Transferring method of powder toner for electrophotograph and transferring apparatus thereof, and filling method of powder toner and the filling apparatus thereof

A transmission method and a technology of a filling device, which are applied to the equipment of the electric recording process using the charge pattern, the electric recording process using the charge pattern, transportation and packaging, etc., and can solve the problems of becoming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

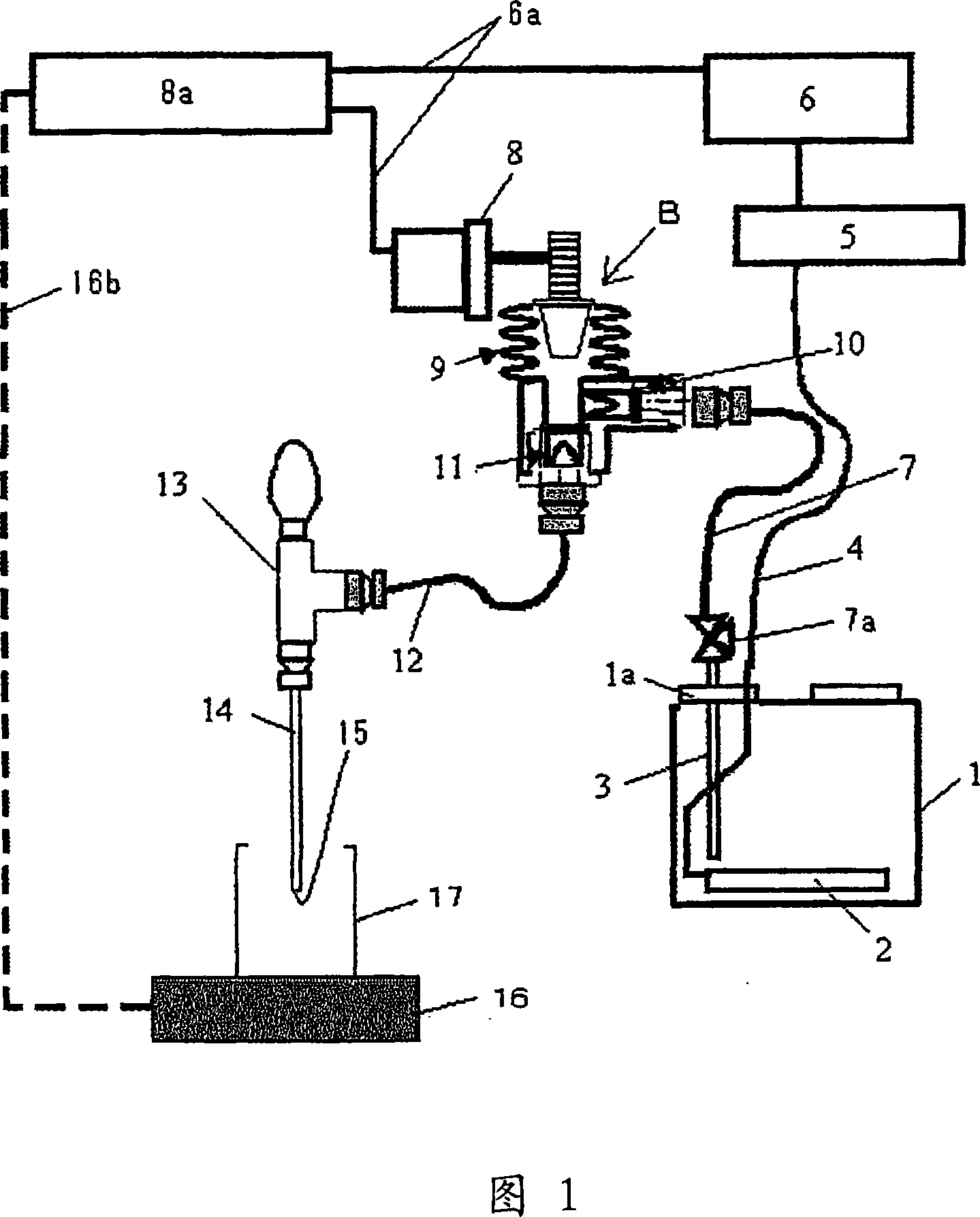

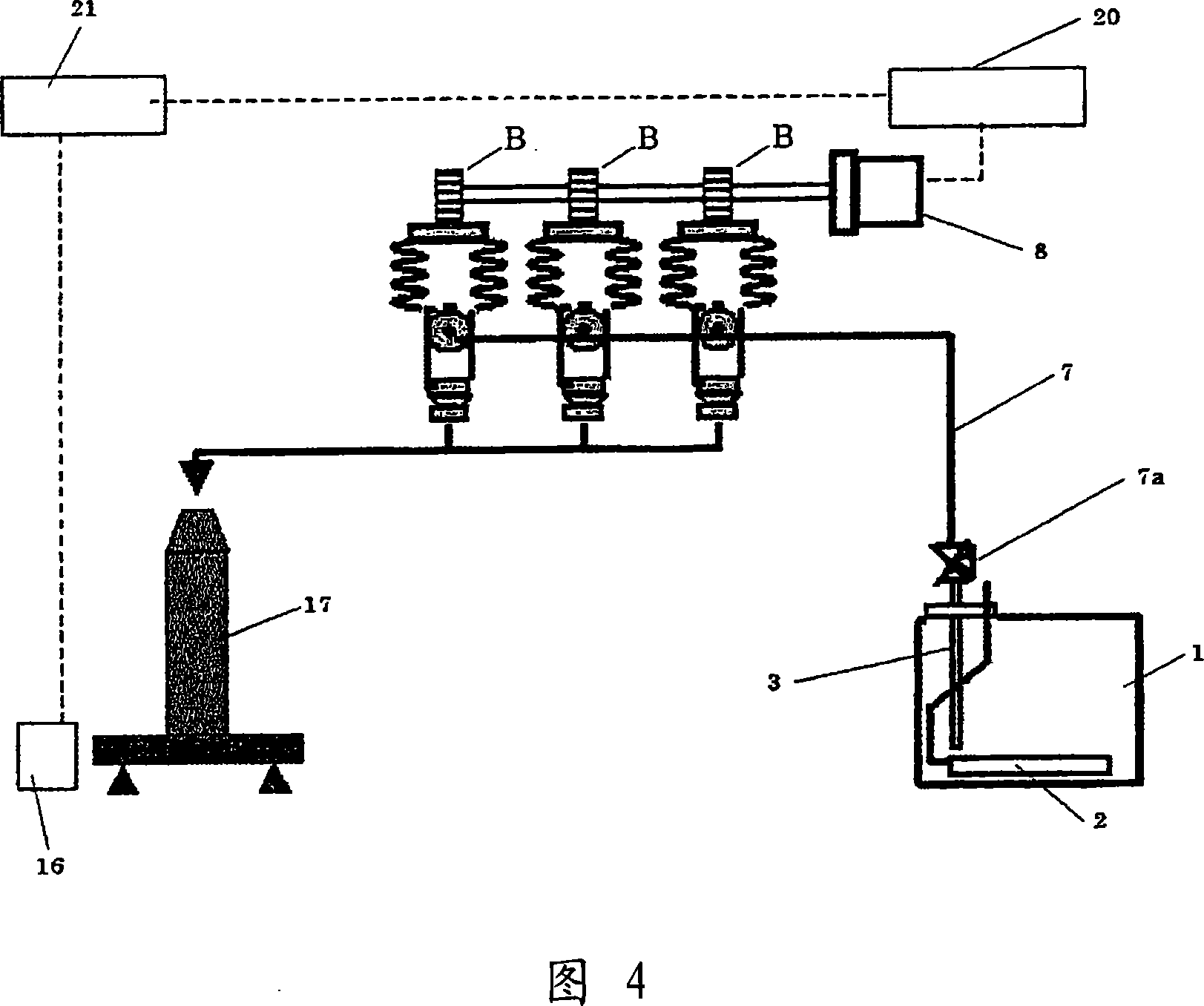

[0080] (Powder Toner Conveying Method and Powder Toner Conveying Device)

[0081] The powder toner conveying method of the present invention fluidizes the powder toner by means of the gas supplied from the gas supply unit to the powder toner storage chamber, sucks the fluidized powder toner by means of the suction unit and Conveying powder toner by discharging the toner into a toner storage container,

[0082] Among them, a reciprocating pump is used to drive the suction unit to suck the powder toner.

[0083] A preferred aspect in this example is as follows: the gas supplied to the sealable, pressurized or non-pressurized powder toner storage chamber by the gas supply unit is regulated and introduced into the powder toner in the powder toner storage chamber a toner fluidizing unit, thereby fluidizing the powder toner in the powder toner storage chamber; suctioning the powder toner storage chamber through a suction inlet of the suction unit, thereby conveying the fluidized po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com