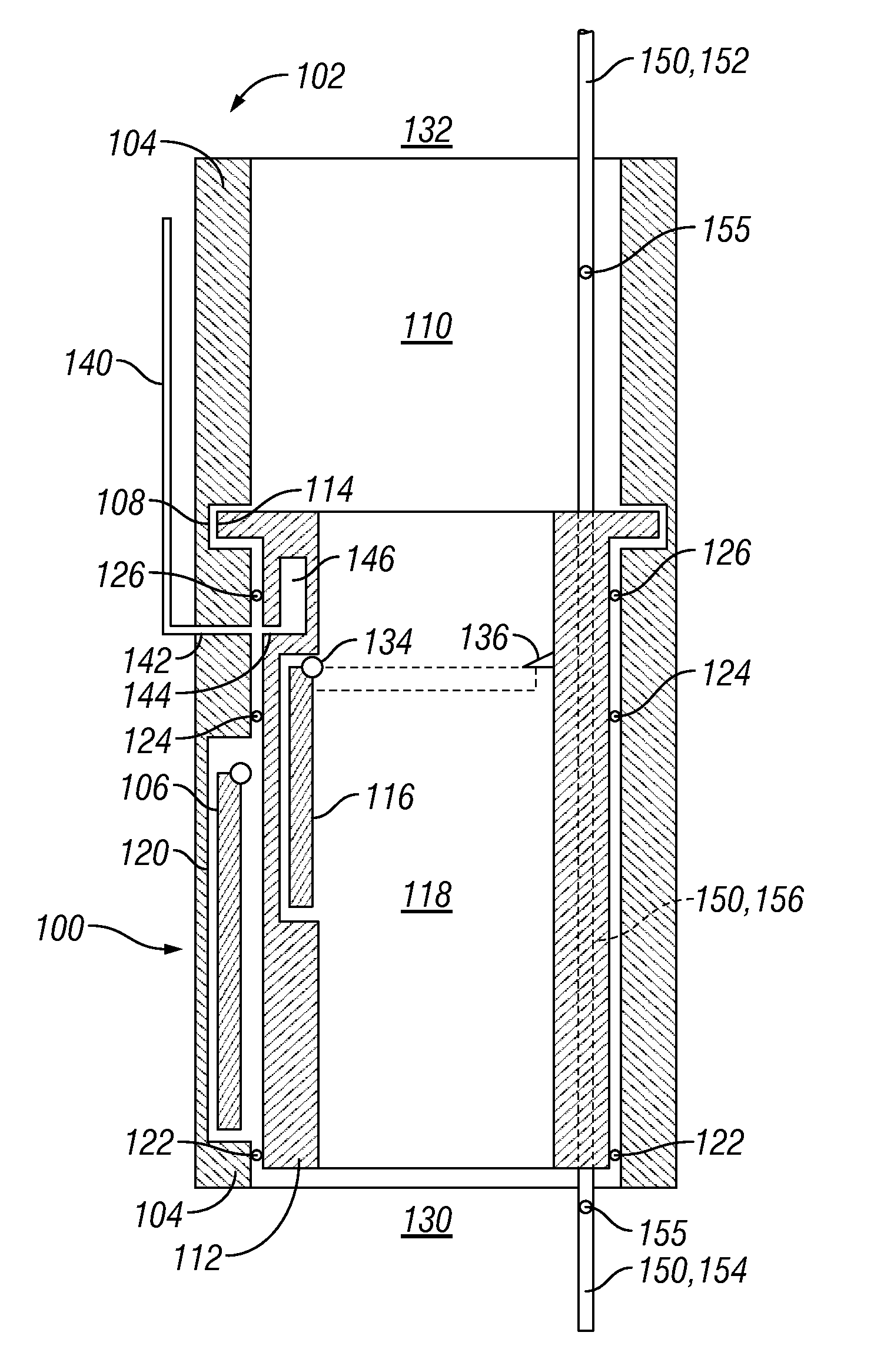

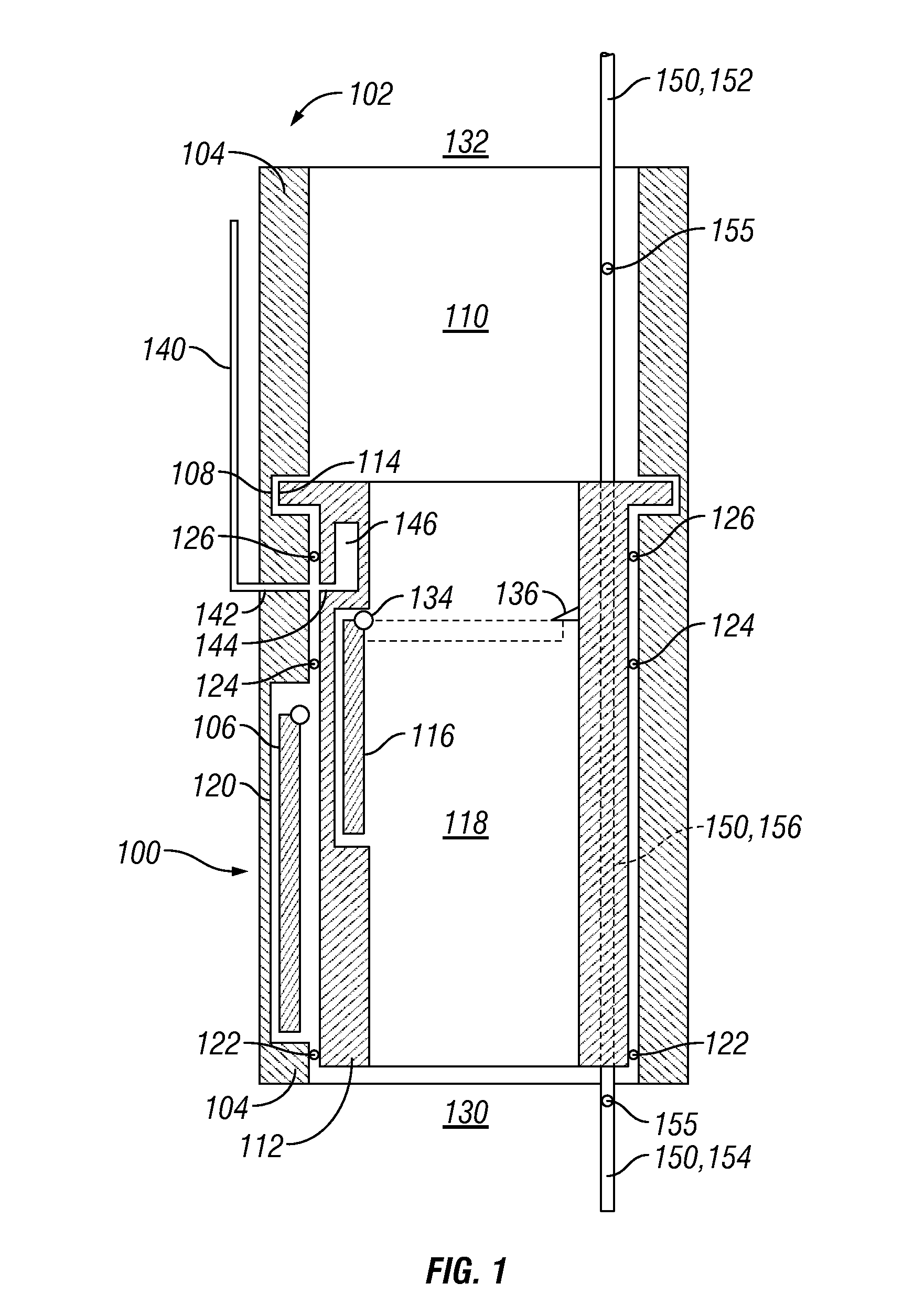

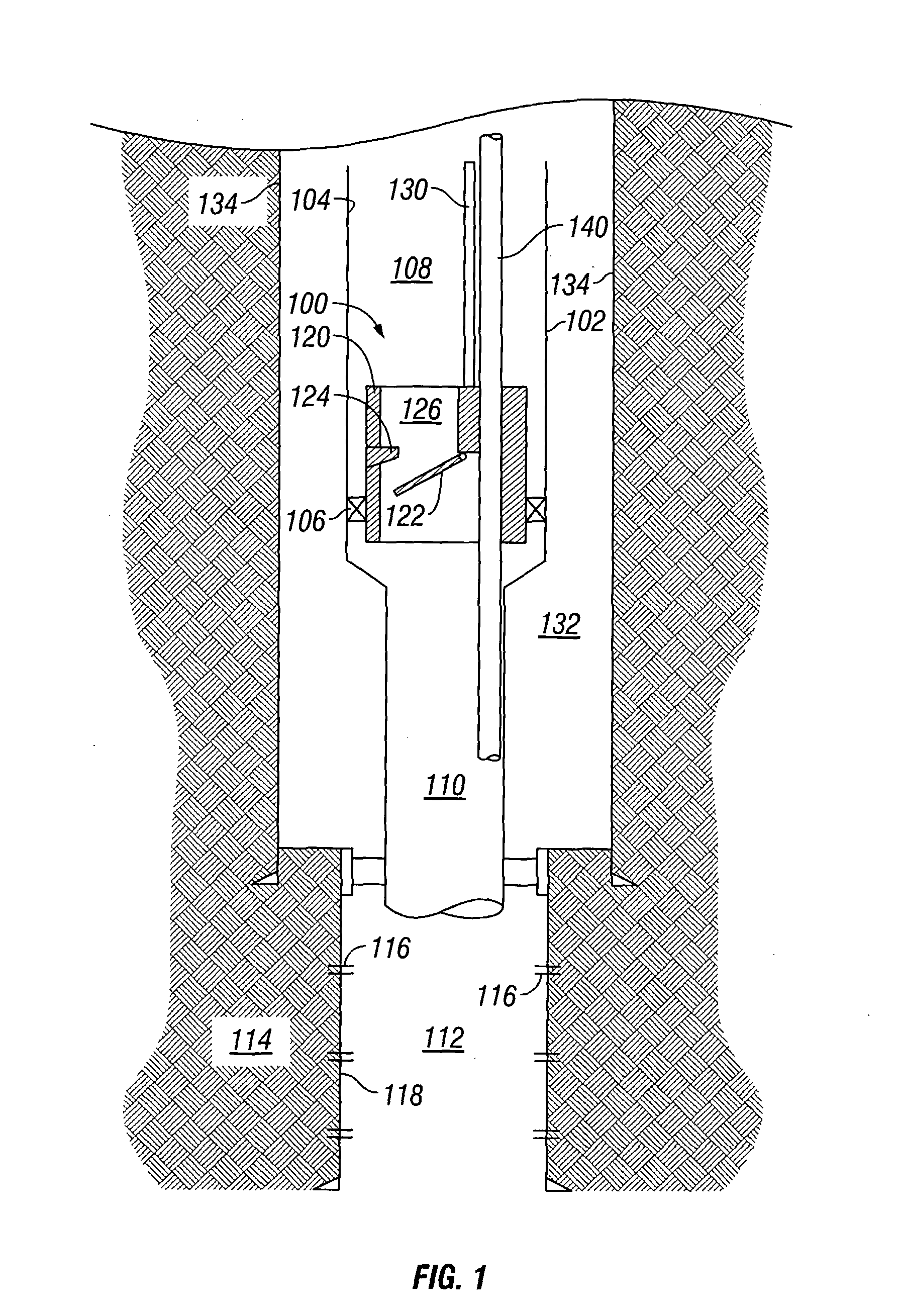

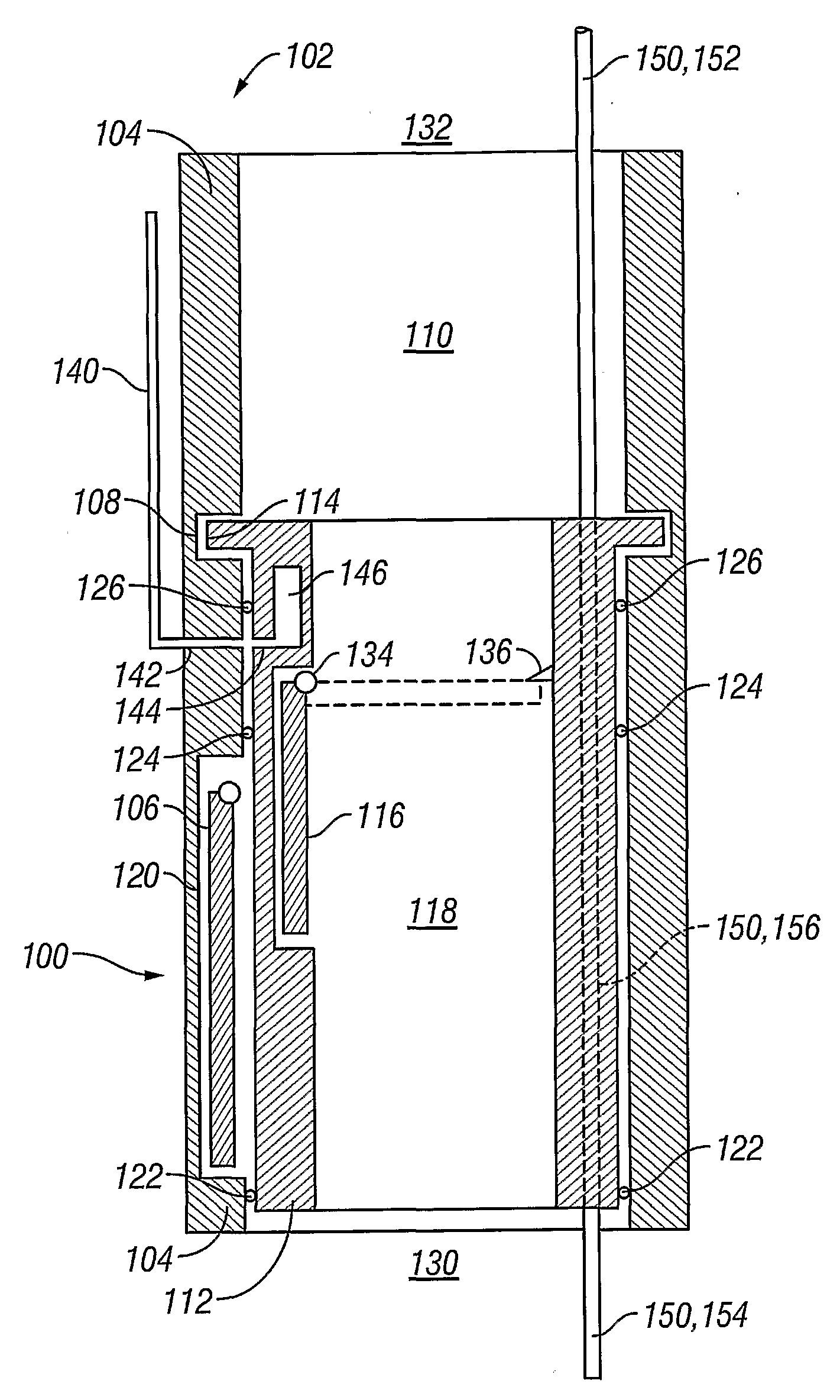

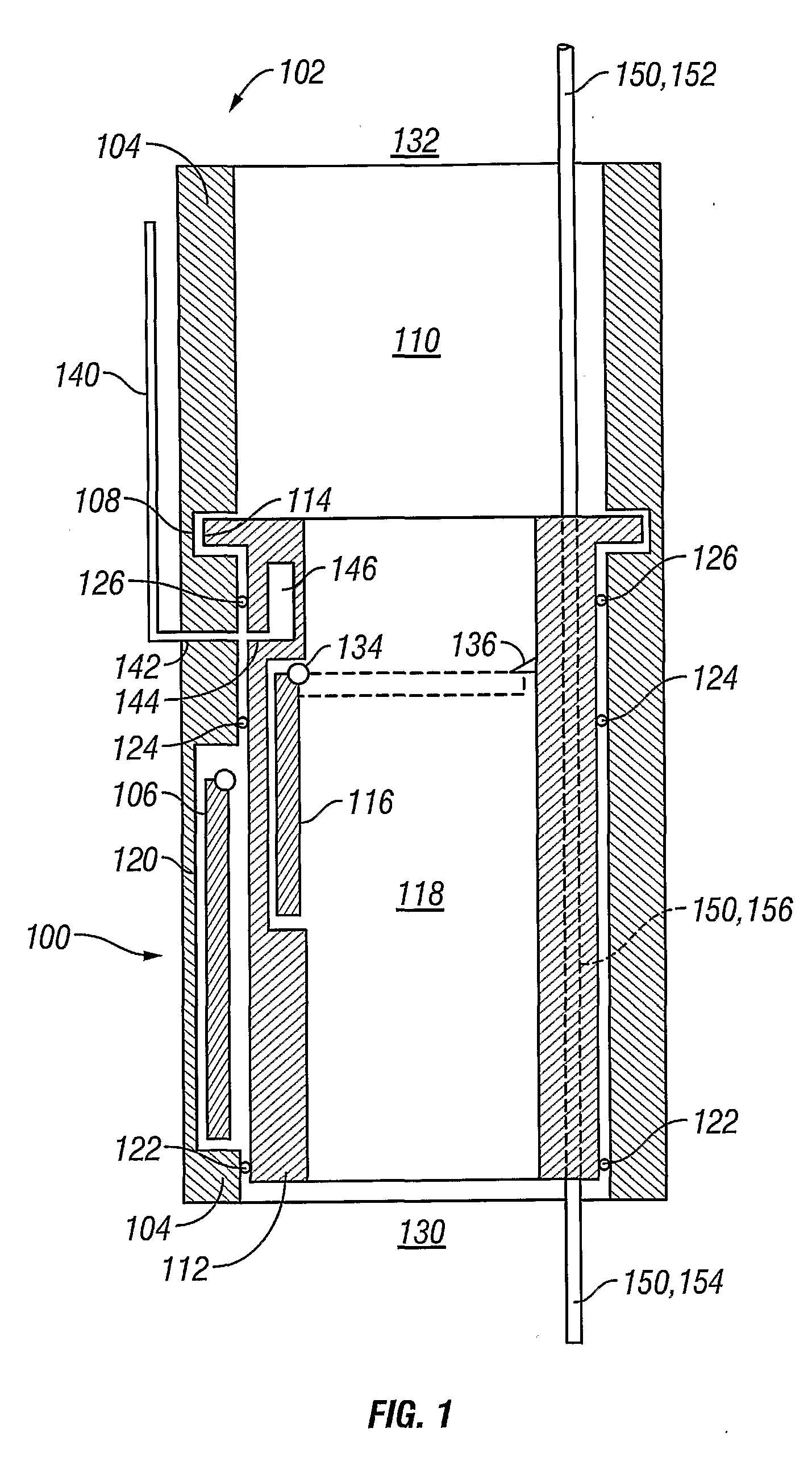

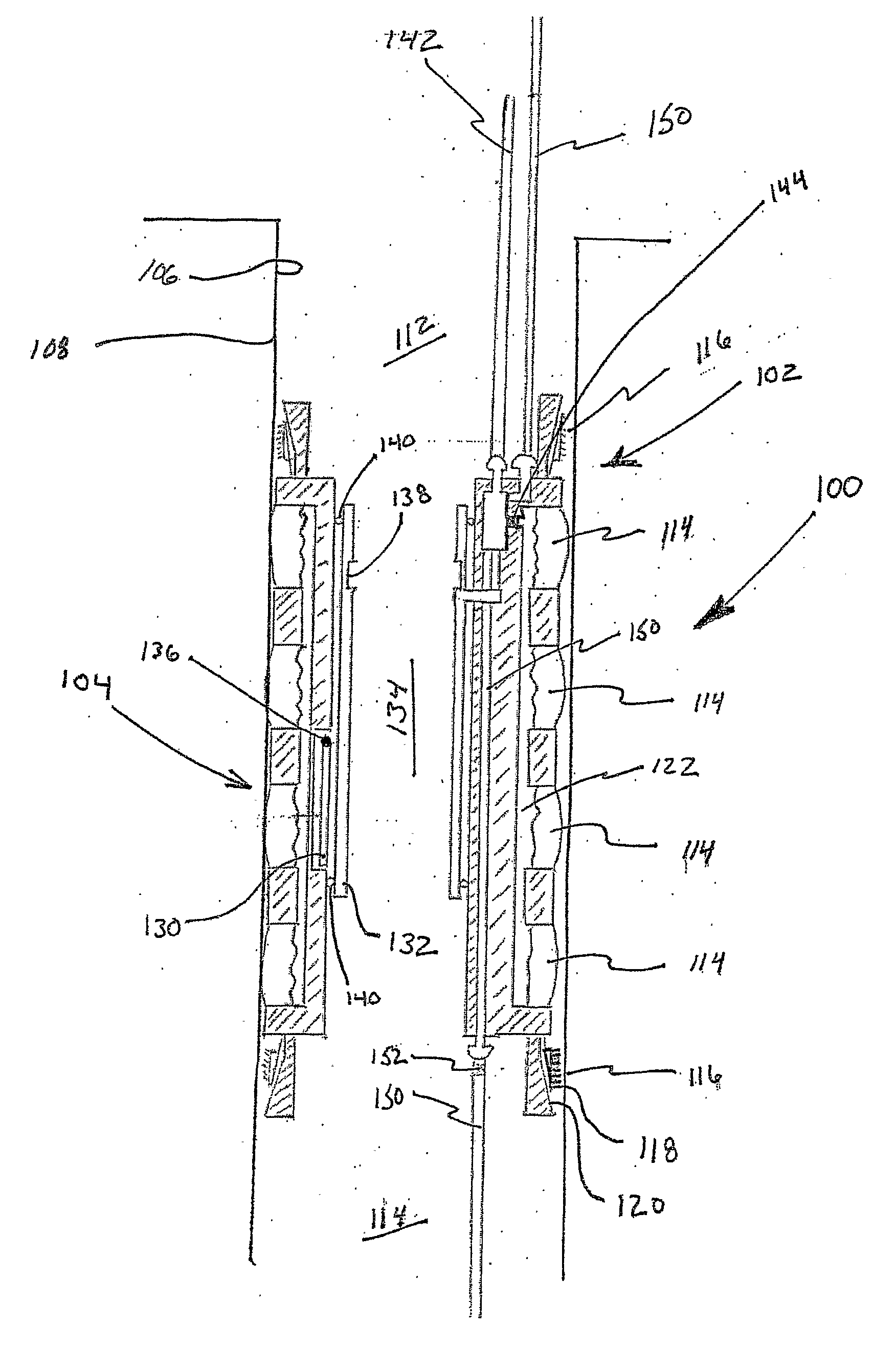

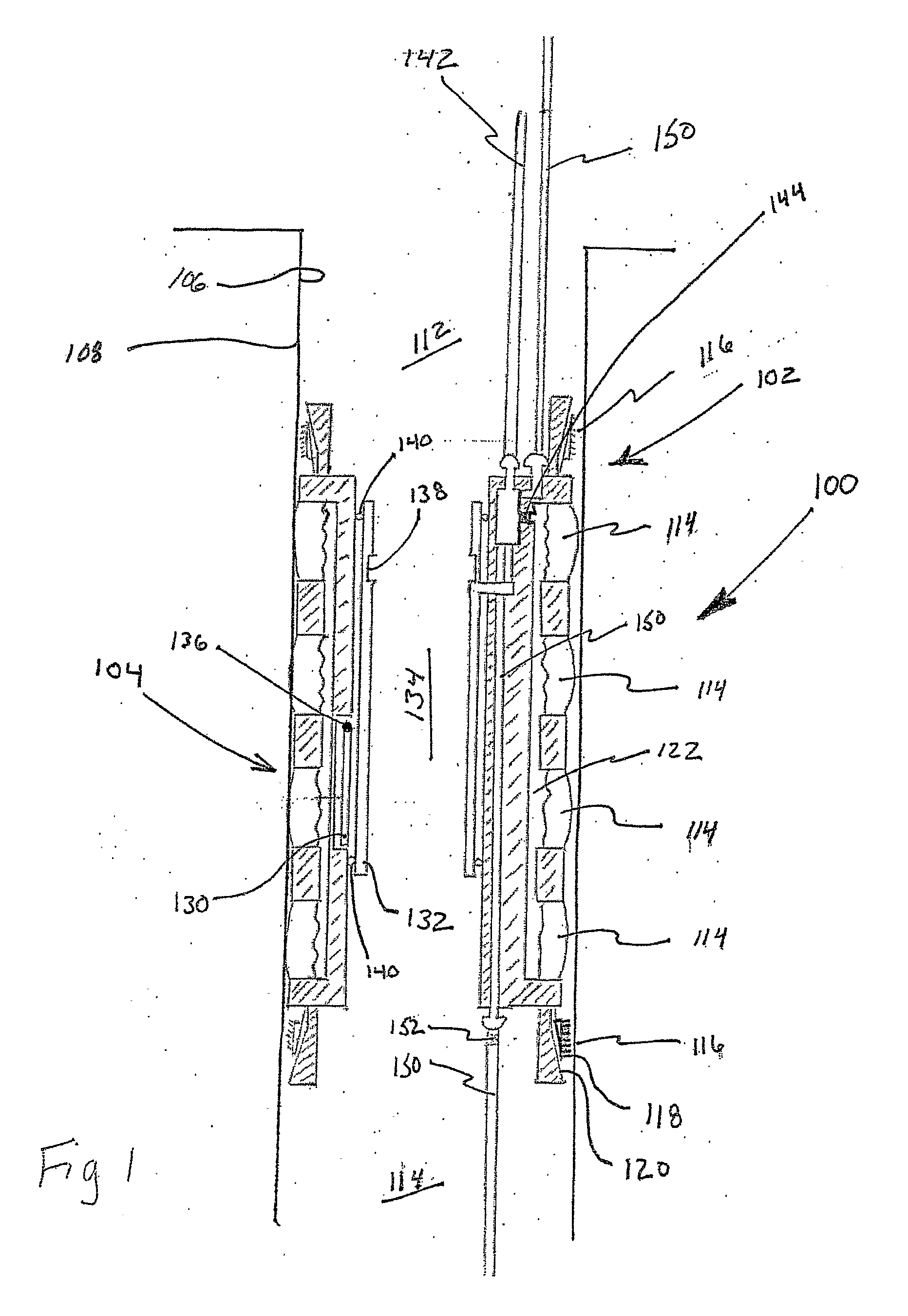

A safety valve (100) replaces an existing safety valve (102) in order to isolate a production zone from a tubing string when closed. Preferably the safety valve (100) includes a flow interruption device (106) displaced by an operating conduit extending from a surface location to the safety valve (100) through the inside of the production tubing. A by-pass conduit (150) allows communication from a surface location to the production zone through the safety valve (100) without affecting the operation of the safety valve (100).

Owner:BAKER HUGHES INC

Downhole safety valve apparatus and method

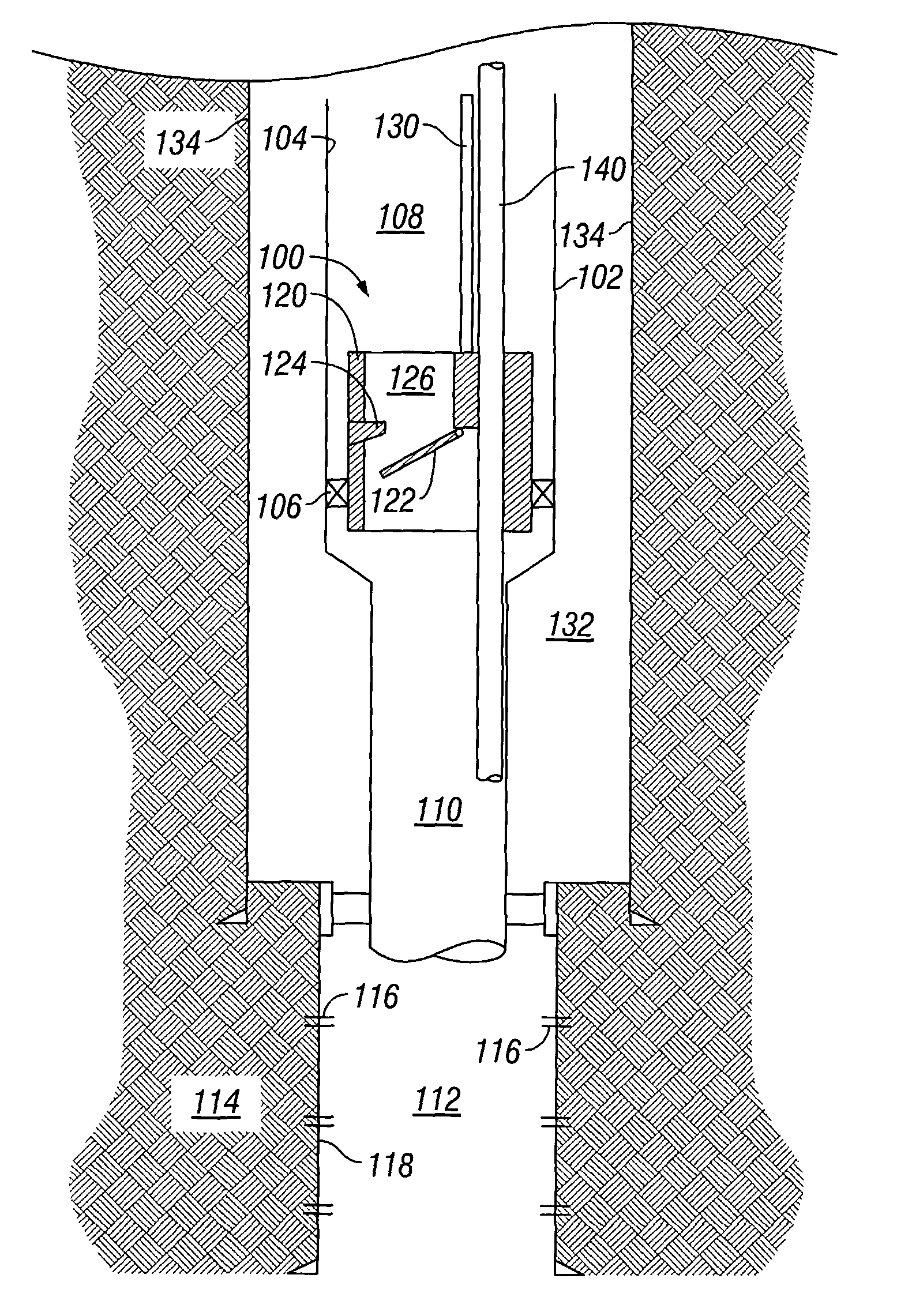

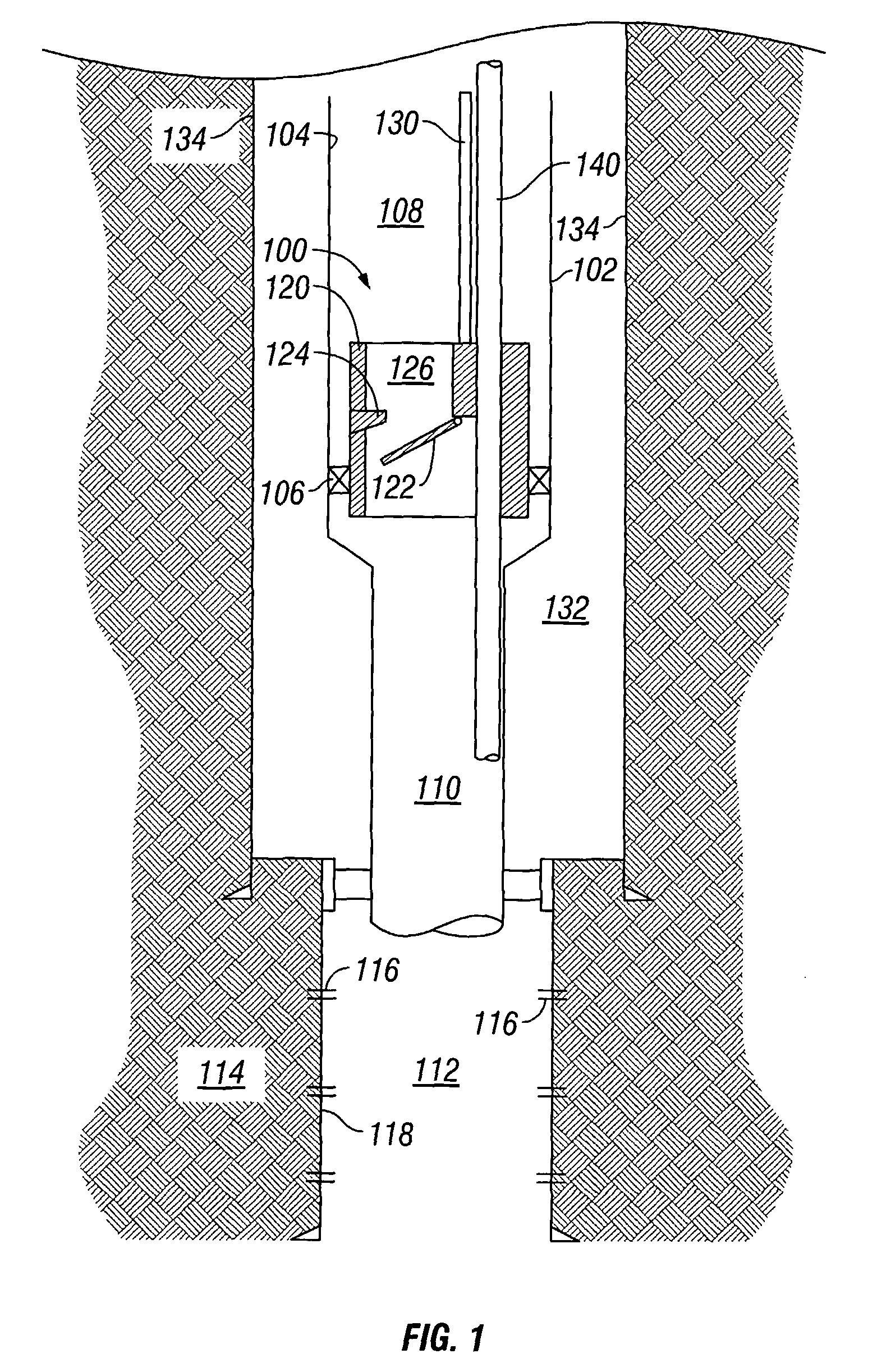

The application discloses a valve, which may include either a safety valve or a storm surge choke valve or the like, to isolate a zone below a valve from a string of production tubing. Preferably, the valve includes a flow interruption surface assembly, such as a flapper valve or a ball valve, displaced by an operating conduit extending from a surface location to the valve through the inside of the production tubing. The application also discloses a bypass-conduit inside the production tubing to allow communication from a surface location to the production zone when the valve is in either an open or a closed location.

Owner:BAKER HUGHES INC

Subsea well with electrical submersible pump above downhole safety valve

A subsea well production system has a natural drive mode and a lift-assist mode using a submersible pump. The submersible pump can be installed while the well is live. The well system has a downhole safety valve in the production tubing. The operator closes the downhole safety valve and lowers an electrical submersible pump assembly into the production tubing. Once landed, the valve is opened and the pump assembly placed in operation.

Owner:BAKER HUGHES INC

Through riser installation of tree block

Owner:VETCO GRAY

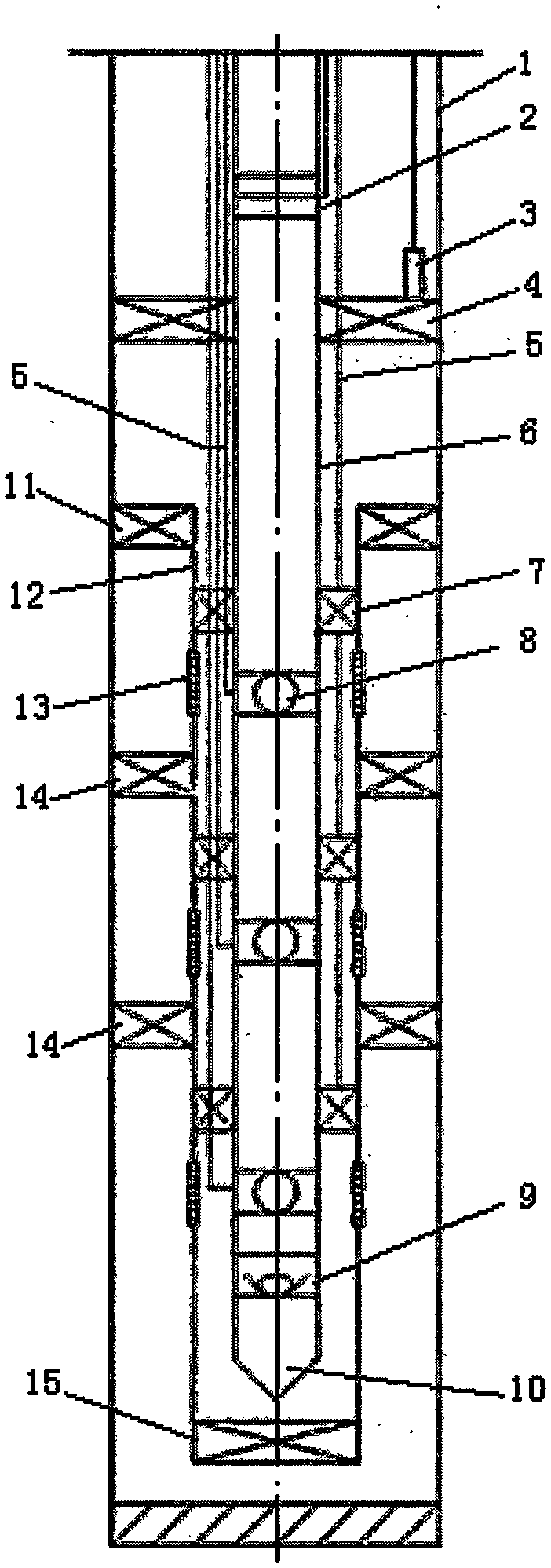

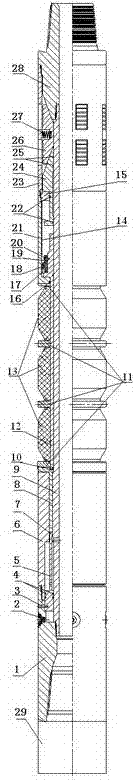

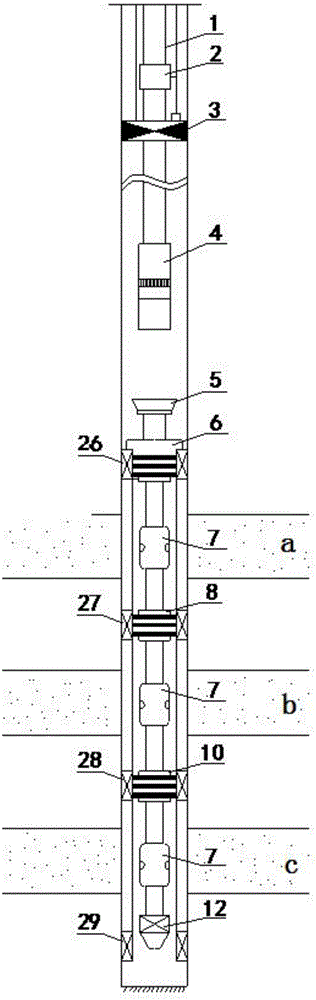

Tubular column for separated layer water injection

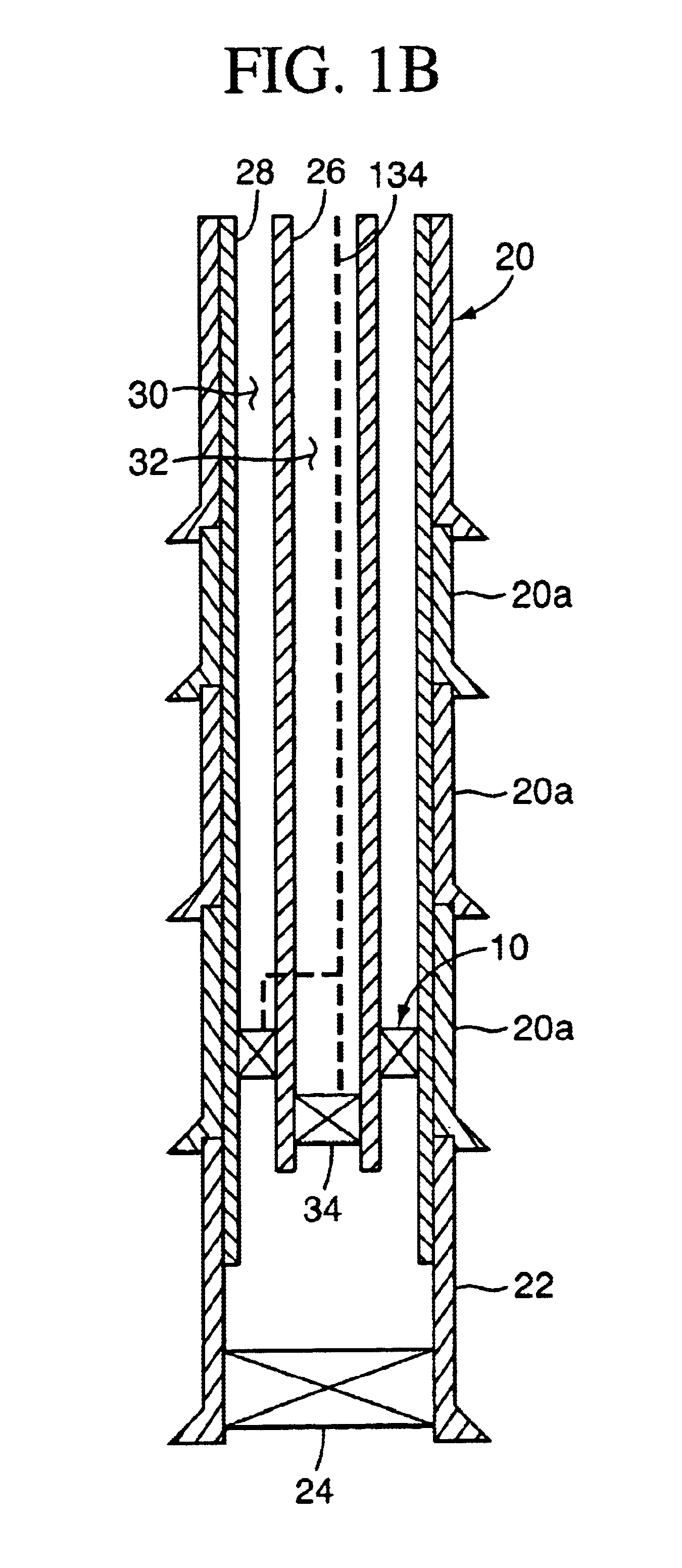

A tubular column for separated layer water injection comprises a subsurface safety valve, an exhaust valve, a multi-tube traverse packer, a hydraulic-control pipeline, hydraulic-control packers, sliding sleeve type water nozzles, a backwashing valve, a suspension packer, a sand-prevention bushing, sand filtering tubes and interlayer packers. An oil tube is sequentially connected with the subsurface safety valve, the multi-tube traverse packer, the corresponding hydraulic-control packer, the corresponding sliding sleeve type water nozzle, the corresponding hydraulic-control packer, the corresponding sliding sleeve type water nozzle, the corresponding hydraulic-control packer, the corresponding sliding sleeve type water nozzle, the backwashing valve and a guide connector. The sand-prevention bushing is installed outside the oil tube in a connected mode. The suspension packer, the corresponding sand filtering tube, the corresponding interlayer packer, the corresponding sand filtering tube, the corresponding interlayer packer, the corresponding sand filtering tube and a plug are sequentially installed on the sand-prevention bushing in a connected mode, and a bushing is arranged on the outmost part. The exhaust valve is installed on the multi-tube traverse packer in a connected mode, the hydraulic-control pipeline is installed on the exhaust valve for control, the hydraulic-control packers are traversed, connected and controlled through the same hydraulic-control pipeline, the sliding sleeve type water nozzles are connected through the hydraulic-control pipeline for control, and the subsurface safety valve is connected with the hydraulic-control pipeline for control.

Owner:李永立

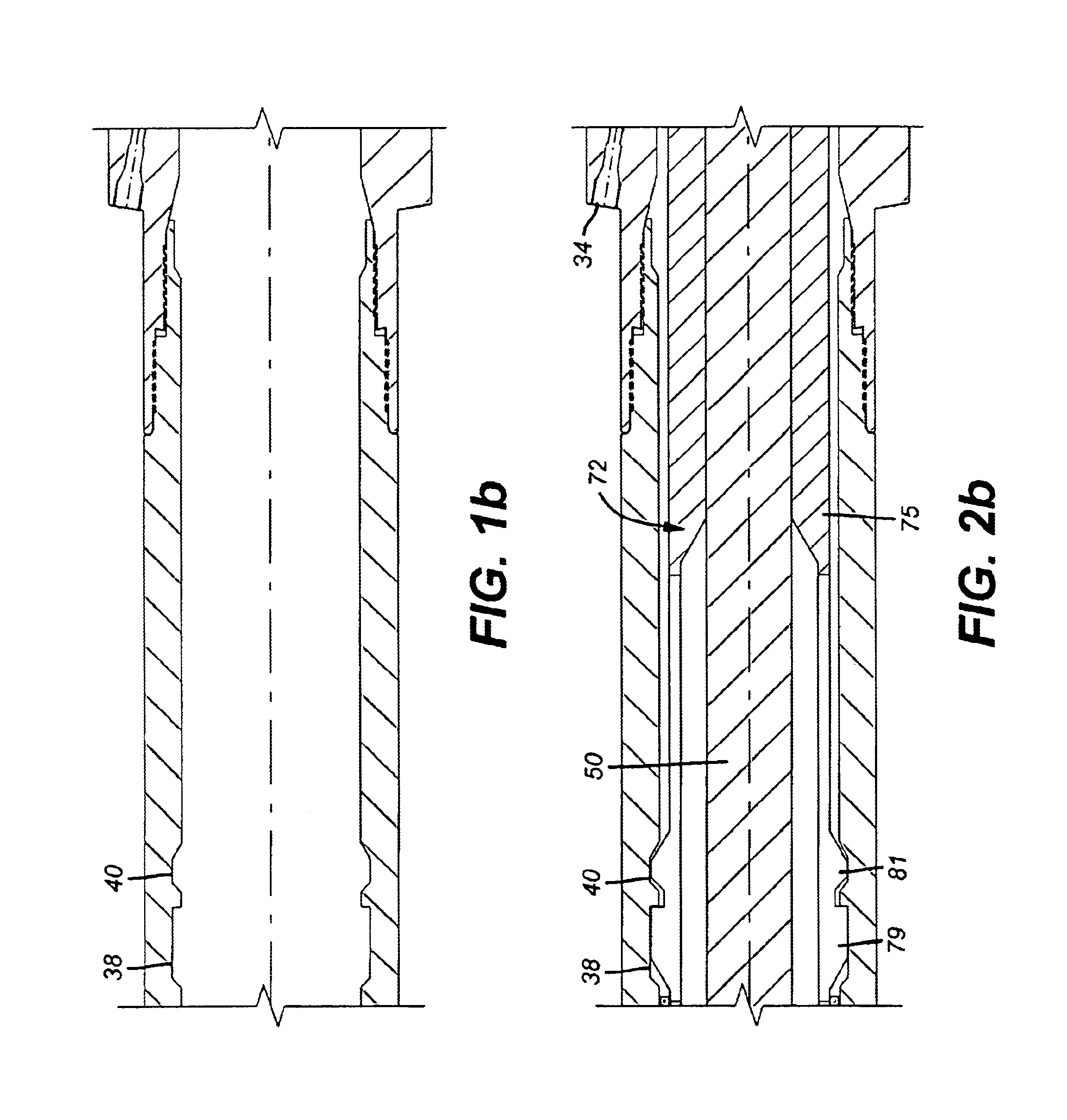

Downhole Safety Valve Apparatus and Method

The application discloses a valve, which may include either a safety valve or a storm surge choke valve or the like, to isolate a zone below a valve from a string of production tubing. Preferably, the valve includes a flow interruption surface assembly, such as a flapper valve or a ball valve, displaced by an operating conduit extending from a surface location to the valve through the inside of the production tubing. The application also discloses a bypass-conduit inside the production tubing to allow communication from a surface location to the production zone when the valve is in either an open or a closed location.

Owner:BAKER HUGHES INC

Downhole Safety Valve Apparatus and Method

A safety valve (100) replaces an existing safety valve (102) in order to isolate a production zone from a tubing string when closed. Preferably the safety valve (100) includes a flow interruption device (106) displaced by an operating conduit extending from a surface location to the safety valve (100) through the inside of the production tubing. A by-pass conduit (150) allows communication from a surface location to the production zone through the safety valve (100) without affecting the operation of the safety valve (100).

Owner:BAKER HUGHES INC

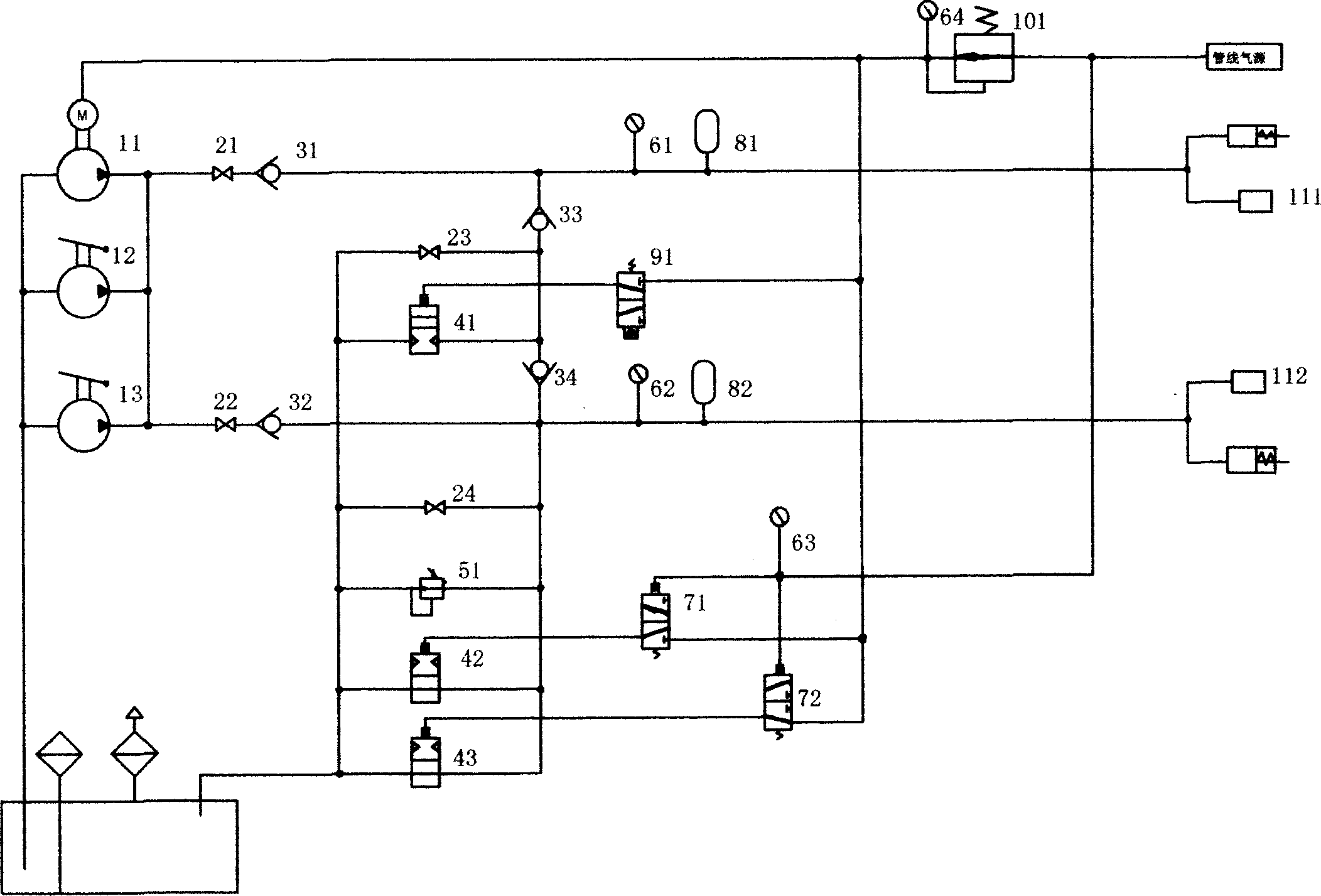

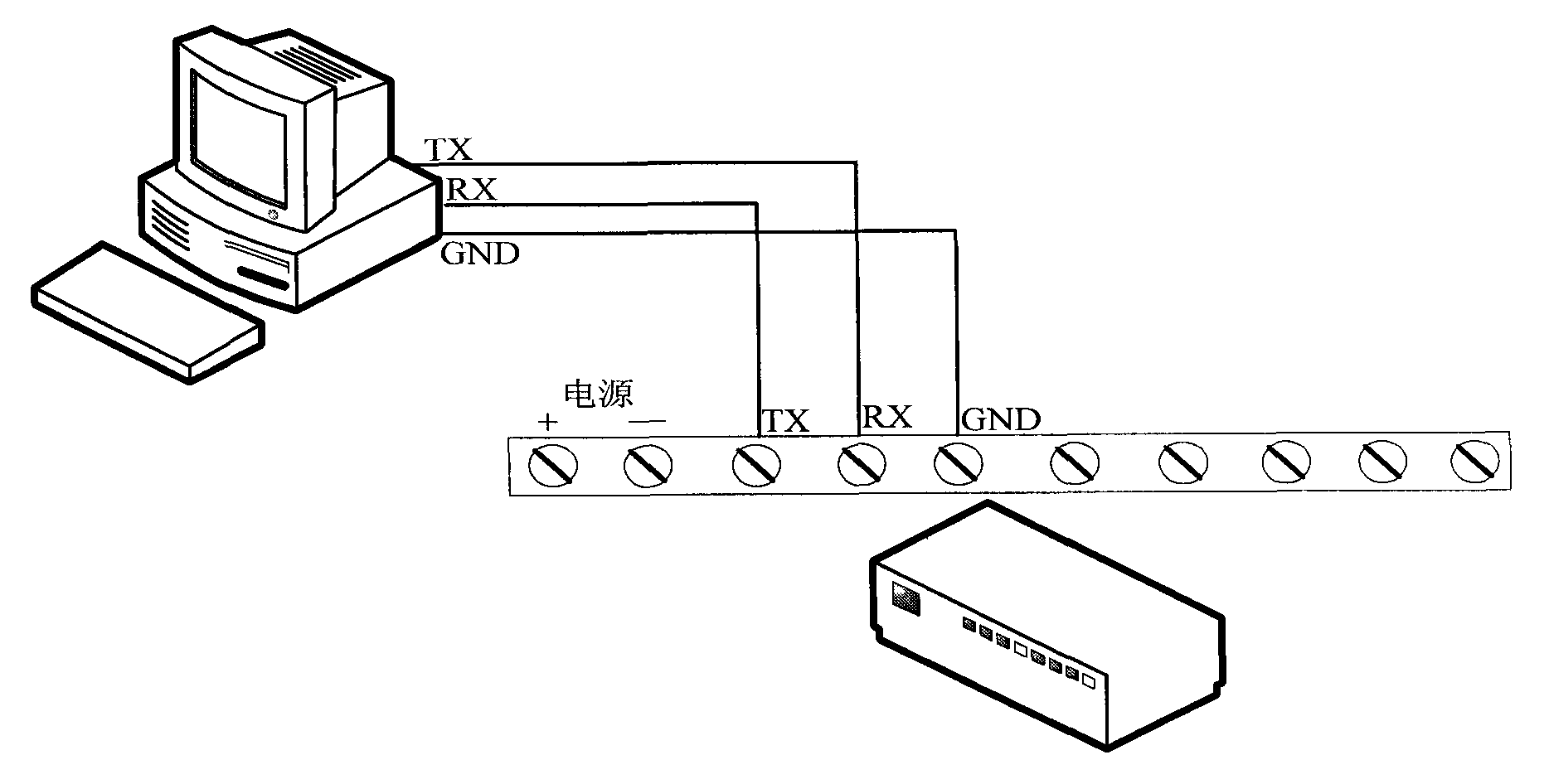

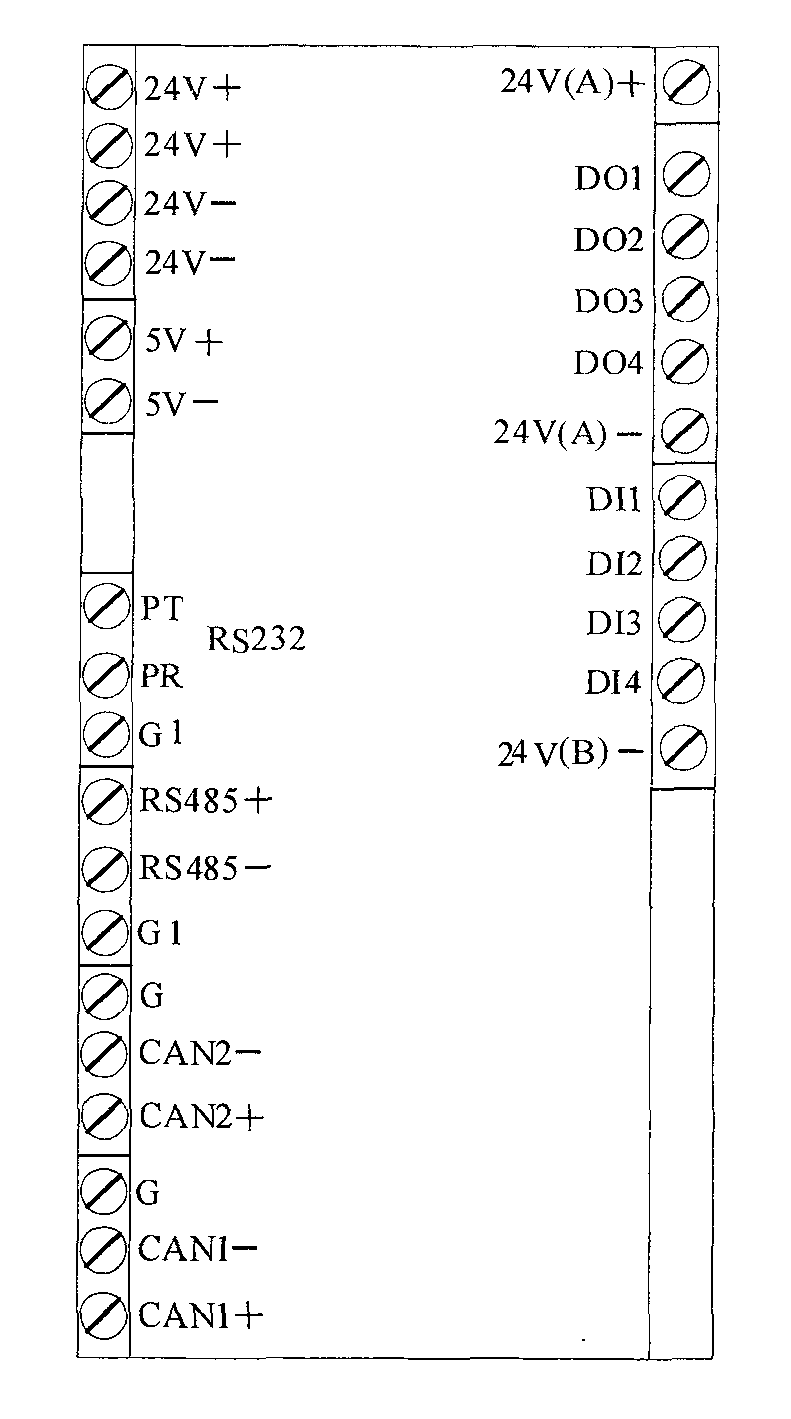

Control system of well mouth release valve

ActiveCN1908365AMeet opening pressure requirementsThere is no security riskWell/borehole valve arrangementsSealing/packingLine tubingControl system

The invention relates to a well safety valve control system, which comprises: an air-powered pressurizing pump and a ground safety valve control circuit, wherein said ground safety valve control circuit comprises one high-pressure needle valve, one-way valve, a pressure meter, and an energy accumulator; one overflow valve is between the one-way valve and the pressure meter; one end of high-pressure needle valve is connected to the air-powered pressurizing pump; one end of energy accumulator is connected to the ground safety valve and connected to the air source; another high-pressure needle valve is between the one-way valve and the pressure meter; the under-well safety valve control circuit is between the air-powered pressurizing pump and the under-well safety valve; said circuit comprises one high-pressure needle valve, one-way valve, pressure meter, and energy accumulator which are connected; another branch is between the one-way valve and the pressure meter, whose another end is connected between the one-way valve and the pressure meter; said branch has two one-way valves; one high-pressure needle valve is between two one-way valves.

Owner:深圳市弗赛特科技股份有限公司

Downhole safety valve

InactiveUS20060157255A1Prevents sudden loss of pressureConstructionsFluid removalEngineeringDownhole safety valve

Owner:WEATHERFORD TECH HLDG LLC

Downhole safety valve

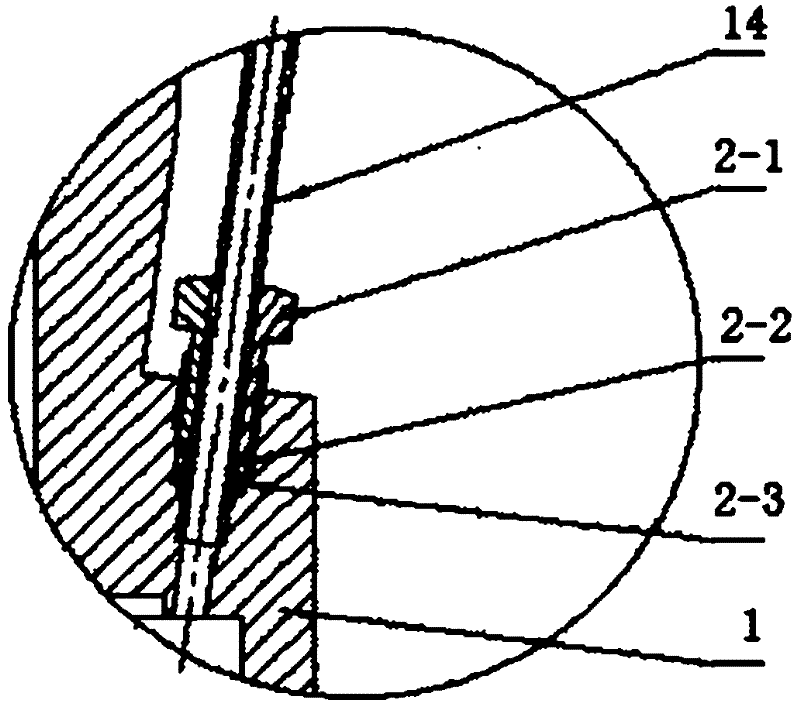

ActiveCN102409998AChange connection methodSolve the sealing problemWell/borehole valve arrangementsSealing/packingControl lineEngineering

The invention discloses a downhole safety valve, wherein a central tube is arranged in a main body consisting of a top joint, a valve body, an outer cylinder and a tail joint connected sequentially; the upper end of the top joint and the lower end of the tail joint are respectively connected with an external oil tube; a corrugated tube assembly is arranged in the gap between the outer cylinder and the central tube, and the bottom end of the corrugated tube assembly is connected with a positioning ring fixed on the peripheral wall of the central tube; a boss is formed on the inner wall of the lower port of the outer cylinder, a pressure spring is sleeved on the periphery of the central tube between the lower side of the positioning ring and the boss, and a plate valve assembly is connected to the bottom end of the outer cylinder; the top joint is provided with a control line, the control line is embedded on the top joint through a control line connection assembly and communicated with a hydraulic oil passage formed in the valve body wall, and the bottom port of the hydraulic oil passage in the valve body wall is connected with the top end of the corrugated tube assembly. The downhole safety valve can be used in extreme environment with well conditions such as super high temperature steam thermal recovery, high gas tightness requirement, ultradeep installation, high sandiness environment and high corrosion.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Downhole Safety Valve Apparatus and Method

ActiveUS20080210438A1Preventing fluidic communicationMake up for deficienciesConstructionsFluid removalEngineeringFlap valve

The application discloses a safety valve including a flapper valve and a packer assembly to be installed in a bore to isolate a first zone from a second zone. Preferably, the safety valve includes a hydraulic conduit bypassing the flapper valve to allow communication therethrough when the valve is closed. Furthermore, the safety valve preferably allows unobstructed passage of tools and fluids therethrough when the flapper valve is open. The application discloses a method to install a safety valve in an existing string of tubing by deploying a packer assembly having an integral safety valve.

Owner:BAKER HUGHES INC

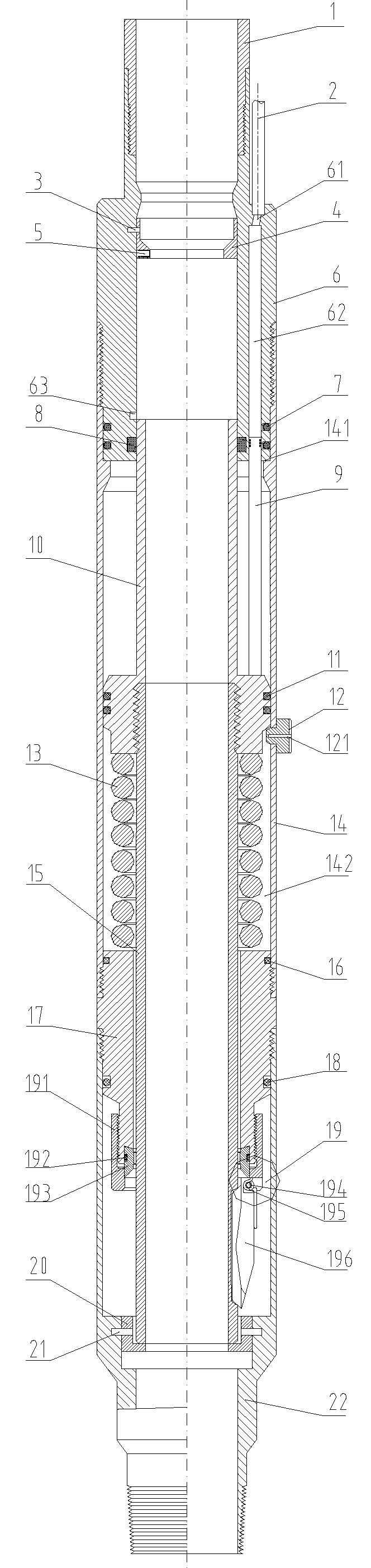

Downhole safety valve

InactiveCN110173233AExtended service lifeSave material purchase costWell/borehole valve arrangementsSealing/packingLine tubingUpper joint

A downhole safety valve is connected into an oil pipe; a hydraulic cavity in an upper joint is provided with a piston rod; the hydraulic cavity is connected with a hydraulic control pipeline; the tailis connected with a spring sleeve; a spring in the spring sleeve is located between a driving pipe and an upper valve seat; the upper valve seat is connected with the spring sleeve; the driving pipeis connected with an upper central pipe; the driving pipe is in clearance fit with the upper joint; the upper valve seat is in clearance fit with the upper central pipe; the upper valve seat is connected with an upper valve plate; the upper valve seat is internally provided with an upper self-balancing component; the spring sleeve is connected with a transition joint A; the transition joint A is fixedly connected with a lower valve seat; a shear pin is connected with the lower valve seat; the lower valve seat is connected with a lower valve plate; the lower valve seat is provided with a lowerself-balancing component; and the lower valve seat is connected with a lower joint. Through the design of the upper-lower two-stage valve plates or more-stage valve plates, and by increasing the pressure of the control pipeline, a secondary valve plate is controlled to open and close by pushing the upper central pipe to cut the shear pin in the lower valve seat; and the service life of the safetyvalve is prolonged, and the material procurement cost of oil fields is reduced.

Owner:XI'AN PETROLEUM UNIVERSITY

Self-balancing downhole safety valve

InactiveCN103821477APromote repairEasy to open and closeWell/borehole valve arrangementsSealing/packingUpper jointEngineering

The invention belongs to the field of oil-gas field development, and particularly relates to a self-balancing downhole safety valve. The self-balancing downhole safety valve is of a columnar annular structure and comprises an upper joint, a piston sleeve, a spring sleeve, a connecting joint, a lower joint, a drive pipe, a center pipe, a spring and a valve base structure. The self-balancing downhole safety valve is characterized in that the upper joint, the piston sleeve, the spring sleeve, the connecting joint and the lower joint are sequentially fixedly connected to form a hollow shell, the drive pipe, the center pipe, the spring and the valve base structure are arranged in the shell formed by the upper joint, the piston sleeve, the spring sleeve, the connecting joint and the lower joint, the drive pipe is fixedly connected with the center pipe, the spring is arranged on the center pipe, the top end and the bottom end of the spring abut against the bottom of the drive pipe and the top of the connecting joint respectively, and the valve base structure is arranged at the lower end of the connecting joint. According to the self-balancing downhole safety valve, the opening and closing actions of an oil well in a normal work state can be excellently finished, the reliable later-period repair function is designed, and therefore reliability of a well mouth safety system is greatly improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Downhole blow-out preventer with automatic controlling and anchoring function

The invention relates to a downhole blow-out preventer with an automatic controlling and anchoring function, which is used in a condition of occurring well kick or blowout in a drilling process of an oil and gas field. The downhole blow-out preventer can be used for automatically turning on a shut-in well underground, and can be used for de-blocking the preventer in time according to demands. According to the technical scheme, an underground safety valve is mounted in a drill column on a drill pipe; a base sealing and anchoring device is mounted on the downhole blow-out preventer; a lower joint is connected with a lower part drill pipe; an outer wall one-way valve assembly is mounted on an outer cylinder; a switching-on pin is mounted on the outer cylinder and a pressurizing piston; the outer cylinder is fixed by the lower joint; the pressurizing piston is mounted outside a center pipe; a rubber cylinder base is in close contact with a separation ring; the lower end of an outer center pipe is in contact with the rubber cylinder base, and a distance is reserved between the upper end of the outer center pipe and an anchoring tilt cone; a blow-out prevention sealing rubber cylinder is in tight contact with the outer center pipe; and an anchoring tile, the center pipe and an anchoring tile sleeve are fixedly arranged by an upper joint. The downhole blow-out preventer can be used for effectively preventing the blowout underground, so anchoring, blowout prevention and operation while drilling when the well kicks can be realized; the reliable operation is realized; and the drilling efficiency can be improved.

Owner:SOUTHWEST PETROLEUM UNIV

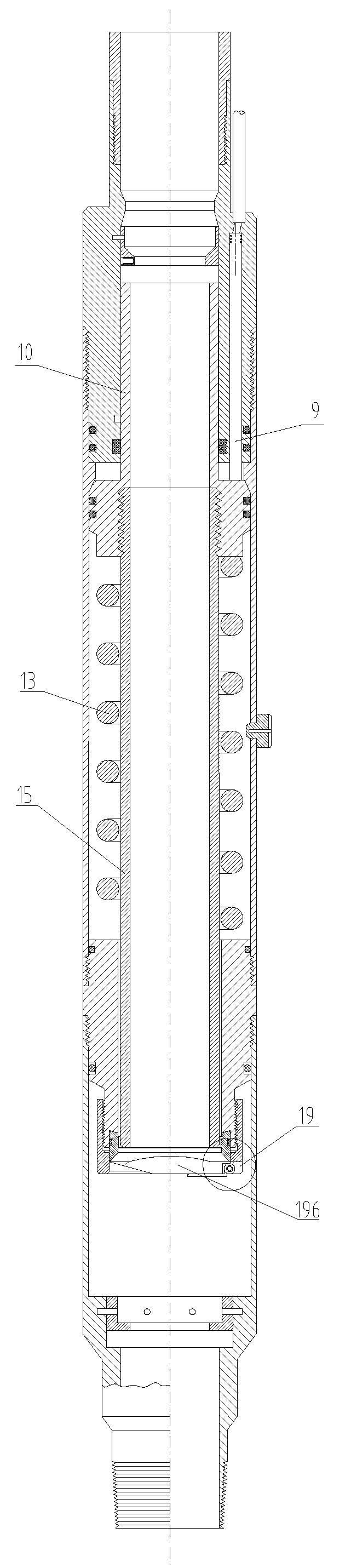

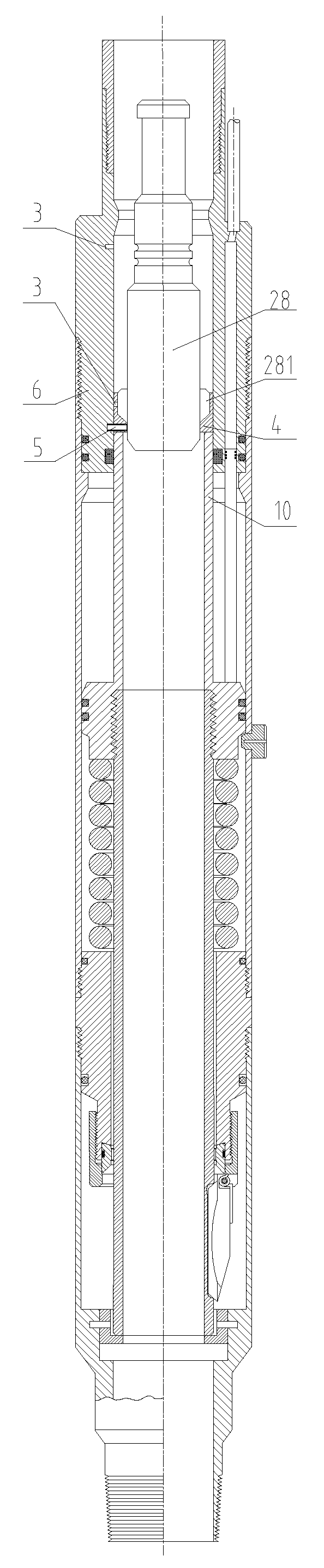

Full electric driving downhole safety valve

ActiveCN110005371AQuick responseImprove working conditionsOperating means/releasing devices for valvesConstructionsEngineeringPower unit

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

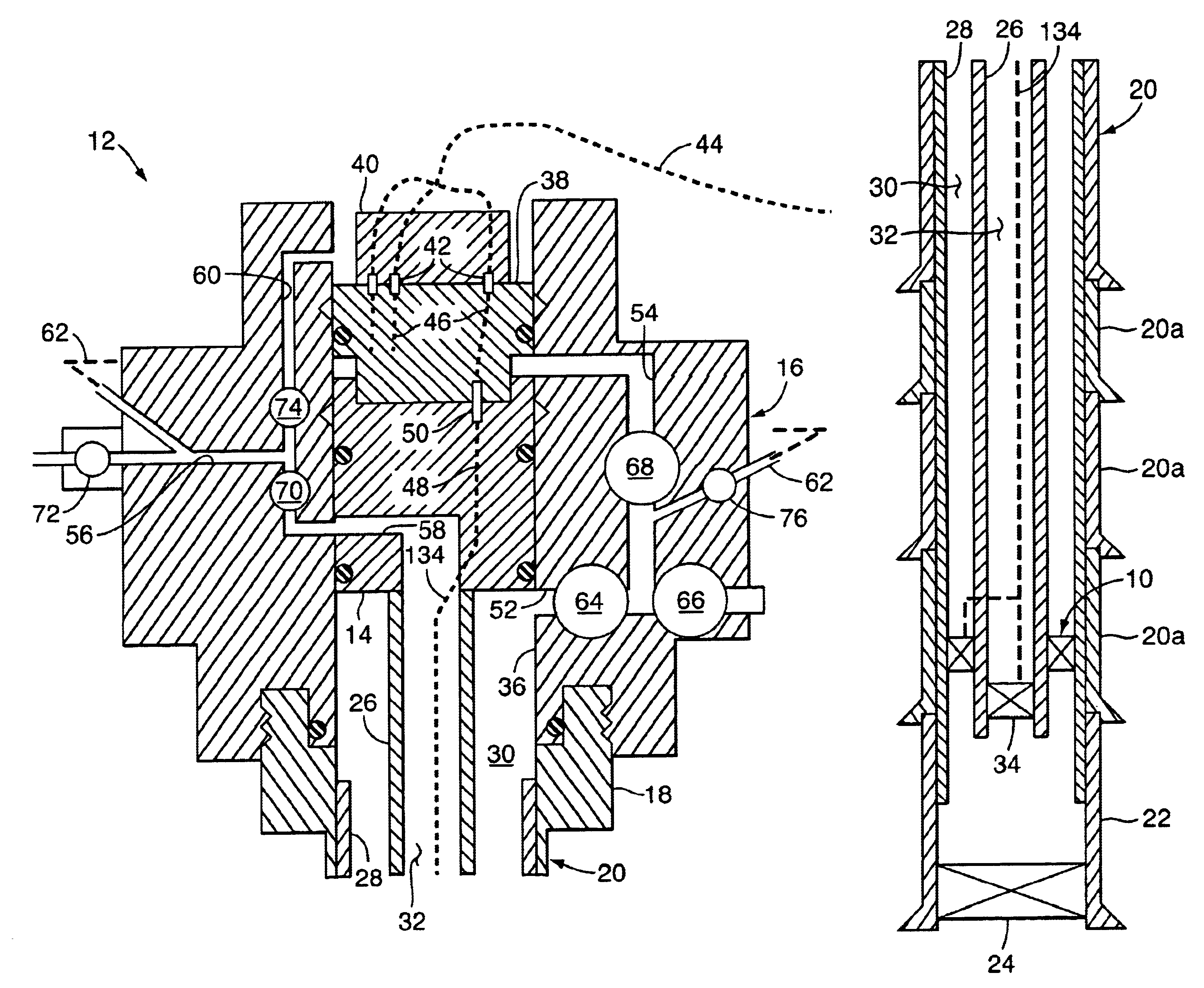

Through-Riser Installation of Tree Block

A subsea well assembly has a tubing hanger that lands and seals in a wellhead housing. A tree block is lowered through the drilling riser into engagement with the tubing hanger. The tree block has a lower portion that inserts and latches into the bore of the wellhead housing. The drilling riser is disconnected, and a module is lowered onto the tree block, the module having a choke and controls for controlling the well. The master valve for production is the downhole safety valve in the tubing. The wing production valve is a ball valve located in the flow passage of the tree block.

Owner:VETCO GRAY

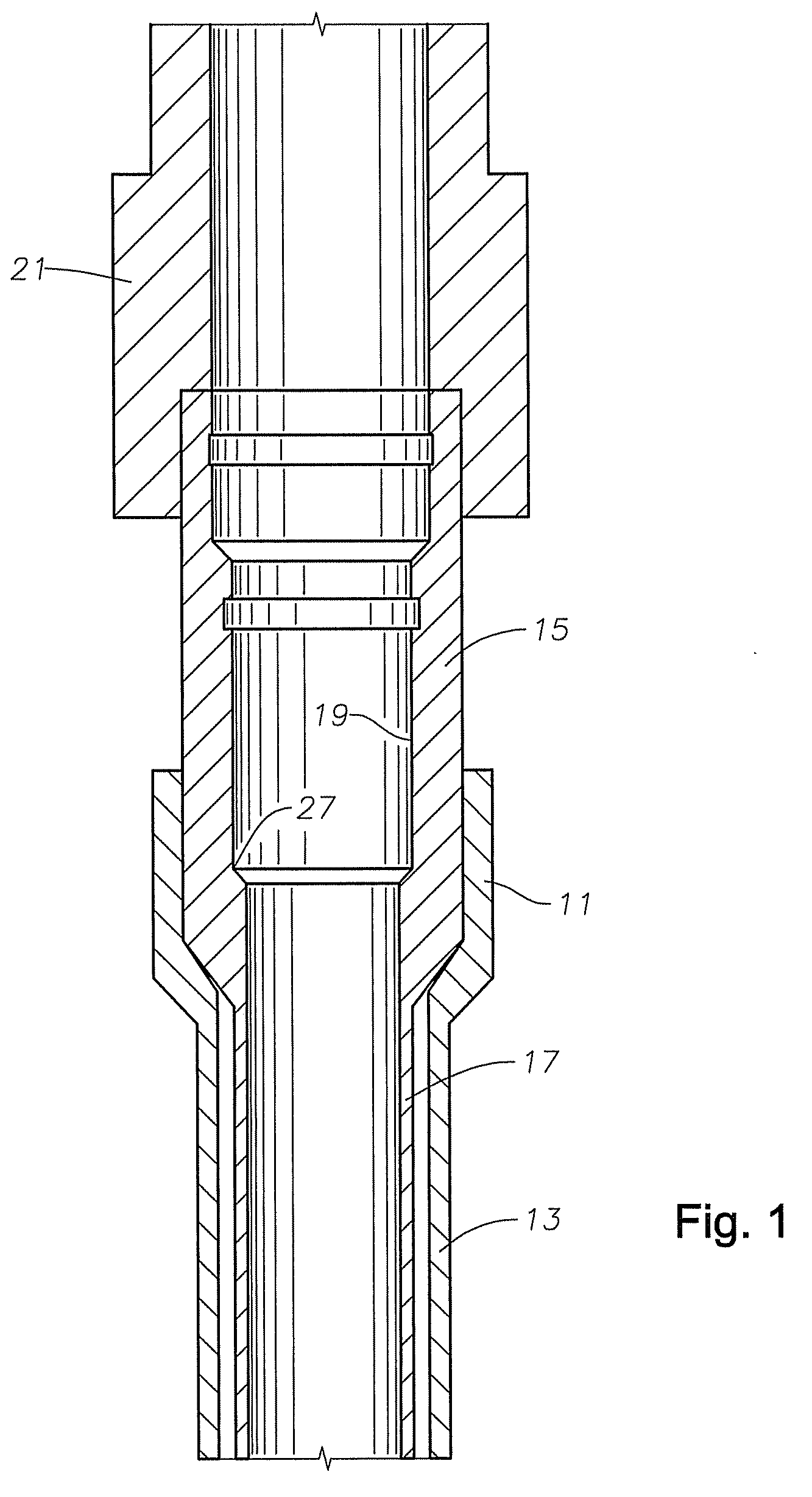

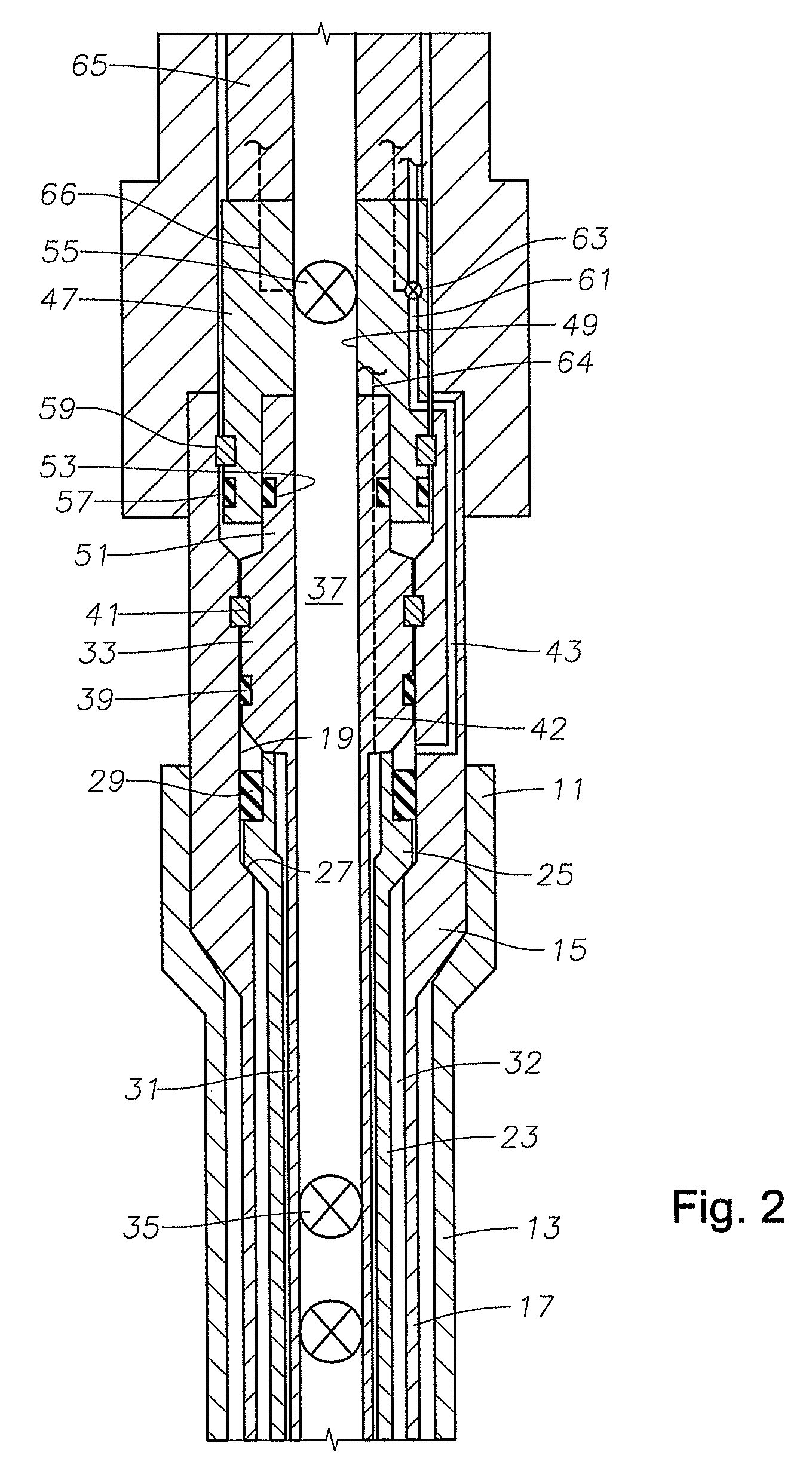

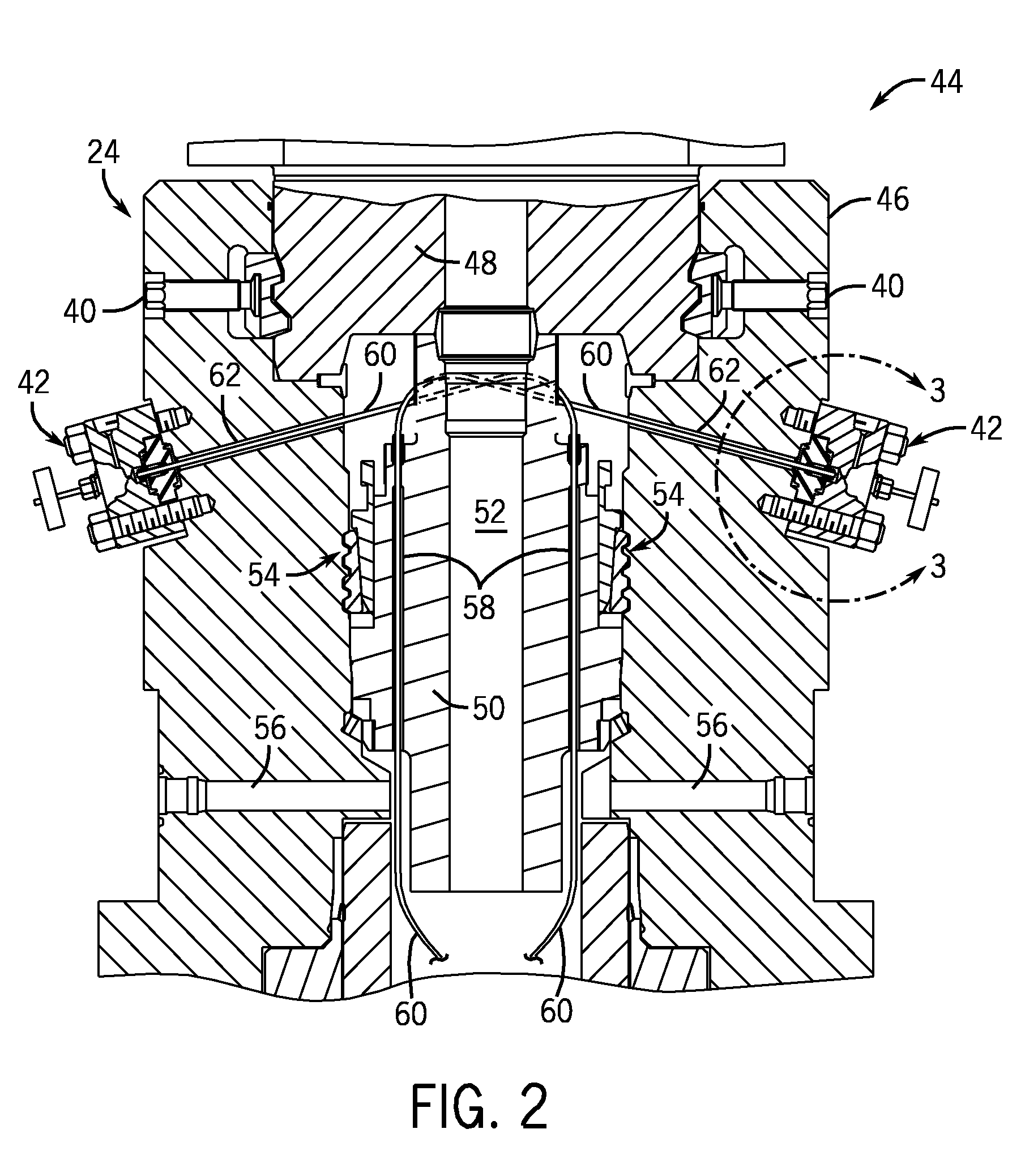

Downhole safety valve for central circulation completion system

A downhole safety valve for a central circulation completion system having concentric inner and outer tubular members defining a production bore therebetween comprises a generally cylindrical body which includes an outer surface which is sealed to the outer tubular member and an axial through bore to which the inner tubular member is secured. In this manner, the downhole safety valve forms a pressure barrier between a first portion of the production bore located below the body and a second portion of the production bore located above the body. The downhole safety valve further comprises at least one flow passage which extends through the body and communicates between the first and second portions of the production bore, and at least one closure member which is disposed across the flow passage to control fluid flow between the first and second portions of the production bore.

Owner:FMC TECH INC

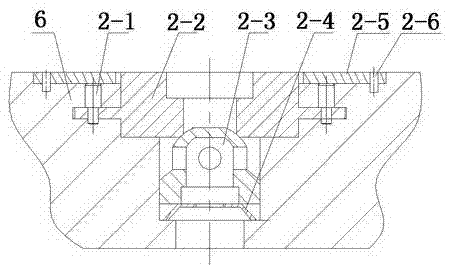

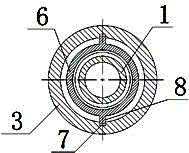

Sliding sleeve type subsurface safety valve

InactiveCN104314520AQuick responseNo air leakageConstructionsWell/borehole valve arrangementsDownhole safety valveEngineering

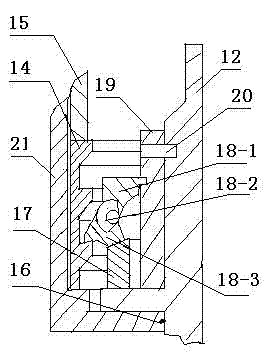

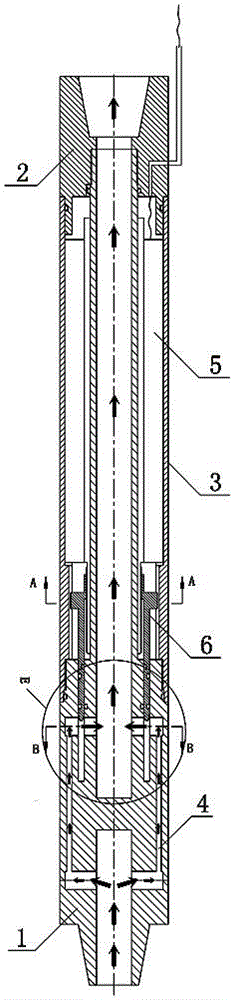

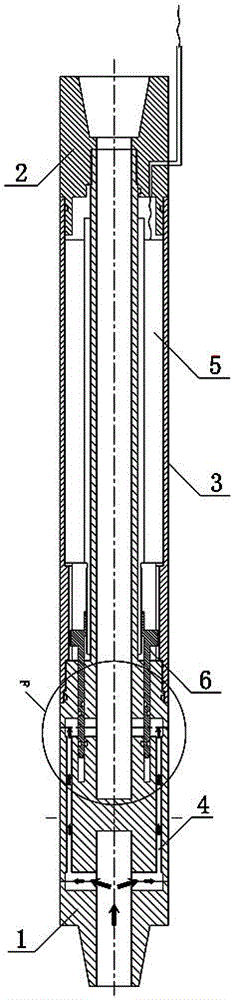

The invention relates to a sliding sleeve type subsurface safety valve. The sliding sleeve type subsurface safety valve comprises a lower joint (1), an upper joint (2), a housing (3), a power device (5) and a sliding sleeve (6), wherein an oil gas passage (4) is arranged inside the lower joint (1); a thin shaft part at the upper part of the lower joint (1) is matched and connected with the upper joint (2) through threads; a thick shaft part at the lower part of the lower joint (1) and the upper joint (2) are respectively matched with the housing (3); an annular inserting groove (11) is formed in the inner part of the lower joint (1) in the axial direction; the power device (5) is mounted in a closed cavity formed by the lower joint (1), the upper joint (2) and the housing (3); the sliding sleeve (6) comprises a connecting part (6) and an isolating part (10); the connecting part (9) is connected with the output end of the power device (5); the isolating part (10) is matched with the annular inserting groove (11) in an inserting connection mode. The sliding sleeve type subsurface safety valve has the advantages of rapid and sensitive reaction, complete isolation and reusing.

Owner:SOUTHWEST PETROLEUM UNIV

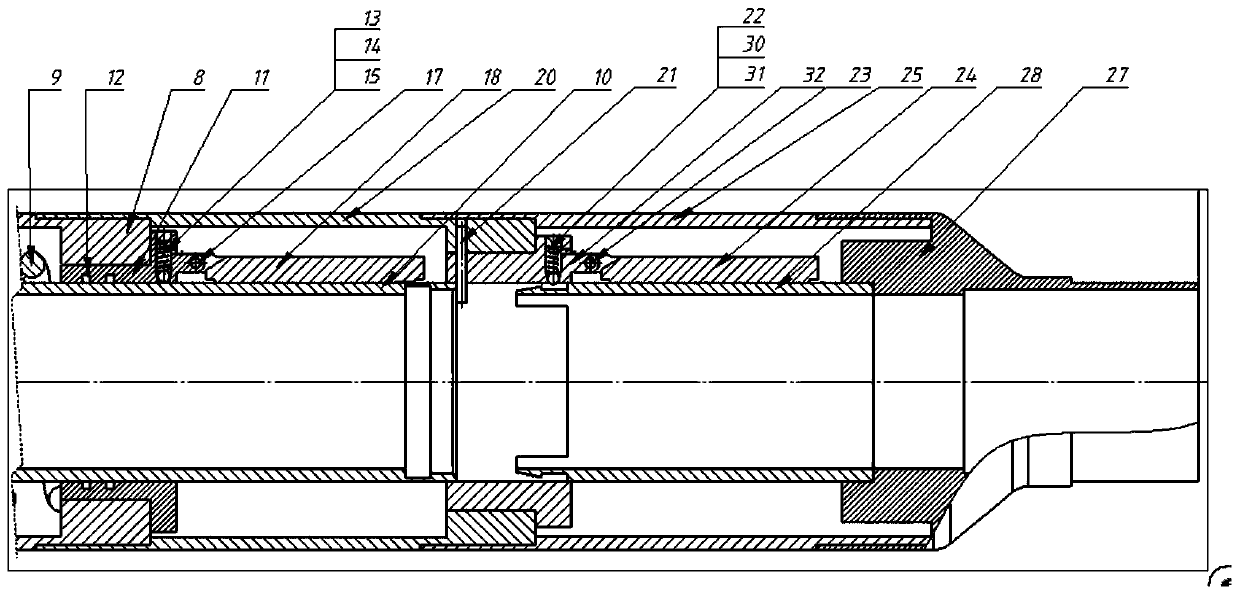

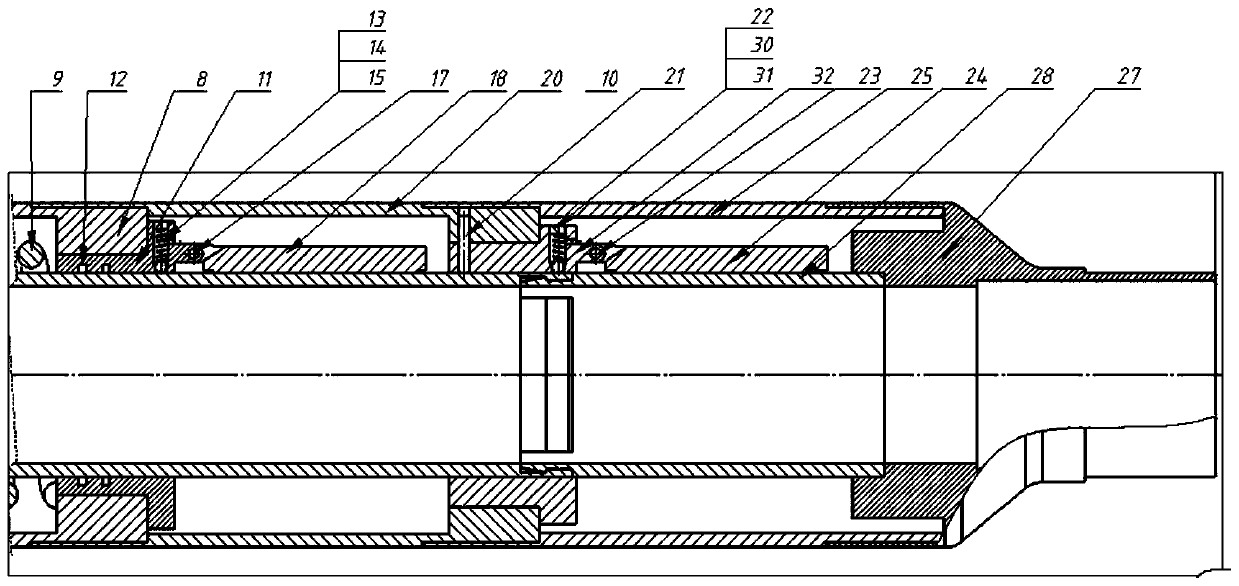

Dual-flap-valve type downhole safety valve

ActiveCN104499993AEnsure safetyImproves sealing reliabilityWell/borehole valve arrangementsSealing/packingLine tubingEngineering

The invention discloses a dual-flap-valve type downhole safety valve which comprises an outer shell formed by sequentially connecting an upper short piece, a middle short piece and a lower short piece, wherein the inner cavity of the middle short piece is provided with a spring; the inner cavity of the upper short piece is provided with a piston pipe; the piston pipe is of a cylinder structure; the pipe wall of the upper short piece is internally provided with at least two plunger holes for mounting plungers along an axial direction; the upper ends of the plunger holes are connected with the outside by virtue of a hydraulic pipeline joint; each plunger hole is internally provided with a group of plunger assemblies; the lower opening of the middle short piece is connected with an upper valve base by virtue of threads; an upper flap valve is arranged below the upper valve base; the convex shoulder of the inner cavity of the lower short piece is connected with a lower valve base by virtue of threads, and a lower flap valve is arranged below the lower valve base is provided with. According to the dual-flap-valve type downhole safety valve, a dual-flap-valve structure is adopted and the two plungers are adopted for driving, so that double shut of downhole pressure is realized, the dual-flap-valve type downhole safety valve is simple in structure and reliable in operation.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

System and method for terminating tubing

A technique is provided for terminating tubing. In the technique, a tubing termination assembly is used to terminate control line tubing from a downhole safety valve at a wellhead component. The tubing termination assembly utilizes a seal ring to form a seal around control line tubing extending from a port through a wellhead component. A seating surface is provided in the seal ring, rather than in the wellhead component, to which a seal member is abutted to form the seal with the control line tubing. The seal ring also comprises a threaded portion to enable a threaded member to urge the seal member against the seating surface.

Owner:VAULT PRESSURE CONTROL LLC

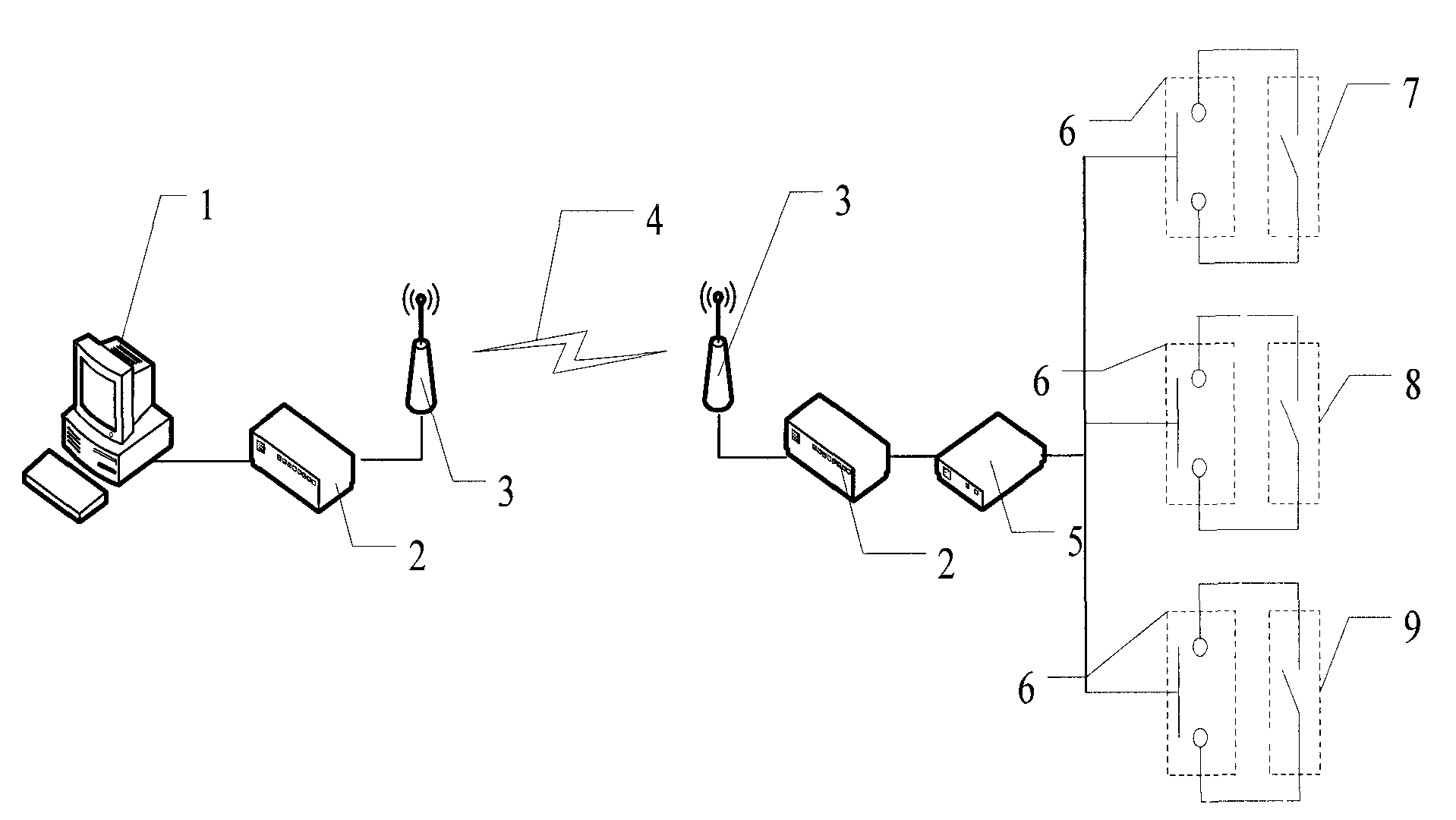

Remote control device and method of offshore oil and gas well safety valve

InactiveCN101819434AImprove securityIncrease the level of automationTotal factory controlProgramme total factory controlMicrocontrollerGeneral Packet Radio Service

The invention relates to a remote control device and a method of an offshore oil and gas well safety valve, belonging to the field of safety valve remote control. The remote control device of the offshore oil and gas well safety valve comprises a master control center upper computer, GPRS (General Packet Radio Service) modules, antennae, a safety valve single chip control device and electromagnetic relays, wherein the land master control center upper computer is sequentially connected with a first GRPS module, a first antenna, a second GPRS module, a second antenna, the safety valve single chip control device, a first electromagnetic relay, a second electromagnetic relay and a third electromagnetic relay; the three electromagnetic relays are in parallel connections; and the first electromagnetic relay is connected with a subsurface safety valve, the second electromagnetic relay is connected with a wellhead safety valve, and the third electromagnetic relay is connected with a well casing safety valve. The invention improves the safety and the automation level of the production of the offshore oil and gas well platform, and has the advantages of powerful function, simple installation, convenient use, safety and reliability.

Owner:NORTHEASTERN UNIV

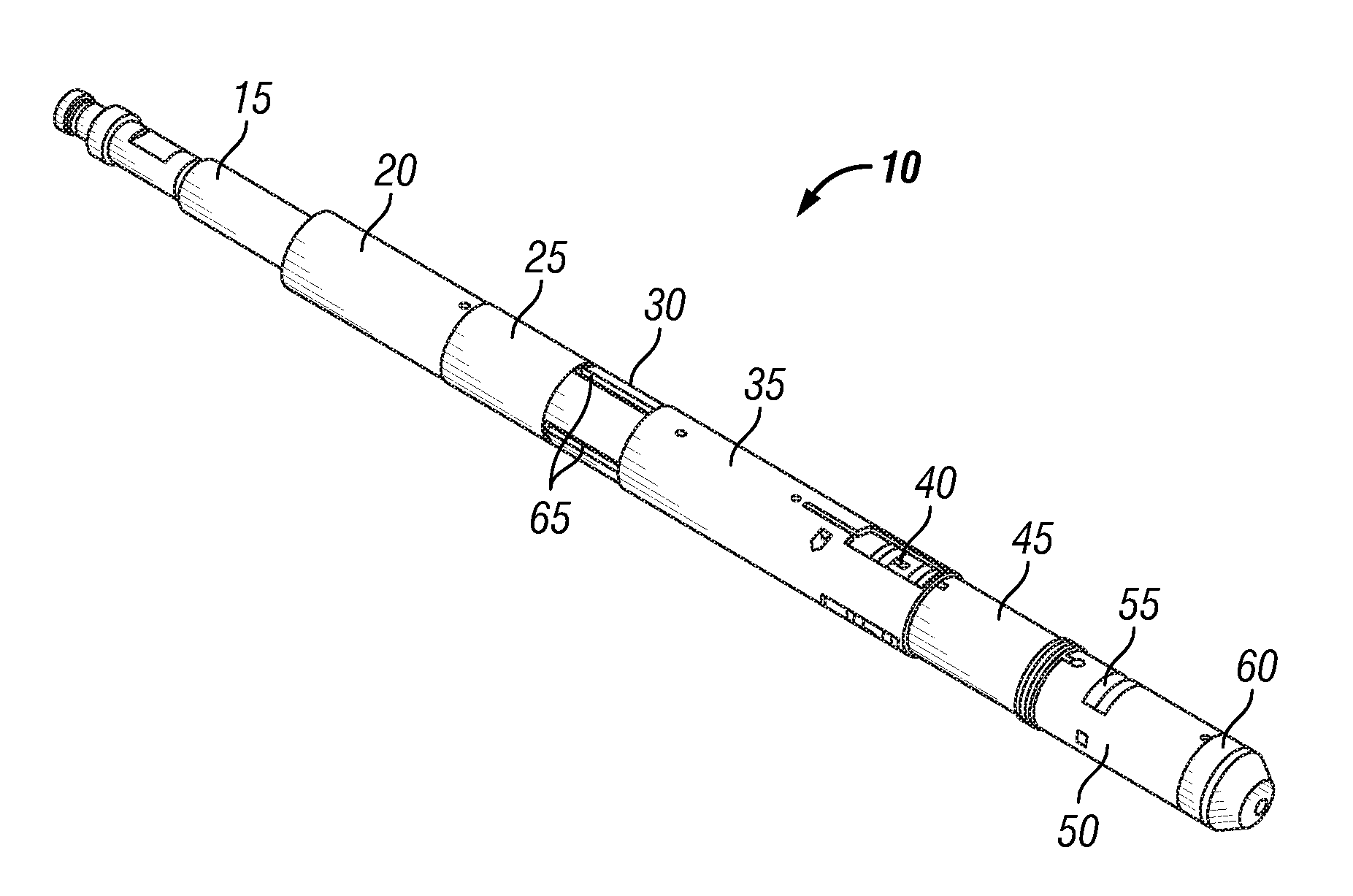

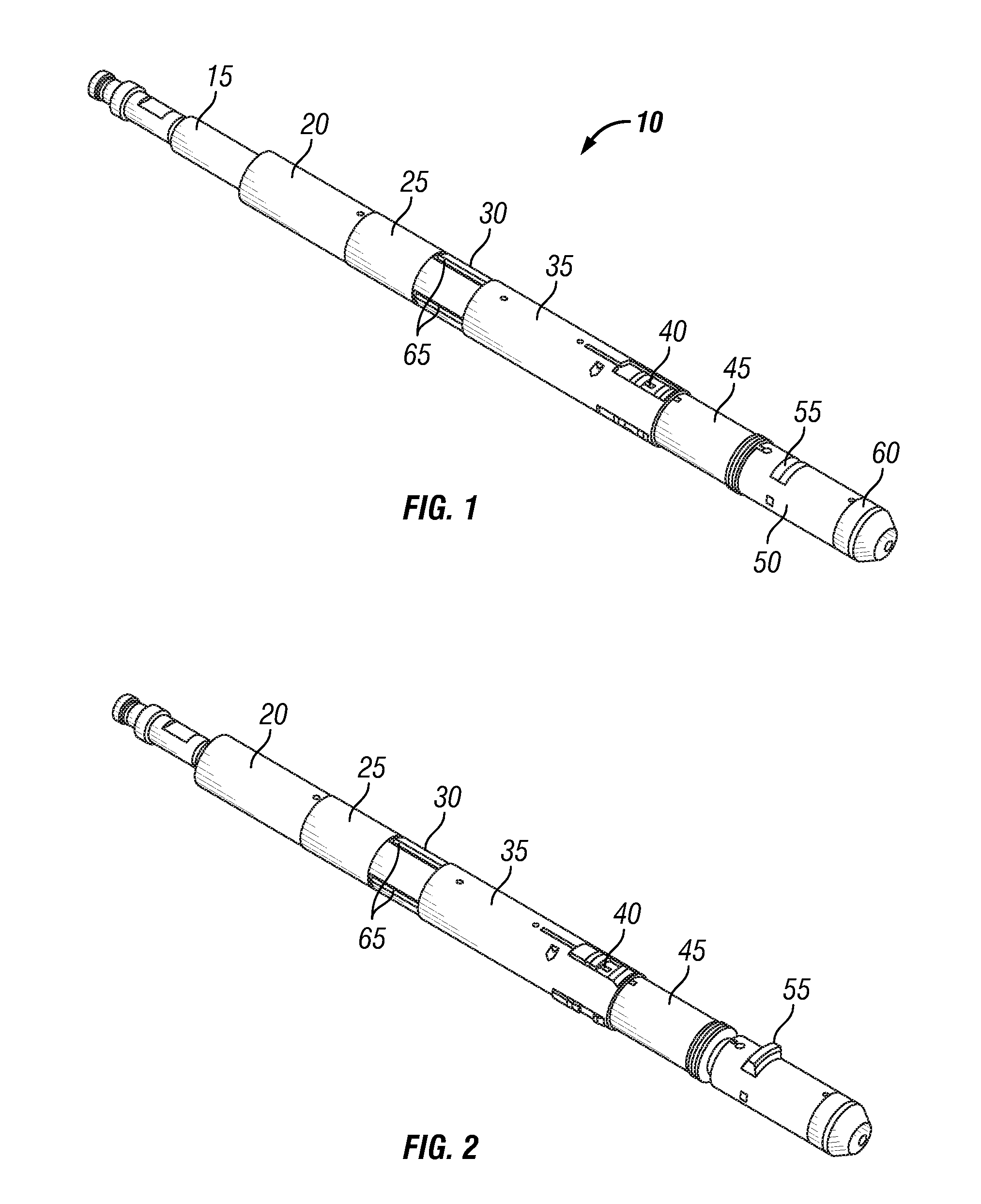

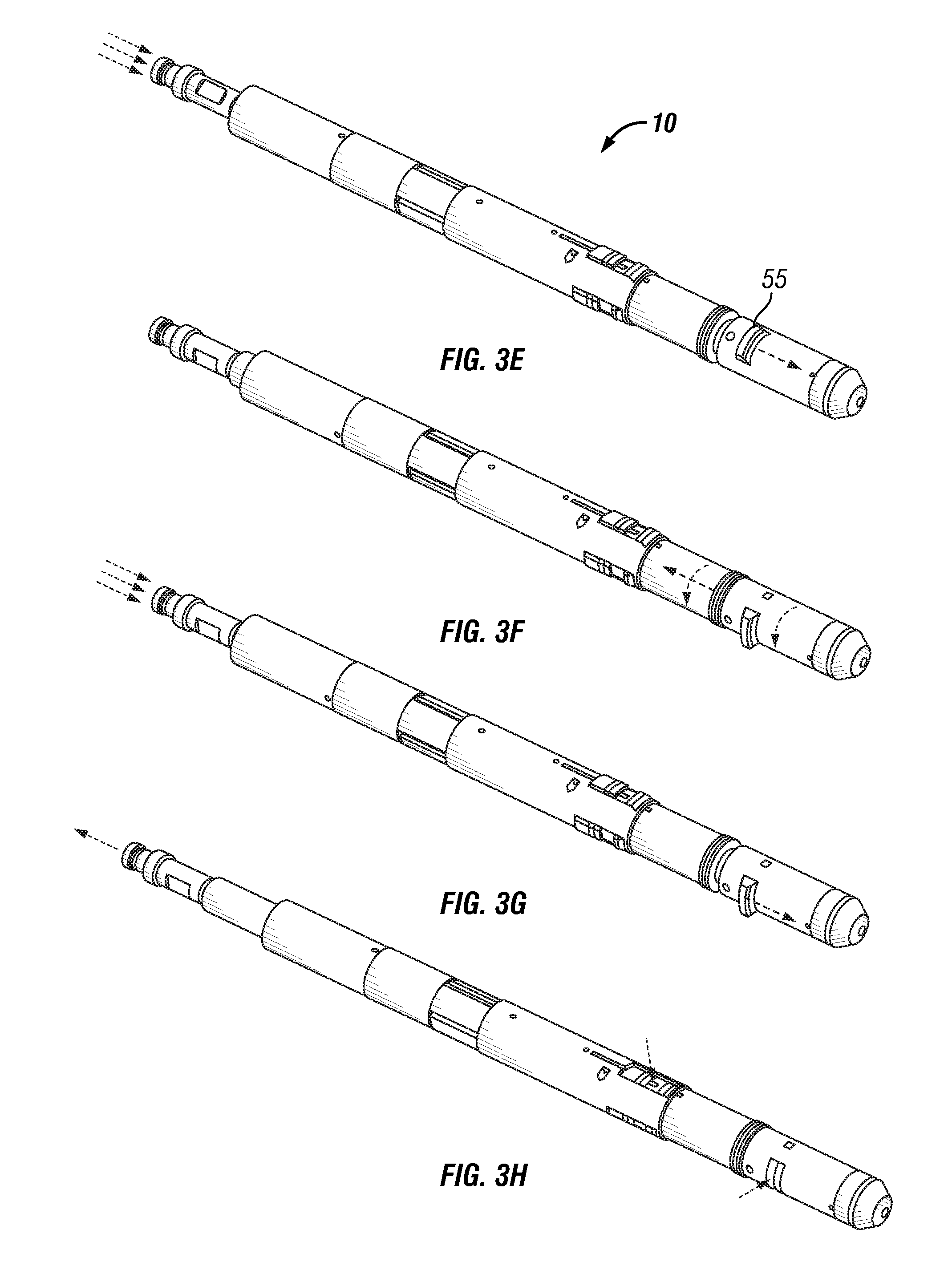

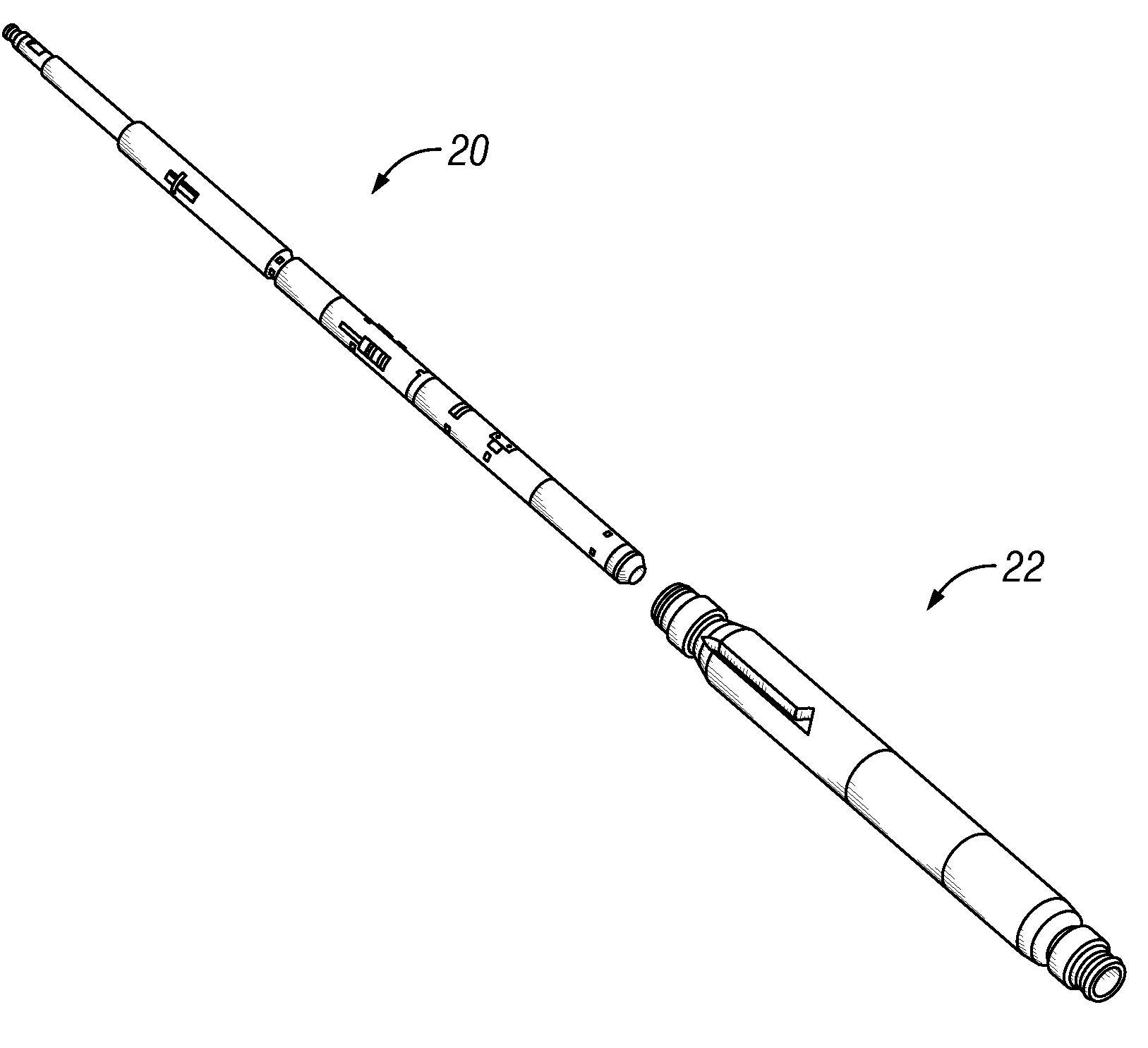

Radial indexing communication tool and method for subsurface safety valve with communication component

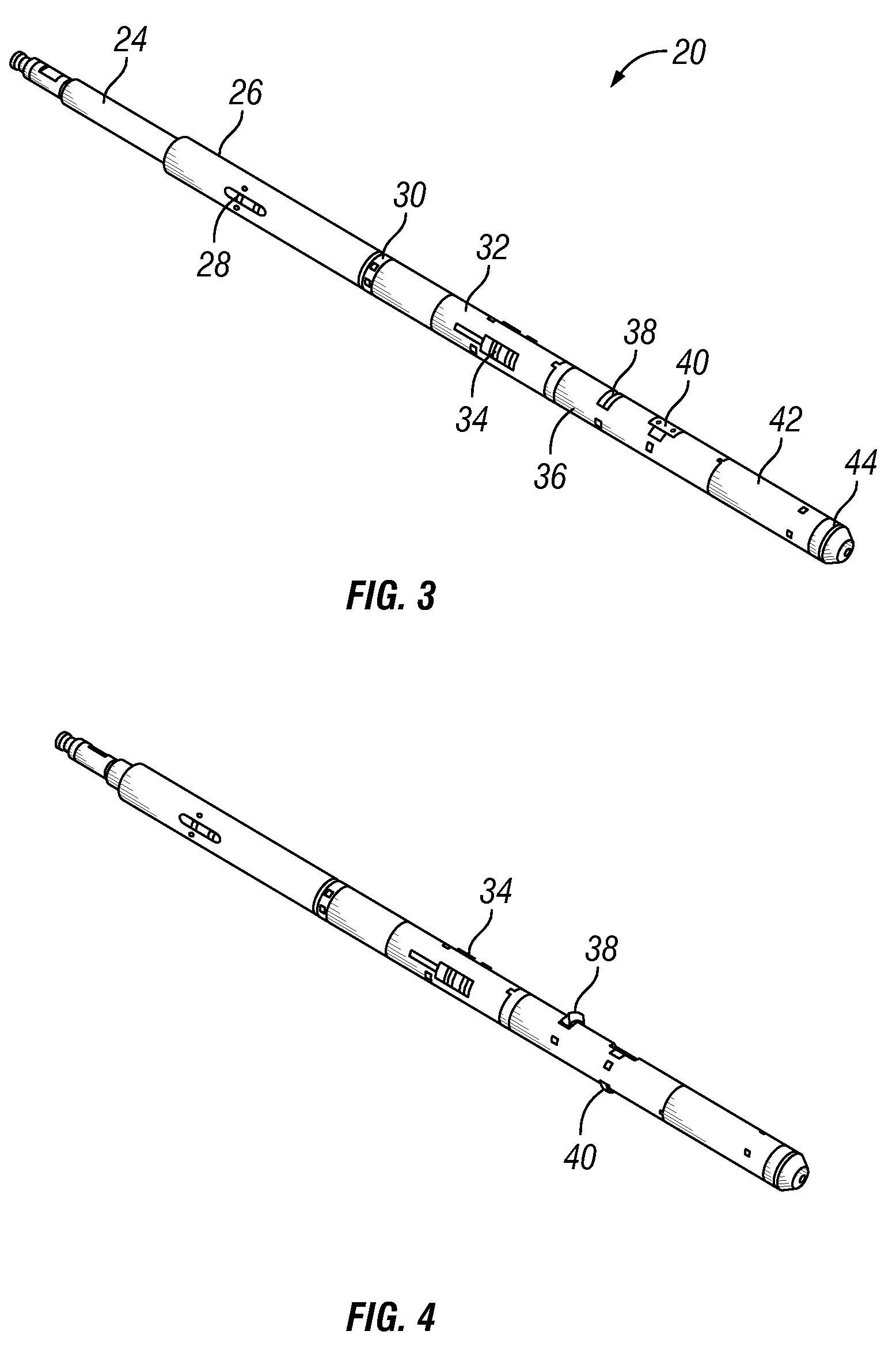

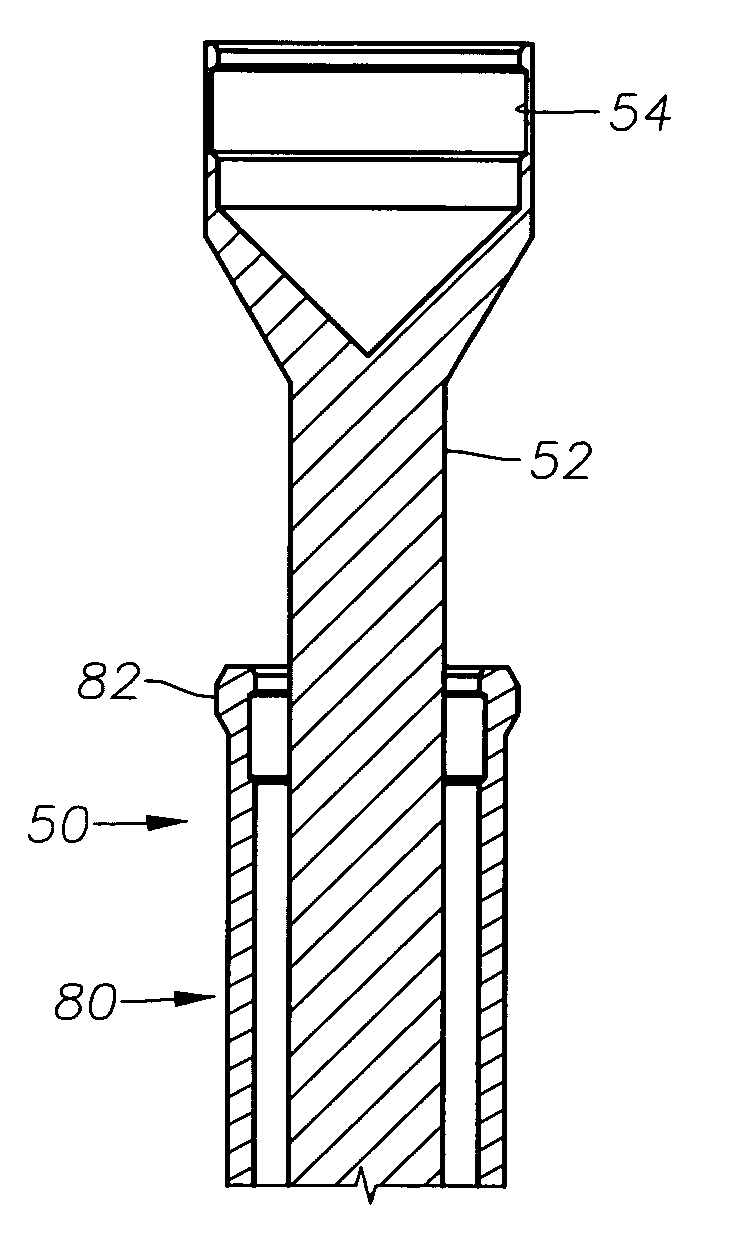

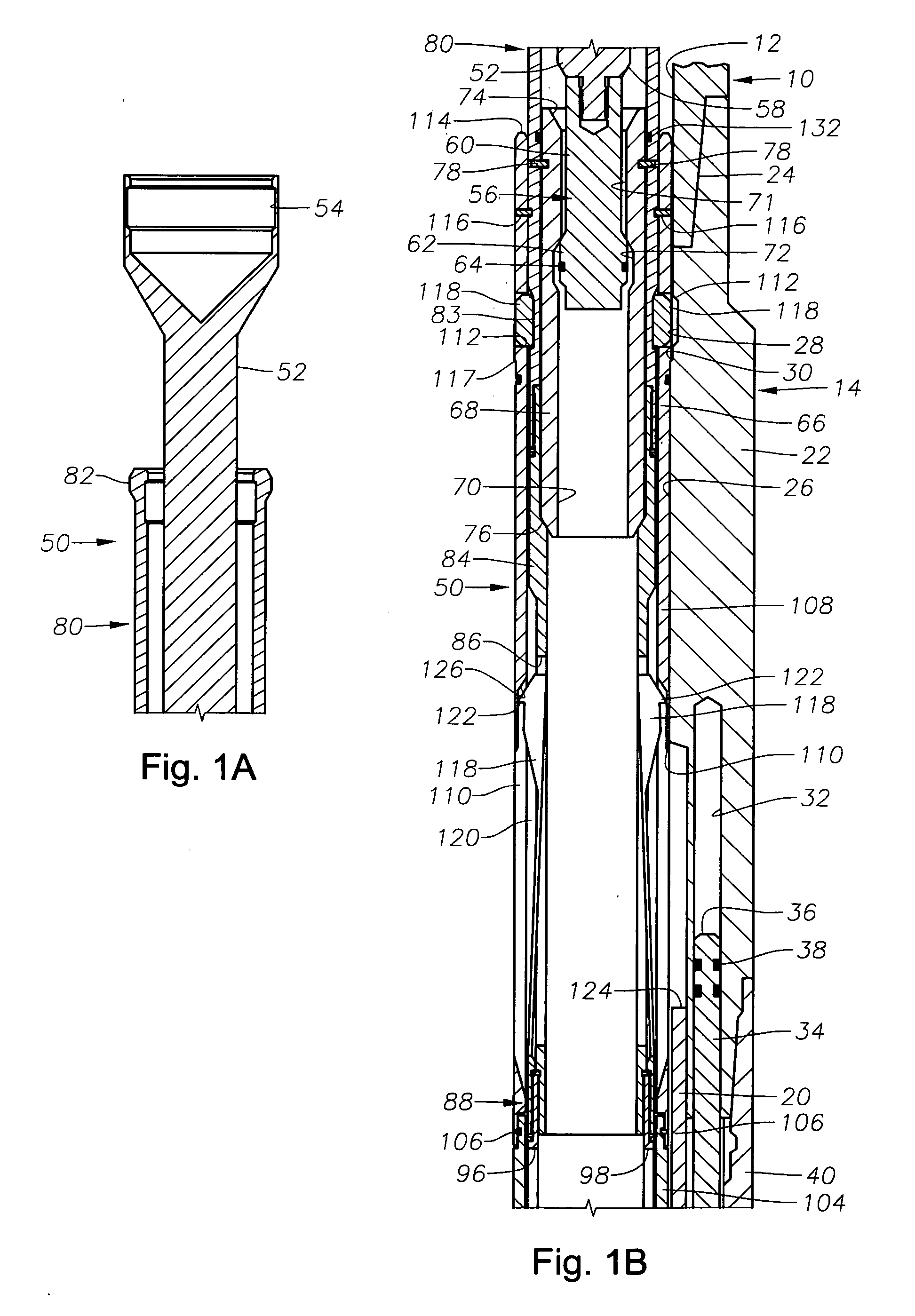

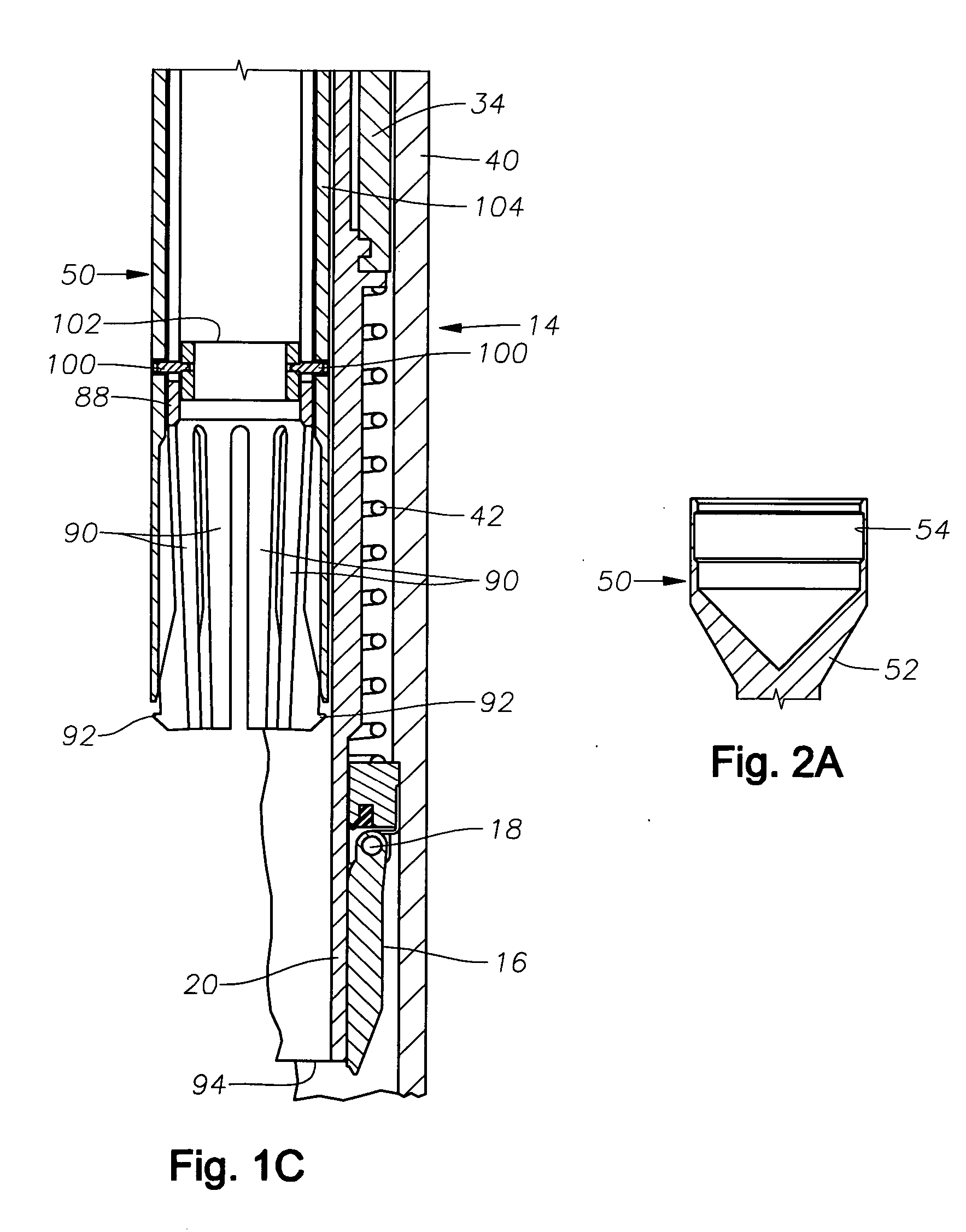

ActiveUS7918280B2Continued jarring and rotating stepsDrill bitsFluid removalEngineeringDownhole safety valve

A communication tool apparatus is described which is adapted to provide selective communication of control fluid through a downhole tool, such as a safety valve. The downhole safety valve is a tubing retrievable subsurface safety valve (“TRSSSV”). The communication tool may be run downhole and within the TRSSSV. Once within the TRSSSV, the communication tool apparatus activates a cutting device within the TRSSSV such that communication of control fluid through the TRSSSV is possible. A replacement safety valve run on a wireline may then be inserted into the TRSSSV and be operated via the control fluid line, as a new communication path created by the communication tool described herein. A method of using the communication tool apparatus is also described.

Owner:BAKER HUGHES INC

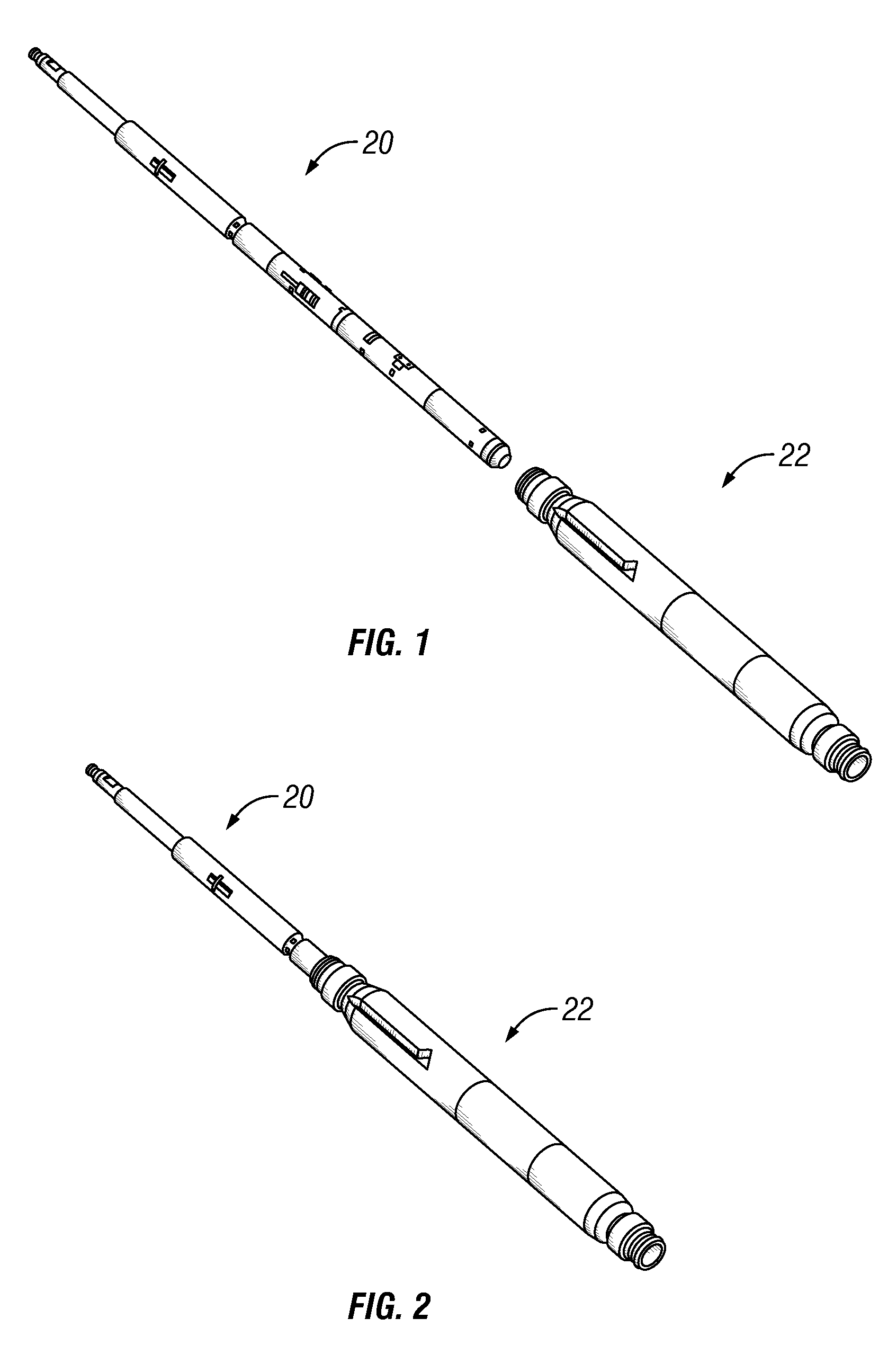

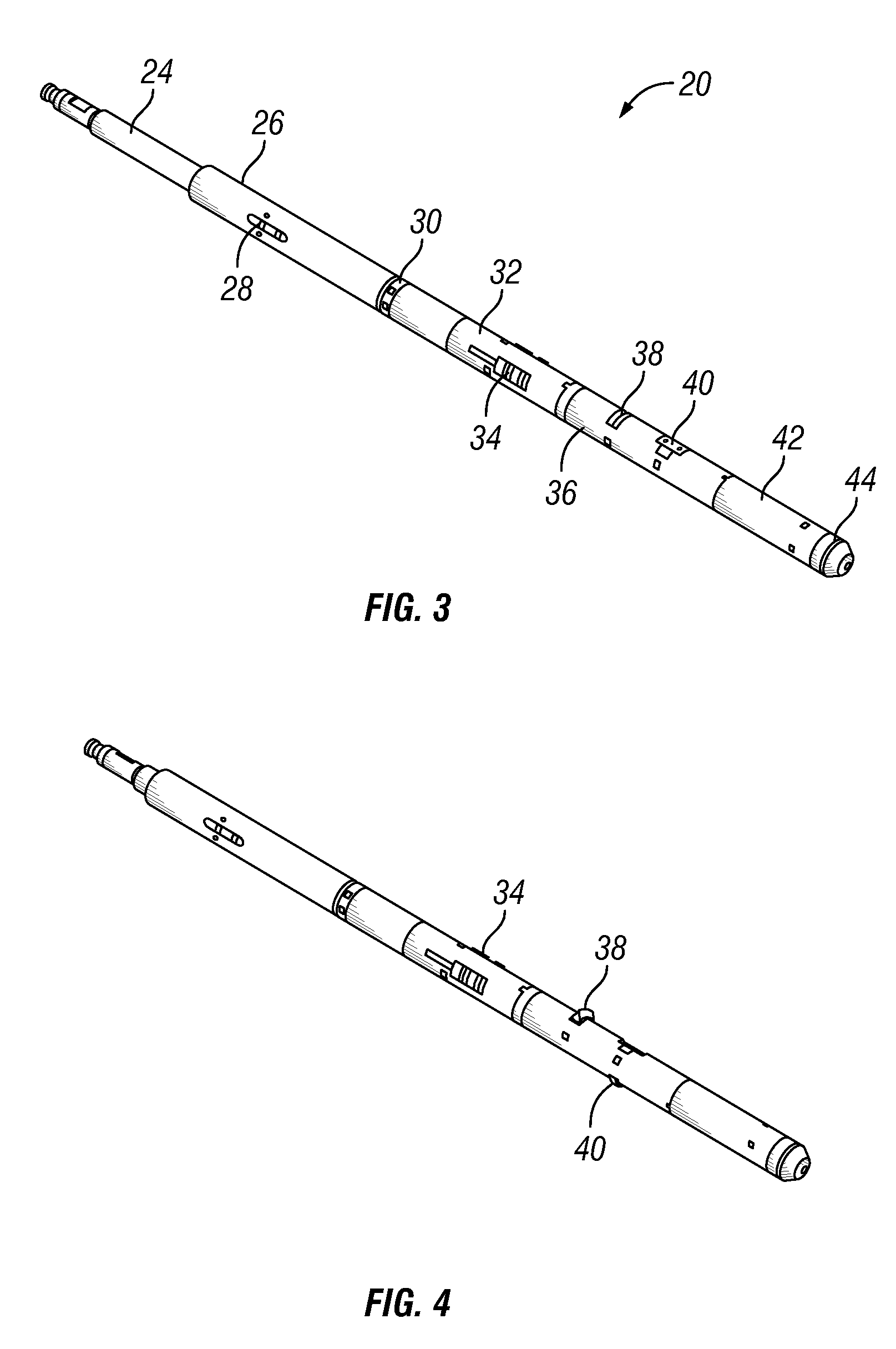

Flow tube exercising tool

InactiveUS20070062687A1Without risk of damageConstructionsCleaning apparatusStreamflowDownhole safety valve

A flow tube exercising tool and method for use are described for actuating the flow tube of a downhole safety valve in order to remove build ups of scale and debris from the safety valve and ensure proper operation. The exercising tool provides a lower engagement portion that underlies the lower end of the safety valve flow tube so that upward movement of portions of the exercising tool will move the flow tube upwardly. An upper engagement portion overlies the upper end of the flow tube so that downward movement of portions of the exercising tool will move the flow tube downwardly. Only a single trip of the flow tube exercising tool is necessary to accomplish multiple upward and downward movements of the flow tube.

Owner:BAKER HUGHES INC

Communication tool and method for a subsurface safety valve with communication component

InactiveUS20080196891A1Continued jarring and rotating stepsSurveyDrill bitsDownhole safety valveEngineering

A communication tool apparatus is described which is adapted to provide selective communication of control fluid through a downhole device such as a safety valve. The downhole safety valve is a tubing retrievable subsurface safety valve (“TRSSSV”). The communication tool may be run downhole and within the TRSSSV. Once within the TRSSSV, the communication tool apparatus activates a cutting device within the TRSSSV such that communication of control fluid through the TRSSSV is possible. A replacement safety valve run on a wireline may then be inserted into the TRSSSV and be operated via the control fluid line, as a new communication path created by the communication tool described herein. A method of using the communication tool apparatus is also described.

Owner:BJ SERVICES CO

Radial indexing communication tool and method for subsurface safety valve with communication component

ActiveUS20080190623A1Continued jarring and rotating stepsDrill bitsFluid removalEngineeringDownhole safety valve

A communication tool apparatus is described which is adapted to provide selective communication of control fluid through a downhole tool, such as a safety valve. The downhole safety valve is a tubing retrievable subsurface safety valve (“TRSSSV”). The communication tool may be run downhole and within the TRSSSV. Once within the TRSSSV, the communication tool apparatus activates a cutting device within the TRSSSV such that communication of control fluid through the TRSSSV is possible. A replacement safety valve run on a wireline may then be inserted into the TRSSSV and be operated via the control fluid line, as a new communication path created by the communication tool described herein. A method of using the communication tool apparatus is also described.

Owner:BAKER HUGHES INC

Pressure control type intelligent production pipe column capable of injecting acid by layer selection and production method

ActiveCN106640026ASimple structureEasy to operateDrilling rodsFlexible member pumpsProduction stringMethods of production

The invention discloses a pressure control type intelligent production pipe column capable of injecting acid by layer selection and a production method. The production pipe column comprises an upper-section pipe column provided with an underground safety valve, a passing cable packer and an electric submersible pump, and a lower-section releasing layered pipe column provided with a releasing tool, a positioning seal, a first inserting seal, a second inserting seal and a guide screw plug; pressure control switches are arranged at a plurality of positions of the production pipe column respectively; and the production method comprises the steps of manufacturing the production pipe column, mounting the pressure control switches, putting in the releasing layered pipe column and the upper-section pipe column, remotely controlling and pressurizing, digging in turn and exploring water, acidifying at a fixed point and the like. The pressure control type intelligent production pipe column and the production method, disclosed by the invention, have the advantages that the production pipe column can work only if the releasing layered pipe column is put for one time, and an instrument or the pipe column does not need to be detached; the technical difficulty of large-inclination well layered water control and oil extracting can be effectively solved; water finding, water control, layer-adjusting production and fixed-point acidifying of different oil layers are realized through remotely controlling the pressure control switches on the ground; and the acid can effectively enter a target reservoir stratum in an acidifying process.

Owner:CHINA NAT OFFSHORE OIL CORP +2

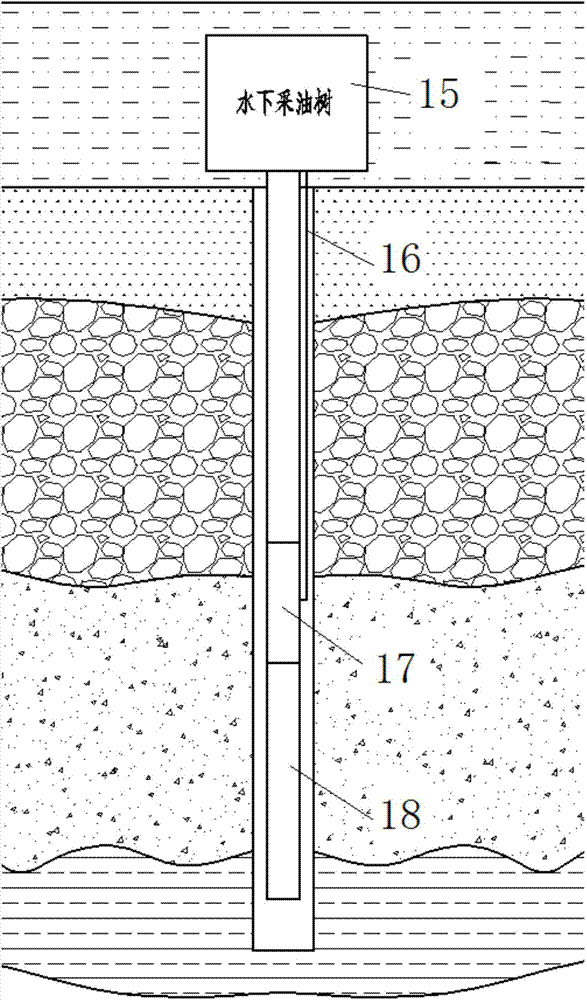

Downhole gas-liquid separation lifting technology pipe column

ActiveCN109723409AAvoid the risk of secondary effusionAvoid Lift InhibitionFluid removalLiquid ratioVapor–liquid separator

The invention belongs to the technical field of oilfield exploitation, and discloses a downhole gas-liquid separation lifting technology pipe column. The pipe column comprises a liquid production sleeve, a downhole safety valve, a liquid blocking device, a gas production oil pipe locating joint, a gas production oil pipe, a cable packer, a liquid production oil pipe, a liquid production oil pipe locating joint, a speed gas production oil pipe, a Y joint, an inserting sealing device, a work cylinder, an adjusting cable, a gas course adjusting device, a power cable, an electric pump, a pump operating duty device, a gas-liquid separator and a top packer which are arranged in a production sleeve. Independent gas-phase and liquid-phase flow passages are constructed, the secondary liquid accumulation risk of a gas course passage and the lifting inhibiting influence of liquid-course fluid on gas-course fluid are effectively avoided, three constructed independent flowing passages are providedwith safety containment devices, and the safety of production operation on the sea can be ensured; the downhole gas-liquid separation lifting technology pipe column has the advantages that operation and construction are convenient, the work stability is high, and the amount of treated liquid and gas is large, and can be widely applied to the lifting technology of oil wells of the high gas-liquid ratio and liquid accumulation gas wells of the large water production amount in offshore oilfields.

Owner:CNOOC ENERGY TECH & SERVICES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com