Downhole safety valve

A technology of safety valve and valve body, which is applied in the direction of wellbore/well valve device, wellbore/well parts, earthwork drilling and mining, etc. It can solve the problem of limited number of uses, difficulty in meeting ultra-deep installation, sealing surface jamming, etc. Problems, to achieve the effect of increasing the number of uses and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

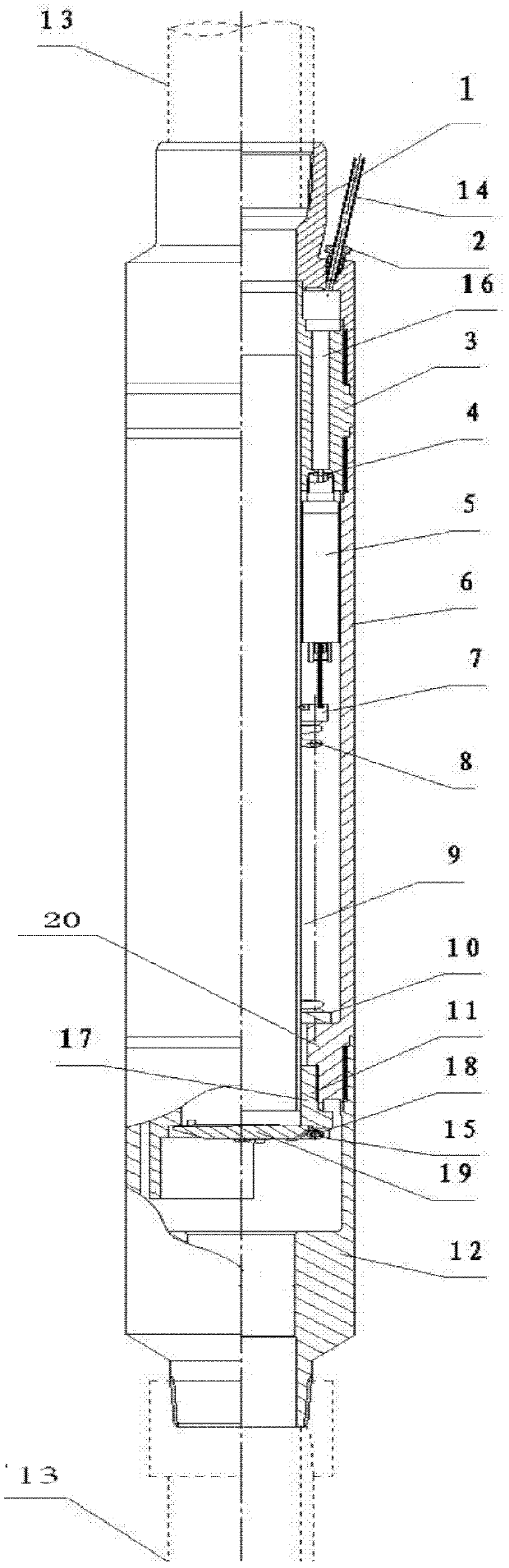

[0042] A downhole safety valve of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

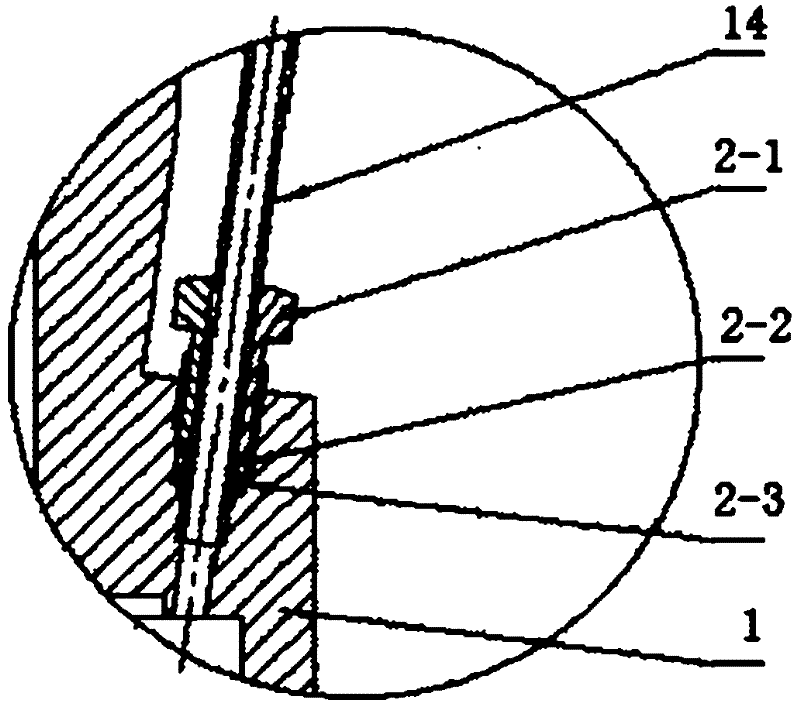

[0043] Such as figure 1 As shown, a downhole safety valve of the present invention includes a body consisting of a top joint 1, a valve body 3, an outer cylinder 6 and a tail joint 12 connected in sequence, and the material of the body is processed from a corresponding metal suitable for well conditions. As a result, the main body is the casing that connects the oil pipe and other moving parts.

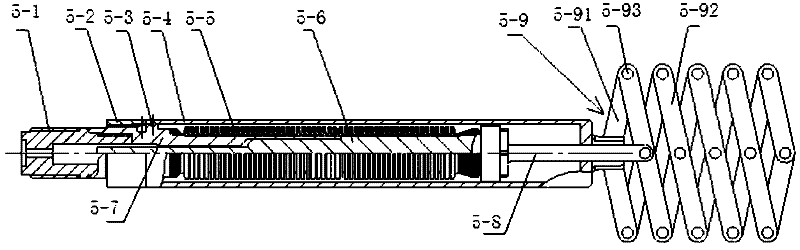

[0044]A center pipe 9 is arranged in the body, the upper end of the top joint 1 and the lower end of the tail joint 12 are respectively connected to the external oil pipe 13, and a bellows is arranged in the gap between the outer cylinder 6 and the center pipe 9 Assembly 5, the bottom end of the bellows assembly 5 is connected to the positioning ring 7 fixed on the peripheral wall of the central tube 9, and the lower end of the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com