Pretension and lay-off method and device of crane jib for ship

A technology of marine cranes and cranes, which is applied to the pre-tensioning of the booms of marine cranes, and in the field of marine cranes. It can solve the problems of large bending moment and deformation, reduce the bending moment and deformation of the boom, and achieve self-weight reduction. Bending moment peak value, effect of reducing span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

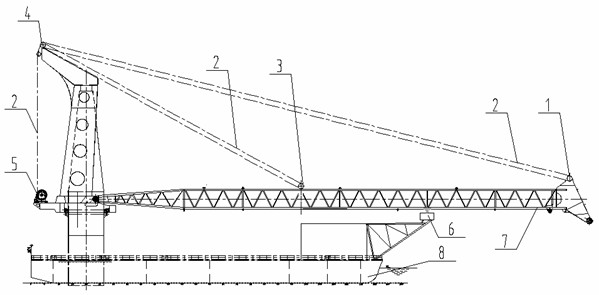

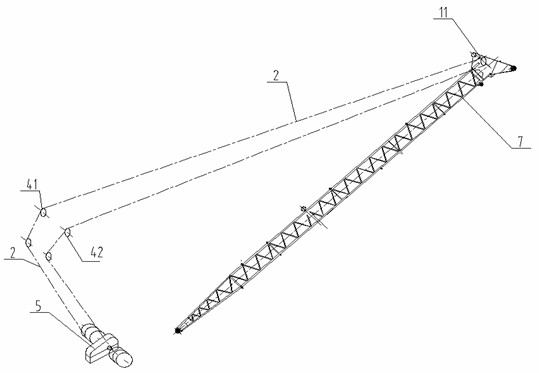

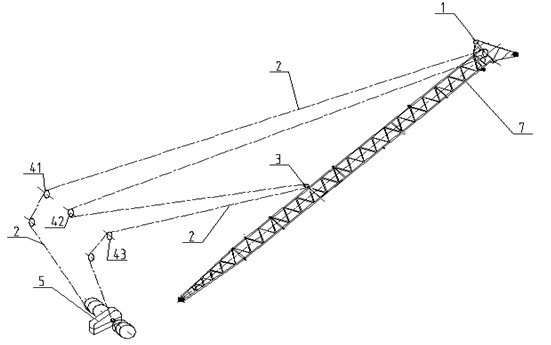

[0029] See figure 2 , The first structural diagram used in the method for preloading the boom of the marine crane of the present invention, the top of the marine crane is provided with a top pulley block 4, and the two sides of the marine crane are respectively provided with a winch 5 and a boom 7 with brakes, and the boom 7 A boom head pulley block 1 is provided at the end of the winch 5, and a luffing wire rope 2 is connected to the boom head pulley block 1 through the top pulley block 4 on the winch 5. The top pulley block 4 includes a first top pulley 41 and a second top pulley 42. The boom head pulley group 1 includes a first head pulley 11. One end of the luffing wire rope 2 is wound and fixed on the winch 5, and one end sequentially bypasses the first top pulley 41, the first head pulley 11, and the second top pulley 42 , And then wound on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com