Vertical assembling tool for automobile engine ball head assembly

An automobile engine and ball joint assembly technology, applied in the field of auto parts, can solve the problems affecting the performance of the ball joint and the ball pin, affecting the performance of the ball joint and the ball pin, and the wear of the ball pin and the ball bowl.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

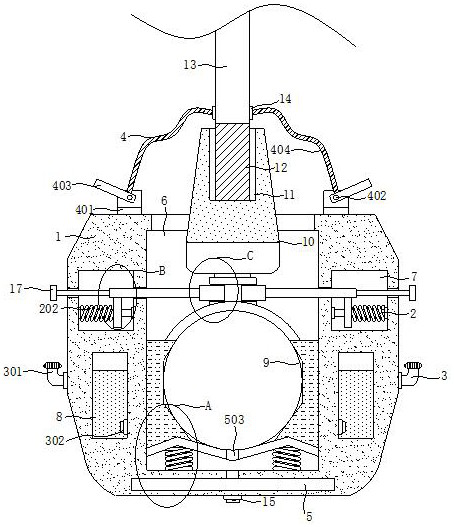

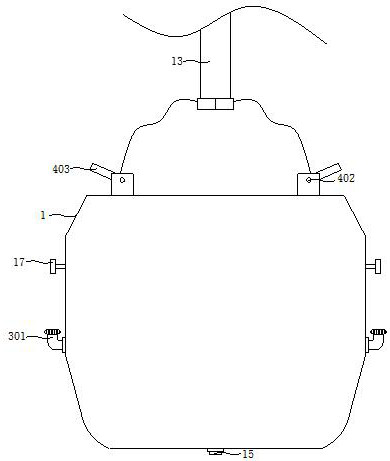

[0028] see Figure 1-7 , the present invention provides a technical solution: a vertical assembly tool for an automobile engine ball head assembly, including a ball seat 1, a limit mechanism 2, a lubricating mechanism 3 and a shock absorbing mechanism 5 are arranged inside the ball seat 1, and the ball seat 1 is provided with a dust-proof mechanism 4, and the inside of the ball seat 1 is provided with a first cavity 6, a second cavity 7, and a lubricating oil cavity 8, and the second cavity 7 and the lubricating oil cavity 8 are in two groups and are The center is symmetrical, the ball seat 1 is provided with a ball pin 9 inside, and the top of the ball pin 9 is provided with a connecting block 10 .

[0029] Further, an oil discharge pipe 15 is fixedly installed on the bottom of the ball seat 1, and one end of the oil discharge pipe 15 communicates with the inside of the oil storage chamber 504, and the other end of the oil discharge pipe 15 is threaded with a threaded cap, so...

Embodiment 2

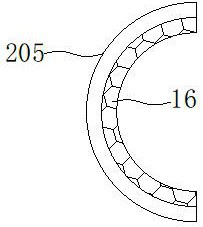

[0032] see Figure 1-7, on the basis of Embodiment 1, the limiting mechanism 2 includes a sliding rod 201, a return spring 202, a sliding plate 203, a sliding cross bar 204, a limiting frame 205 and a limiting plate 206, and the sliding rod 201 is fixedly installed in the second chamber Inside the body 7, the return spring 202 is sleeved on the outer wall of the slide bar 201, the slide plate 203 is slidably mounted on the outer wall of the slide bar 201, and one end of the return spring 202 is fixedly connected with the outer wall of one side of the slide plate 203, and the return spring 202 The other end of the ball seat 1 is fixedly connected, the sliding cross bar 204 is fixedly installed on the top of the sliding plate 203, the inside of the ball seat 1 is provided with an opening, and one end of the sliding cross bar 204 passes through the opening on the ball seat 1 and extends to the first The inside of the cavity 6 is fixedly installed with a limit frame 205, the limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com