Integrated electrode for lithium sulphur battery and preparation method of integrated electrode

A lithium-sulfur battery and electrode technology, used in battery electrodes, non-aqueous electrolyte battery electrodes, lithium batteries, etc., can solve problems such as affecting battery cycle stability, easily decomposing or dissolving, reducing battery energy density, etc., to achieve a good cycle. Effects of stability, mass reduction, and energy density improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 5g of sucrose, dissolve it in deionized water, add 0.5g of 98% sulfuric acid to form slurry A, the concentration of slurry A is 90%, and the area is 6.25cm 2 The carbon paper (thickness is 90μm), impregnate it into slurry A, take it out after completely infiltrating, dry at 80°C for 12 hours, and dry at 160°C for 6 hours. ; Then the impregnated carbon paper was transferred to a tube furnace protected by argon, and fired at 900°C for 5h, and then lowered to room temperature. Transfer the calcined carbon paper to the gas-phase sulfur filling device (the gas-phase sulfur filling device is a closed container, and the container is filled with sulfur vapor during the sulfur filling process), and after filling sulfur at 300°C for 2 hours, the integrated product prepared by the present invention can be obtained. Electrode, wherein the sulfur content is 95%. The electrochemical performance was tested by assembling a button cell in an argon-filled glove box.

[0035] Depe...

Embodiment 2

[0038] Weigh 5g of phenolic resin (concentration is 60%), dilute it in ethanol to form slurry A, the concentration of slurry A is 5%, and the area is 6.25cm 2 Immerse the nickel foam into the slurry A, take it out after it is completely soaked, and dry it at 80°C for 12 hours. After multiple immersions, keep the pore residual rate of the nickel foam itself at 95%; then transfer the impregnated nickel foam to Calcined at 800°C for 3h in a tube furnace protected by argon, then cooled to room temperature. The roasted nickel foam is transferred to a gas-phase sulfur charging device, and after sulfur charging at 300° C. for 2 hours, the integrated electrode prepared by the present invention is obtained, wherein the sulfur charging amount is 5%. The electrochemical performance was tested by assembling a button cell in an argon-filled glove box.

Embodiment 3

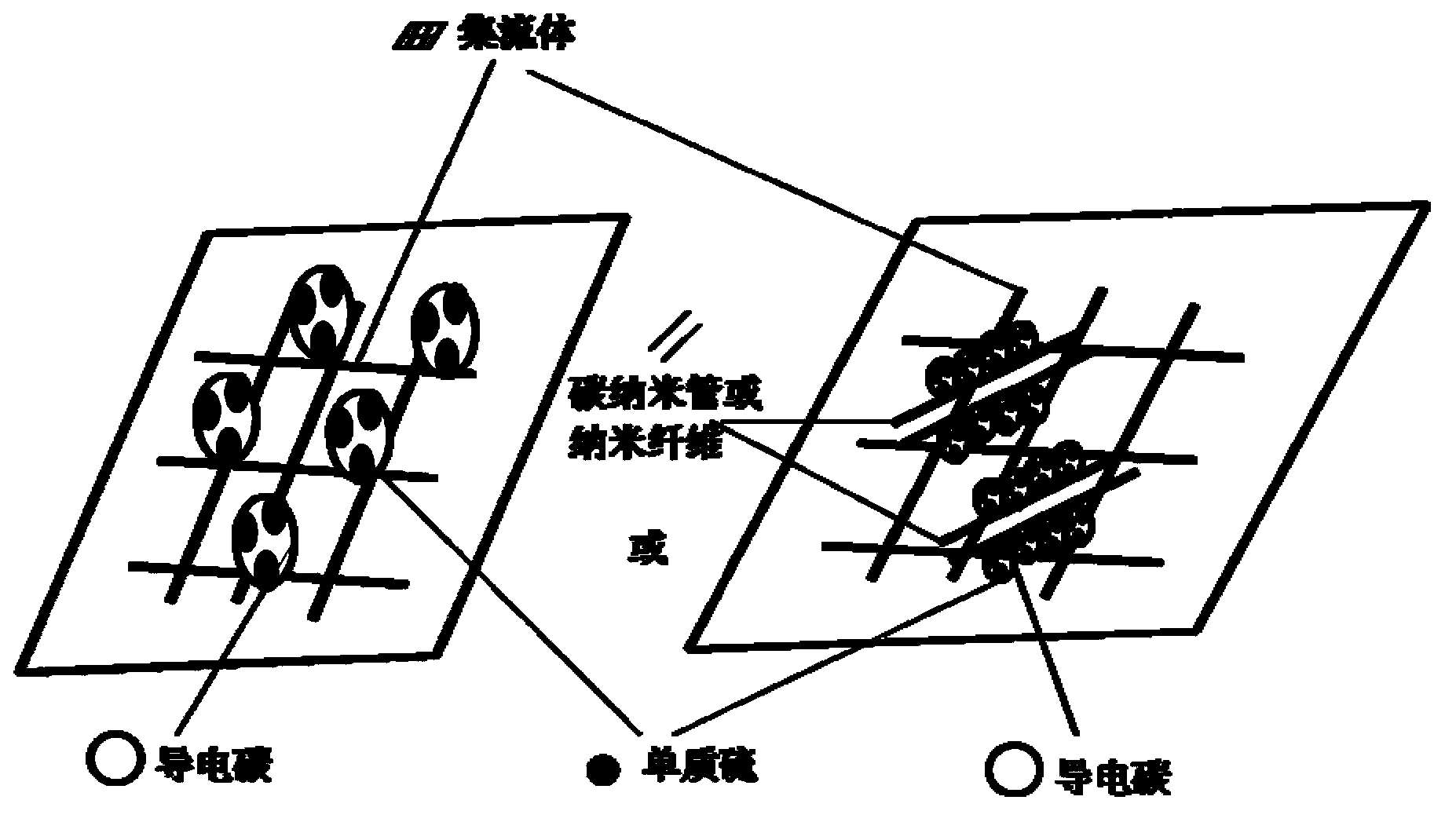

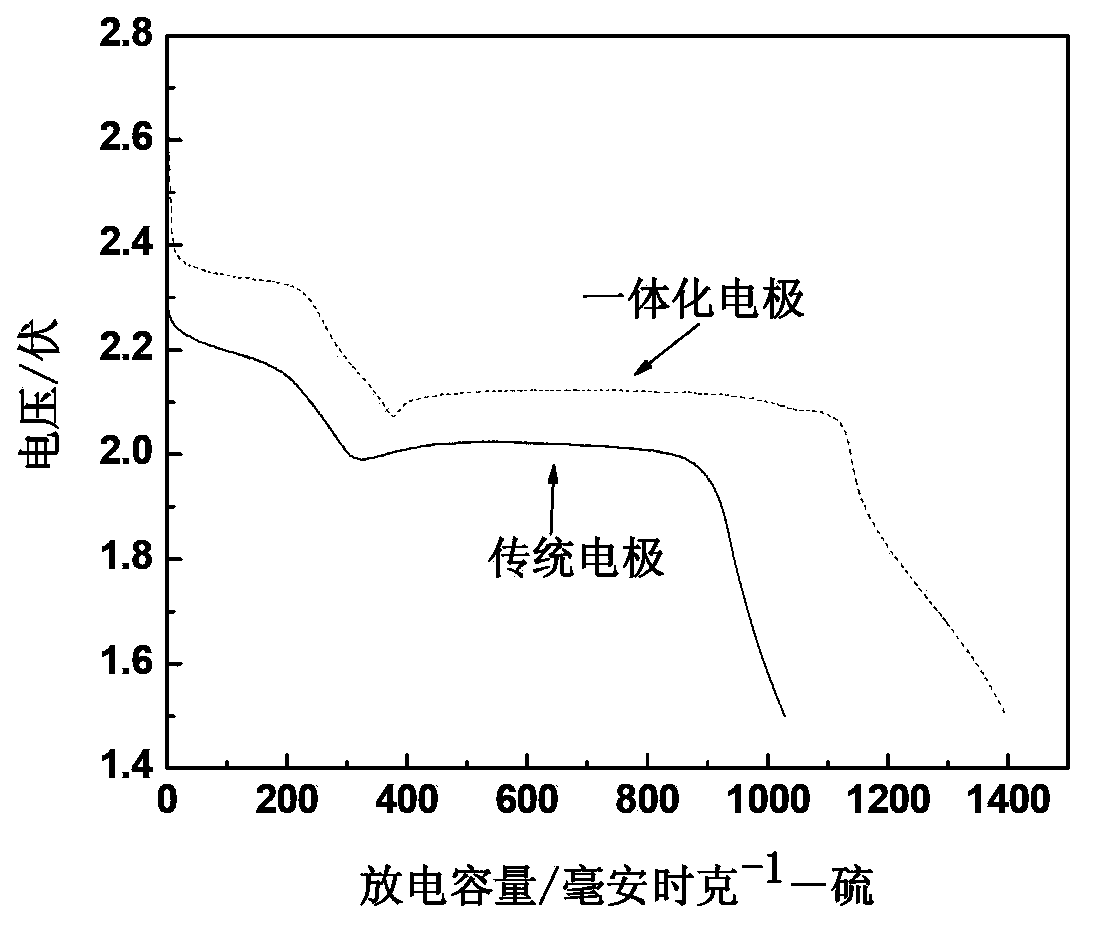

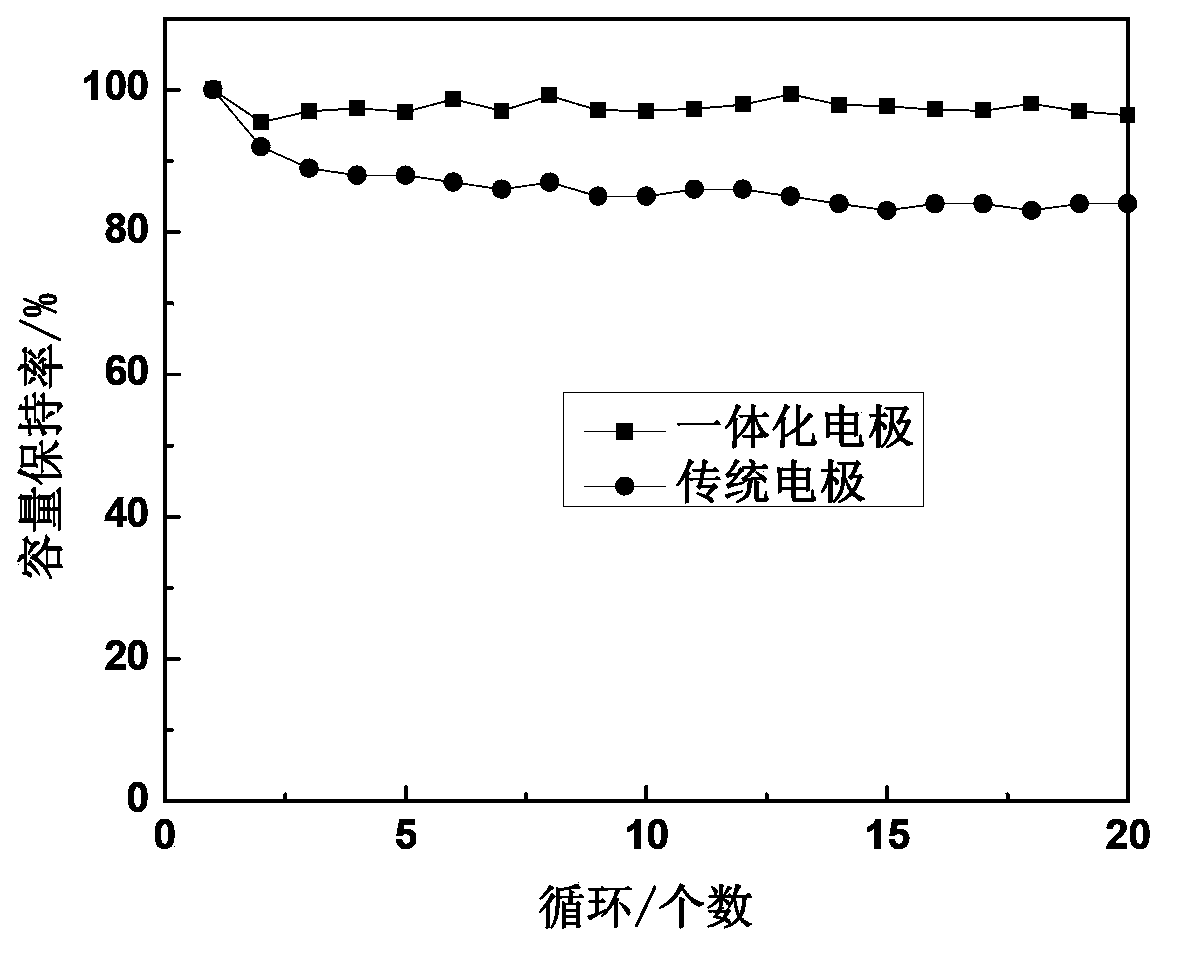

[0040] Weigh 5g of phenolic resin (concentration: 60%), dilute it in ethanol, add 0.6g of carbon nanotubes, stir well to form slurry A, the concentration of slurry A is 40%, and the area is 6.25cm 2 Scrape-coat the carbon paper from the slurry A on the carbon paper, dry at 80°C for 12 hours, and the residual porosity of the carbon paper itself is 50%; In the furnace, bake at 900°C for 3h, then drop to room temperature. The integrated electrode prepared by the present invention is obtained by filling the calcined carbon paper with sulfur by melting method, wherein the sulfur filling amount is 75%. The electrochemical performance was tested by assembling a button cell in an argon-filled glove box. See attached for specific data figure 2 , attached image 3 .

[0041] The comparative example is the discharge performance of a button battery assembled with a carbon-sulfur composite prepared by using phenolic resin as the carbon source (sulfur-filling content of 75%) and electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com