Tubular column for separated layer water injection

A layered water injection and pipe string technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of small backwash channel, heavy workload, low injection precision, etc., and achieve fast installation and operation Convenience, improvement of development efficiency, and advanced structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

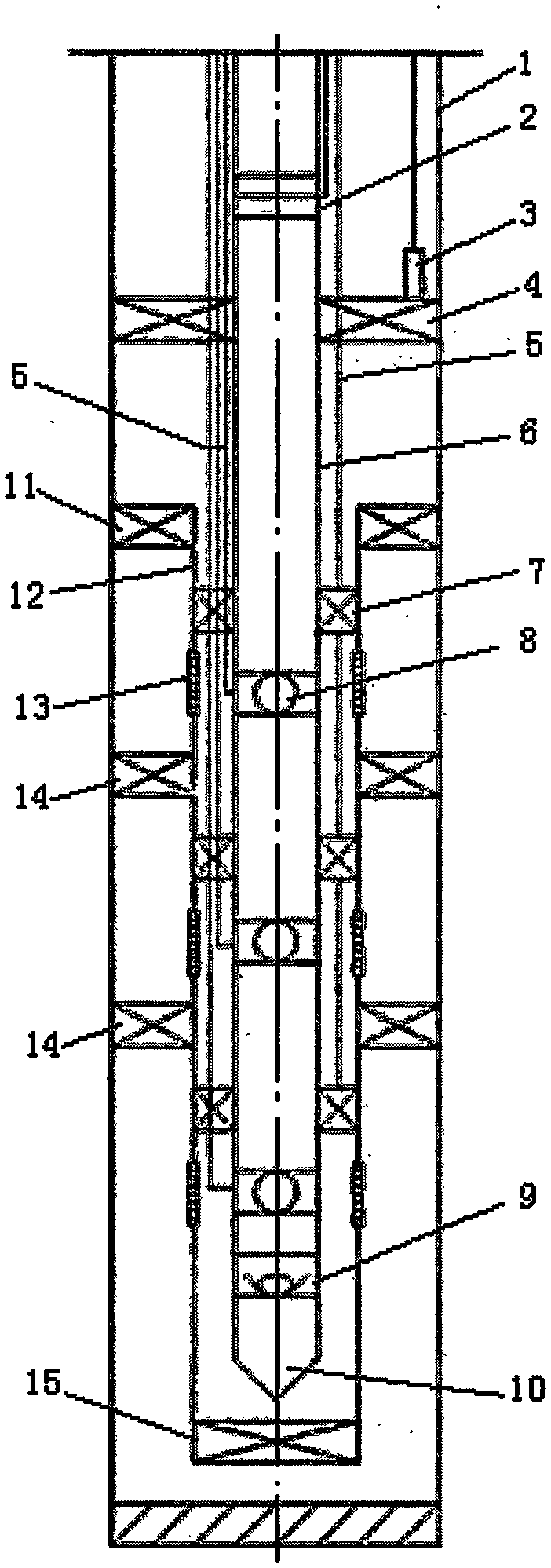

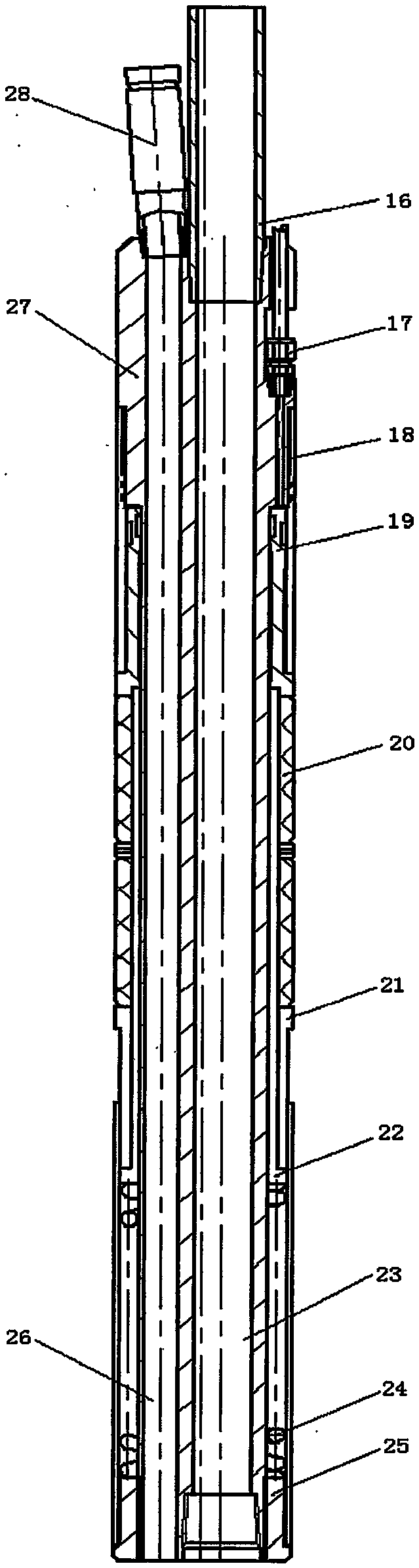

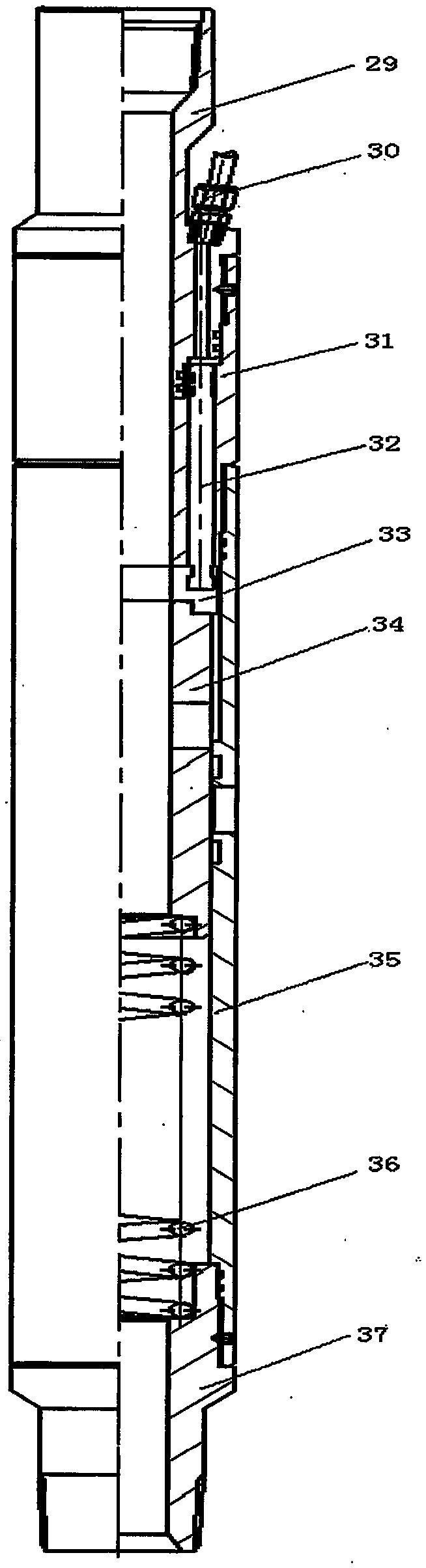

[0020] refer to Figure 1-Figure 5 , a layered water injection string, including a casing 1, a downhole safety valve 2, an exhaust valve 3, a multi-tubular through-type packer 4, a hydraulic control pipeline 5, a tubing 6, a hydraulic control packer 7, a slide Sleeve nozzle 8, backwash valve 9, guide joint 10, suspension packer 11, sand control casing 12, sand filter pipe 13, interlayer packer 14 and wire plug 15. The tubing 6 is sequentially connected with the downhole safety valve 2, the multi-tubular through-type packer 4, the hydraulic control packer 7, the sliding sleeve nozzle 8, the hydraulic control packer 7, the sliding sleeve nozzle 8, the hydraulic control seal Spacer 7, sliding sleeve water nozzle 8, backwash valve 9, guide joint 10, sand control casing 12 is installed and connected to oil pipe 6, and suspension packer 11 and sand filter pipe are installed and connected to sand control casing 12 in sequence 13. Interlayer packer 14, filter sand pipe 13, interlayer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com