Compaction vibration system for high-rise building foundation

A technology for high-rise buildings and vibration systems, applied in construction, soil protection, infrastructure engineering and other directions, can solve problems such as the inability to guarantee the safety of building foundations, poor performance, uneven compaction, etc. Short consumption time, good compaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

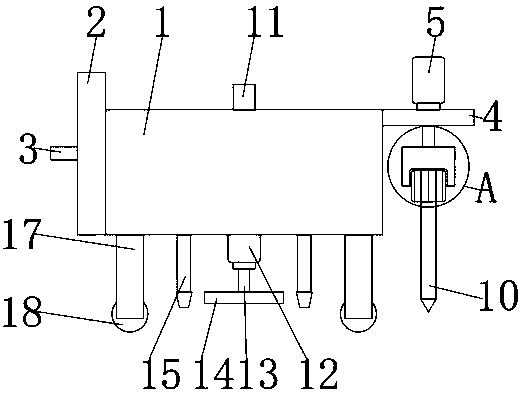

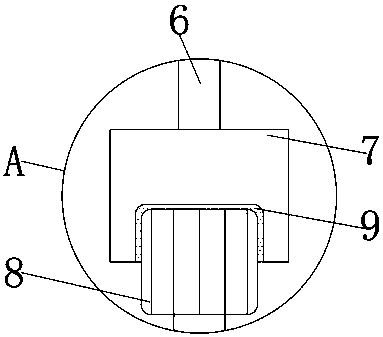

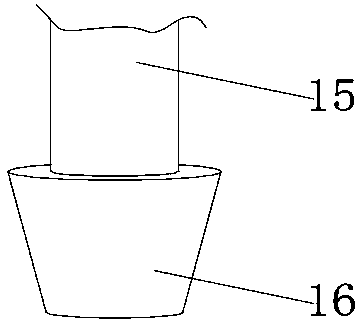

[0038] Such as Figure 1-4 As shown, a compaction vibration system for a high-rise building foundation includes a body 1, one side of the body 1 is fixedly connected with a first fixed plate 2, the inner bottom wall of the body 1 is provided with a through hole, and a part of the first fixed plate 2 The push handle 3 is fixedly connected to the middle part of the side, the second fixed plate 4 is fixedly connected to the top of the other side of the body 1, the top of the second fixed plate 4 is fixedly connected to the first hydraulic cylinder 5, and the bottom end of the first hydraulic cylinder 5 is fixedly connected to There is a first piston rod 6, and the bottom end of the first piston rod 6 is fixedly connected with a fixed block 7, and the bottom end of the first piston rod 6 passes through the second fixed plate 4 and is fixedly connected with the top of the fixed block 7. The bottom is provided with a groove, and the bottom of the fixed block 7 is fixedly connected w...

Embodiment 2

[0045] A compaction vibration system for the foundation of a high-rise building, comprising a body 1, one side of the body 1 is fixedly connected with a first fixing plate 2, the inner bottom wall of the body 1 is provided with a through hole, and the middle part of one side of the first fixing plate 2 is fixed The push handle 3 is connected, the top of the other side of the body 1 is fixedly connected with the second fixed plate 4, the top of the second fixed plate 4 is fixedly connected with the first hydraulic cylinder 5, and the bottom end of the first hydraulic cylinder 5 is fixedly connected with the first hydraulic cylinder 5. Piston rod 6, the bottom end of first piston rod 6 is fixedly connected with fixed block 7, and the bottom end of first piston rod 6 runs through second fixed plate 4 and is fixedly connected with the top of fixed block 7, and the bottom of fixed block 7 is provided with Groove, the bottom of fixed block 7 is fixedly connected with vibrating motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com