Downhole gas-liquid separation lifting technology pipe column

A technology of gas-liquid separation and process string, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of poor applicability and continuous liquid drainage, so as to broaden the application range and avoid lifting inhibition , the effect of avoiding the risk of secondary effusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

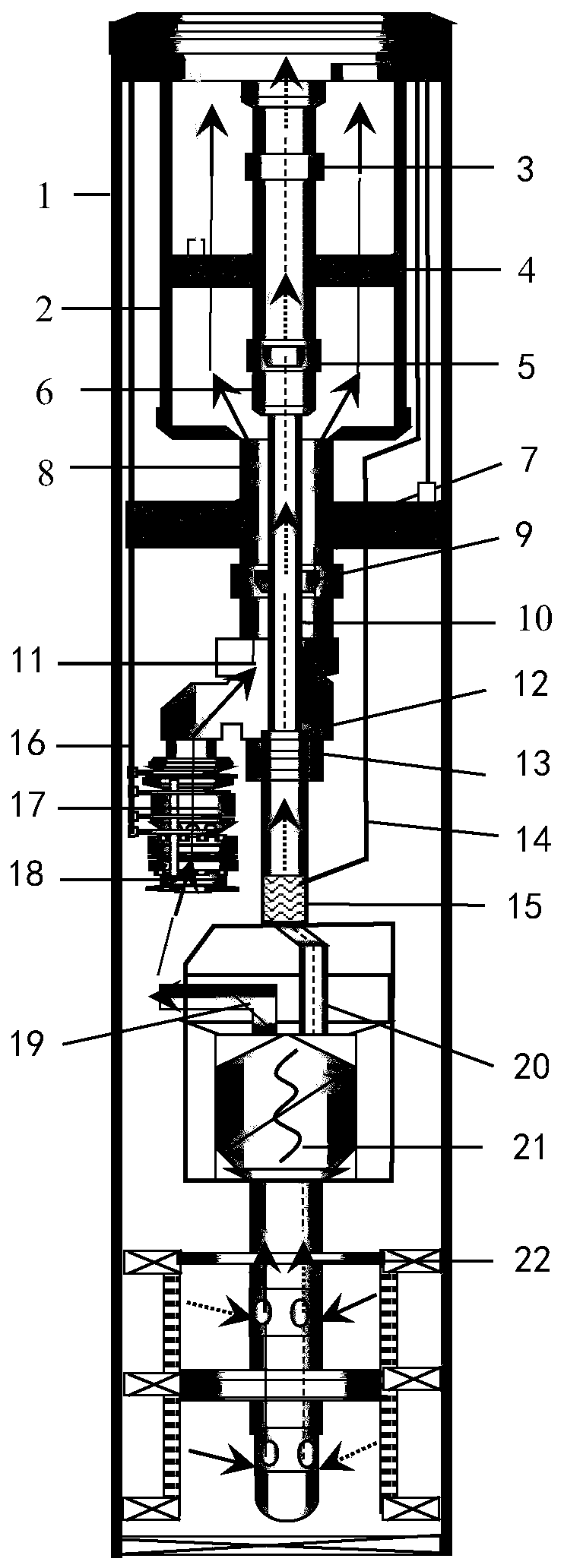

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0021] Such as figure 1 As shown, the present invention provides a downhole gas-liquid separation and lifting process string, which includes a liquid production casing 2 arranged in a production casing 1, a downhole safety valve 3, an isolation liquid passing device 4, a production casing Gas oil pipe seat joint 5, gas oil pipe 6, cable packer 7, liquid oil pipe 8, liquid oil pipe seat joint 9, speed gas oil pipe 10, Y joint 11, insertion seal 12, working cylinder 13, control cable 14. Gas path adjustment device 15, power cable 16, electric pump 17, pump working condition 18, liquid outlet 19, gas outlet 20, gas-liquid separator 21, top packer 22.

[0022] The liquid collection casing 2 is arranged in the production casing 1, and the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com