Full-automatic coffee capsule filling machine suitable for coarse coffee powder

A coffee capsule, fully automatic technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of prolonged packaging time, waste, and affecting drinking, so as to improve space utilization, reduce filling time, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

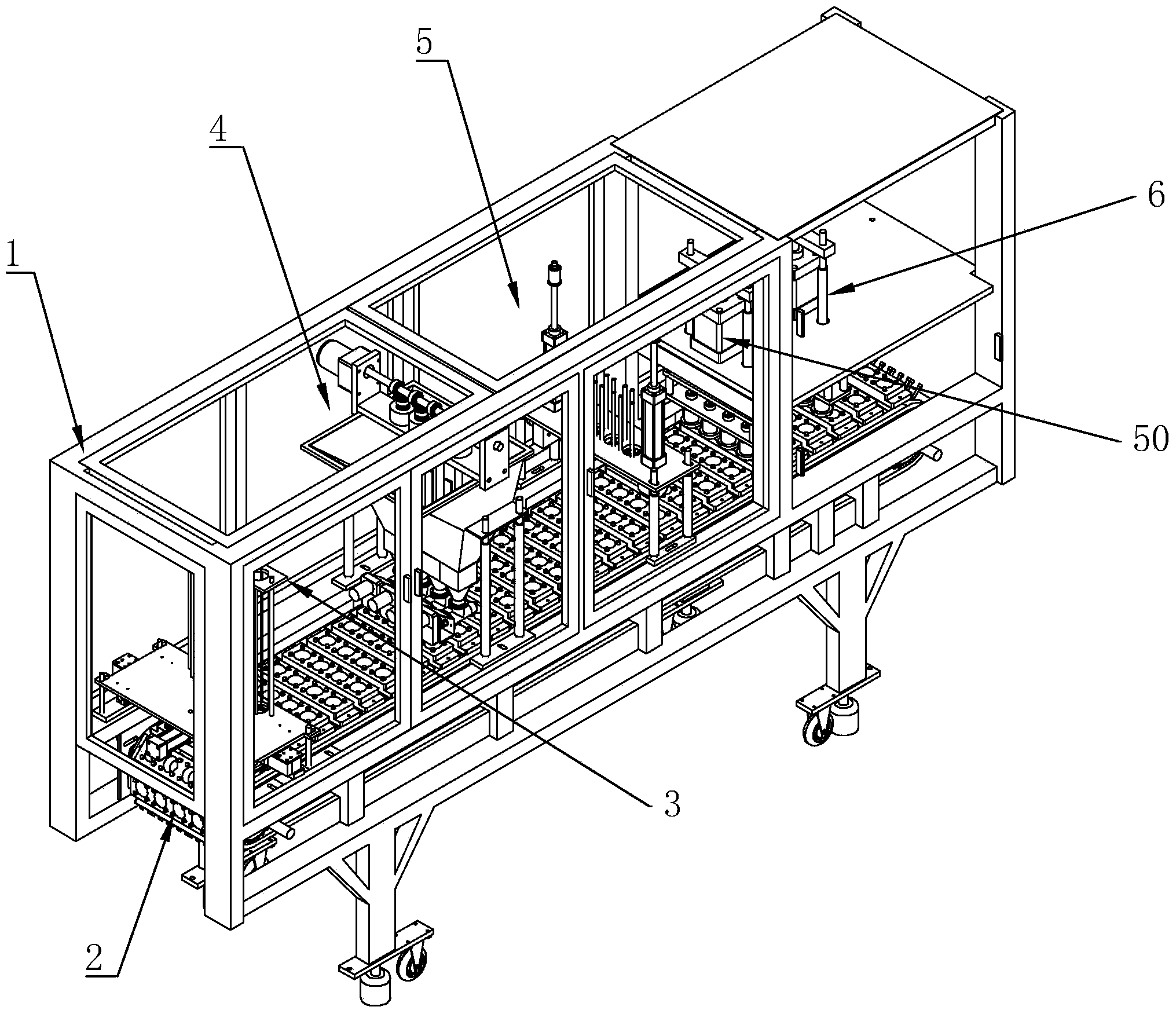

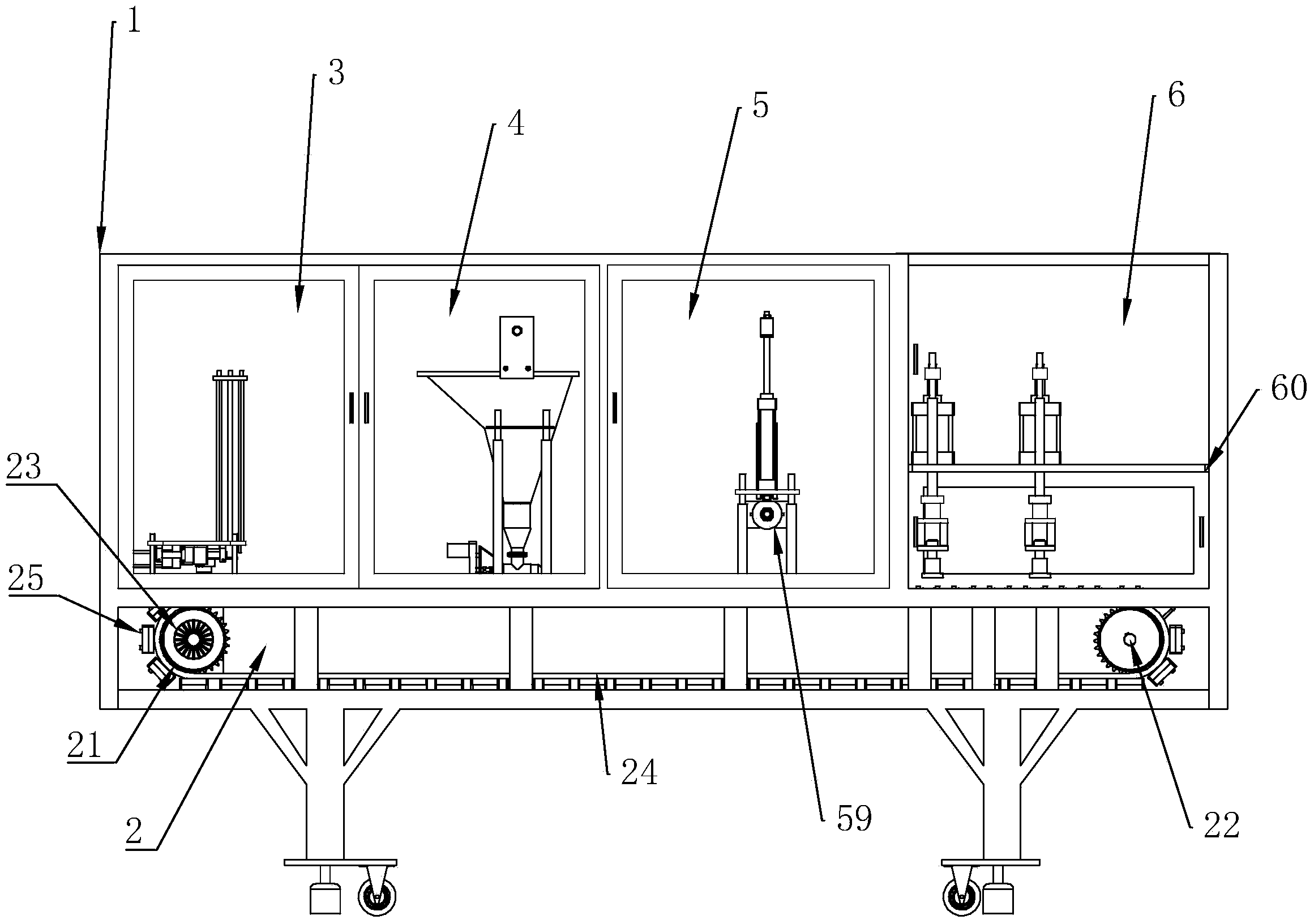

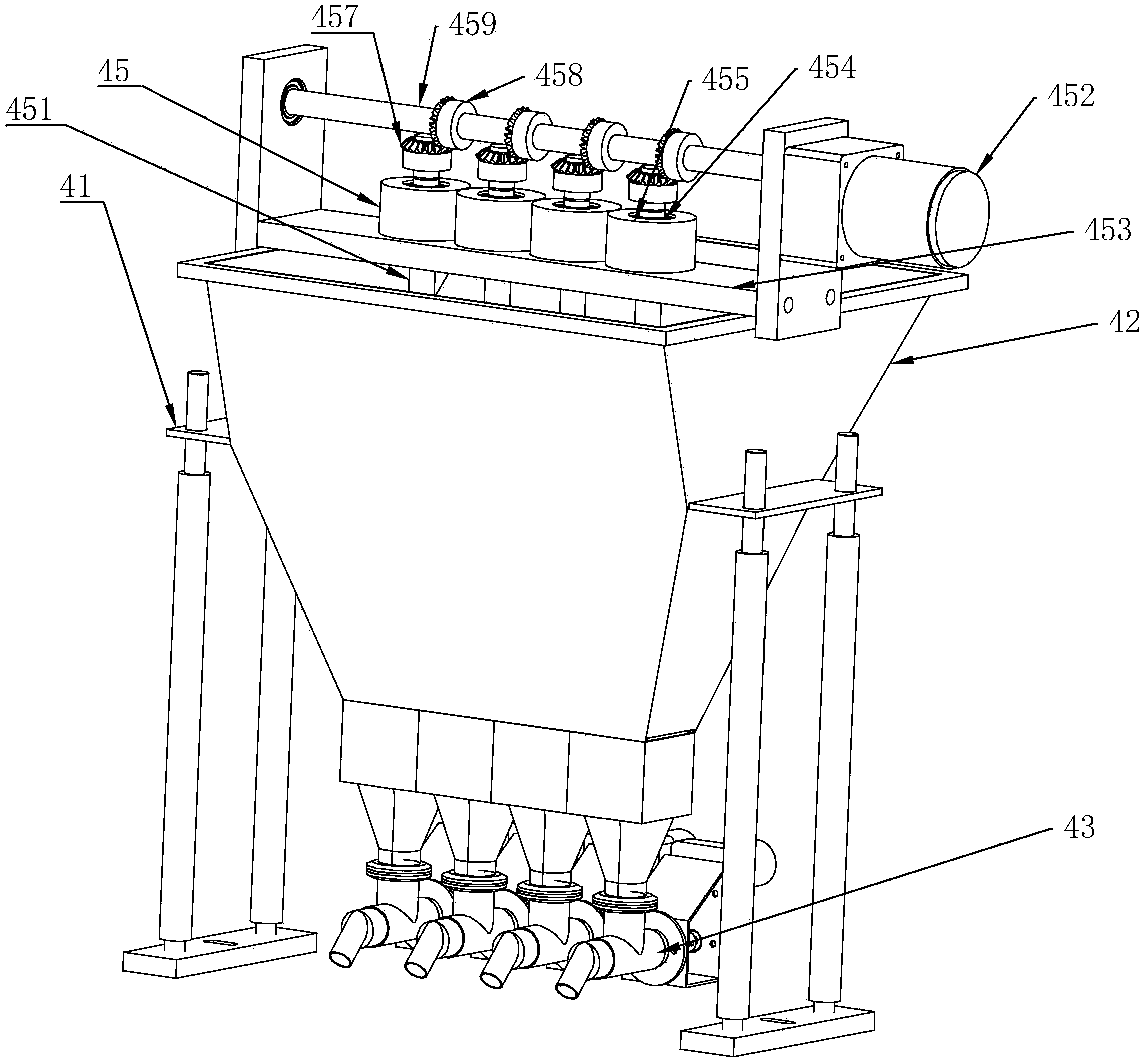

[0045] refer to Figure 1 to Figure 10 The embodiment of the fully automatic coffee filling line of the present invention will be further described.

[0046] There is a certain difference between the filling of coarse coffee powder and the filling of fine coffee powder. The filling of coarse coffee powder does not need to be compacted after filling like the filling of fine coffee powder. Compacting the coarse coffee powder will not only cause waste of resources, prolong the filling time, reduce work efficiency, but also cause damage to the coarse coffee powder, resulting in poor taste of the coarse coffee powder.

[0047] A fully automatic coffee capsule filling machine suitable for coarse coffee powder, comprising a main support 1 and a transmission device 2, the transmission device 2 is arranged on the main support 1, and is sequentially provided with a cup dropping device 3, a feeding device 4, a suction Membrane device 5, film sealing device 6, described feeding device 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com