Liquid hydrogen vaporization and self-pressurizing device

A vaporization device and self-pressurization technology, which is applied in the direction of hydrogen technology, pressure vessels, equipment installed in pressure vessels, etc., can solve the problems of many equipment and high energy consumption, and achieve the effect of simplifying the process and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

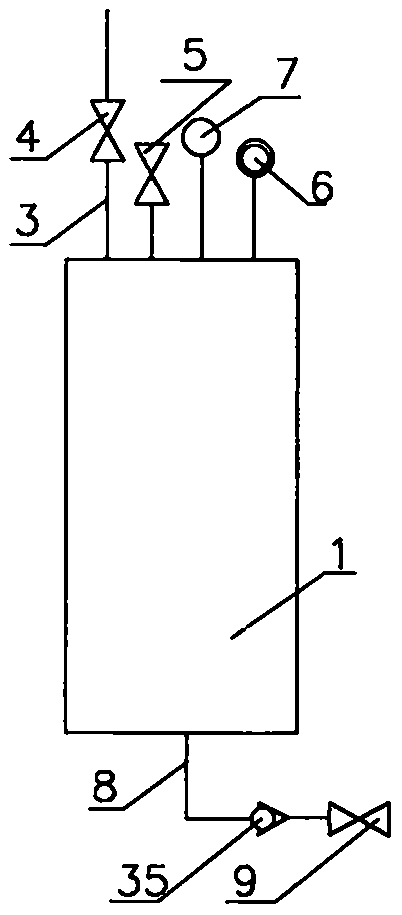

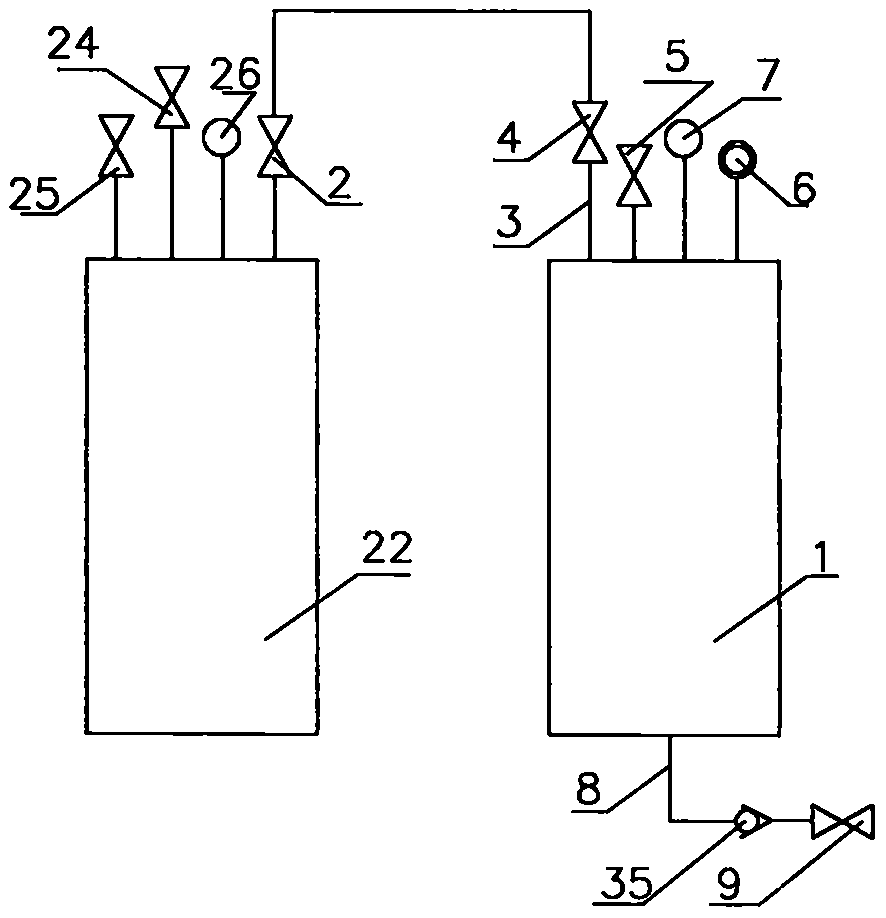

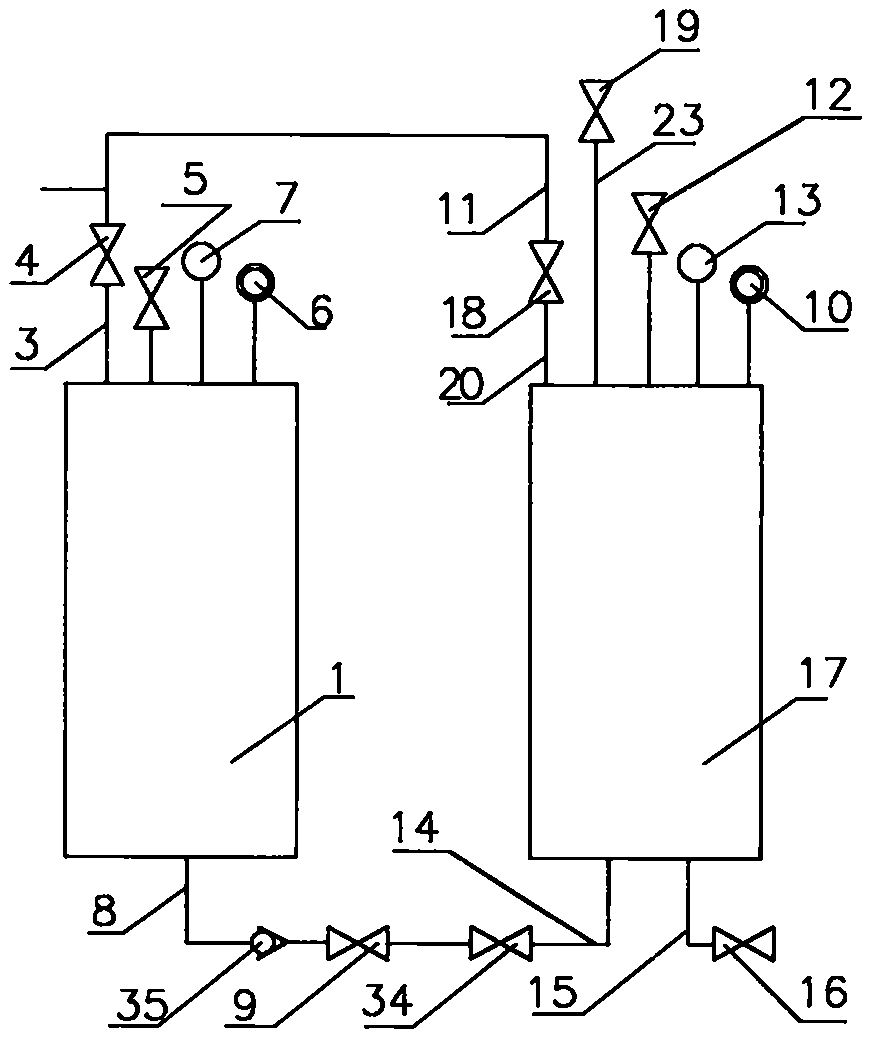

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0035] A liquid hydrogen vaporization and self-pressurization device, including a liquid hydrogen vaporizer, the liquid hydrogen vaporizer is provided with a hydrogen output pipeline 3 and a hydrogen output control valve 4 connected thereto, a hydrogen safety control valve 5, and a hydrogen pressure detector 7 and a liquid hydrogen filling pipeline 8; the liquid hydrogen vaporizer is set as a high-pressure liquid hydrogen vaporization device 1, and its working pressure is 10MPa to 200MPa.

[0036] Vaporizer is a kind of equipment often used in industrial production. Cryogenic liquid vaporizers, including liquid nitrogen, liquid hydrogen, liquid helium, and liquid oxygen vaporizers, have long been a mature technology and have been applied in many fields, especially LNG vaporizers, which have been widely used. The use of pressure vessels is extre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com