Valve of liquid operation

A fluid and fluid leakage technology, applied to fuel injection devices, engine components, machines/engines, etc. with stress-reducing measures, can solve problems such as damage and destruction of spring components, and achieve the effect of avoiding pressure rise and reducing the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

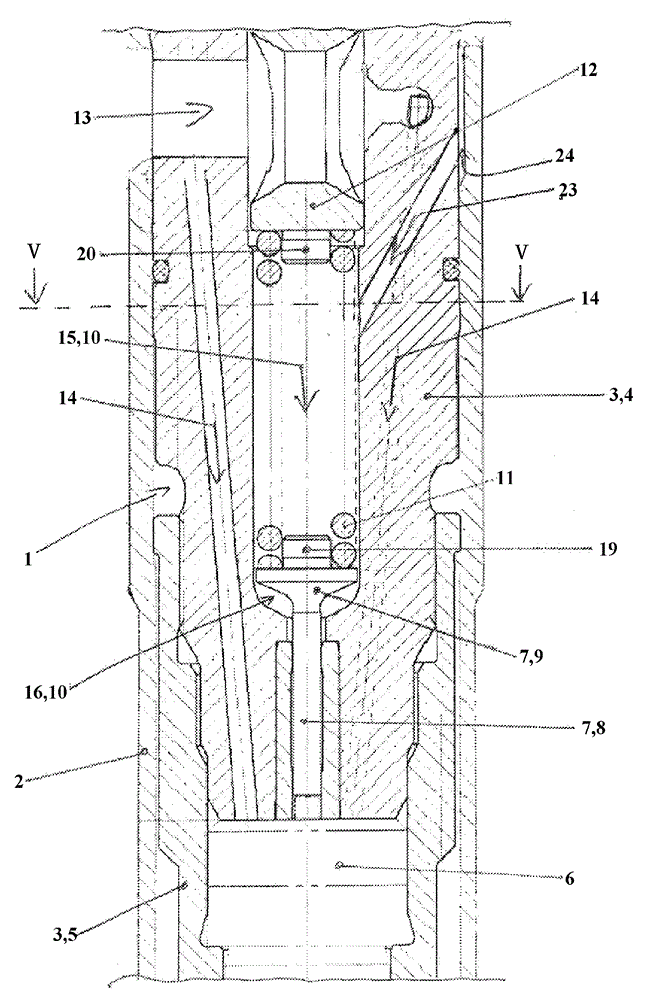

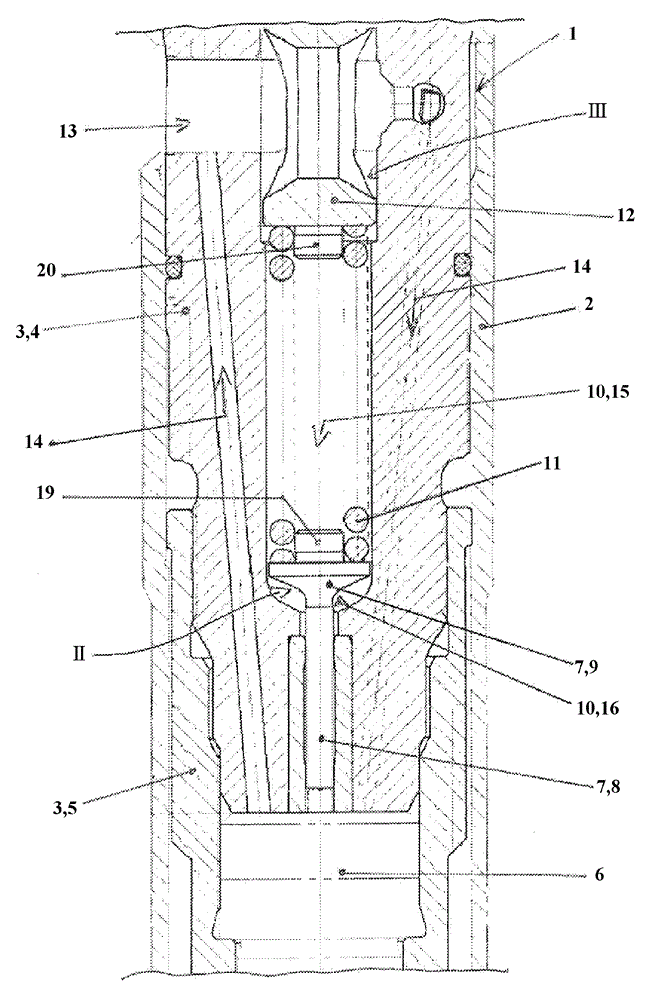

[0045] The invention here relates to a fluid-operated valve, in particular a fuel injection valve for the fuel supply of large diesel engines, preferably for the fuel supply of marine diesel internal combustion engines operating on heavy fuel oil.

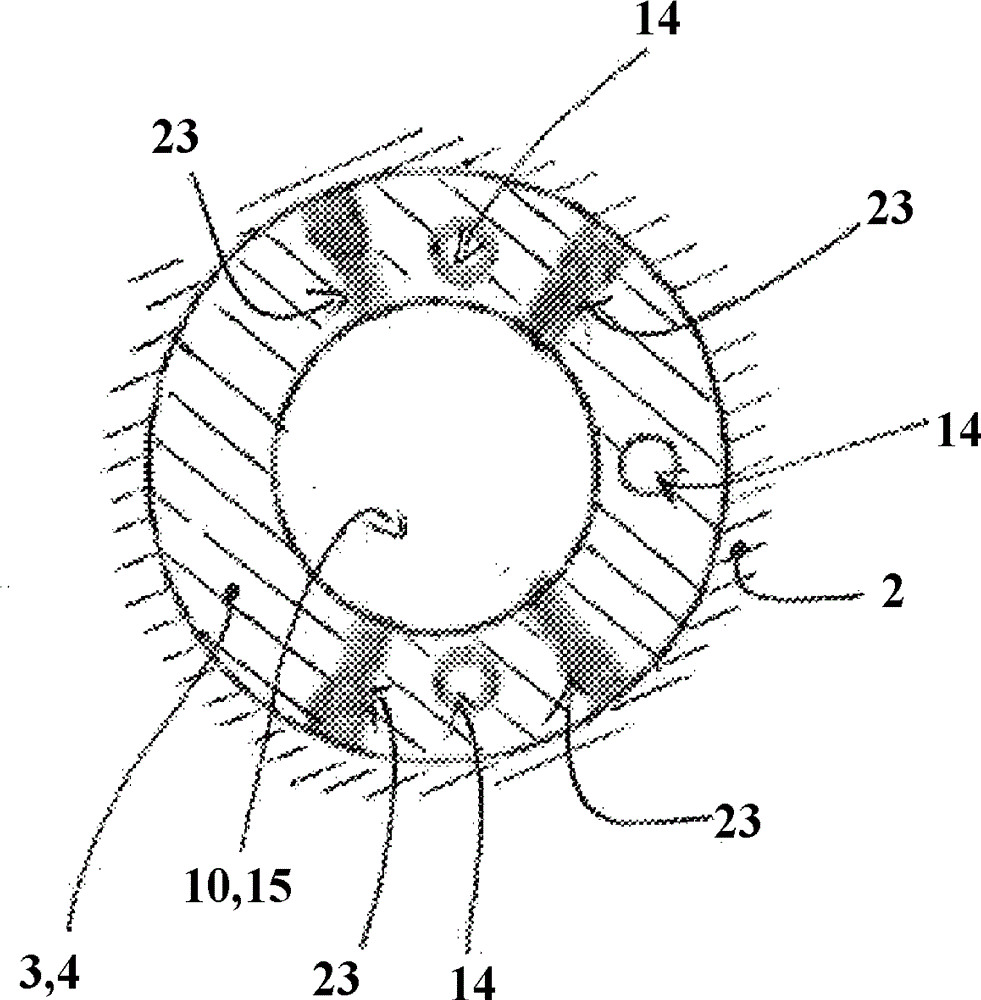

[0046] figure 1 A partial cross section through fuel injector 1 is shown in section, fuel injector 1 being arranged in receptacle 2 . The receptacle 2 can be a cylinder head of an internal combustion engine. figure 1 The fuel injector has a valve housing 3 which, in the exemplary embodiment shown, consists of two sections 4 , 5 screwed together. The valve housing 3 is in figure 1 The upper section 4 shown in is screwed into the valve housing 3 in the figure 1 In the lower section 5 shown in and extends therein segment by segment.

[0047] In the valve housing 3, in figure 1 In its lower section 5 , a valve body 6 in the form of a nozzle needle is guided, which interacts with a valve seat provided by the lower section 5 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com