Motor, stator core, stator segment, and machining method thereof

A processing method and stator core technology are applied in the manufacture of stator/rotor bodies, motor generators, prefabricated windings embedded in motors, etc., which can solve the problems of reduced processing efficiency, long duration of potting and curing processes, etc., and achieve improved Processing efficiency, filling time and curing time are shortened, and convenience is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] It can be seen from the background technology that the processing requirements for the potting model are relatively high, and the processing efficiency is low.

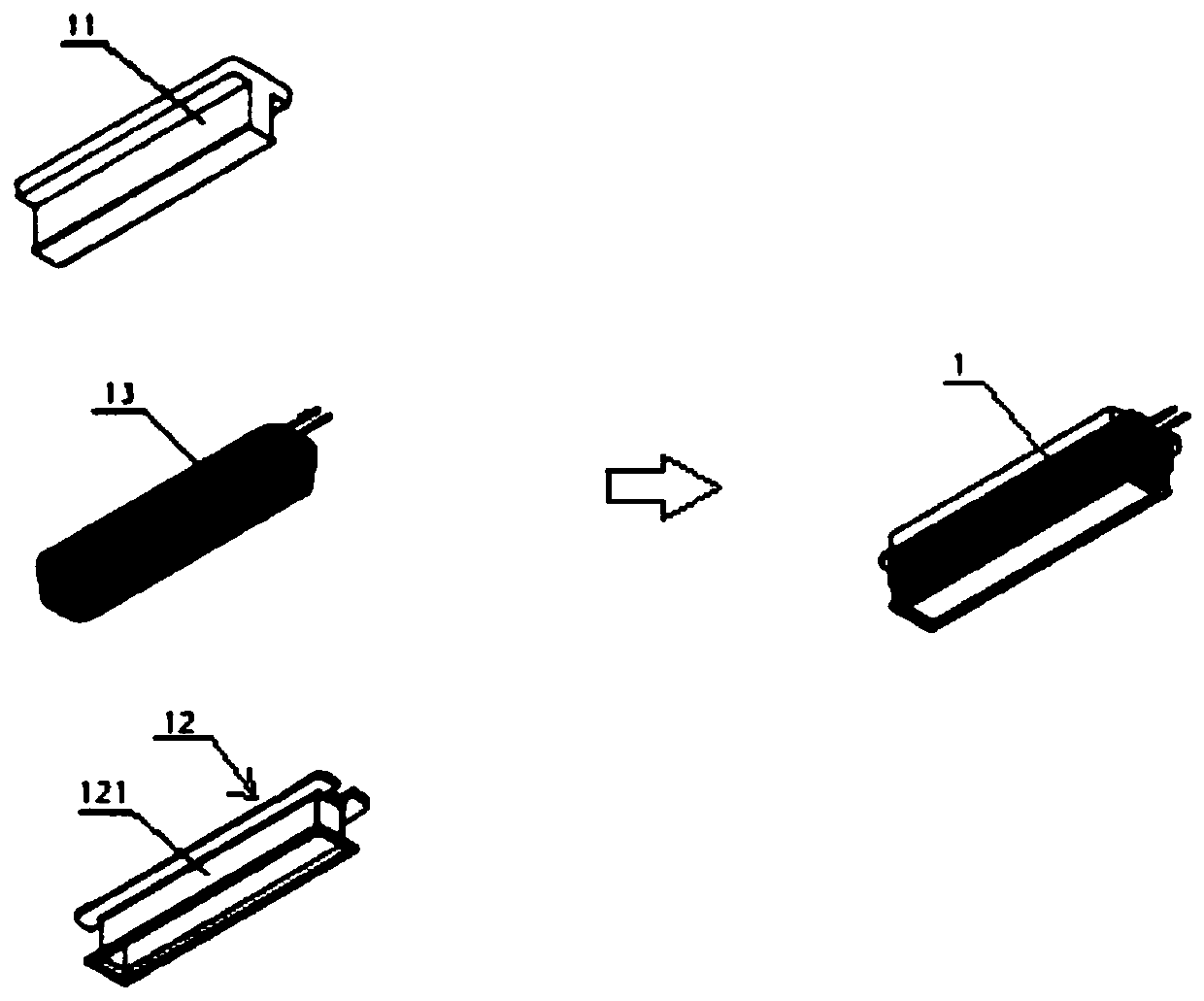

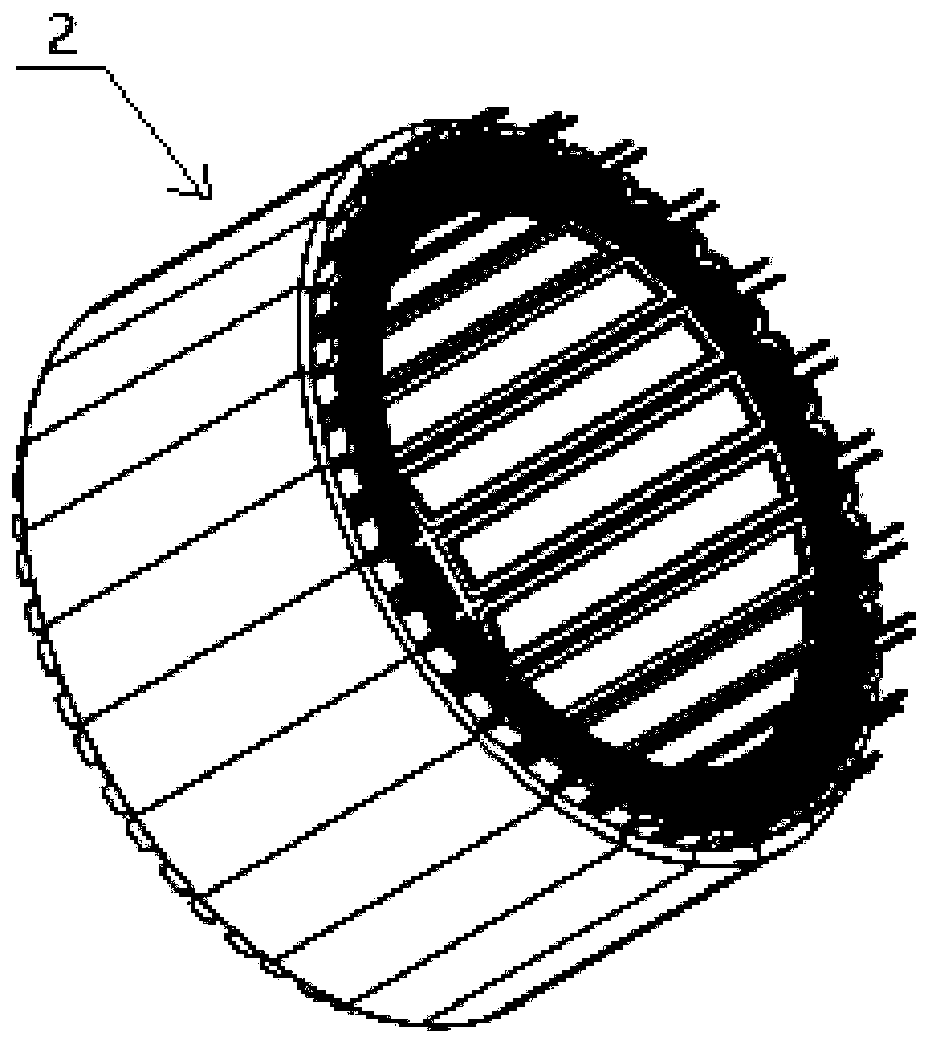

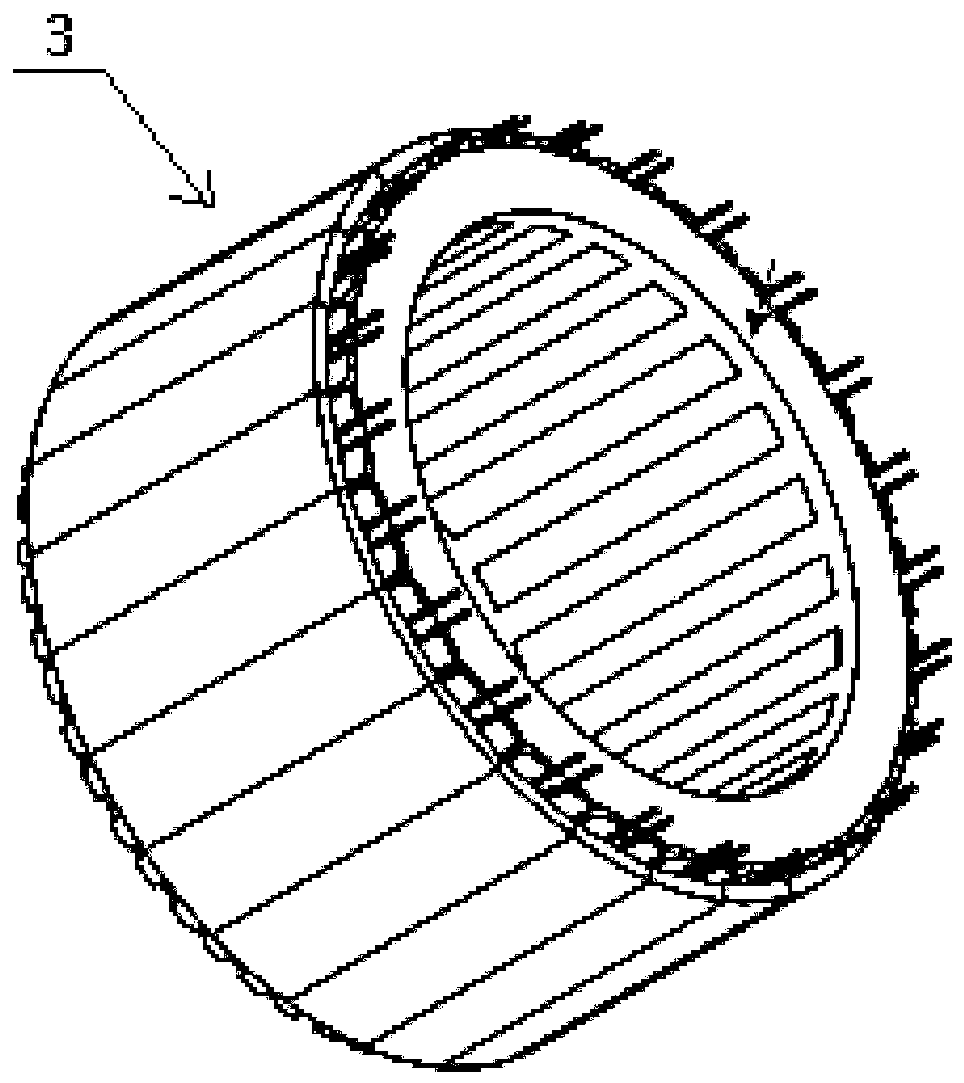

[0050] Please refer to Figure 1-Figure 3 , figure 1 is a structural schematic diagram of a winding stator segment, figure 2 It is a structural schematic diagram of arranging the winding stator segments in a circular ring, image 3 It is a structural schematic diagram of a stator core.

[0051] Such as Figure 1-Figure 3 As shown, in a stator core processing method, the iron core segment 11 is first inserted into the corresponding iron core segment insertion slot (not shown in the figure) of the iron core insulating sleeve 12, and then the winding 13 is The concentrated winding is wound on the winding winding groove 121 of the core insulating sleeve 12 to obtain the winding stator segment 1, and a plurality of winding stator segments 1 wound with the concentrated winding are arranged into a ring in a side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com