Pressure control type intelligent production pipe column capable of injecting acid by layer selection and production method

An intelligent production and pipe string technology, applied in drilling pipes, casings, earthwork drilling and mining, etc., can solve the problems of insignificant acidification effect, failure to achieve layered and fixed-point acidification, and large difference in pressure between layers, so as to achieve acidification. The effect of obvious effect, easy operation and simple structure of pipe string

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the present invention easier to understand, the technical solutions and technical effects of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

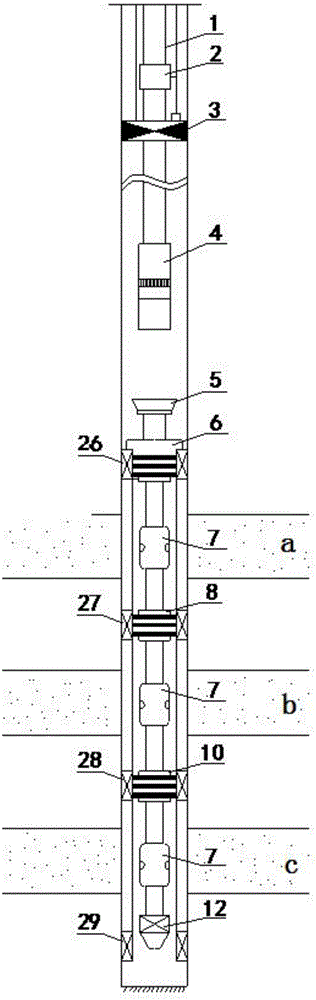

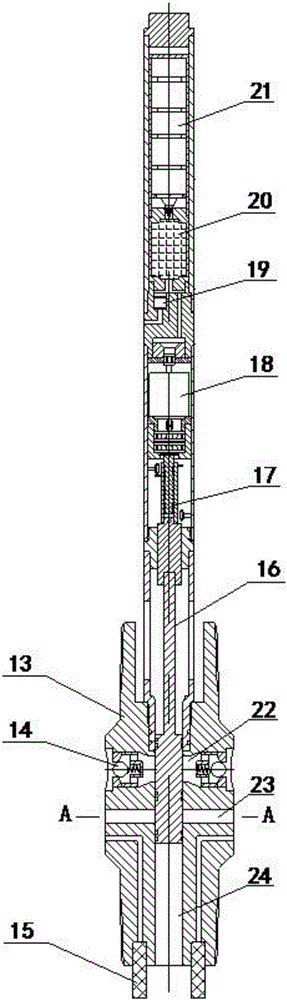

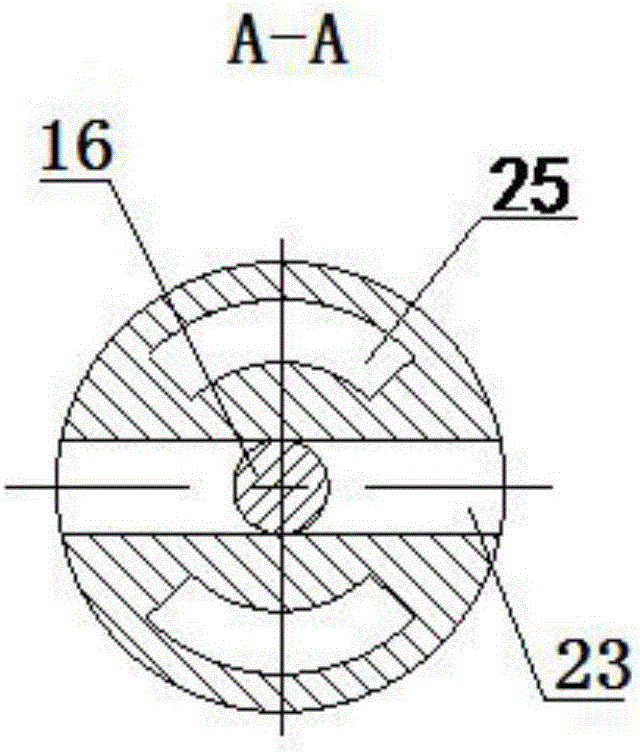

[0033] Such as figure 1 As shown, the optional layer-by-layer pressure-controlled intelligent production string of the present invention includes an upper string and a lower layered string; the upper string is installed on the tubing 1 sequentially from top to bottom The downhole safety valve 2, the cable packer 3 and the electric submersible pump 4; the lower part of the layered pipe string includes a hand tool 5, a positioning seal 6, and a positioning seal respectively installed on the guide shaft from top to bottom The first insert seal 8, the second insert seal 10 and the guide screw plug 12, between the positioning seal 6 and the first insert seal 8, between the first insert seal 8 and the second insert seal 10 and all A pressure contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com