A liquid slag flow control device with quick replacement and accident handling functions

A flow control device and a technology for liquid slag, applied in the field of blast furnace slag waste heat recovery, can solve problems such as high temperature corrosion, and achieve the effects of deteriorating the operating environment, preventing splashing, and preventing cooling and condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

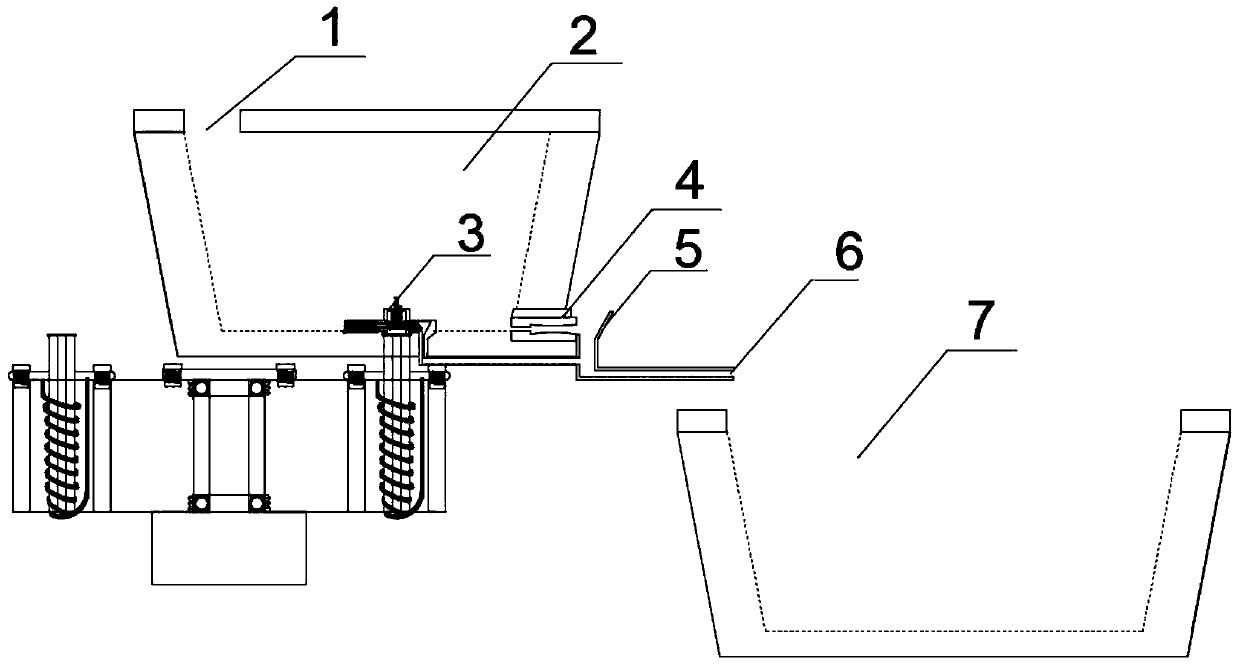

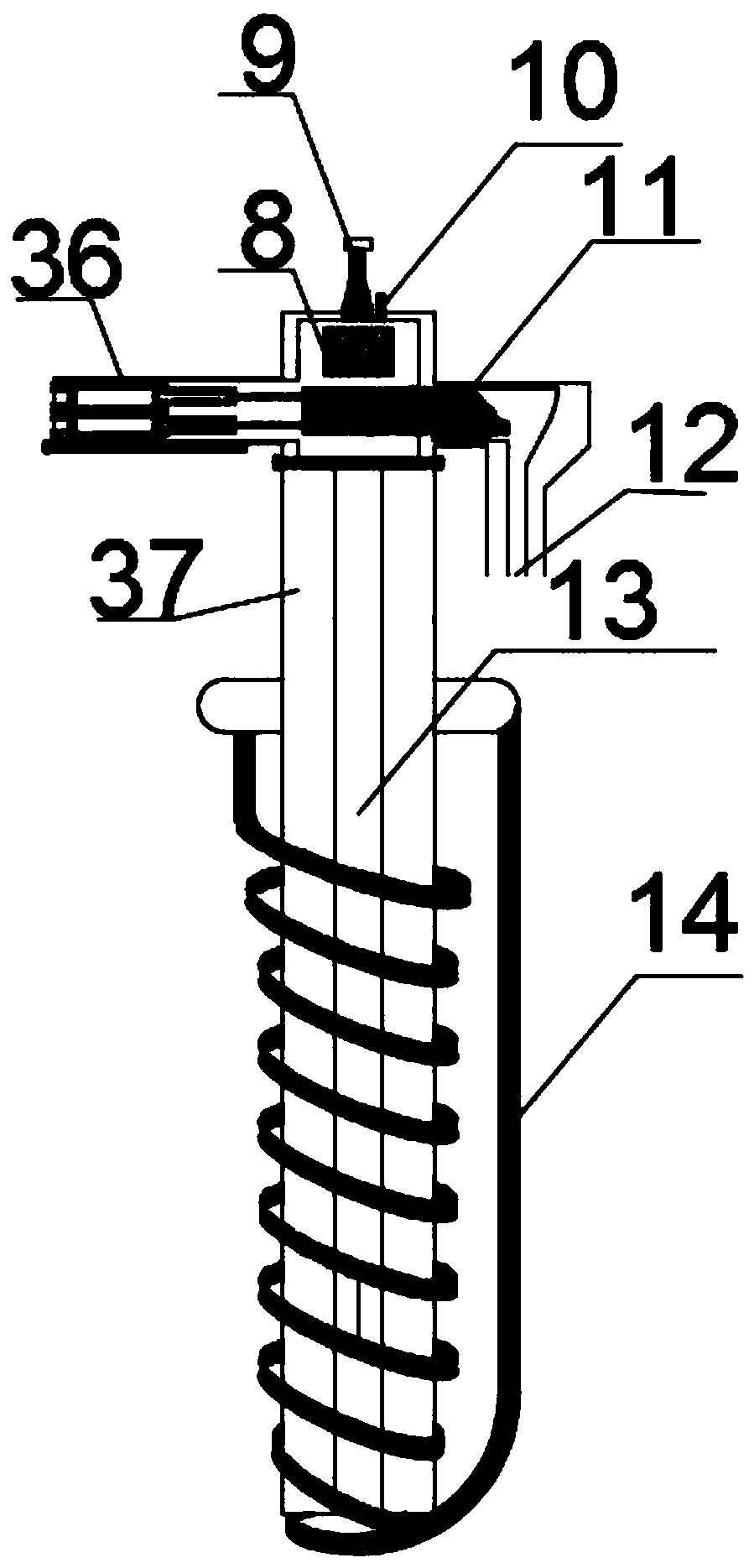

[0032] see Figure 1 to Figure 7 As shown, the present invention has a liquid slag flow control device with quick replacement and accident handling functions, including a slag bag; a slag bag inner chamber 2 is arranged in the slag bag; Slag inlet 1; a slag dropping device 3 with a turntable is installed at the bottom of the slag ladle, and liquid slag can flow out through the slag dropping device 3 with a turntable and enter the subsequent processing unit. At the same time, the bottom side wall of the slag bag is provided with a slag bag accident slag discharge sizing nozzle 4 and a normal working sizing nozzle 19; The bottom of the slag discharge baffle 5 is provided with an accident slag collection outlet 6, and the liquid slag can enter the accident slag pit 7 at the bottom by the accident slag collection outlet 6, and is used to discharge the slag in the slag bag during an accident.

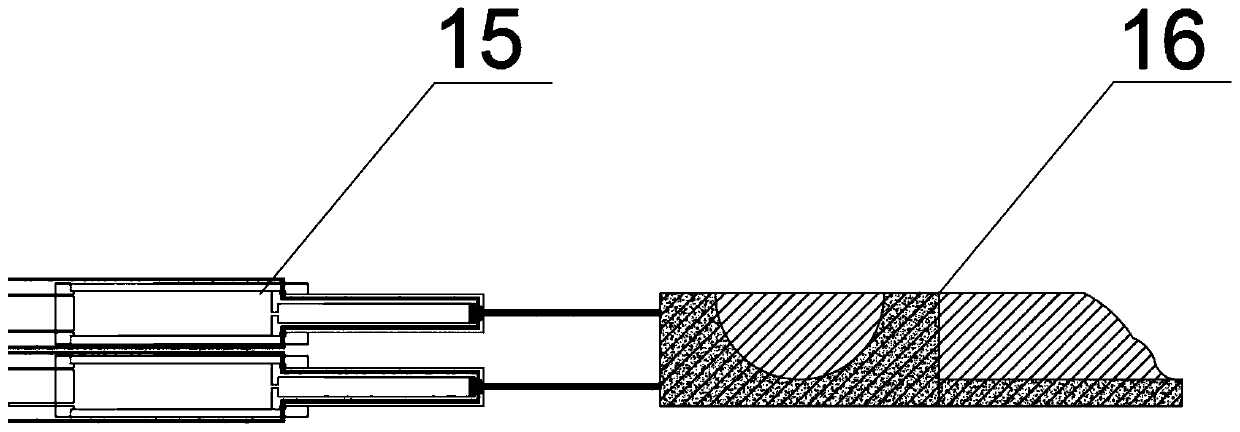

[0033] The outside of the sizing nozzle 19 in normal operation is covered with a sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com