Patriot retrievable production packer

a production packer and patriot technology, applied in the field of returnable production packers, can solve the problems of increasing complexity of parts and their manufacture, and achieve the effect of reducing the complexity of parts and reducing the cost of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

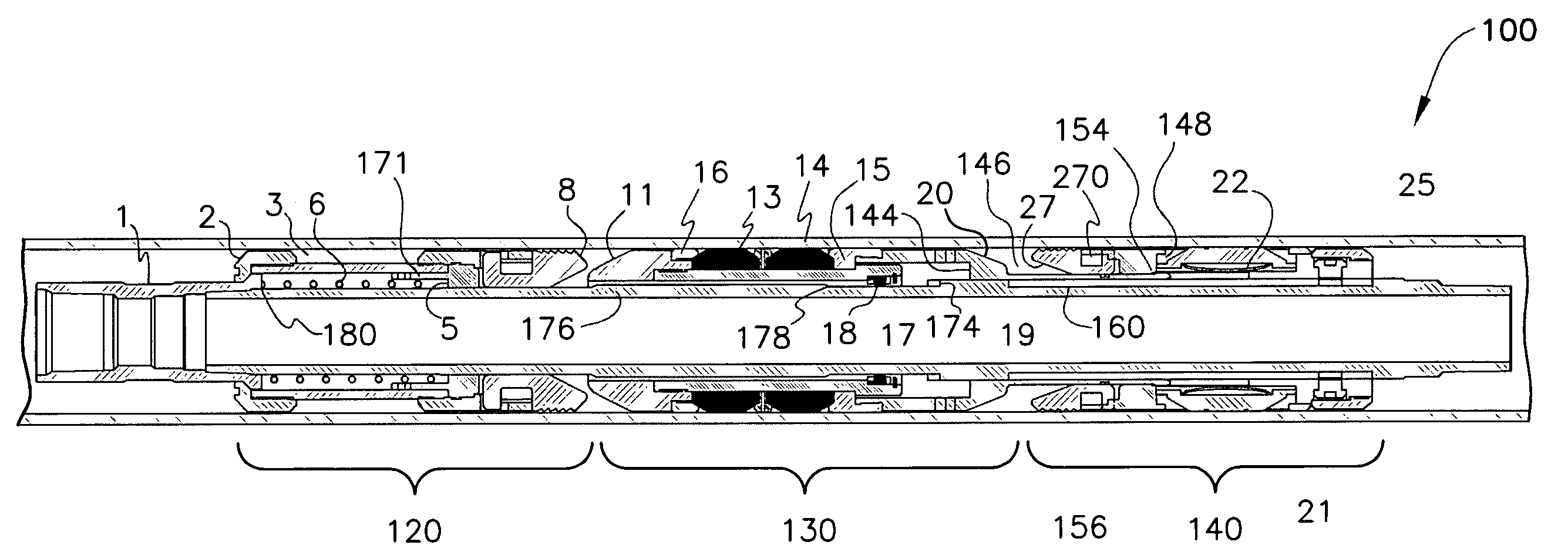

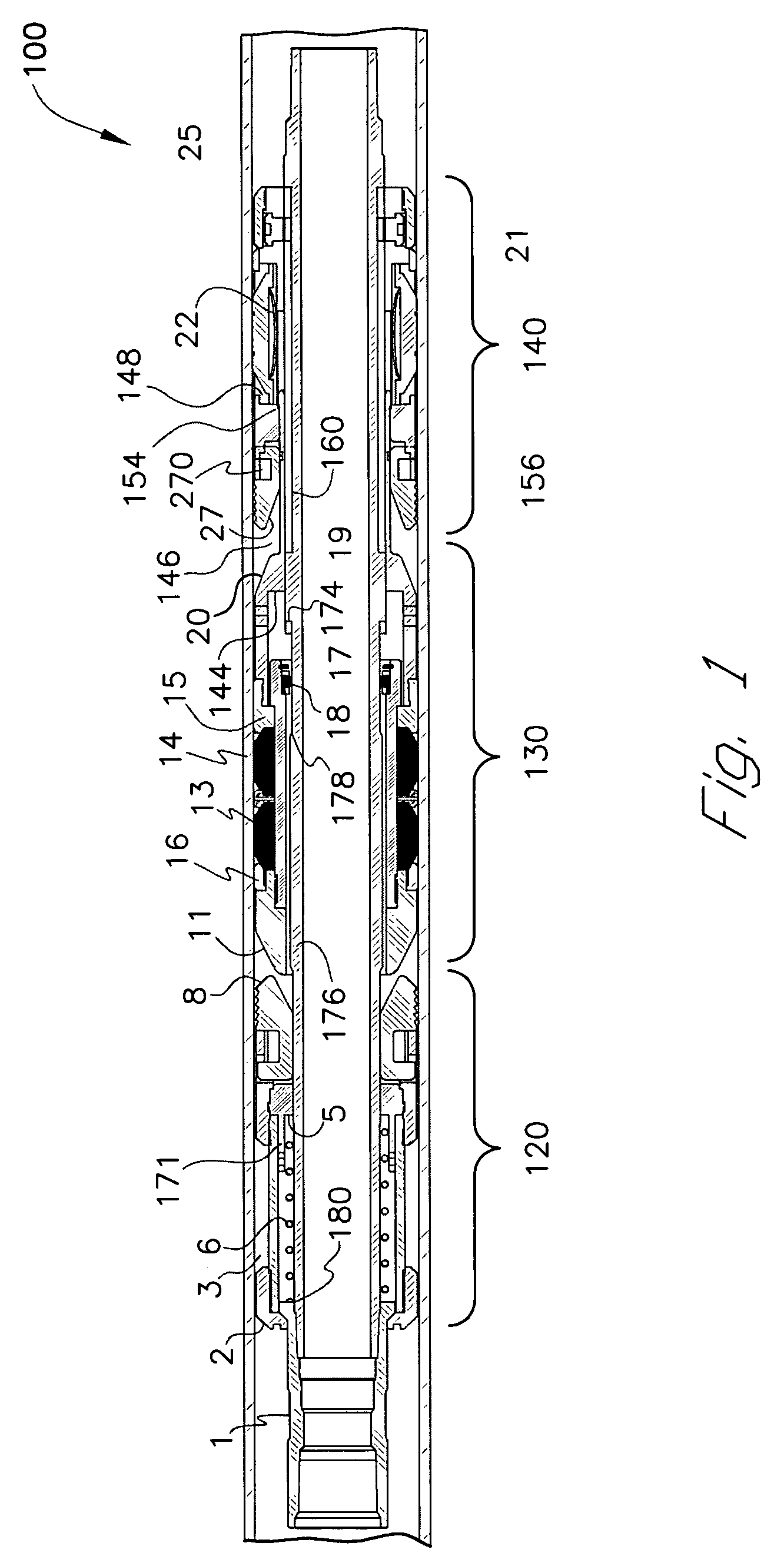

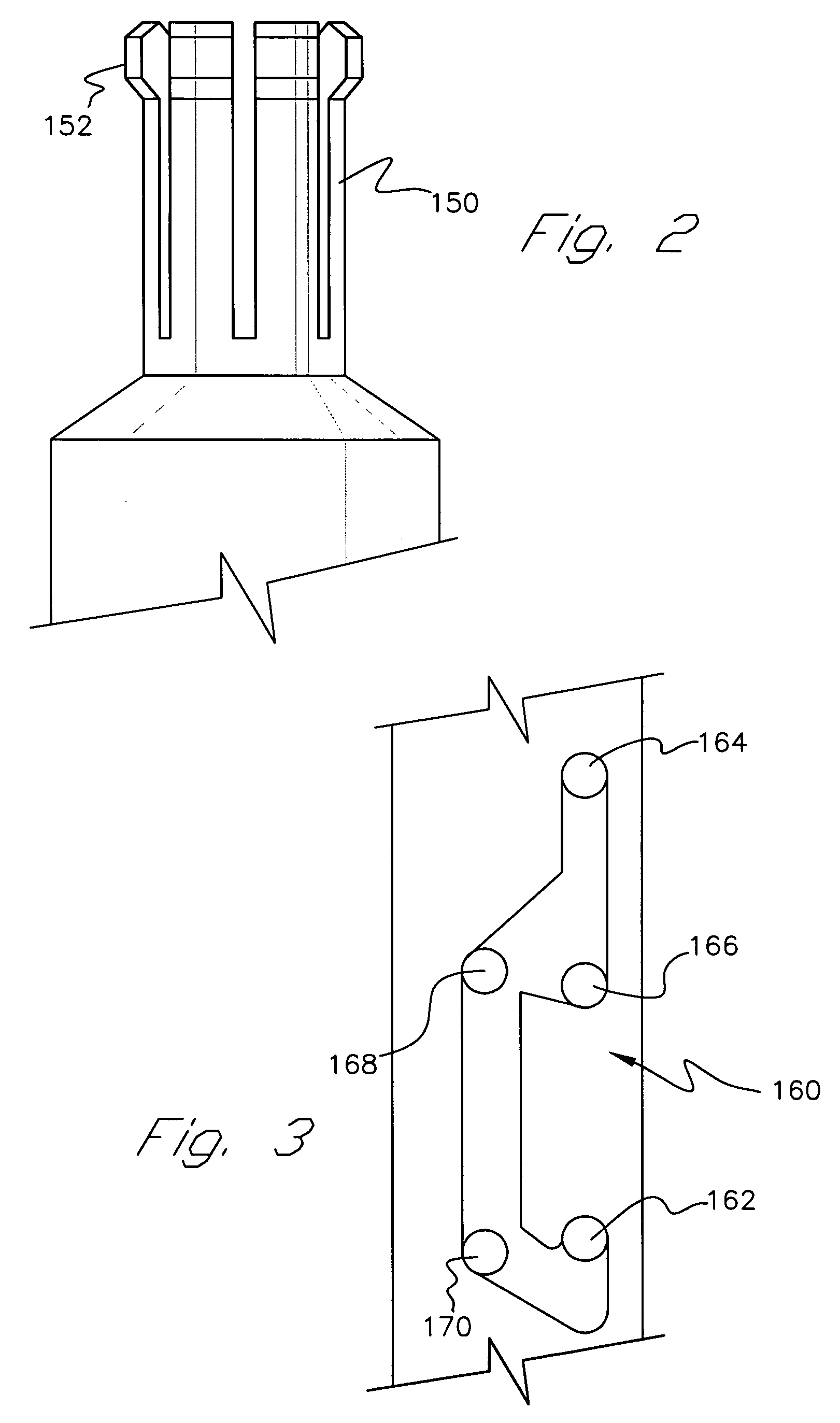

[0018] The present invention relates to a retrievable packer tool 100. Illustratively, a production packer tool is shown which has as its main purpose to be installed in a wellbore to seal the zone above the packer from the zone below the packer. Since conditions around the well bore can change, the packers may have to be moved, removed, or reinserted. Since the tools are positioned a great distance below the earth and the size of the wellbore is extremely small, it is impractical to send a man to retrieve the tools. The distances also make it a major undertaking to send any tool in to manipulate the tool. The size and distance between the operator and the tool and the limited room to manipulate the tool inside the wellbore leave only a few kinds of motion that can be used to act on the tool to change the orientation or operation of the tool. Among these ranges of actions available are pushing downward on the tool, lifting upward on the tool, clockwise or counterclockwise rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com