Novel horizontal well sand preventing well completion structure

A technology for horizontal wells and well structures, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve problems such as the decline in oil or natural gas production, horizontal wells that cannot work normally, and the quality of well completion is not guaranteed. Achieve the effects of low filling process cost, low cost, and guaranteed filling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

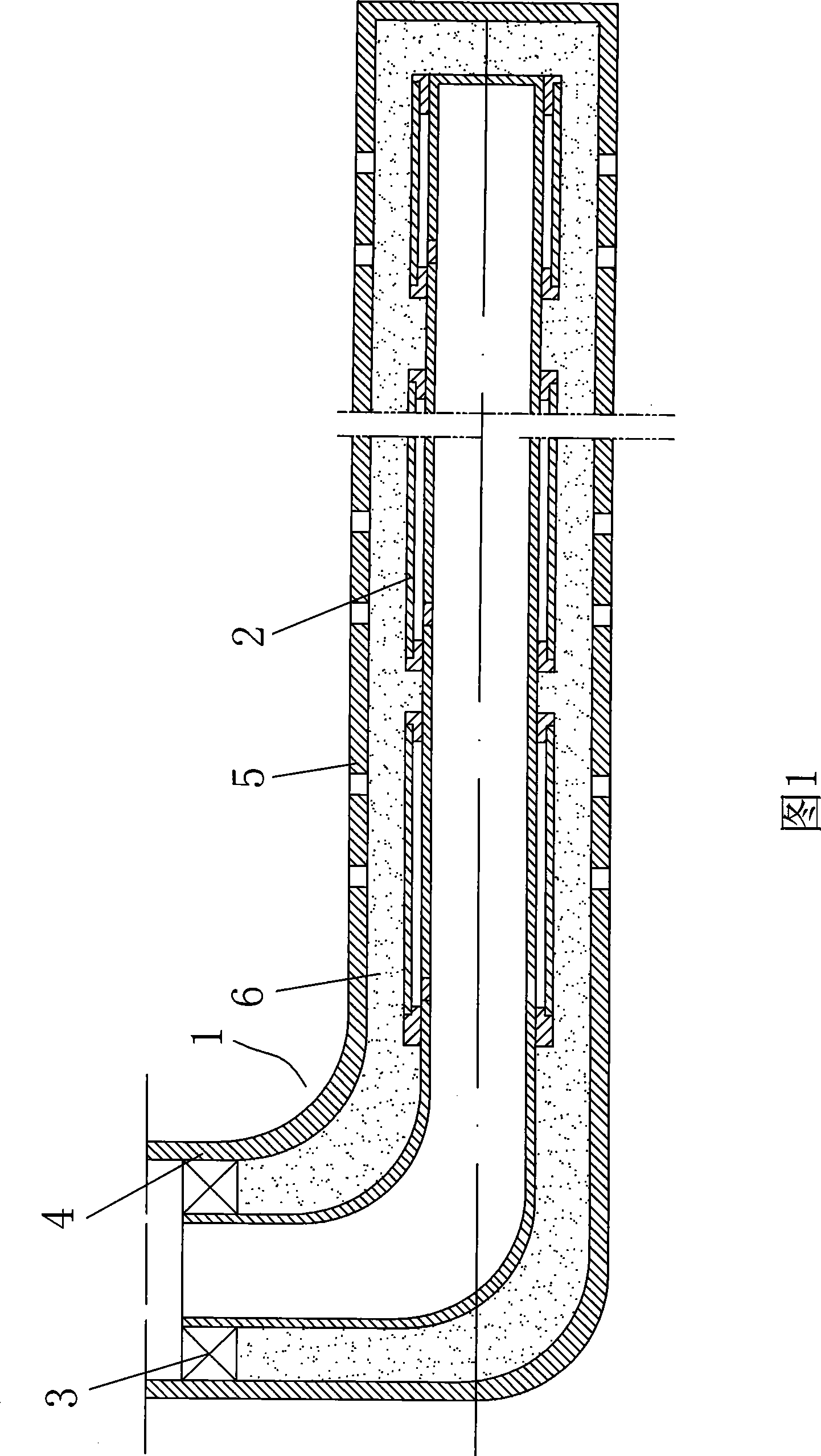

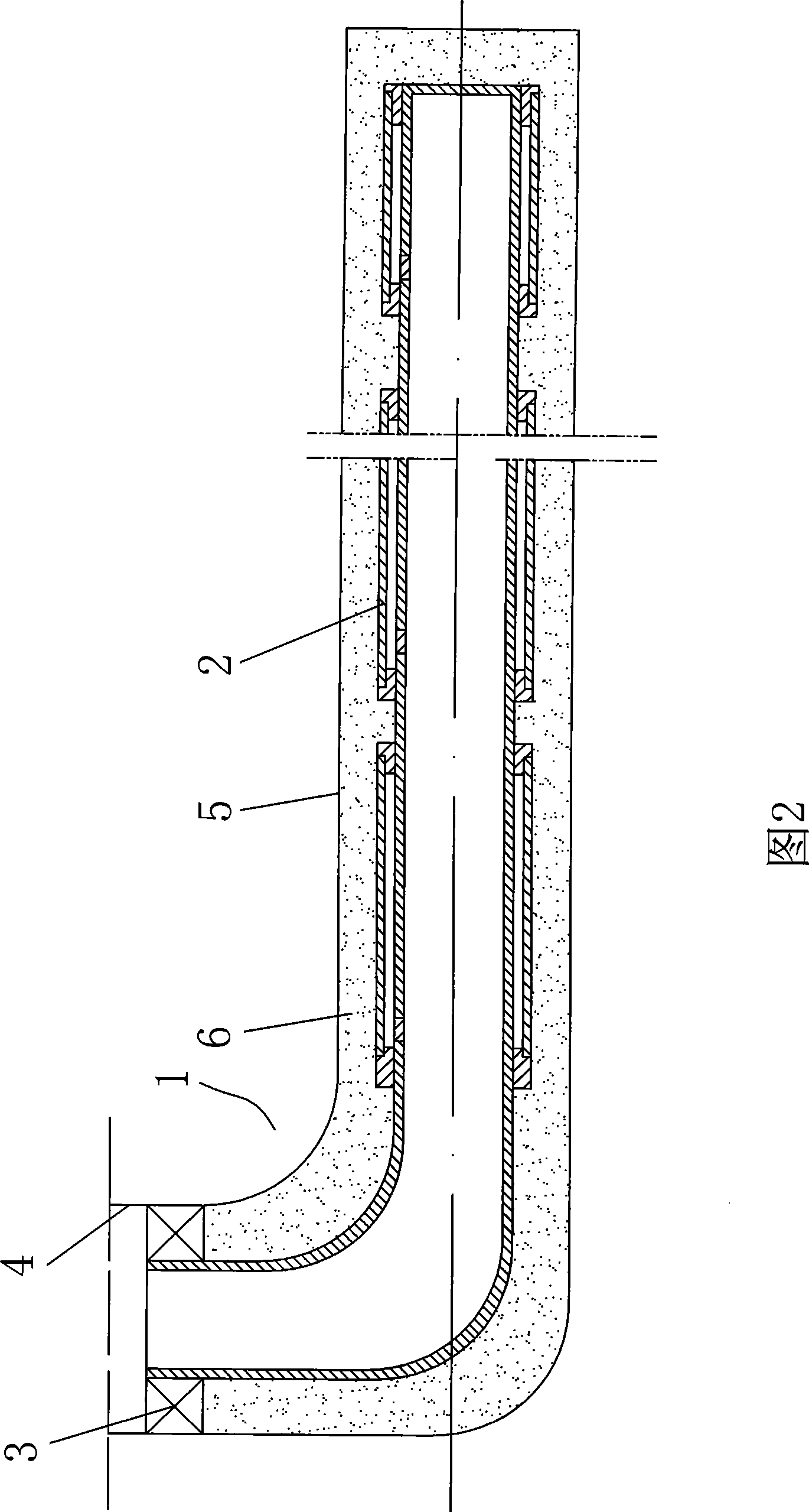

[0023] As shown in Figures 1 and 2, a new sand control completion structure for horizontal wells includes: a borehole wall 1 and a sand control pipe 2, the borehole wall 1 is composed of an ascending section 4 and a horizontal section 5, and the ascending section 4 of the borehole wall With casing, the end of the horizontal section 5 close to the ascending section 4 is the root end, and the end away from the ascending section 4 is the finger end. The angle between the horizontal section 5 of the well wall 1 and the horizontal plane is 0 degrees, 10 degrees or 20 degrees. , the horizontal section 5 can be inclined upwards or downwards, and the sand control pipe 2 is located in the horizontal section 5 of the well wall 1 and is fixedly connected with the well wall 1. It is characterized in that the sand control pipe 2 and the well wall The cavity between 1 is filled with glassy hollow particles 6 .

[0024] Glassy hollow particles 6 are hollow beads in fly ash formed after combu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com