Underground nitrogen-making induced flow completion pipe string having pressure monitoring function

A technology for pressure monitoring and well completion strings, which is applied in wellbore/well components, measurement, production fluids, etc. It can solve problems such as high risk, the string does not have the function of inducing blowout, and low efficiency, and achieves the prospect of wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

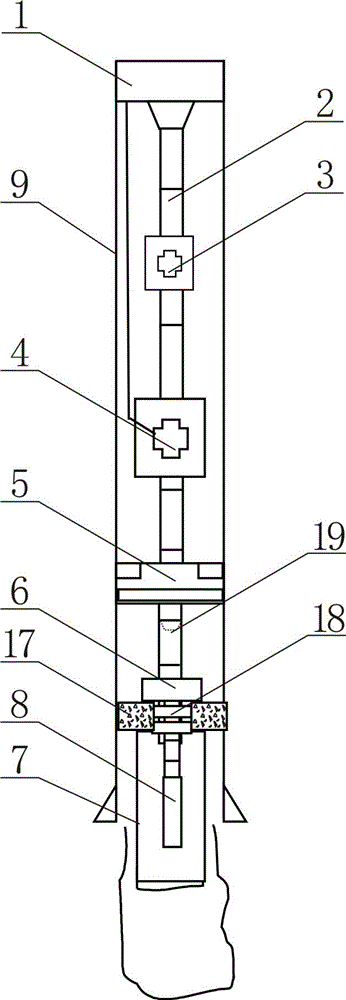

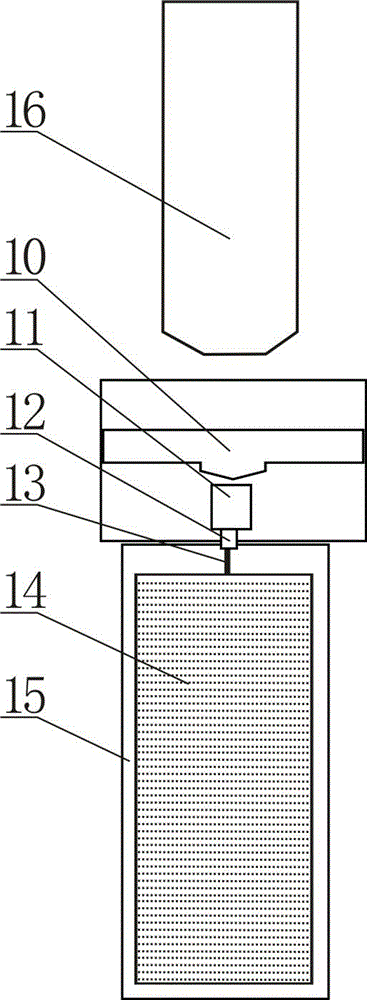

[0020] Such as figure 1 , 2 As shown, the downhole nitrogen generating blowout completion string with pressure monitoring function is mainly composed of tubing hanger 1, tubing 2, downhole safety valve 3, downhole pressure gauge 4, production packer 5, working cylinder 19, insertion and positioning Sealing 6, blind pipe 7 and downhole nitrogen generating blowout device 8, wherein the upper end of the oil pipe 2 is suspended in the oil well 9 through the oil pipe hanger 1, downhole safety valve 3, downhole pressure gauge 4, production packer 5 and the work cylinder 19 are respectively arranged on the oil pipe 2, and the lower end of the oil pipe 2 is connected with the blind pipe 7 through the insertion positioning seal 6, and the insertion positioning seal 6 is inserted into the sealing cylinder of the sand control packer 17 in the oil well 9, and the downhole construction The nitrogen spraying device 8 is inserted into the dead pipe 7 . A sealing ring 18 is provided between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com