Vacuum pump

A vacuum pump and vacuum technology, applied in the direction of pumps, rotary piston pumps, rotary piston machines, etc., can solve the problems of complex design, high relative speed, etc., and achieve the effect of long service life, high suction performance, and low-cost structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

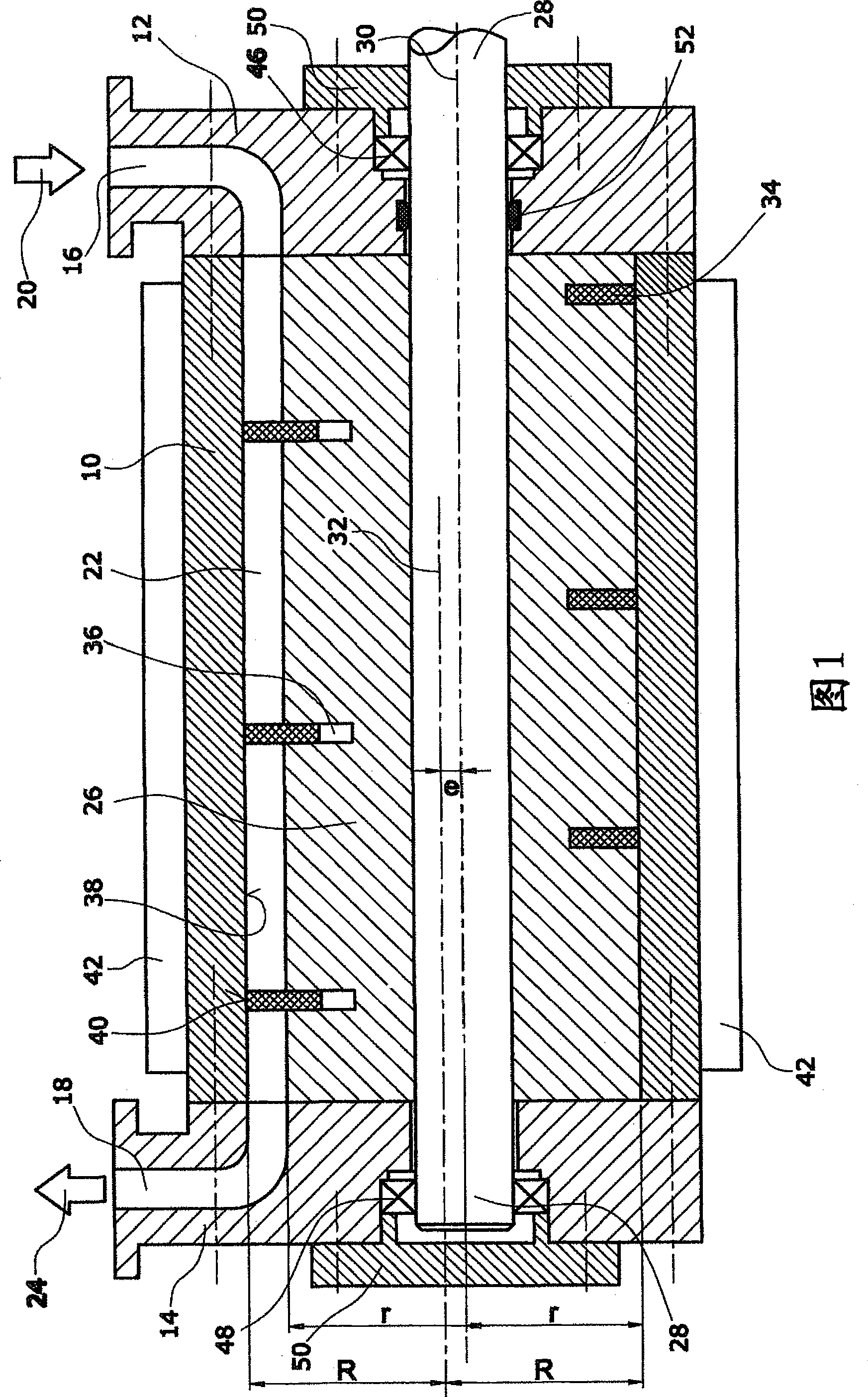

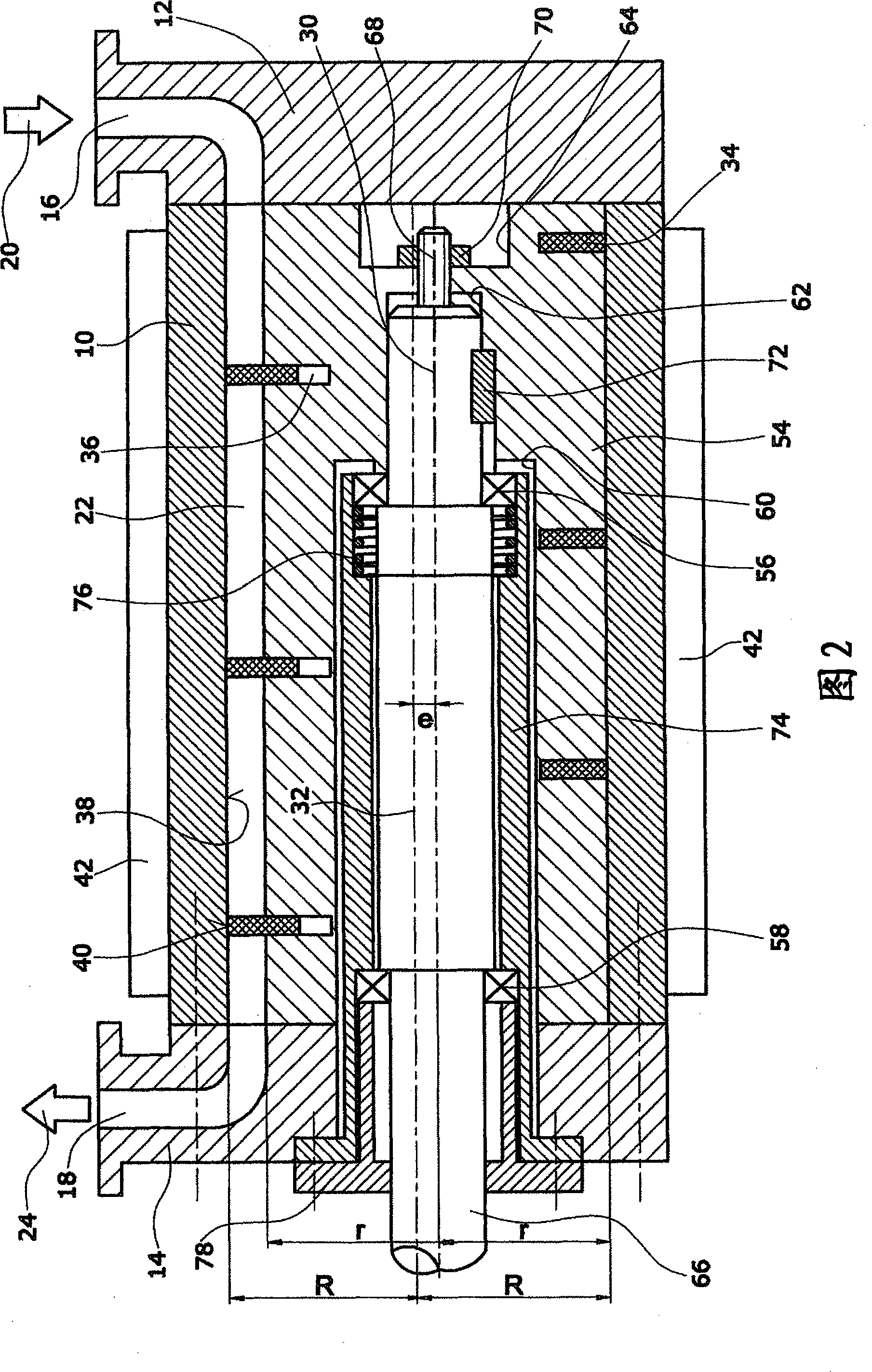

[0027]According to a first preferred embodiment of the invention ( FIG. 1 ), the vacuum pump comprises a stationary housing 10 . The housing 10 is closed by an inlet cover 12 and an outlet cover 14 . The inlet cover 12 includes an inlet 16 connected to the space to be evacuated. The outlet cover 14 is provided with a connection 18 for venting the gas drawn from the space to be evacuated. In this way, gas can move from the space to be evacuated via the inlet 16 into the cylindrical interior space 22 of the housing 10 in the direction of arrow 20 and via said outlet connection 18 provided in the outlet cover 14 in the direction of arrow 24 Leave the interior space.

[0028] A cylindrical propeller 26 is positioned inside the cylindrical space 22 . The propeller 26 is arranged concentrically with the shaft 28 . Thus, the central axis 30 of the propeller corresponds to the central axis of the shaft 28 . The shaft 28 is arranged eccentrically within the cylindrical inner space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com