Ceramic slip composite bridge plug

A composite bridge and ceramic technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve problems such as eccentric grinding and milling casing, stuck pipe, and complexity, so as to change wellbore conditions and improve Work efficiency, fast milling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

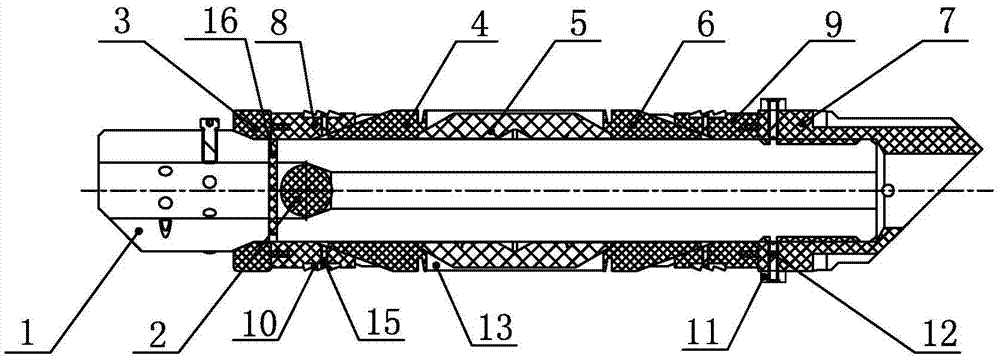

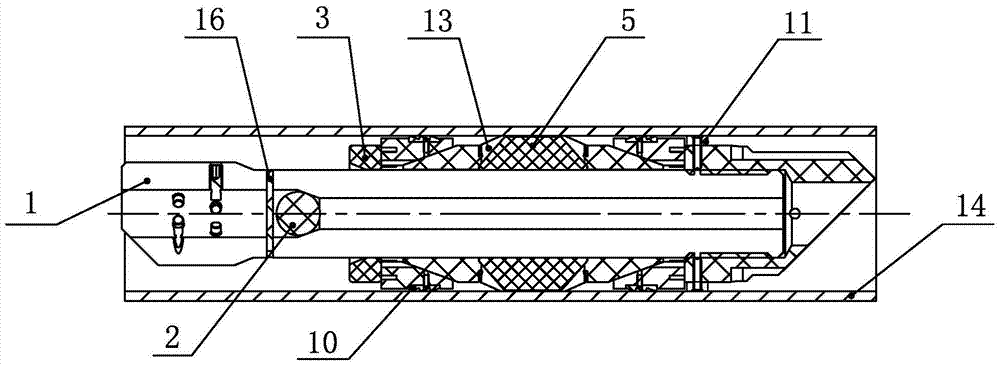

[0014] Such as Figure 1 to Figure 2 As shown, the ceramic slip composite bridge plug of the present invention includes a central tube 1, and the outer circumference of the central tube 1 is sequentially sleeved with a push ring 3, an upper positioning vertebral body 4, a rubber tube 5, and a lower positioning vertebral body. Body 6, spacer ring 7, spacer ring 7 is fixedly connected with central tube 1, push ring 3, upper positioning vertebral body 4, rubber tube 5 and lower positioning vertebral body 6 can all move along the axial direction of central tube 1, and upper positioning vertebral body The circumference of the body 4 is provided with a plurality of upper bases 8, and one end of the upper base 8 abuts against the push ring 3, and the upper base 8 can move along the generatrix direction of the upper positioning vertebral body 4; the circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com