Metal mine transverse drift four-mining one-reserving retreat mining structure and method

A technology for piercing veins and mines, applied in surface mining, mining equipment, underground mining, etc., can solve problems such as loss of copper mines and no reports, and achieve the effects of improving safety, improving mining efficiency, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present application is not limited by the following examples, and specific implementation manners can be determined according to the technical solutions of the present application and actual conditions.

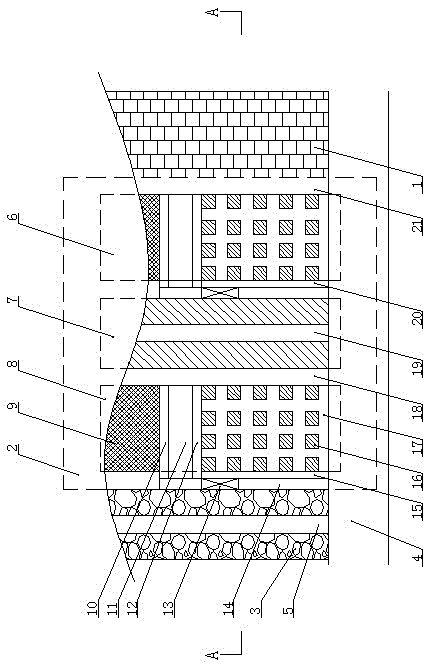

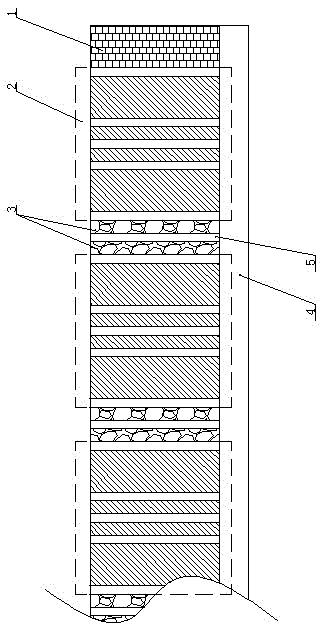

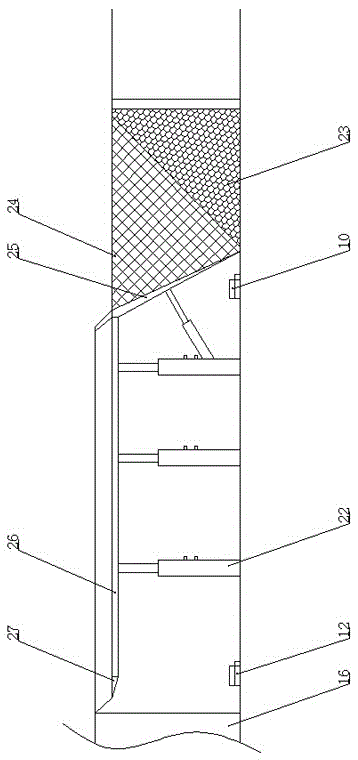

[0028] Example: such as figure 1 , 2 As shown, the metal mine cross-vein mining, four-stay-one-retreat mining structure includes a vein-along roadway 4 close to the vein along the extension direction of the vein 1, and mining areas 2 arranged at equidistant intervals on the vein, and between two mining areas 2 There is an interval reserve mining area 3, and the primary mining area 8 and the reserve mining area 6 located on both sides are arranged in the described mining area 2, and the reserve mining area 7 between the primary mining area 8 and the reserve mining area 6 is arranged. Both sides of mining area 8, both sides of reserve mining area 6, and the central part of reserve mining area 7 are all provided with piercing vein roadway, and in primary mining area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com