Golf bar head equipped with hollow shock-absorbing material and air pressure function and production method thereof

A golf club head and club head technology, which is applied to golf balls, golf clubs, rackets, etc., can solve the problems of air bag gas leakage, hitting panel bounce off the club head, air bag falling off, etc., to achieve good hitting The effect of ball rebound and hitting feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

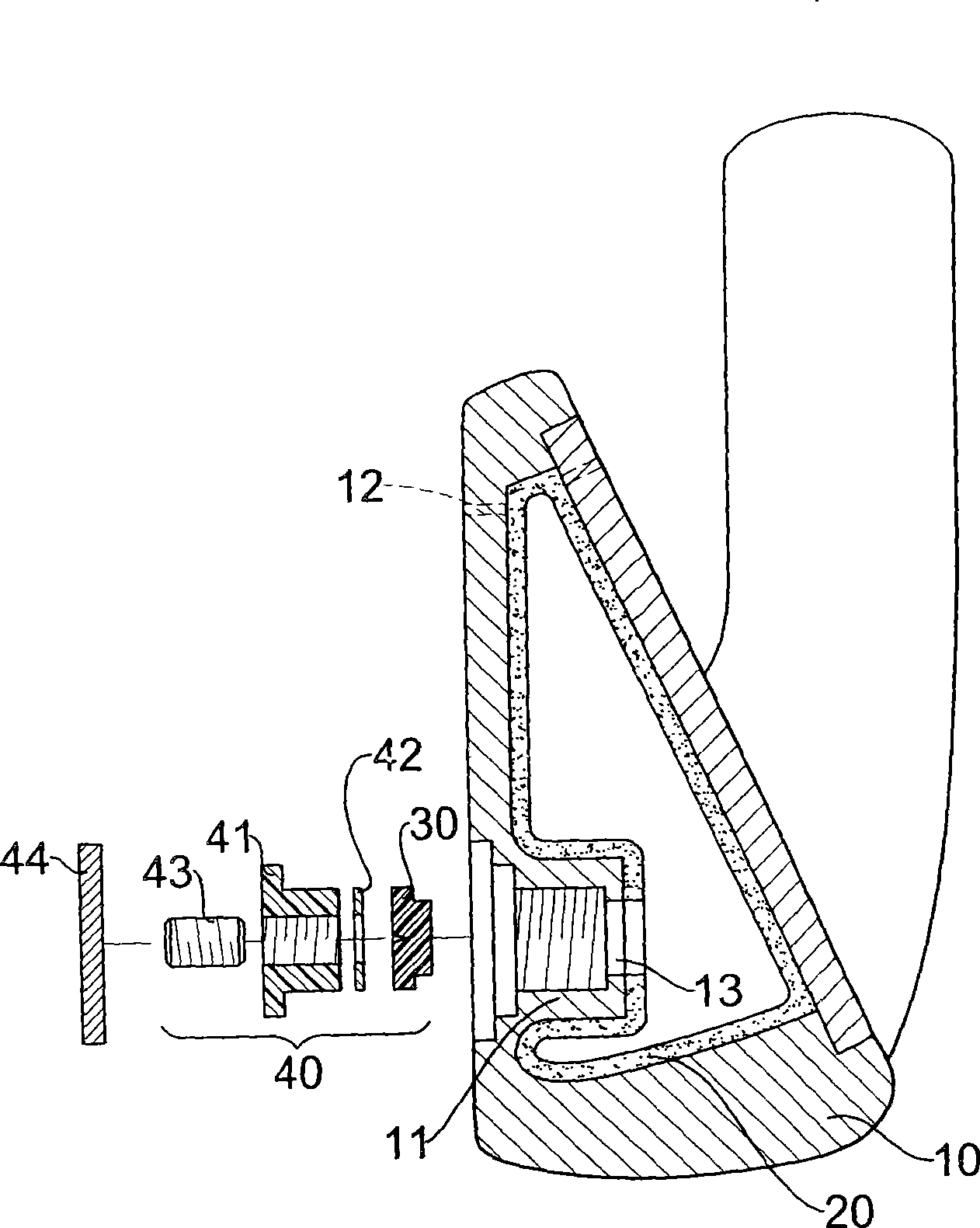

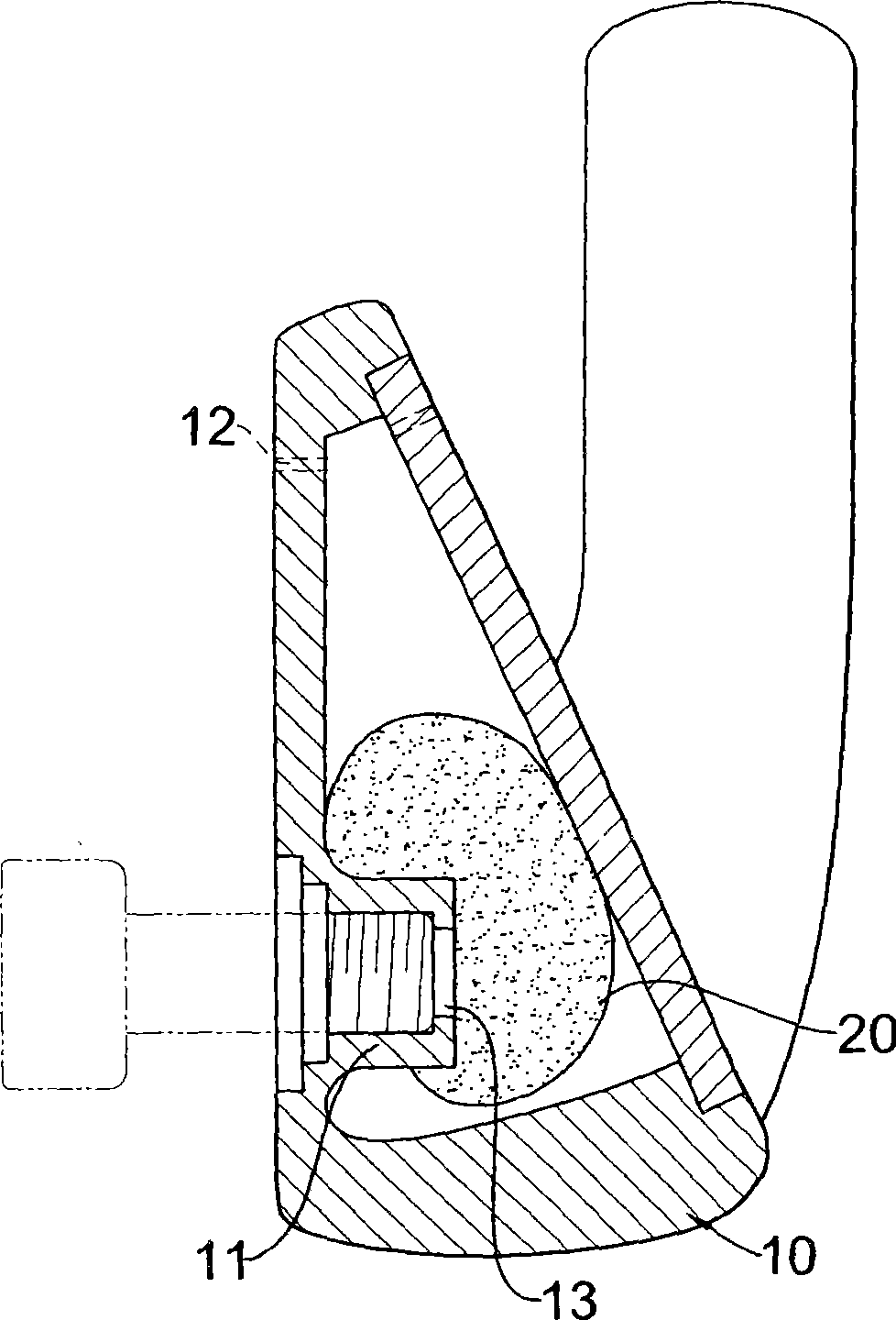

[0040] Please refer to figure 1 As shown, the present invention is a golf club head provided with a hollow gas-blocking shock-absorbing material and an air pressure function. The exhaust hole 12 of the club head 10, a gas-blocking shock-absorbing material 20 adhered to the inner wall of the club head 10, and a screwing device 40 arranged on the female screw seat 11 of the club head 10 are jointly composed, and the screw Closing device is made of a male screw seat 41, an elastic air-filling cushion 30, a screw 43 and decorative parts 44.

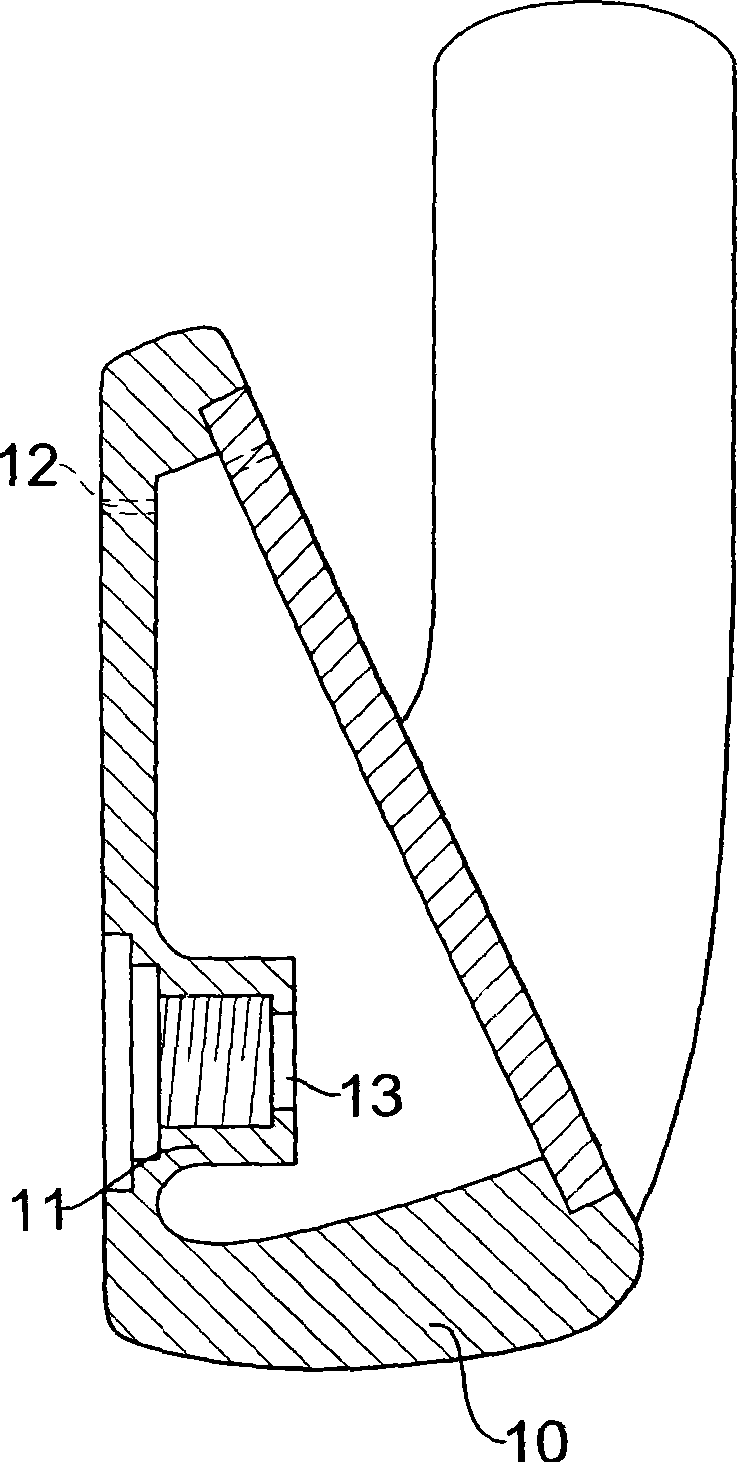

[0041] Please refer to figure 2 As shown, the rear side of the hollow golf club head 10 forms a female screw seat 11 and at least one exhaust hole 12, and the female screw seat 11 is recessed inwardly from the side of the club head to present a circular groove The shape of the female screw seat 11 forms a thread on the inner wall of the circular groove and forms a through hole 13 at the bottom end for injection into the gas-blocking shock-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com