Composite pipe hydraulic expansion method, manufacturing device and obtained composite pipe

A composite pipe and hydraulic technology, applied in the field of composite pipes, can solve problems such as inconvenience in processing, and achieve the effects of short filling time, high efficiency, and preventing seal failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

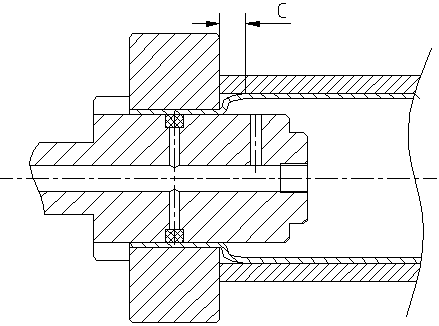

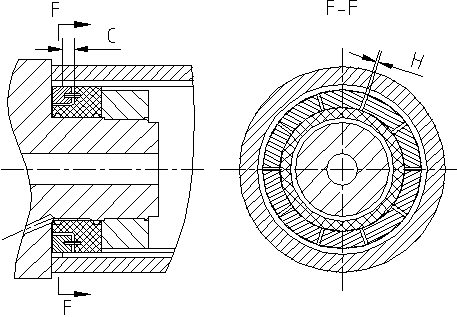

[0072] image 3 It is an embodiment of the present invention and is suitable for use when the compounded pipe is relatively short.

[0073] The plug 4 is an integral rod body, and sealing rings 5 are installed at both ends. The plug 4 is provided with passages communicating with the inner ring of the sealing ring 5 and the inner cavity of the inner pipe 2 respectively, and the passage connected with the inner ring of the sealing ring 5 passes through A The liquid is introduced through the mouth of the inner tube 3, and the channel connected with the inner cavity of the inner tube 3 is introduced into the liquid through the B port; the outer tube 2 and the inner tube 3 that need to be bulged are first set together; then the collar 1 is installed close to the two ends of the outer tube 2 and fixed, the inner diameter of the collar 1 is equal to the inner diameter of the outer tube 2; then the plug 4 with the sealing ring 5 installed is inserted into the inner hole of the inner...

Embodiment 2

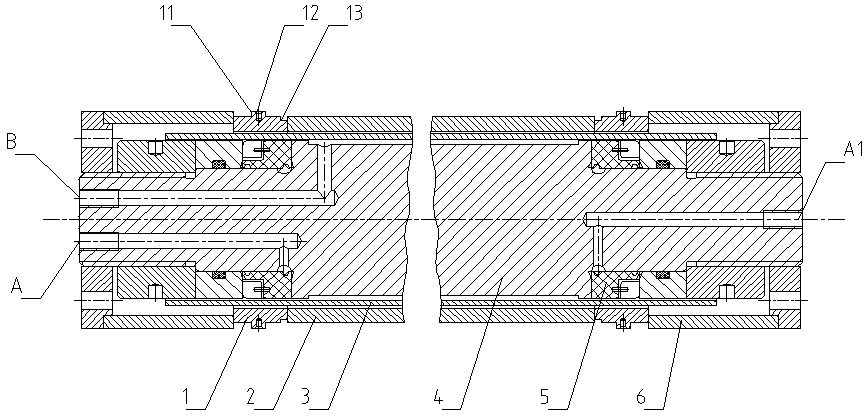

[0081] Figure 4 It is another embodiment of the present invention, and is suitable for use when the expanded tube is relatively long.

[0082] In this embodiment, the plug 4 is a split type, the left plug is fixed, and the right plug is movable, which are respectively installed on both sides of the equipment. For the convenience of comparison, the upper part is the initial state of swelling, and the lower part is Closed state.

[0083]During expansion, the left side plug 4 is fixed, the A port connected to the inner ring of the sealing ring is drawn out on the side, and the B port connected to the inner tube cavity is drawn out in the center; the right side plug is flexibly connected to the sealing seat 7, and connected to the inner The A1 port of the ring is drawn out on the side, and the B1 port connecting the inner tube cavity communicates with the cavity 71 on the sealing seat 7, and communicates with the outside world through the B2 port arranged on the sealing seat 7. ...

Embodiment 3

[0093] Figure 5 It is an embodiment when the plugs of the present invention are all flexibly connected. The plugs on both sides are movable, so the effect is more obvious. The upper part is the final state of bulging, and the lower part is the initial state of bulging.

[0094] This example is Figure 4 The improvement of the embodiment is different in that a positioning structure matching the outer pipe is provided on the plugs 4 on both sides.

[0095] The plug 4 is provided with a stepped boss 41 that matches the outer tube 2. The inner diameter of the stepped boss 41 is larger than the inner diameter of the inner tube 3 and smaller than the inner diameter of the outer tube 2. When expanding, the longer one end of the stepped boss is shortened. The end surface of the platform 41 first touches the end surface of the collar 1 to determine the position of the end of the inner tube 2, and the subsequent deformation of the inner tube 3 is based on this, finally making the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com