High-frequency conical spiral tube type pulse detonation engine

A pulse detonation and engine technology, applied in the direction of machine/engine, rocket engine device, mechanical equipment, etc., can solve the problems of low working frequency and low energy density, achieve short filling time, improve energy density, reduce volume and axis effect on length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

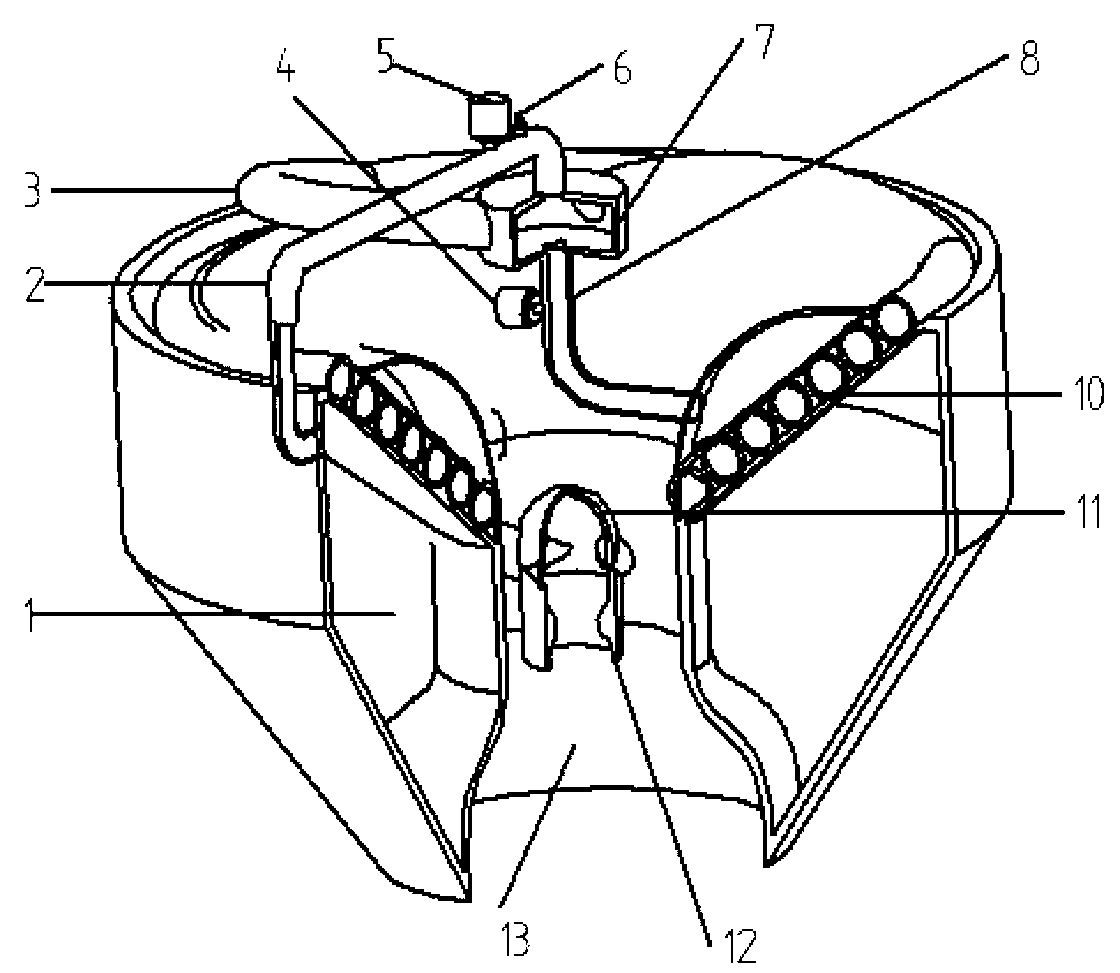

[0026] This embodiment is a high frequency conical helical tube type pulse detonation engine.

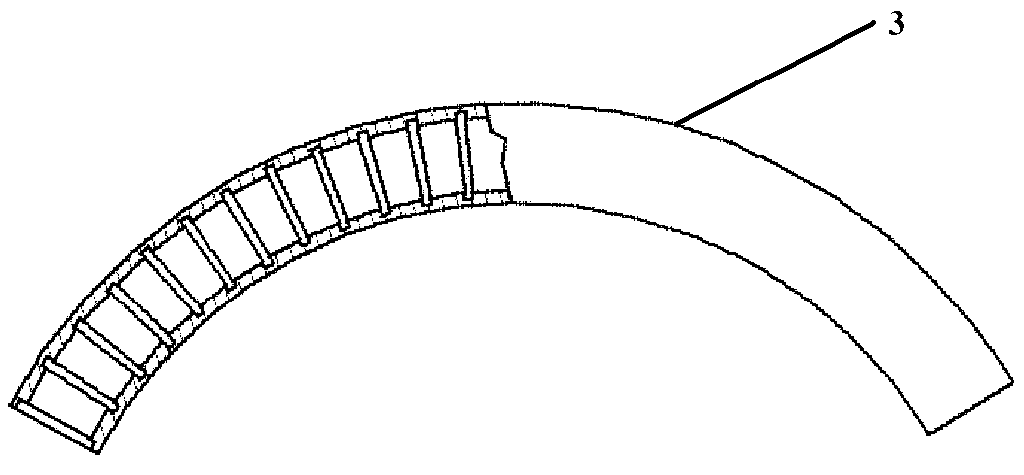

[0027] refer to Figure 1-Figure 8 , The upper half of the outer casing of the high-frequency conical helical tube pulse detonation engine of the present invention is cylindrical, and the lower half is conical. The inner curved surface of the inner shell of the engine forms the channel of the ejector. The channel of the ejector is divided into upper, middle and lower sections. The outlet diameter of the nozzle nozzle 13 is equal to the lower port diameter of the housing. A cavity is formed between the inner and outer shells of the engine, and the cavity is separated by a cone-shaped annular channel 15 to form two chambers, the upper and lower parts. The upper part is smaller for the isolation gas storage chamber 9 to store the isolation gas, and the lower part is larger. The cavity of the oxidant storage chamber 1 stores fuel and oxidant, such as Figure 5 shown.

[0028] A plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com