Horizontal production-injection well completion structure possessing flow control function

A technology for injection-production wells and well structures, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve the problems of preventing axial channeling of water or gas, inability to apply annular packers, well Wall deformation and other problems, to achieve the effect of low cost, compact filling, and strong anti-channeling ability in the axial direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

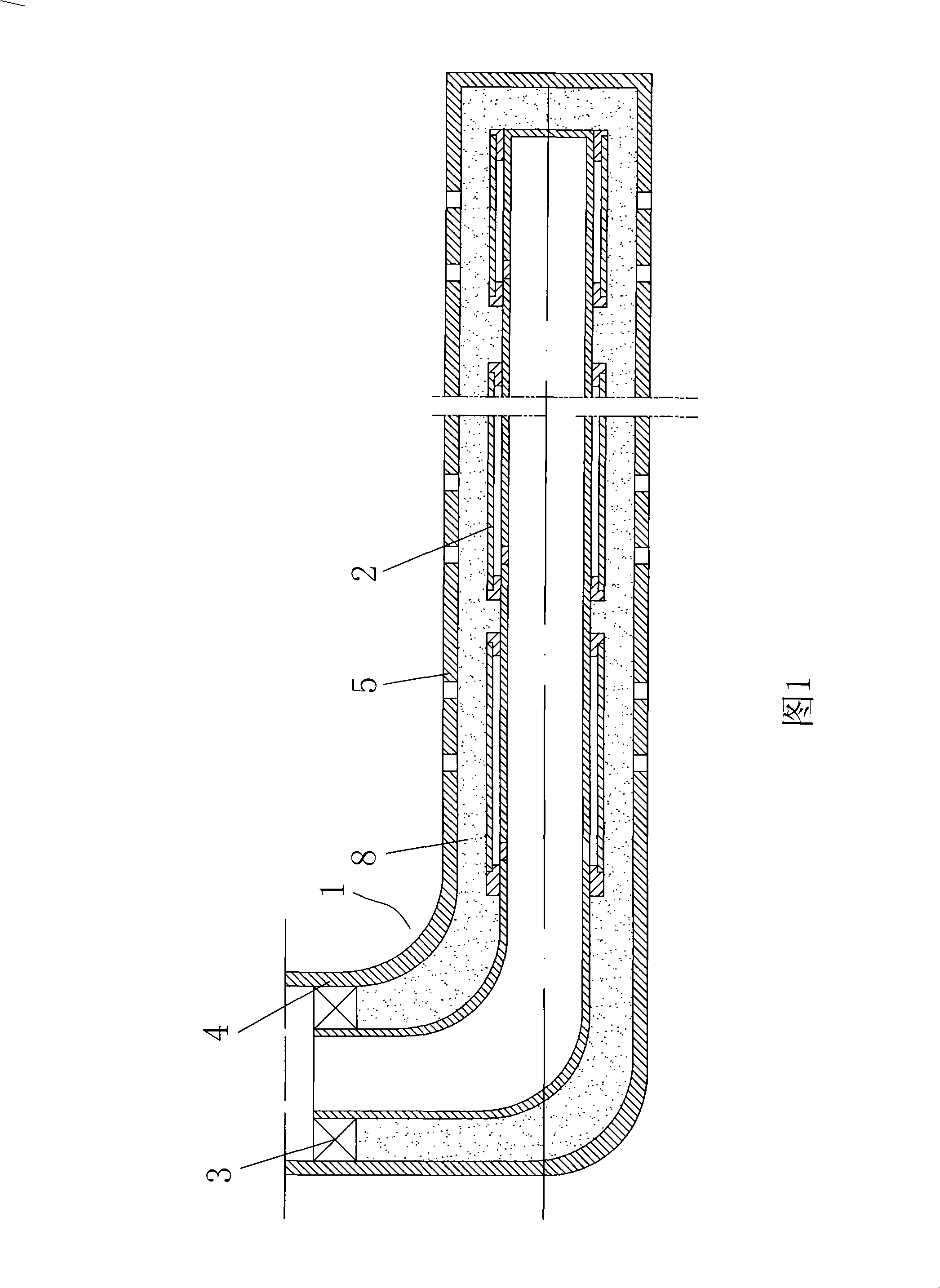

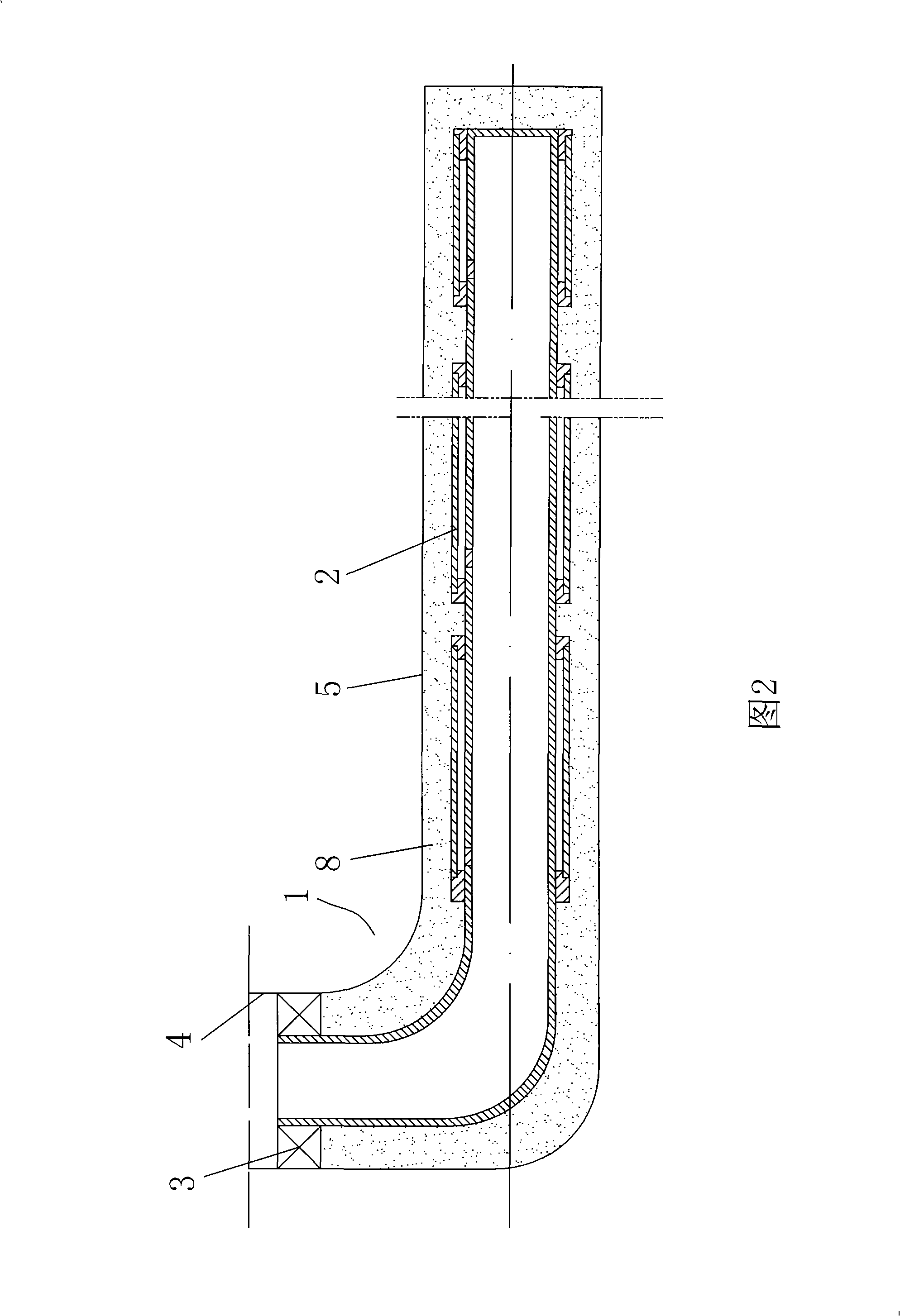

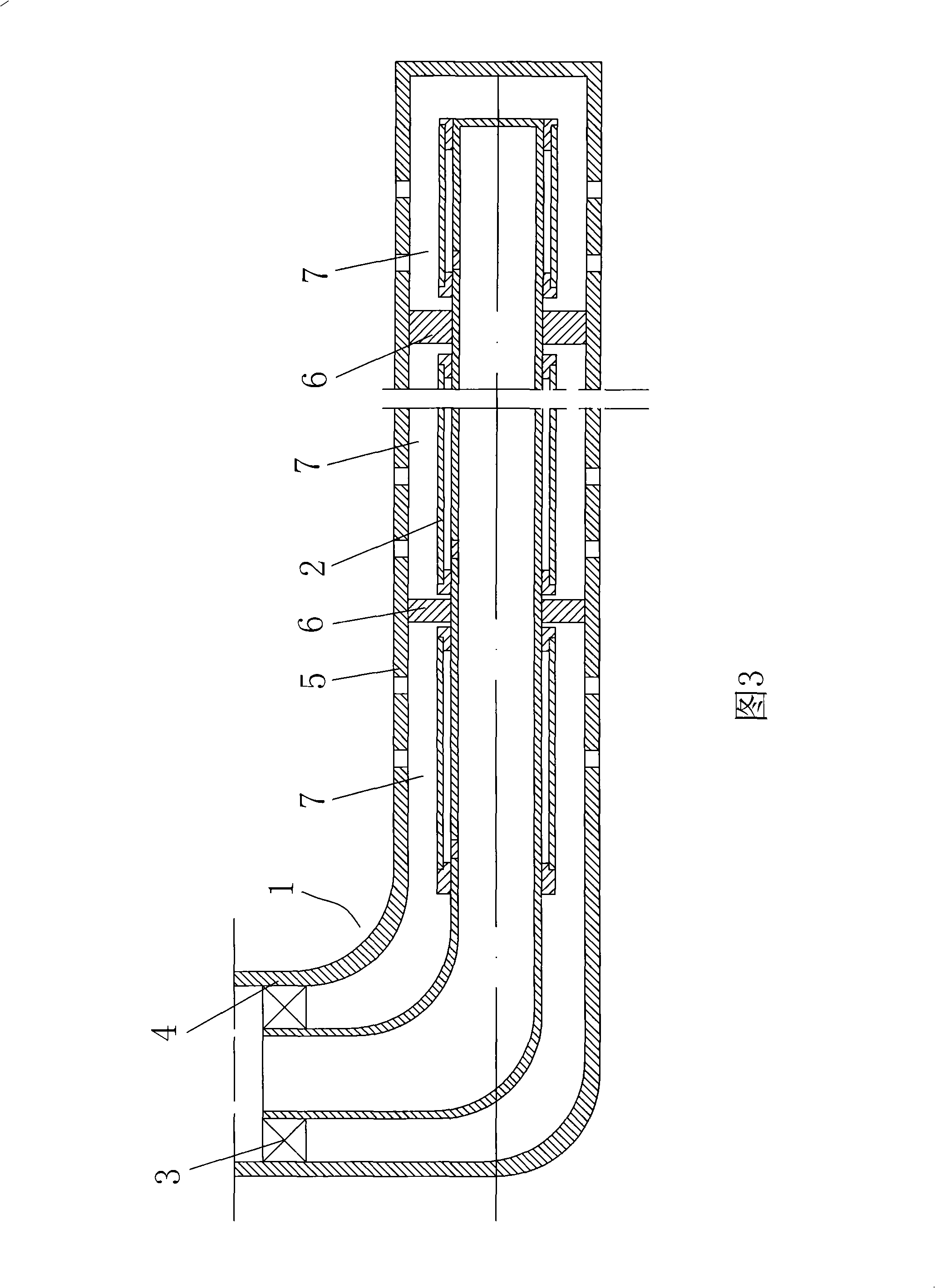

[0033] A kind of horizontal injection-production well completion structure with flow control function of the present invention (as shown in Fig. 1, Fig. 2, wherein Fig. 1 represents the horizontal injection-production well completion structure that the well wall of the horizontal section is casing, and Fig. 2 represents the horizontal The section well wall is the horizontal injection-production well completion structure of the open hole wall formed by drilling), including: the well wall 1 and the flow control filter 2, the well wall 1 is composed of the ascending section 4 and the horizontal section 5, and the horizontal section of the well wall The angle between 5 and the horizontal plane is 0 degrees, 10 degrees or 20 degrees, and the front end of the horizontal section 5 of the well wall can be inclined upwards or downwards, and the flow control filter 2 is located on the well wall The horizontal section 5 of the horizontal section 5 is fixedly connected with the well wall 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com