Short wheelchair frame extrusion casting system

A squeeze casting and frame technology, which is applied in the squeeze casting system field of short wheelchair frames, can solve the problems of increasing the difficulty of casting machining, large surface deformation of castings, and large porosity of castings, achieving small porosity, The effect of short filling time and fewer shrinkage defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

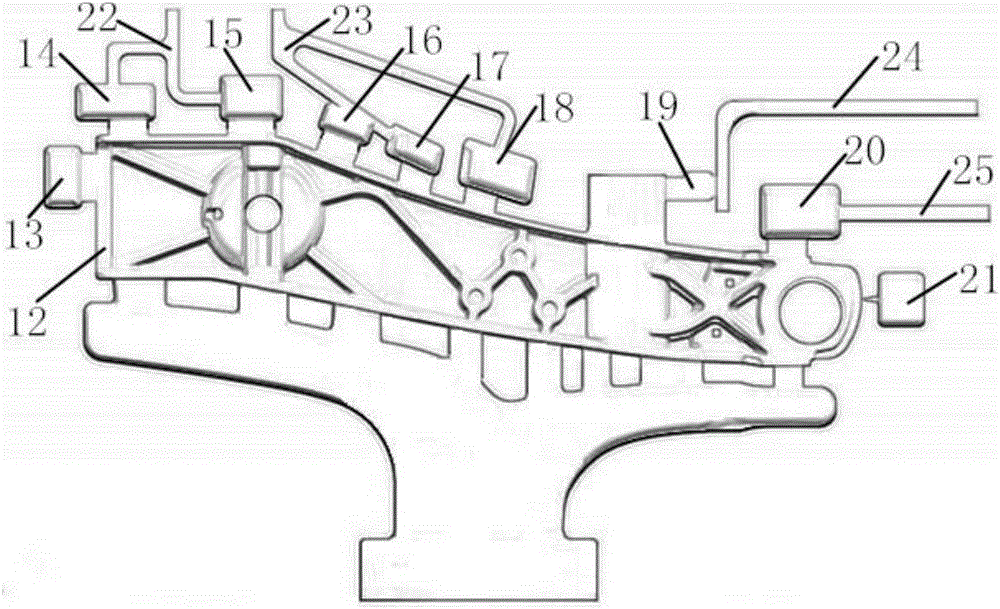

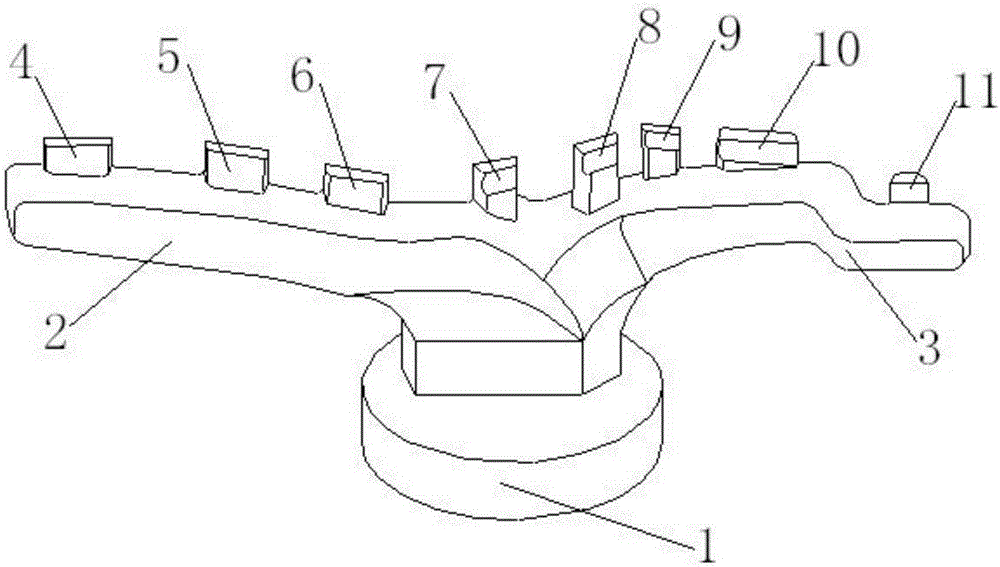

[0012] The invention provides a squeeze casting system for a wheelchair short frame, such as figure 1 and figure 2 Shown are the structural schematic diagram of the system and the structural schematic diagram of the runner respectively.

[0013] The system includes a material handle 1, a long main runner 2, a short main runner 3, a runner, a casting cavity 12, a slag bag and an exhaust block. The material handle 1 extends a long main runner along the left and right sides respectively. 2 and a short sprue 3, the long sprue 2 and the short sprue 3 form a semi-enclosed structure surrounding one side of the casting cavity 12, the long sprue 2 and the short sprue 3 are in the same shape as the casting Eight runners are arranged on the side where the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com