Dust collection device

A technology of dust collection device and suction port, which is applied to the installation of vacuum cleaners, mechanical devices for controlling suction, and electrical equipment. It can solve problems such as the inability to achieve the best match for garbage adsorption requirements, the inability of garbage to quickly absorb electric energy, and inconvenient operation. Achieve the effect of improving the suction effect, increasing the service life and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

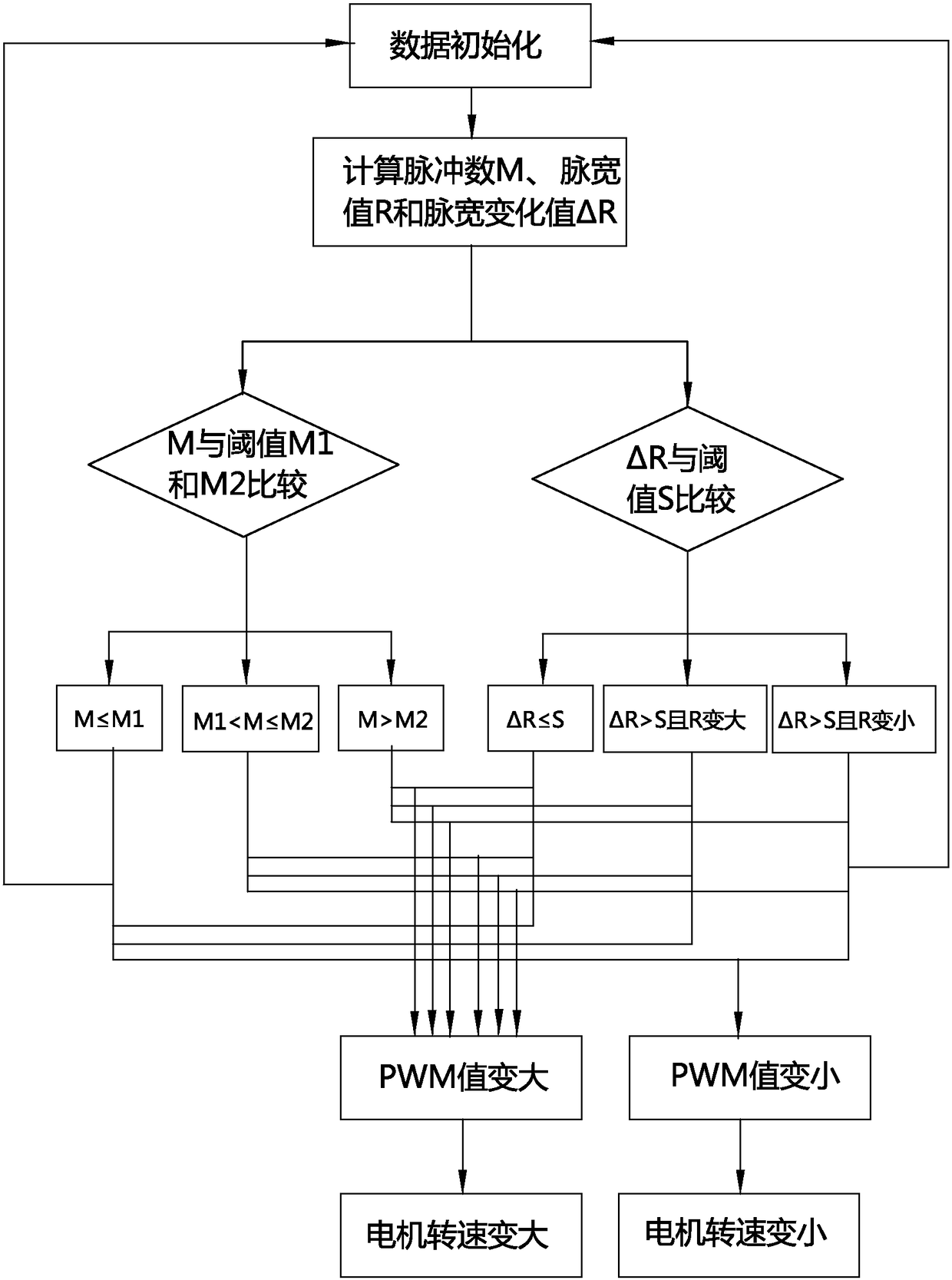

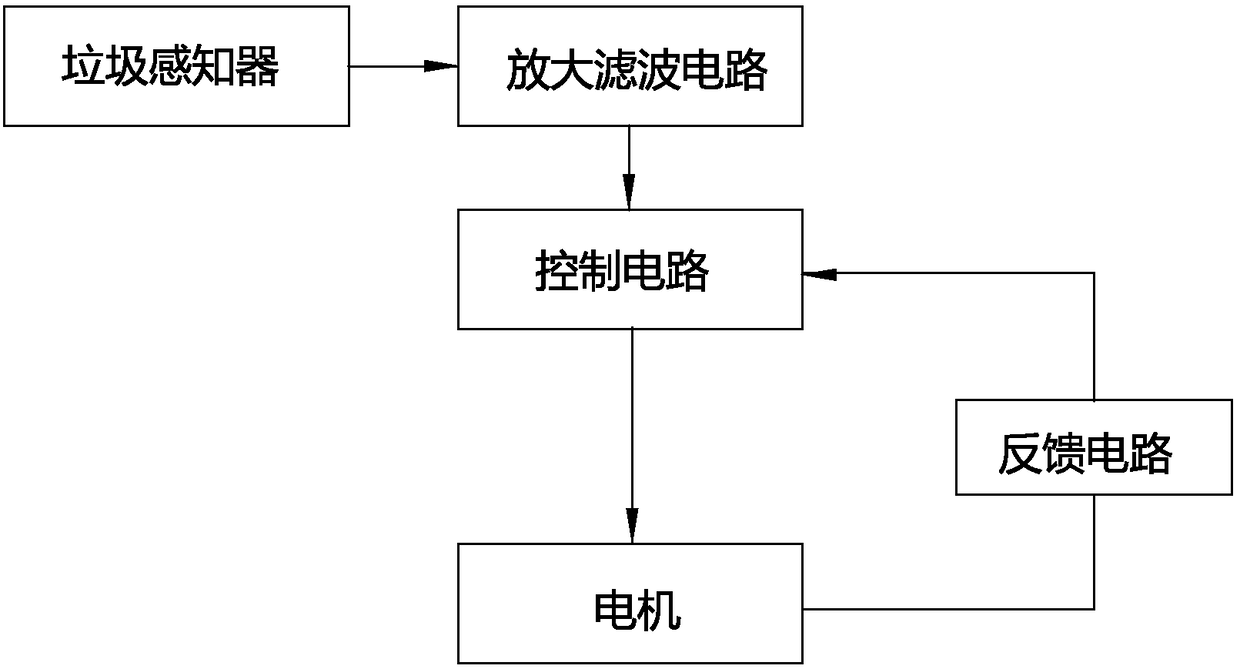

[0029] This embodiment provides a dust collection device, such as figure 1 and figure 2 As shown, it includes a housing, a suction motor, and a control circuit connected to the suction motor. The housing is provided with a suction port for garbage suction, and the suction port is provided with a garbage sensor. The garbage sensor is electrically connected to the control circuit. The vacuum device adopts the following steps to control the work of the suction motor:

[0030] Step 1: Data initialization;

[0031] Step 2: The garbage sensor senses the garbage, and the control circuit starts timing when the level changes, and starts to calculate the number of pulses M, the pulse width R and the pulse width change value ΔR;

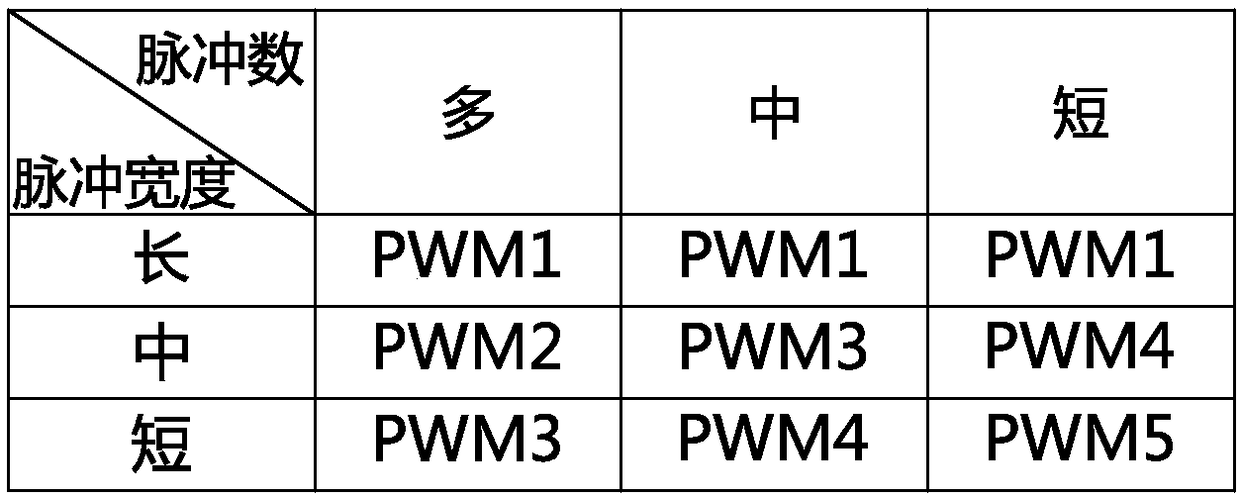

[0032] Step 3: When the timing reaches the preset time T, the control circuit records the value M of the current pulse. The control circuit is preset with a first pulse threshold M1, a second pulse threshold M2 and a pulse width change threshold S, where M1S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com