Spoolable coiled tubing completion system

a technology of coiled tubing and completion system, which is applied in the direction of drilling casings, drilling pipes, borehole/well accessories, etc., can solve the problems of complex installation, increased equipment requirements, and increased complexity of installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

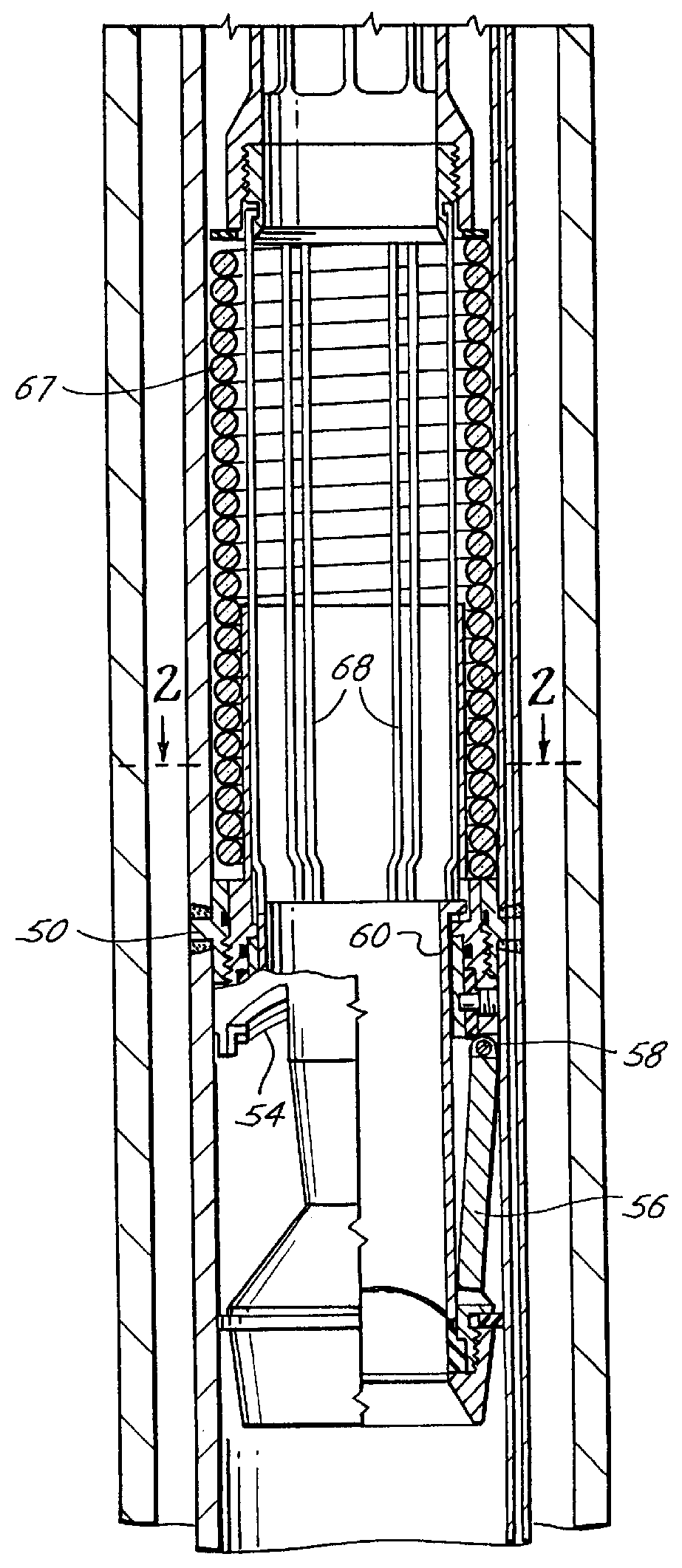

While the spoolable coiled tubing completion system of the present invention will be described, for purposes of illustration only as including a tubing retrievable safety valve, an annular safety valve, one or more concentric gas lift valves, an isolation packer, a landing nipple, a sliding sleeve, a production packer and a pump out plug, many completion systems may utilize only some of this equipment depending upon the particular application.

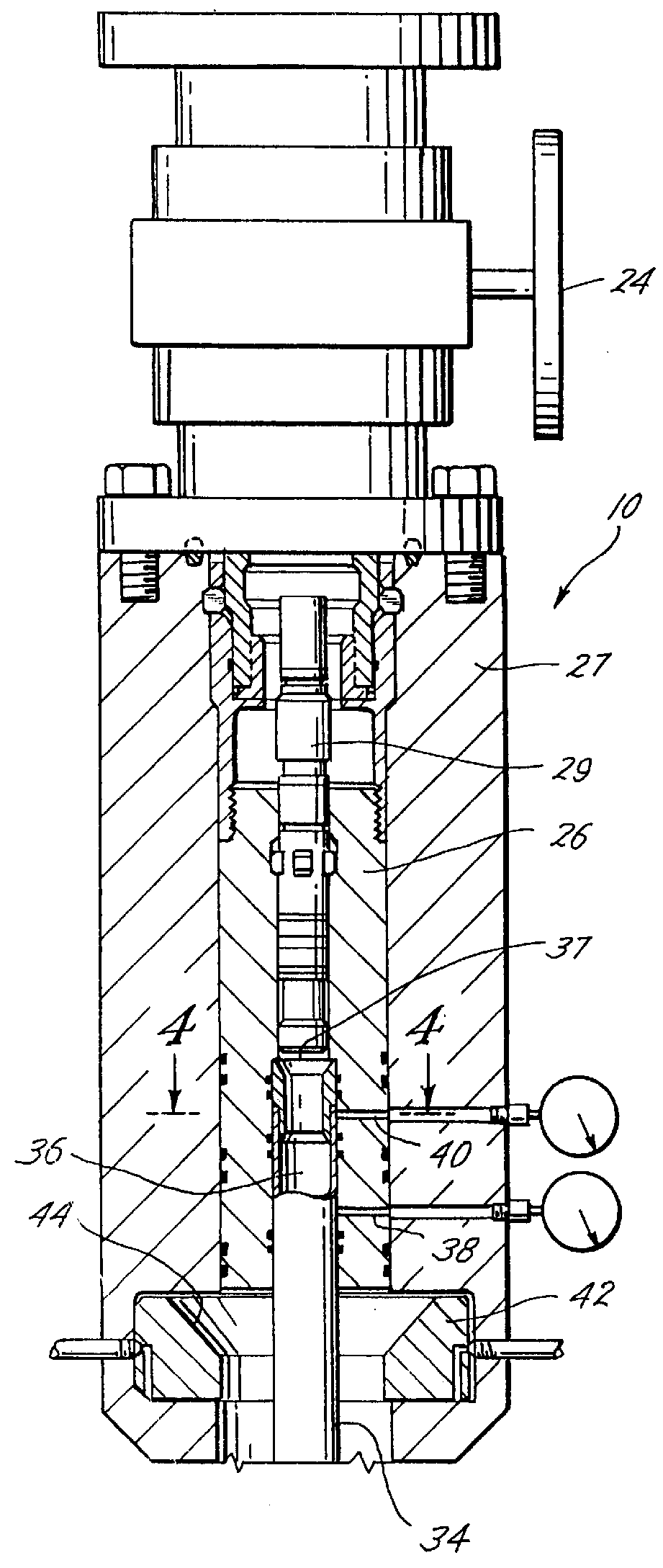

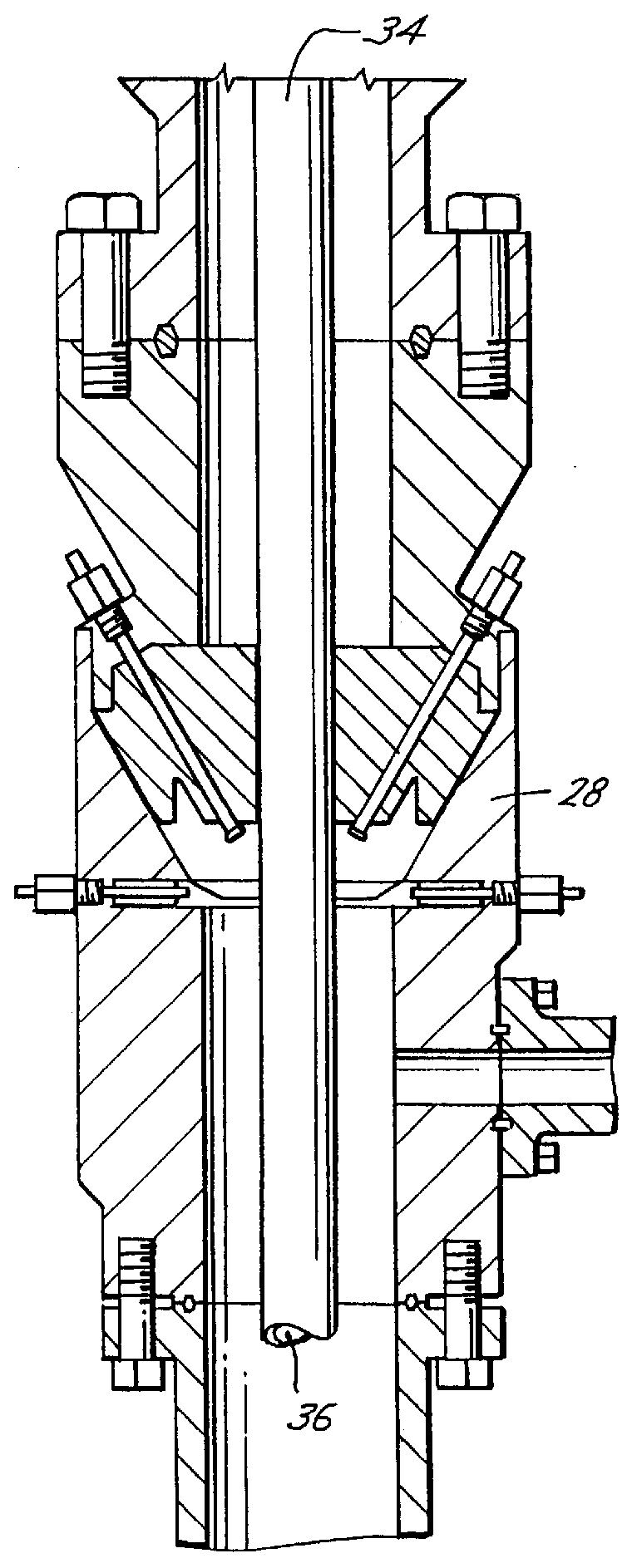

Referring now to FIGS. 1A-1U, the spoolable coiled tubing completion system of the present invention is best seen and is referred to by the reference numeral 10 and is installed and retrieved though a retrieval system generally indicated by the reference numeral 12 (FIG. 15). The completion system 10 is installed and retrieved by the retrieval system 12 which generally includes a mobile truck and power unit 14 having a conventional coiled tubing reel 16 which inserts and removes the completion system 10 through a guide arch 18, an injector head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com