Ammonia Storage Cartridge With Optimized Filling Time, in Particular for a Motor Vehicle Gas Exhaust system

A technology for motor vehicles and exhaust systems, applied in the field of ammonia storage cartridges, can solve problems such as time-consuming and achieve the effect of promoting ammonia circulation and boosting pressure quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

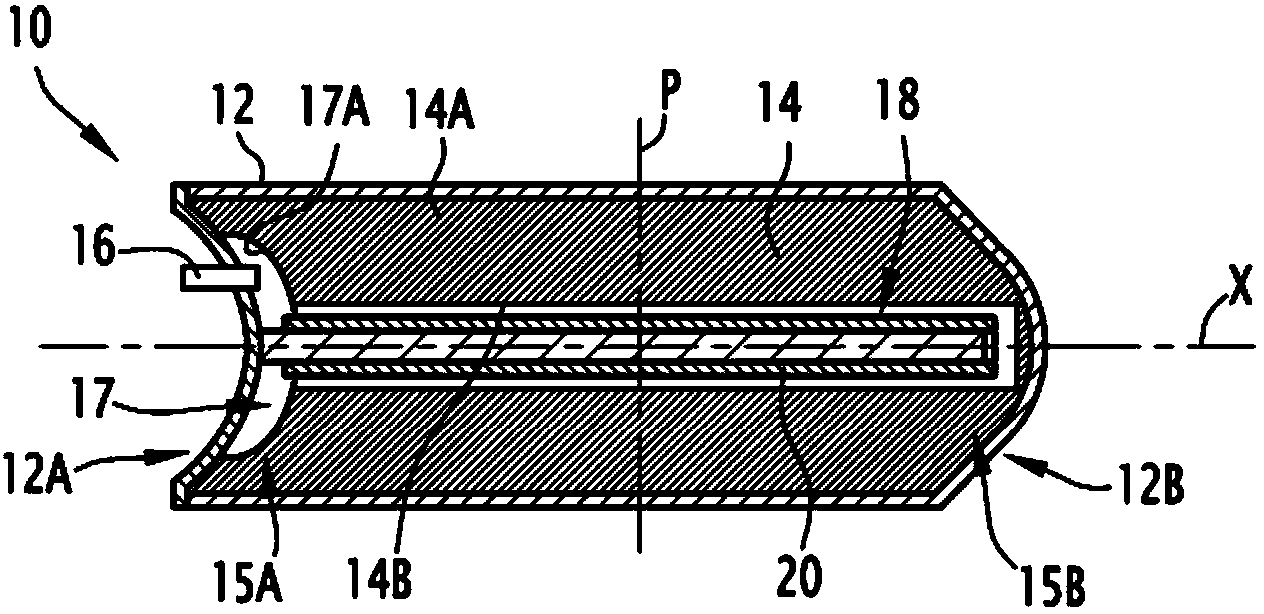

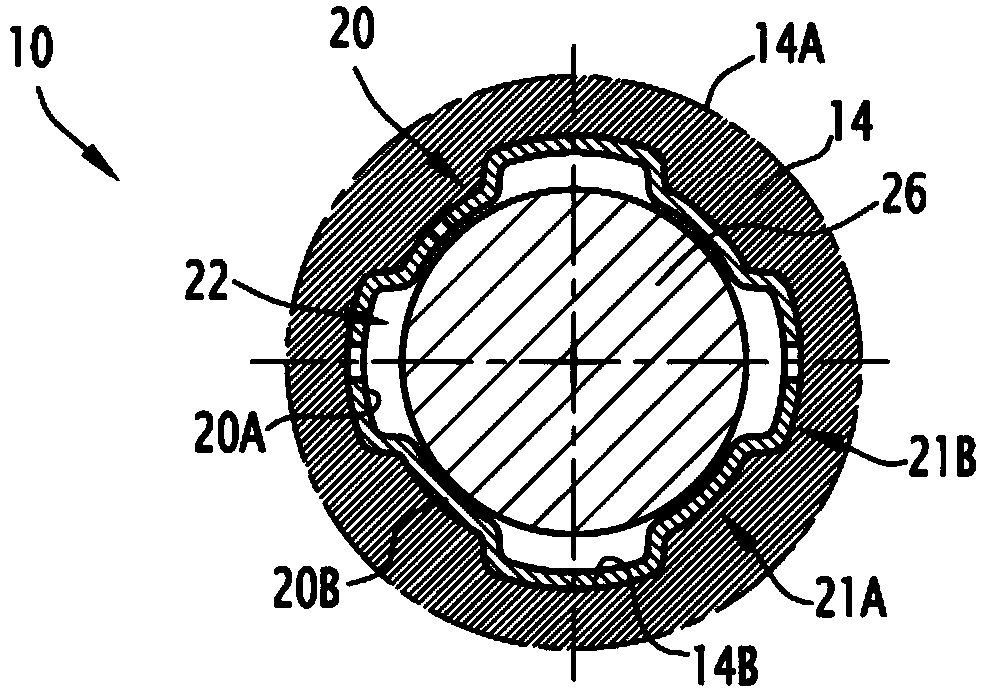

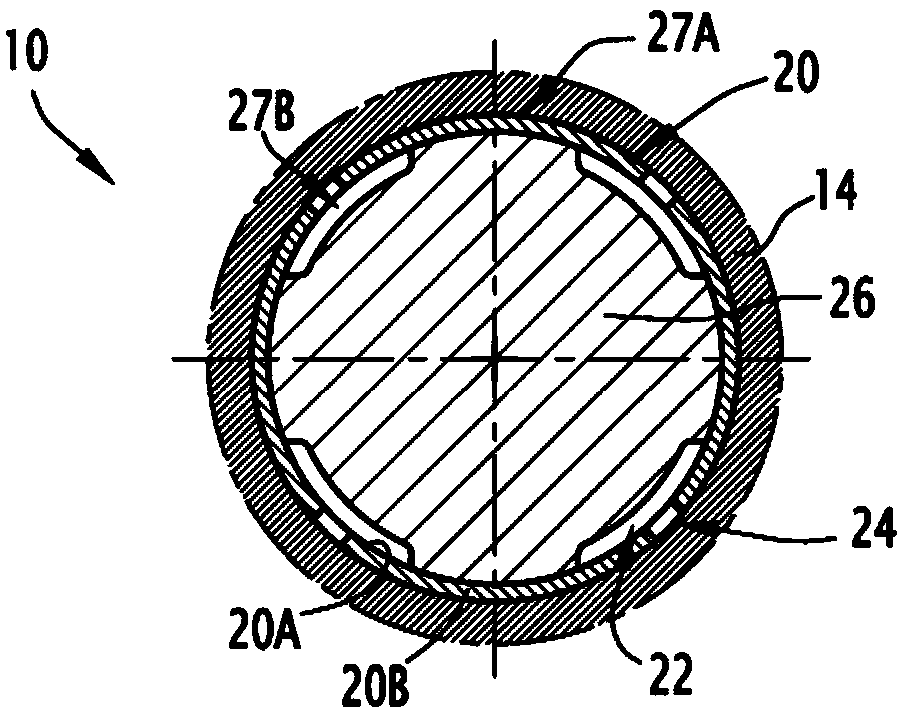

[0041] figure 1 An ammonia storage cartridge 10 according to a first embodiment of the invention is shown.

[0042] Such a cartridge 10 is intended to be equipped in the exhaust system of a motor vehicle, in which ammonia is released.

[0043] The storage cartridge 10 includes an airtight container 12 within which is disposed an ammonia storage component 14 . The storage part 14 is made of a material capable of absorbing or adsorbing ammonia, which is called a storage material.

[0044] According to the described embodiment, the storage member 14 extends along the longitudinal axis X between the first end 15A and the second end 15B.

[0045] The storage material corresponds, for example, to one of the materials described in patent application WO2008 / 077652. Such materials are chosen, for example, from the series known as metalloamine complexes, having the general chemical formula M a (NH 3 ) n x z ,in:

[0046] M is one or more metals from the alkali metal group, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com