Automatic deoiling device for bolt deoiling

A deoiling device and deoiling technology, applied to centrifuges and other directions, can solve the problems of time-consuming and laborious, difficult to remove bolts, and reduce the service life of deoiling components, so as to reduce noise and facilitate unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

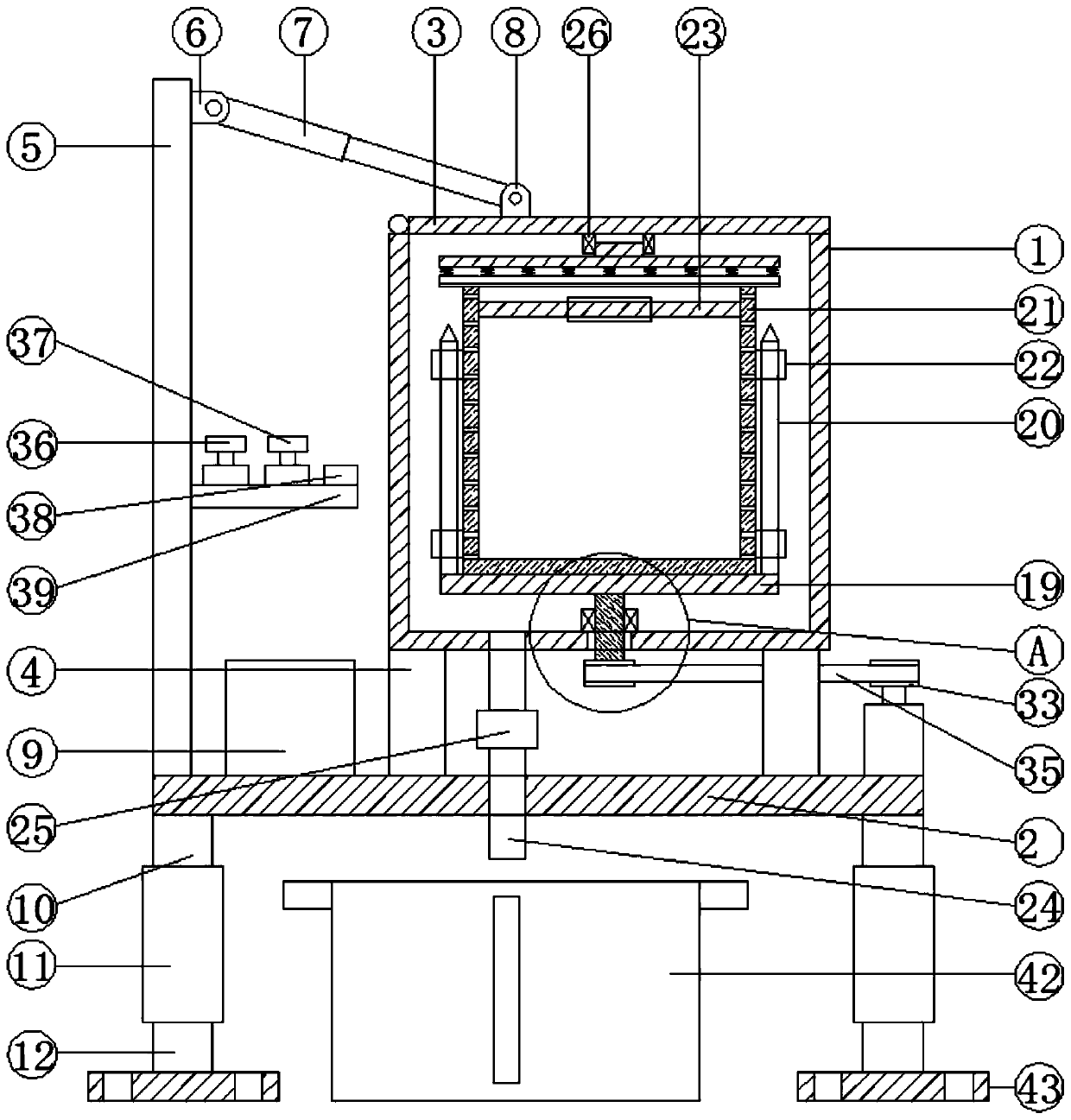

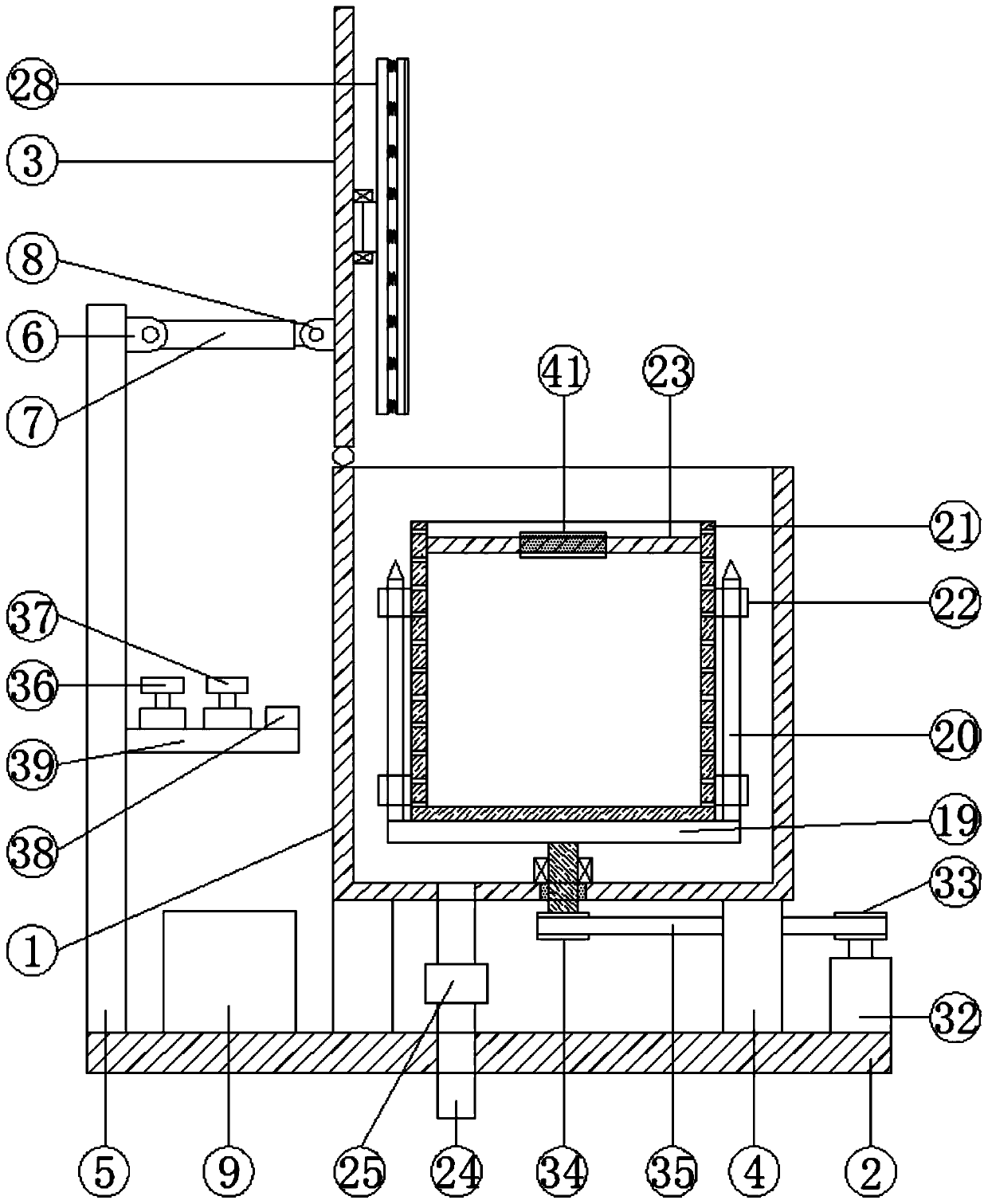

[0036] See Figure 1-6 , According to an embodiment of the present invention, an automatic de-oiling device for bolt de-oiling includes a housing 1 and a workbench 2. The housing 1 has a cylindrical structure, and the housing 1 is movably set on a rotating shaft. There is a cover plate 3, a number of four fixing posts 4 are fixed under the housing 1, and the fixing posts 4 are all fixed on the worktable 2, and one end of the worktable 2 is fixed with a side post 5, The upper end of the side column 5 is fixedly provided with a first hinge base 6, an electric telescopic rod 7 is hinged in the first hinge base 6, and a second hinge base 8 is fixed on the cover plate 3. The electric telescopic rod 7 One end far away from the first hinge base 6 is hinged with the second hinge base 8, the inner wall of the middle part of the side column 5 is provided with a control device, and a PLC controller 9 is fixed on the workbench 2, and the workbench A first sliding rod 10 is fixed under the...

Embodiment 2

[0039] See figure 1 , 5 And 6, for the energy absorbing material 16, the energy absorbing material 16 is ACF artificial cartilage foam; for the pressurizing device, the pressurizing device includes a second bearing 26, and the second bearing 26 is internally fixed There is a second transmission shaft 27, a first circular plate 28 is fixed under the second transmission shaft 27, and a second circular plate 30 is connected under the first circular plate 28 through a plurality of first springs 29. A rubber pad 31 is fixed under the circular plate 30; for the driving device, the driving device includes a motor 32, a first pulley 33, a second pulley 34, and a V-belt 35. The motor 32 is fixed on the workbench 2 Above, the outer wall of the rotating shaft of the motor 32 is fixedly sleeved with a first pulley 33, and the outer wall of the lower end of the first drive shaft 18 is fixedly sleeved with a second pulley 34, the first pulley 33 and the second pulley 34 It is driven by a V-b...

Embodiment 3

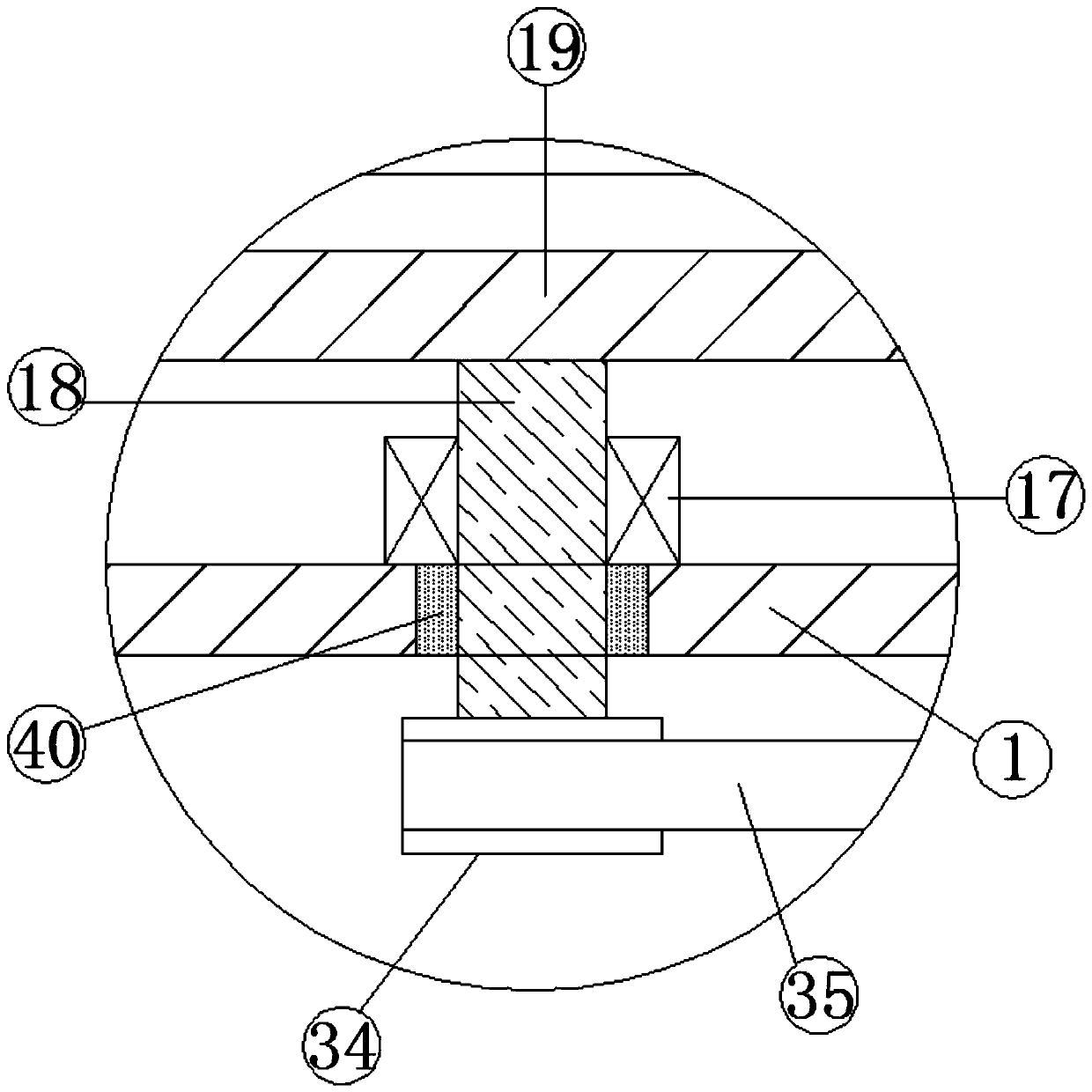

[0042] See figure 1 with 2 For the control device, the control device includes a timing knob 36, a speed control knob 37, a cover opening button 38, and a mounting plate 39. The timing knob 36, the speed control knob 37 and the cover opening button 38 are all Fixed on the mounting plate 39, the mounting plate 39 is fixed on the inner wall of the middle part of the side column 5, the timing knob 36, the speed control knob 37 and the opening button 38 are all connected to the PLC controller 9 electrical connection; for the first transmission shaft 18, the outer wall of the junction between the first transmission shaft 18 and the housing 1 is sleeved with a rotary shaft sealing ring 40, and the rotary shaft sealing ring 40 is fixedly embedded in The bottom of the housing 1.

[0043] Through the above-mentioned solution of the present invention, the timing knob 36 can be used to turn on the motor 32 and control the working time of the motor 32, the speed of the motor 32 can be adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com