Full electric driving downhole safety valve

A safety valve, electric drive technology, applied in the wellbore/well valve device, valve details, valve device and other directions, can solve the problems of limited running depth of safety valve, long response time of hydraulic control, and high requirements for control fluid, Achieve the effect of reliable operation of the equipment, increase the response speed of the safety valve, and improve the working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

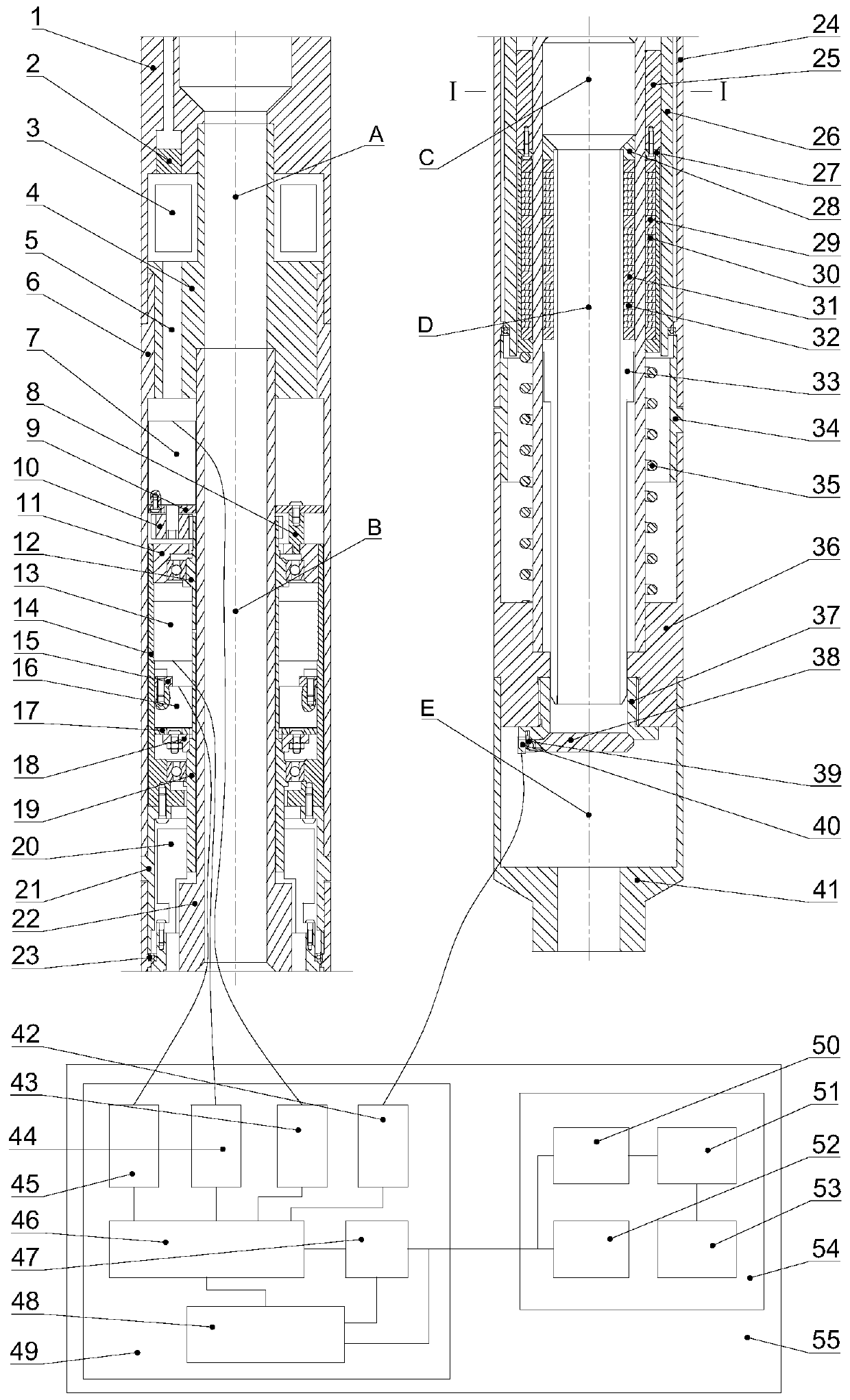

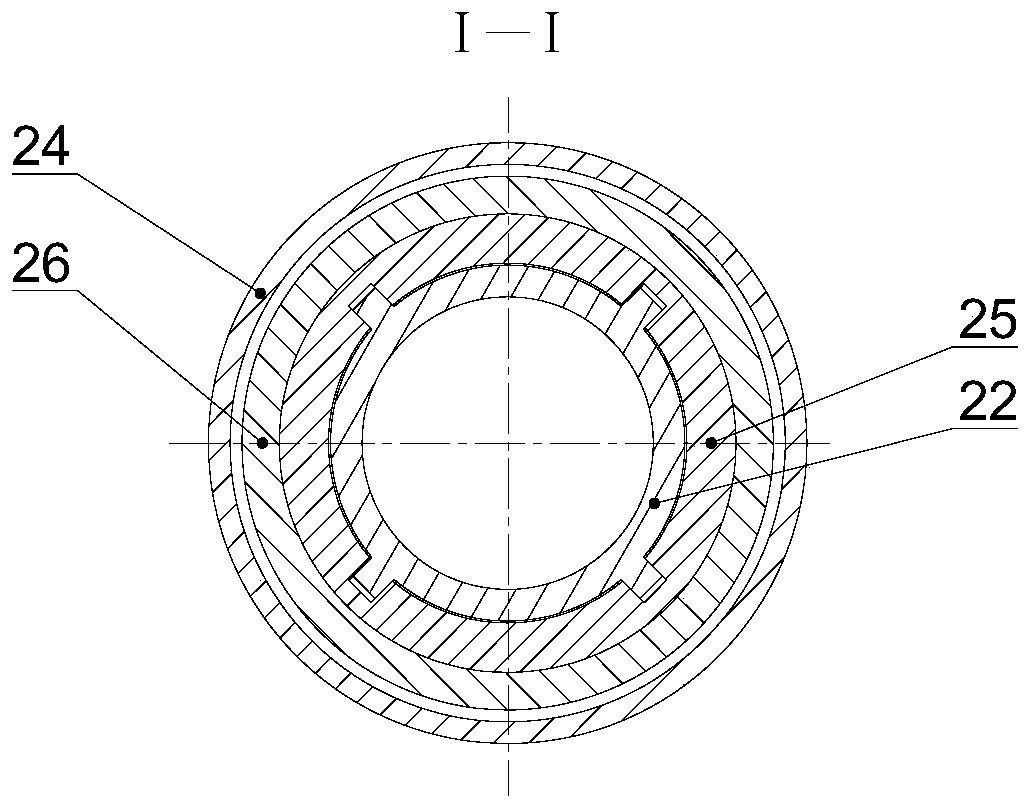

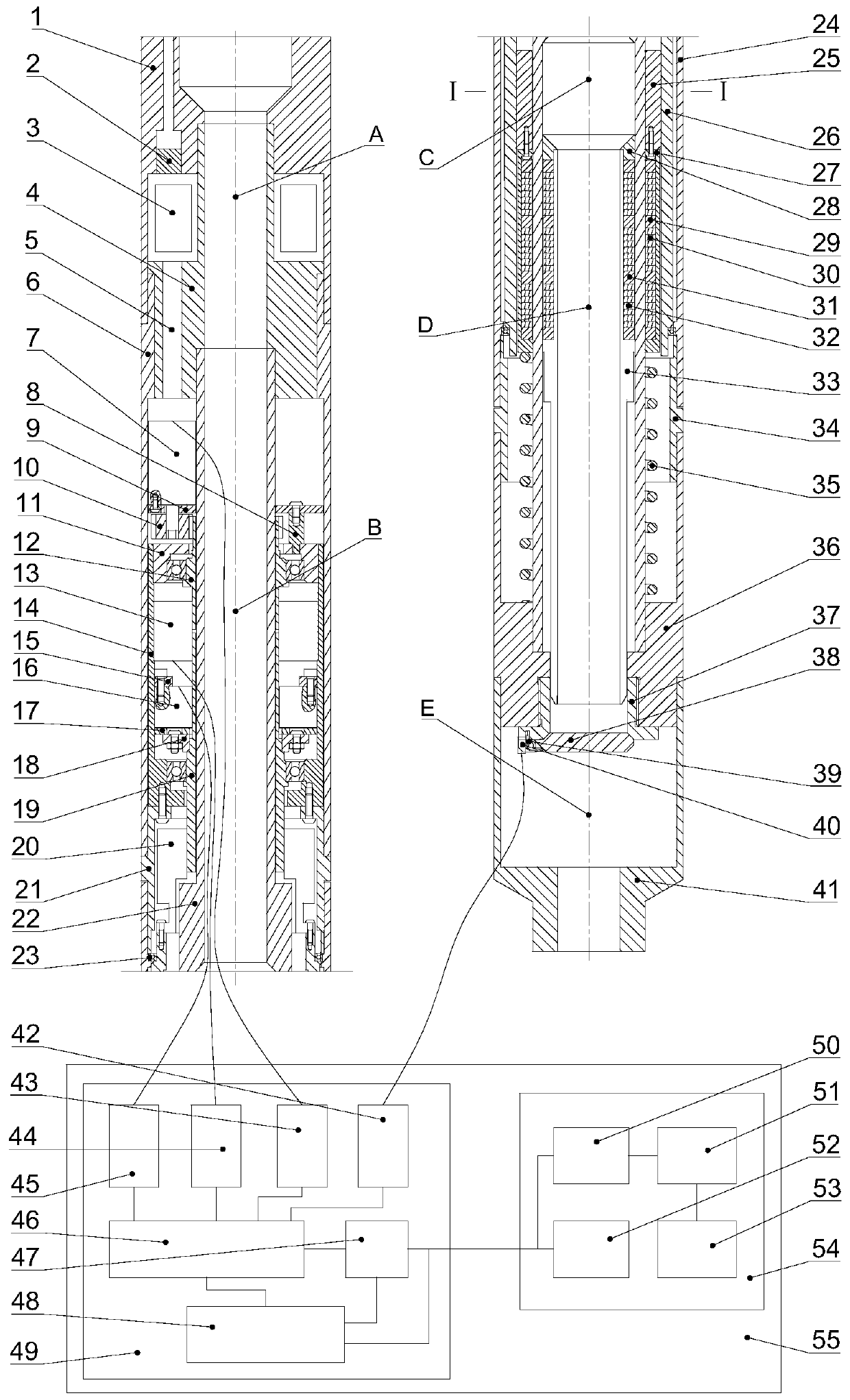

[0020] Such as figure 1 and figure 2 As shown, the all-electrically driven downhole safety valve includes a downhole safety valve mechanism and a downhole safety valve control system 55 .

[0021] The downhole safety valve mechanism includes an electronic cabin module A, a transmission control module B, a motion conversion module C, a magnetic coupling and spring module D, and a valve module E.

[0022] Electronic cabin module A includes oil pipe connection upper joint 1, electrical connector 2, downhole electronic cabin 3, electronic cabin pressure cylinder 4 and electronic cabin wire hole 5. The oil pipe is connected to the upper joint 1 and is threaded with an electrical connector 2 for installing cables; the oil pipe is connected to the upper joint 1 and the pressure-bearing cylinder 4 of the electronic cabin through threads to form a sealed downhole electronic cabin 3 in an annular space, which is used to install the downhole compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com