Fireproof thermal insulation material

A technology of fire prevention, heat preservation and raw materials, applied in the field of building materials, can solve problems such as loss of life and property, environmental pollution, casualties, etc., and achieve the effects of saving land resources, good chemical stability, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

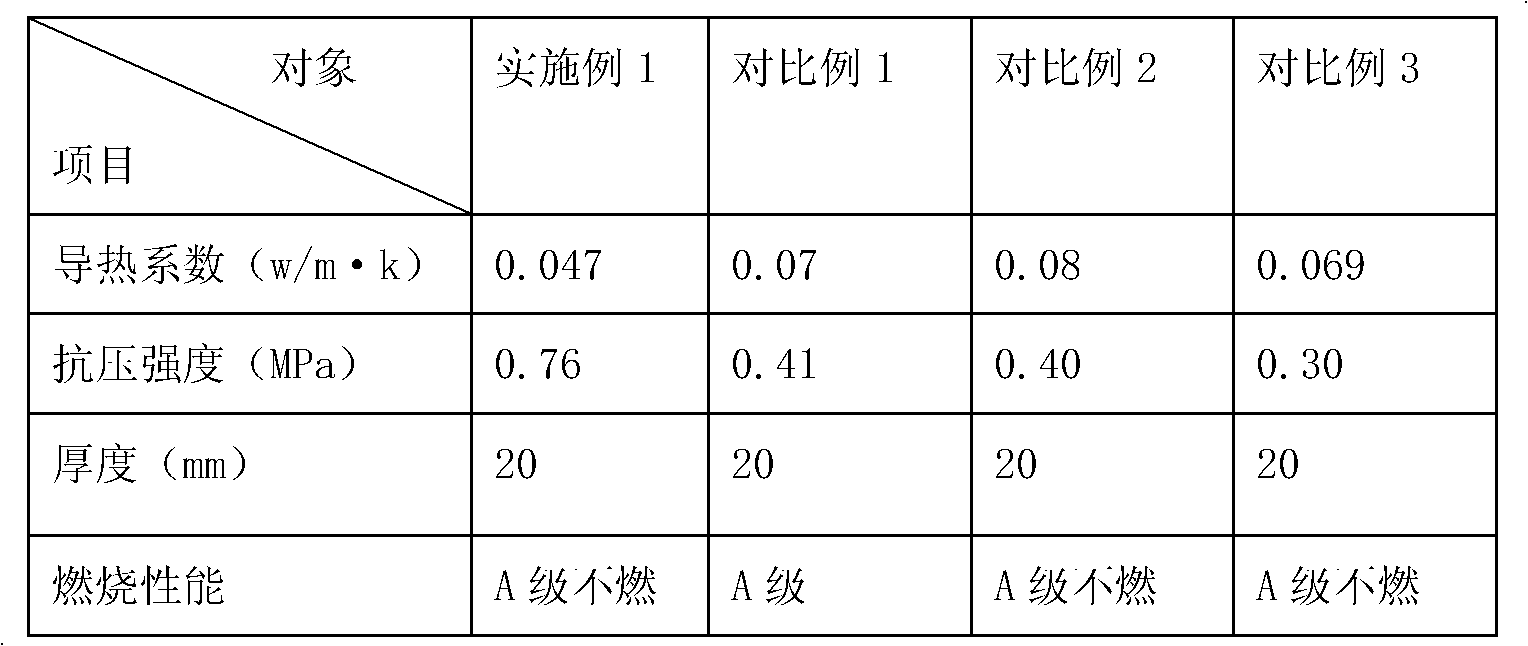

Embodiment 1

[0030] The raw material formula of the fireproof and thermal insulation material is as follows: discarded high-temperature-resistant glass fiber composite filter bag, 28%, scraps cut during the production of high-temperature-resistant glass fiber composite felt, 28%, fly ash, 36%, flocculant, 4% , Cationic starch, 4%.

[0031] The preparation steps are as follows:

[0032] 1. Opening waste high temperature resistant glass fiber composite filter bags and high temperature resistant glass fiber composite mats to produce the leftovers of filter bags: when the recycled high temperature resistant glass fiber composite filter bags and high temperature resistant glass fiber composite felts are used to produce filter bags The cut leftovers are opened into fibers through the opener; the fibers are fluffy. Before opening, the recovered raw materials are rinsed and dried in the sun.

[0033] 2. Slurry preparation: weigh the raw materials according to the above formula, mix them evenly, ...

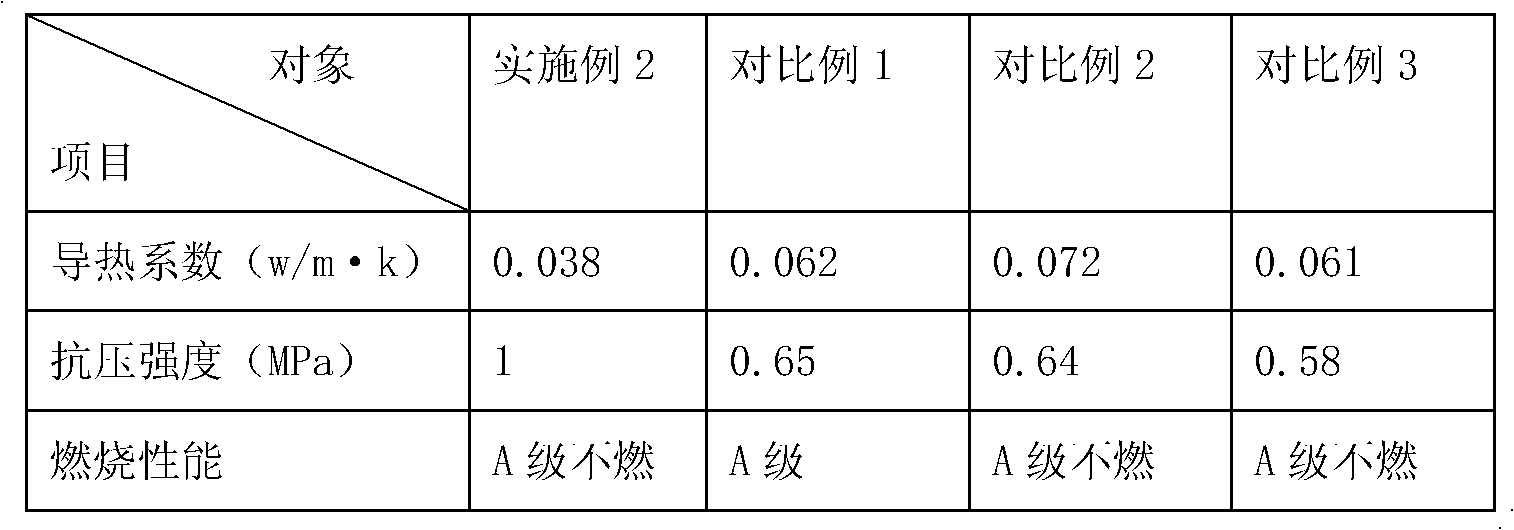

Embodiment 2

[0041] The raw material formula of the fireproof and thermal insulation material is as follows: discarded high-temperature-resistant glass fiber composite filter bag, 33%, scraps cut during the production of high-temperature-resistant glass fiber composite felt, 25%, fly ash, 32%, flocculant, 5% , Cationic starch, 5%.

[0042] The preparation steps are the same as in Example 1.

Embodiment 3

[0044] The raw material formula of the fireproof and thermal insulation material is as follows: discarded high-temperature-resistant glass fiber composite filter bag, 44%, scraps cut during the production of high-temperature-resistant glass fiber composite felt, 18%, fly ash, 26%, flocculant, 6% , Cationic starch, 6%.

[0045] The preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com