Fixed-point dragging continuous liquid drainage tubular column for fixed-point dragging of offshore low-pressure gas well and liquid drainage method of fixed-point dragging continuous liquid drainage tubular column

A technology of drainage pipe and low-pressure gas, which is used in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of reservoir damage, high construction operation cost, and insignificant liquid drainage effect, and achieves easy portability. Liquid effect, damage avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

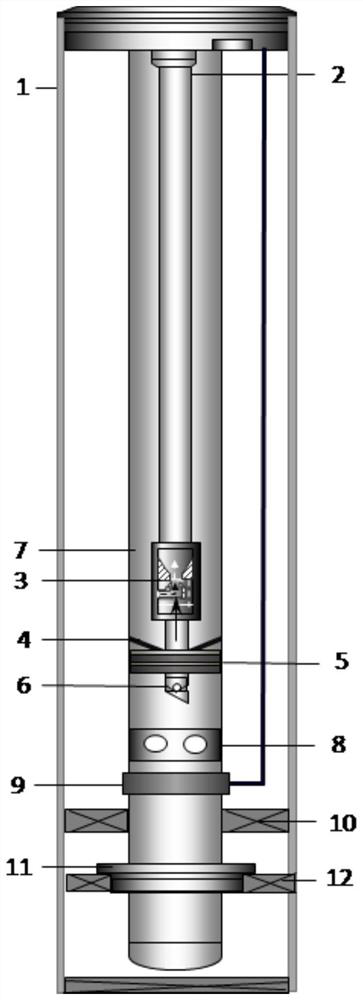

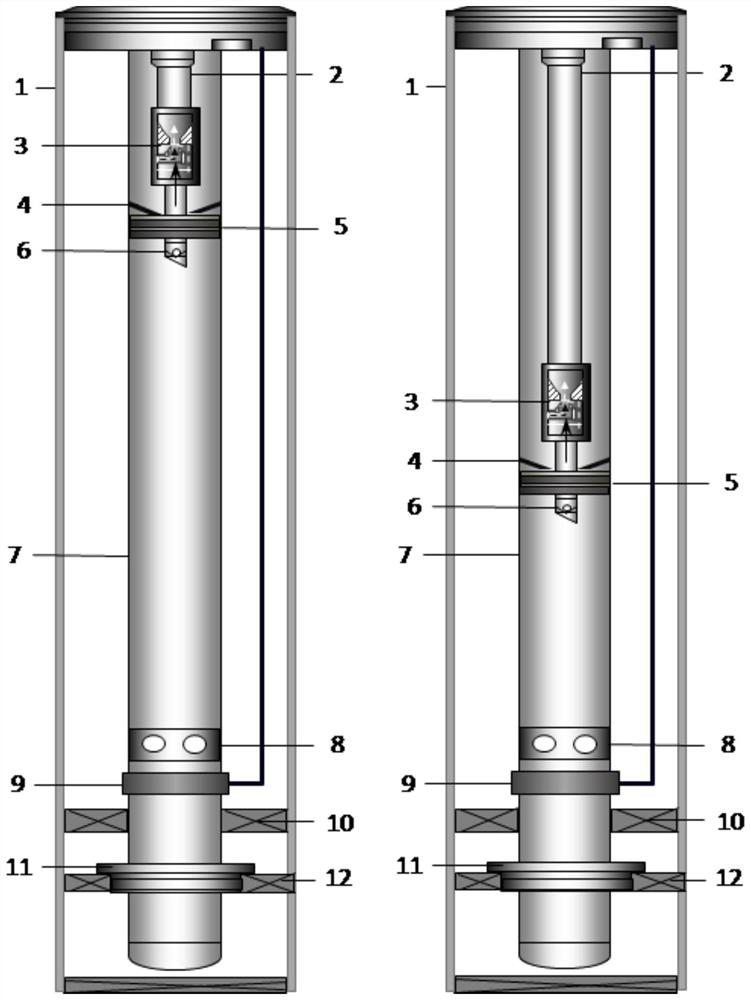

[0029] An offshore low-pressure gas well fixed-point dragging continuous liquid drainage string, including casing 1, coiled tubing 2, gas injection pump 3, in-pipe packer 5, check valve 6, production tubing 7, circulation slide Set 8, deep well safety valve 9, production packer 10, positioning seal 11 and top packer 12;

[0030] The production tubing 7 is set inside the casing 1, the top packer 12 is set between the inner wall of the tail end of the casing 1 and the outer wall of the tail end of the production tubing 7, and a positioning seal is set on the production tubing 7 above the top packer 12 11. On the production tubing 7 above the positioning seal 11, a deep well safety valve 9 and a circulating sliding sleeve 8 are arranged in sequence from bottom to top. The deep well safety valve 9 is used to ensure the emergency safety protection of the fluid in the offshore gas well tubing, and the circulating sliding sleeve 8 is used for During offshore gas well operation, a pro...

Embodiment 2

[0035] On the basis of Embodiment 1, an anti-sand cup 4 is provided between the inner wall of the production tubing 7 above the inline packer 5 and the outer wall of the coiled tubing 2 to prevent sand from accumulating on the inline packer 5 surface to ensure the success rate of lifting and lowering operation of the inner pipe packer 5.

[0036] The inner diameter of the coiled tubing 2 is 1.5, 1.75 or 2 inches.

[0037] Finally, by adopting three types of coiled tubing with an inner diameter of 2, 1.75 or 1.5 inches, because of its smaller inner diameter, the critical liquid-carrying capacity of gas wells in the coiled tubing can be greatly increased, and the liquid drainage function of the velocity string can be greatly improved. Has a good liquid carrying effect.

Embodiment 3

[0039] A method for draining liquids by dragging a continuous draining string at a fixed point without moving a string in an offshore low-pressure gas well, which is carried out according to the following steps:

[0040] Step 1, wellhead treatment: remove the Christmas tree, install the riser, connect the blowout preventer, and tie back the control pipeline;

[0041] Step 2, run the coiled tubing: run the coiled tubing connected with the in-line packer and the gas injection pump to the predetermined depth H 1 ;

[0042] Step 3, setting the inner tubing packer: setting the inner tubing packer by lowering the pressure of the coiled tubing, and simultaneously establishing a semi-closed annular space between the inner wall of the production tubing and the outer wall of the coiled tubing;

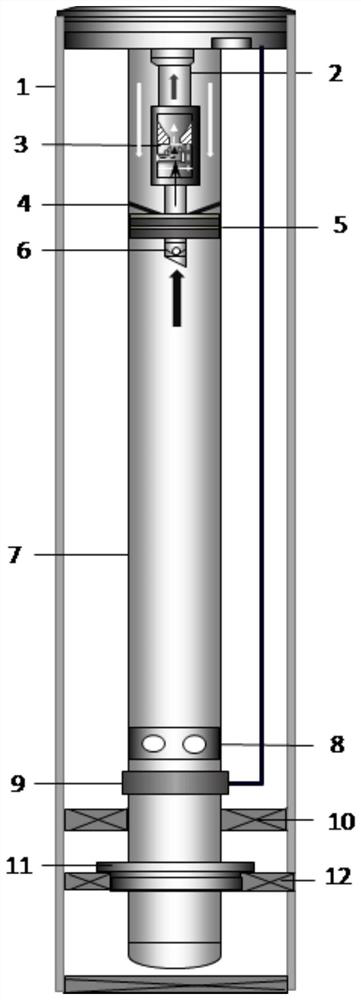

[0043] Step 4, injecting high-pressure gas for continuous liquid drainage: After the in-line packer is set, inject high-pressure gas directly into the semi-closed annular space between the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com