Pipeline type hollow control layer for slope cooling of frozen soil roadbed

A pipeline-type, hollow technology, applied in the direction of roads, roads, climate change adaptation, etc., can solve the problems of slow flow process, low efficiency, and low flow of air beam inside the hollow block, so as to reduce the temperature of sunny slopes and improve the cooling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

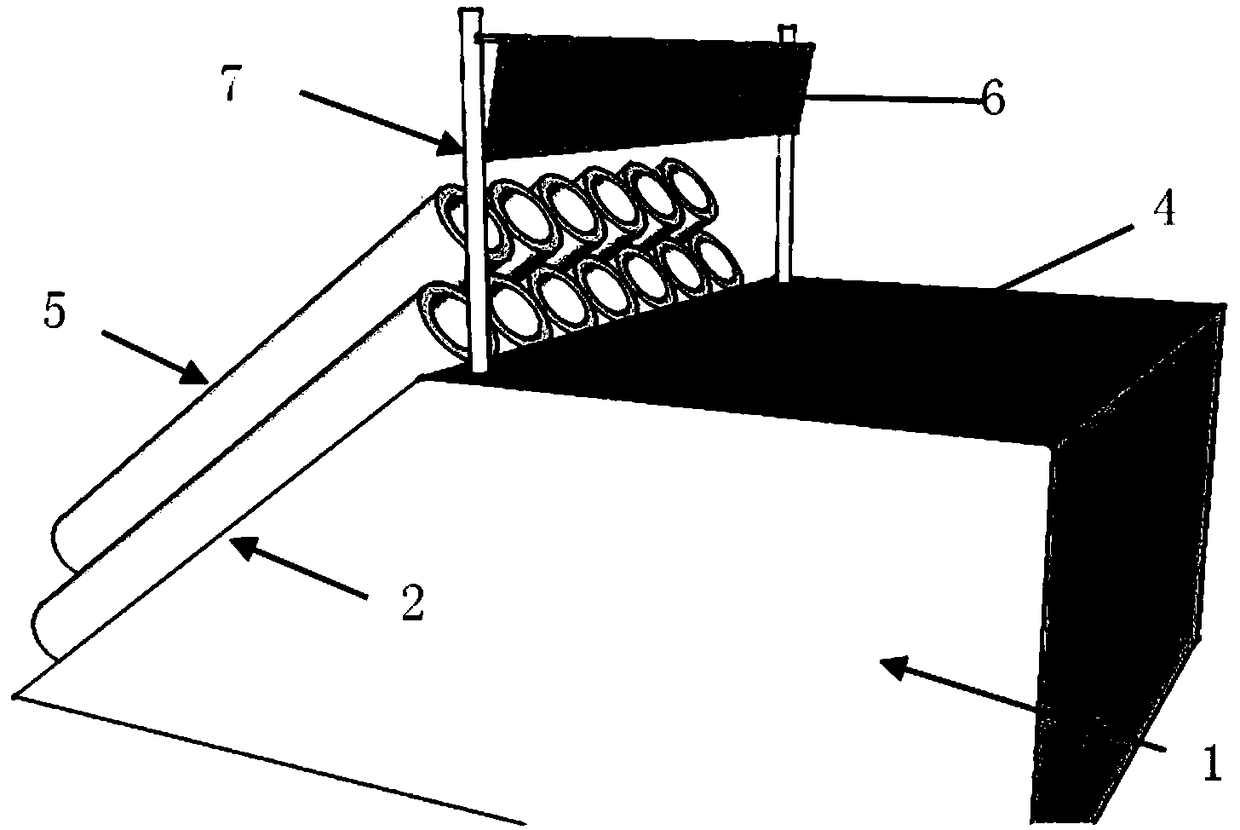

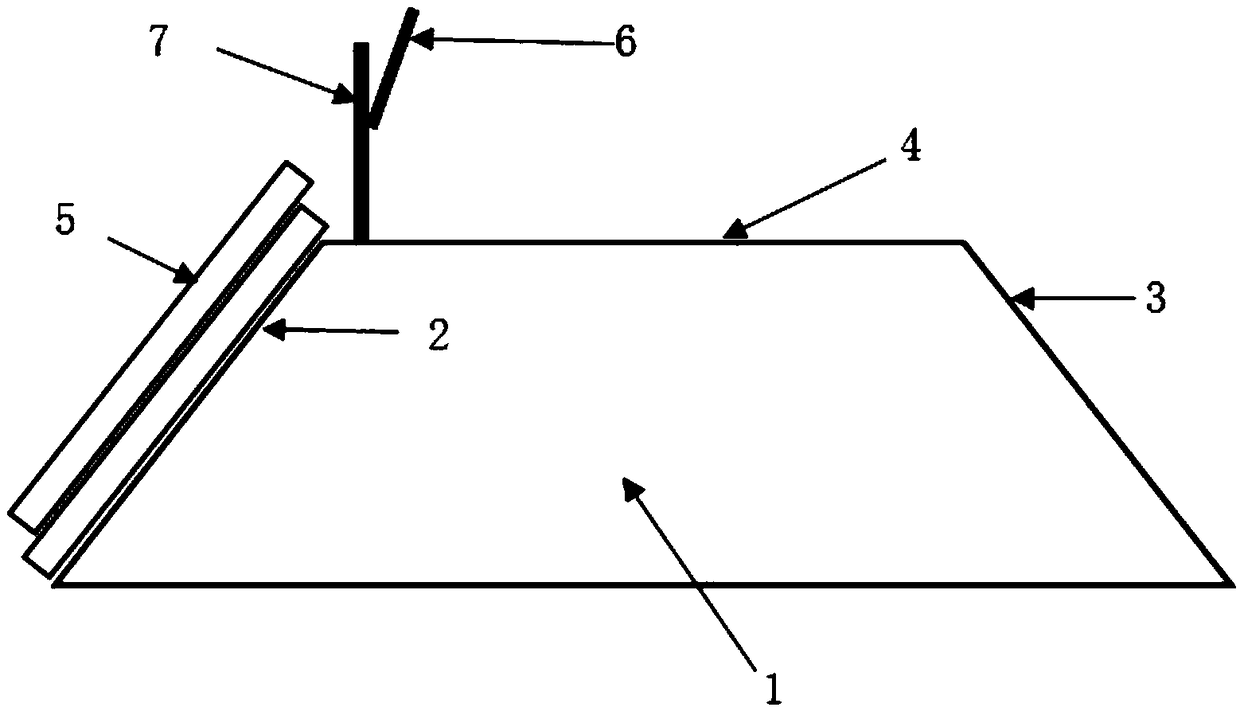

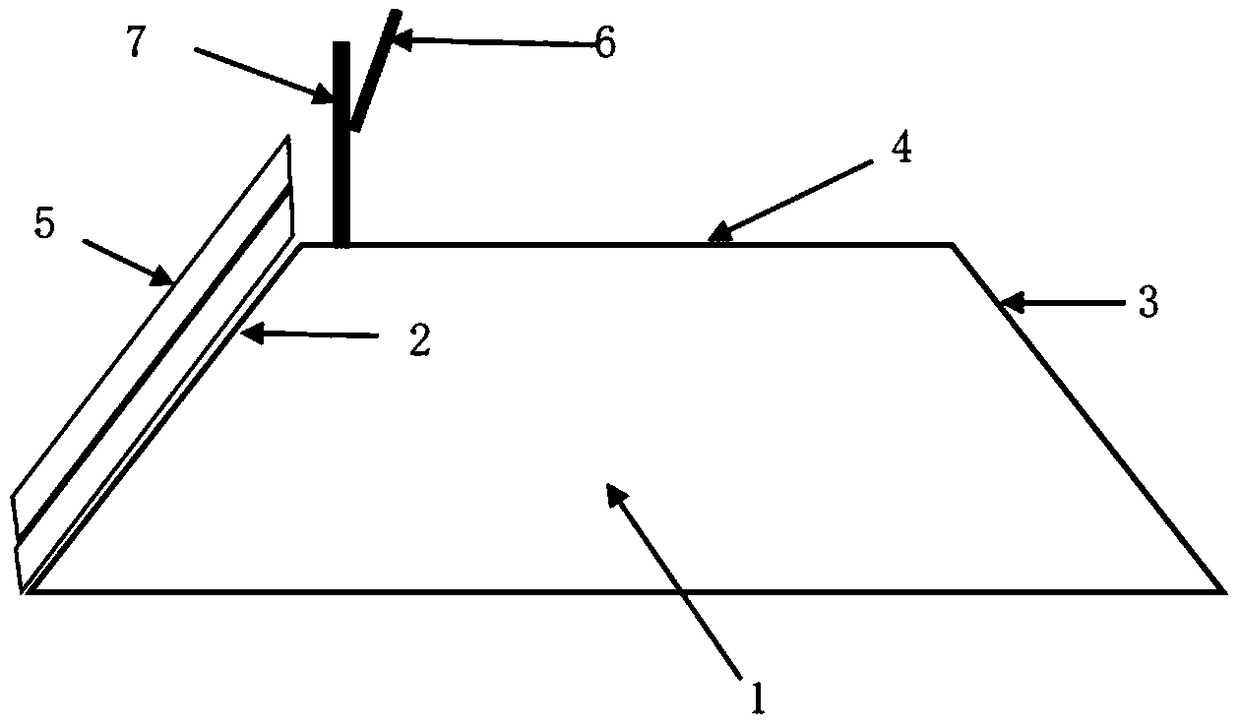

[0041] Reference attached Figure 1~4 , the embodiment of the present invention provides a pipeline-type hollow control layer for cooling the slope of frozen soil subgrade, which is suitable for ordinary height subgrade and high fill subgrade, which is specifically a layer structure formed by a plurality of hollow tubes 5 closely arranged and fixed side by side , including a single-layer structure and a multi-layer stack structure, the multi-layer stack structure is usually 2 to 4 layers; the hollow tube 5 is an integral structure. During implementation, the hollow control layer is laid along the sunny slope surface 2 of the subgrade, and the highest point of the ventilation opening on the side of the road shoulder is -90~150cm away from the road surface.

[0042] It is understandable that the vents on the slope toe side of the pipe-type hollow control layer are set near the slope toe, and can be directly set at the slope toe according to the situation, or the vents can be ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com