Self-balancing downhole safety valve

A safety valve and self-balancing technology, applied in wellbore/well valve device, wellbore/well components, earthmoving and other directions, can solve the problem of controlling leakage of pipeline sealing ring, high-pressure oil entering the piston cavity in the oil jacket space, Problems such as oil wells not working properly to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

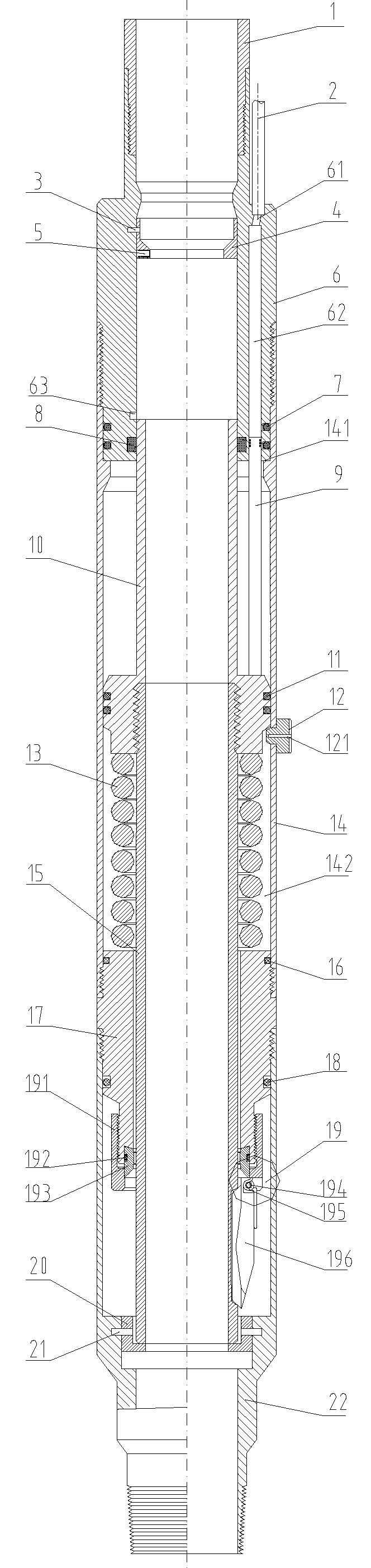

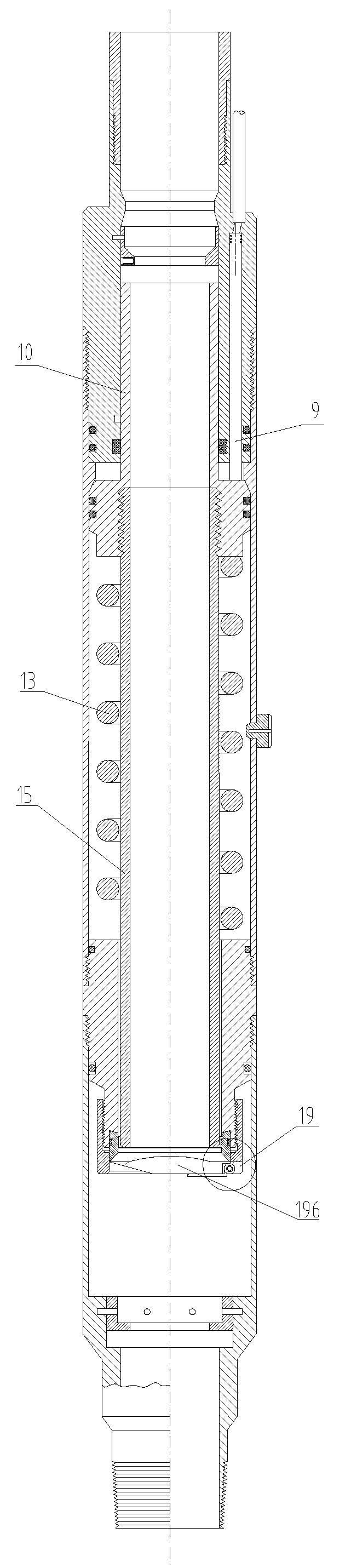

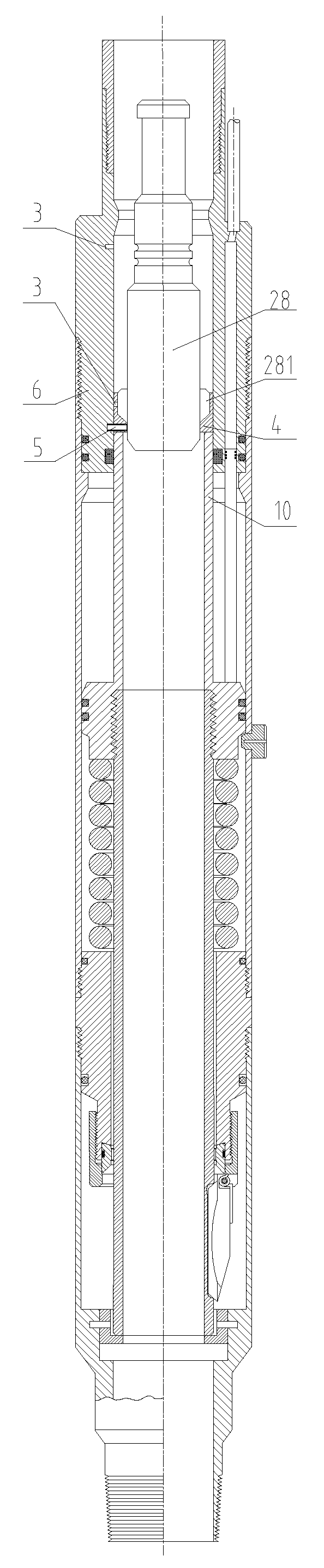

[0015] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the self-balancing downhole safety valve adopts a cylindrical annular structure, including: upper joint 1, piston sleeve 6, spring sleeve 14, connecting joint 17, lower joint 22, driving pipe 10, central pipe 15, spring 13, valve seat structure19.

[0016] The upper joint 1 is a cylindrical shell structure with external threads at the lower end.

[0017] The piston sleeve 6 is a cylindrical shell with a variable cross-section, the outer diameter of the upper section is small, and the outer diameter of the lower section is large. The connecting position of the upper section and the lower section forms a step surface. The opening 61 through which the piston chamber 62 passes, the control pipeline 2 communicates with the piston chamber 62 through the opening 61; the piston chamber 62 is provided with a piston rod 9; There are three sealing rings on the top, the lower end surface of the piston rod 9 is in conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com