Ultra-quiet pavement paving material and application

A paving material and ultra-quiet technology, which is applied in applications, on-site paved condensate pavement, construction, etc., can solve problems such as rutting, congestion, impact on driving safety, poor mechanical properties, etc., and achieve great practical value , Improve driving safety, good sound absorption and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

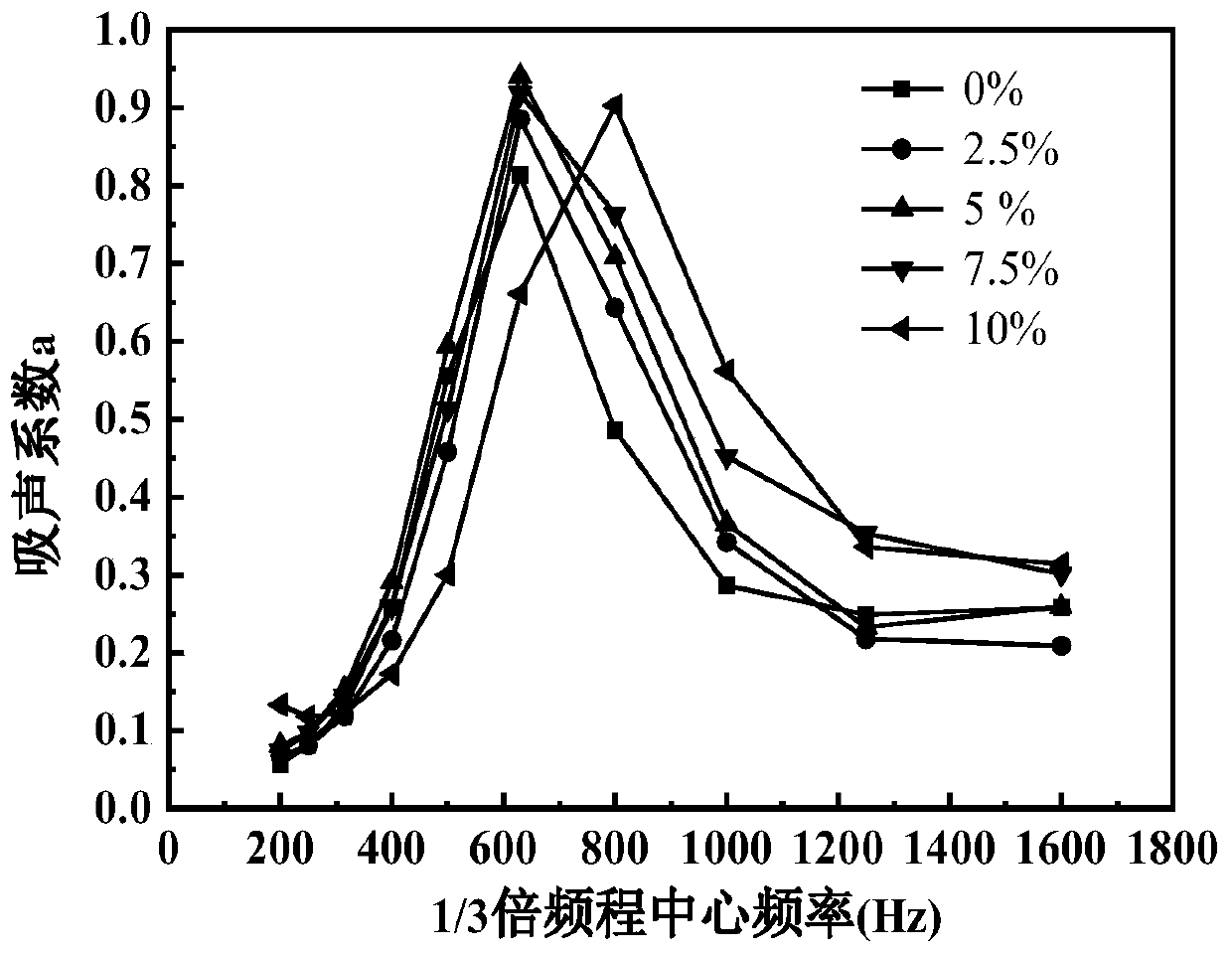

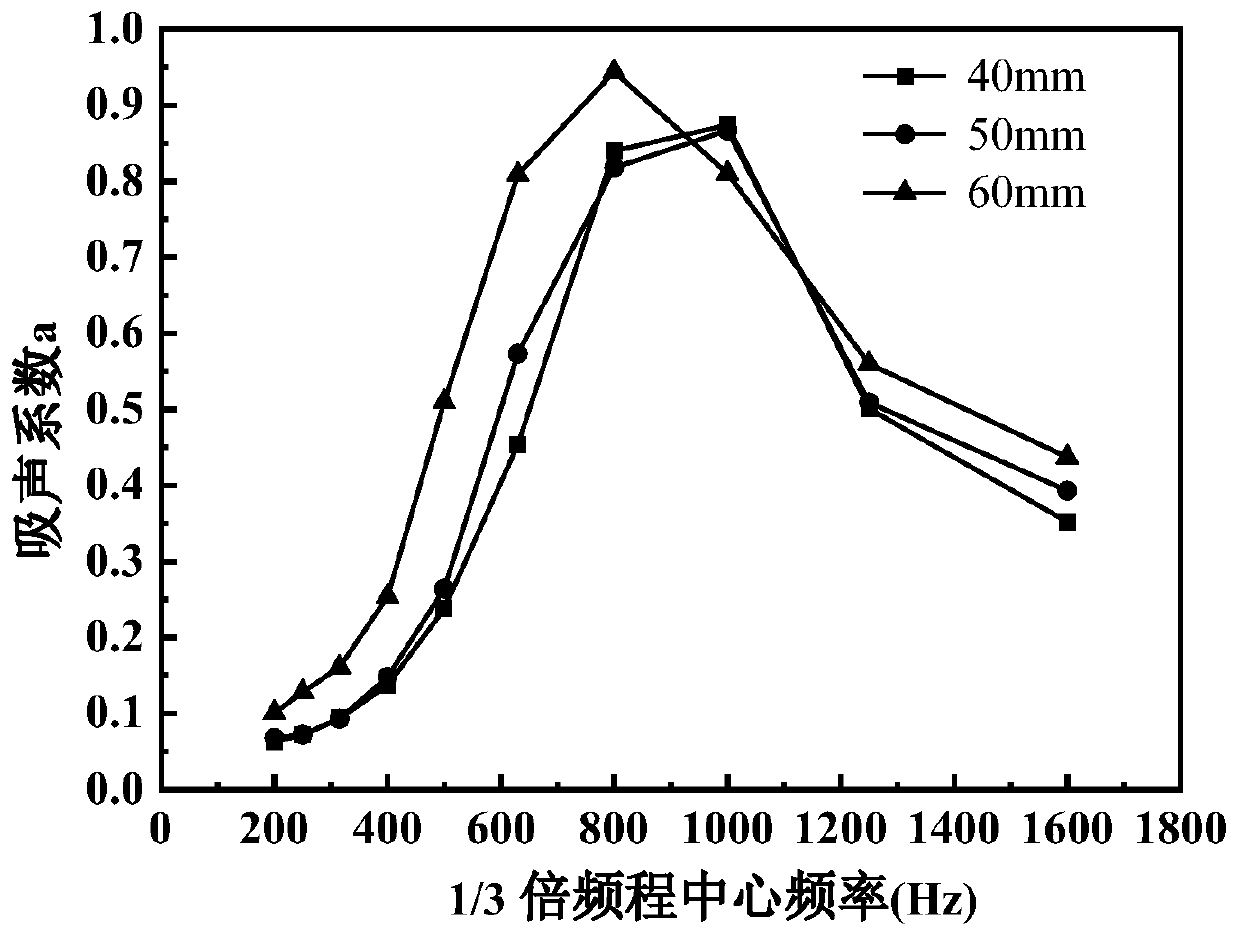

[0043] An ultra-quiet pavement paving material, which is formed by mixing aggregates, waste rubber, and a two-component solvent-free polyurethane binder under normal temperature conditions, and the mass percentage of the two-component solvent-free polyurethane binder is 5.5%, the mass percentage of waste rubber is 10%, and the balance is aggregate.

[0044] The two-component solvent-free polyurethane adhesive is synthesized by the reaction of epoxy resin and polyurethane adhesive prepolymer in a mass ratio of 1:4; the density of the polyurethane adhesive prepolymer is 1.2±0.05g / cm 3 , viscosity 100CPS, solid content 100%, solid peel strength ≥ 10MPa, solid shear strength > 50N / cm 2 .

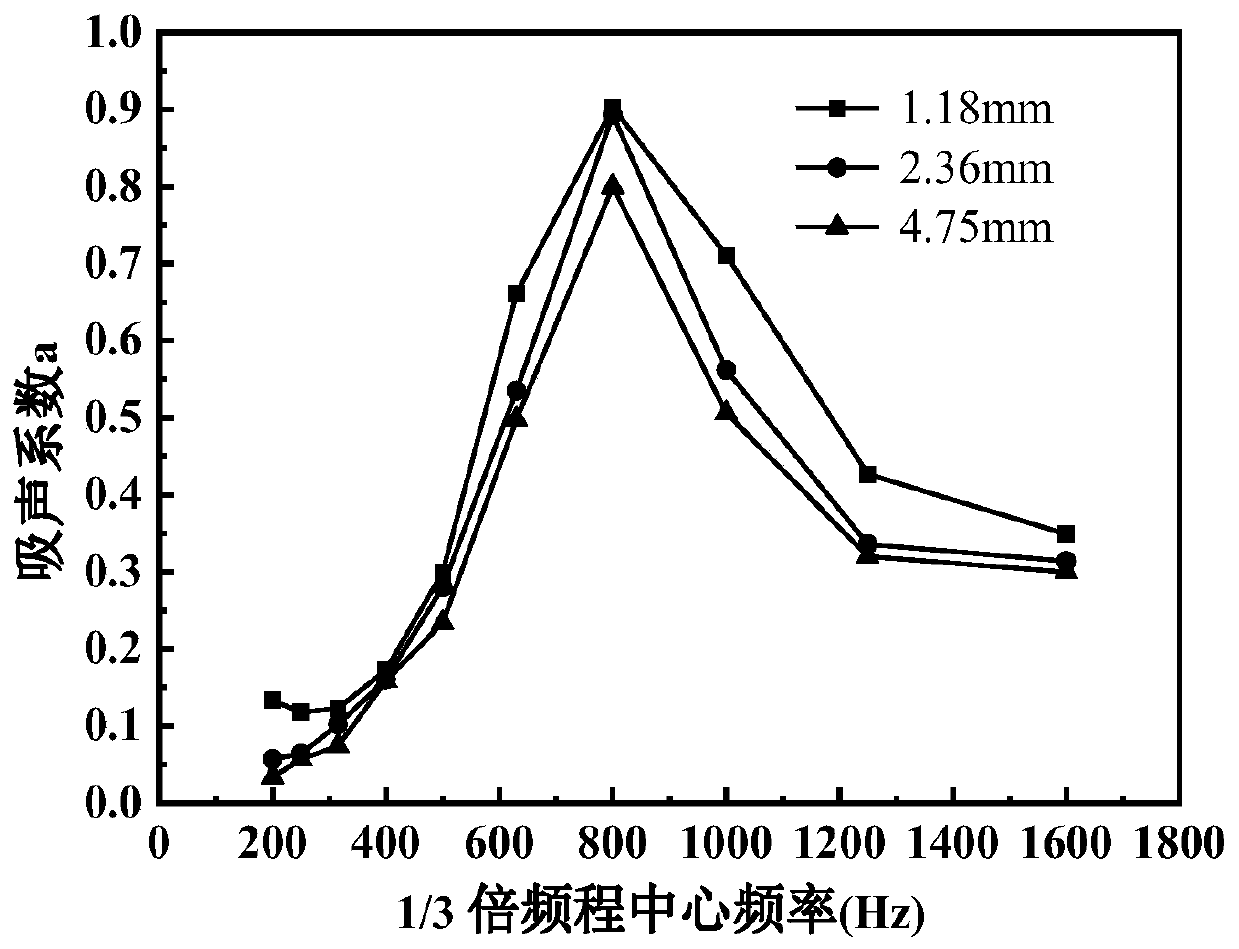

[0045] It is further defined that the aggregates used are limestone aggregates, which are divided into coarse aggregates and fine aggregates; wherein the coarse aggregates have a particle content of <0.075mm by washing method ≤ 0.5%, a polishing value ≥ 42, and a needle flake content ≤ 10%. ...

Embodiment 2

[0049] An ultra-quiet pavement paving material, which is formed by mixing aggregates, waste rubber, and a two-component solvent-free polyurethane binder under normal temperature conditions, and the mass percentage of the two-component solvent-free polyurethane binder is 5%, the mass percentage of waste rubber is 12%, and the balance is aggregate.

[0050] The two-component solvent-free polyurethane adhesive is synthesized by the reaction of epoxy resin and polyurethane adhesive prepolymer in a mass ratio of 1:3; the density of the polyurethane adhesive prepolymer is 1.2±0.05g / cm 3 , viscosity 100CPS, solid content 100%, solid peel strength ≥ 10MPa, solid shear strength > 50N / cm 2 .

[0051] It is further defined that the aggregates used are limestone aggregates, which are divided into coarse aggregates and fine aggregates; wherein the coarse aggregates have a particle content of <0.075mm by washing method ≤ 0.5%, a polishing value ≥ 42, and a needle flake content ≤ 10%. ; ...

Embodiment 3

[0055] An ultra-quiet pavement paving material, which is formed by mixing aggregates, waste rubber, and a two-component solvent-free polyurethane binder under normal temperature conditions, and the mass percentage of the two-component solvent-free polyurethane binder is 6%, the mass percentage of waste rubber is 4%, and the balance is aggregate;

[0056] The two-component solvent-free polyurethane adhesive is synthesized by the reaction of epoxy resin and polyurethane adhesive prepolymer in a mass ratio of 1:6; the density of the polyurethane adhesive prepolymer is 1.2±0.05g / cm 3 , viscosity 100CPS, solid content 100%, solid peel strength ≥ 10MPa, solid shear strength > 50N / cm 2 .

[0057] It is further defined that the aggregates used are limestone aggregates, which are divided into coarse aggregates and fine aggregates; wherein the coarse aggregates have a particle content of <0.075mm by washing method ≤ 0.5%, a polishing value ≥ 40 and a needle flake content ≤ 5% ; Fine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com