Method and filling system for filling bags

A technology of filling equipment and pockets, which is applied in the field of valve pockets, can solve problems such as increased operating costs, achieve the effects of optimizing output, avoiding material leakage, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

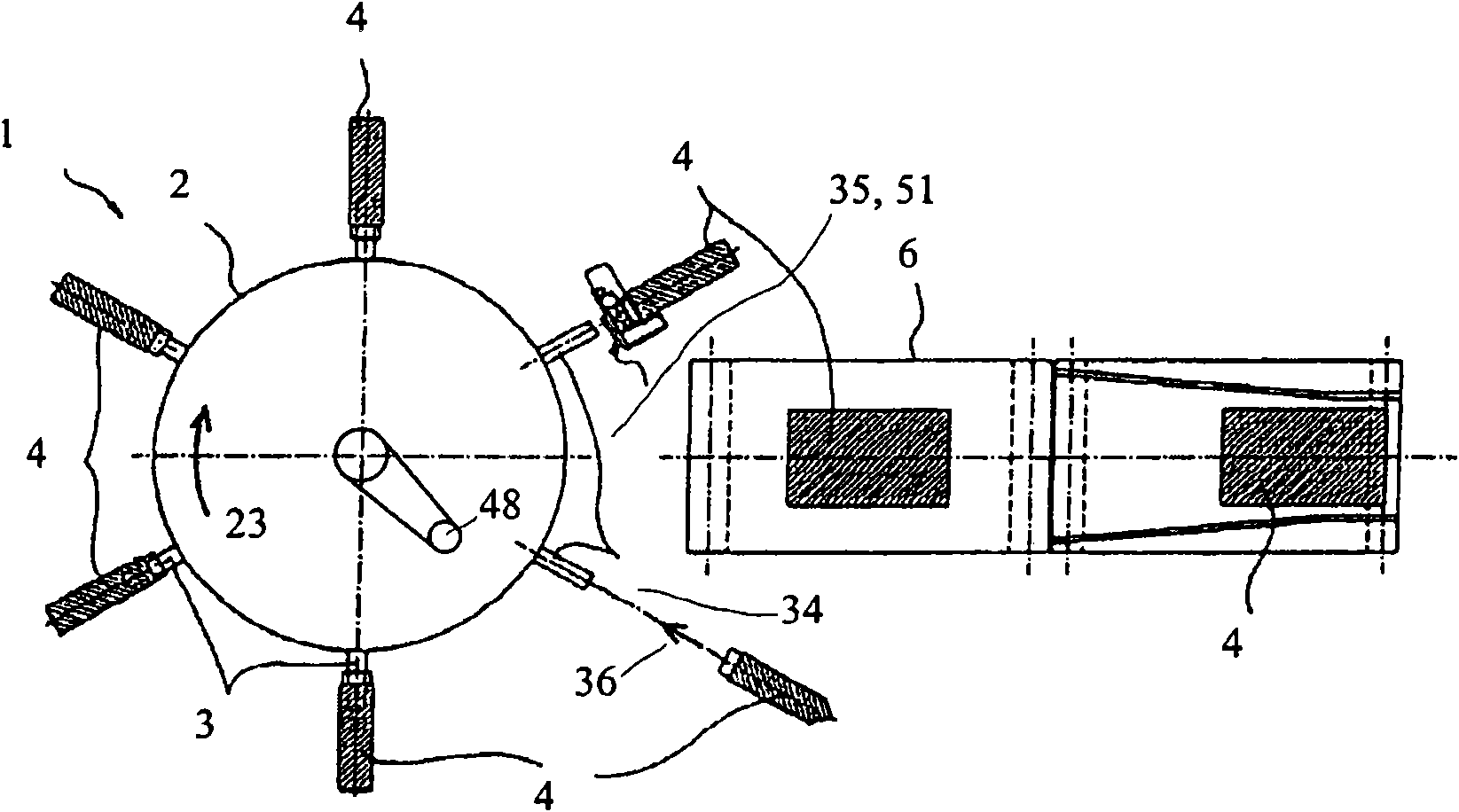

[0074] figure 1 The illustrated filling plant 1 according to the invention comprises a rotary packaging machine 2 which can be driven in the direction of the arrow 23 by means of a drive 48 . The speed of the drive 48 in the form of an electric motor is controlled accordingly in order to control or regulate the rotational speed of the packaging machine 2 .

[0075] The packaging machine 2 includes 6 filling mechanisms in the form of filling nozzles 3, such as Figure 4 In particular, a valve bag 4 with an opening 5 in the form of a valve port is pushed onto the filling spout 3 .

[0076] as in figure 1 According to the invention, the valve bag 4 comes from stock and is removed by means of a gripping mechanism not shown in the drawing and inserted and hung on the filling nozzle 3 by an automatic bag inserting machine, as indicated by arrow 36 in the figure.

[0077] The filling equipment 1 is equipped with a bag unloading conveyor belt 6 for sending away the filled and dumped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com