Lateral shoring device for goods in container and method for reinforcing goods in container

A container and top support technology, applied in the field of transportation, can solve the problems of unfavorable reuse, inability to guarantee the strength of the building structure, and inability to guarantee the quality of wood, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

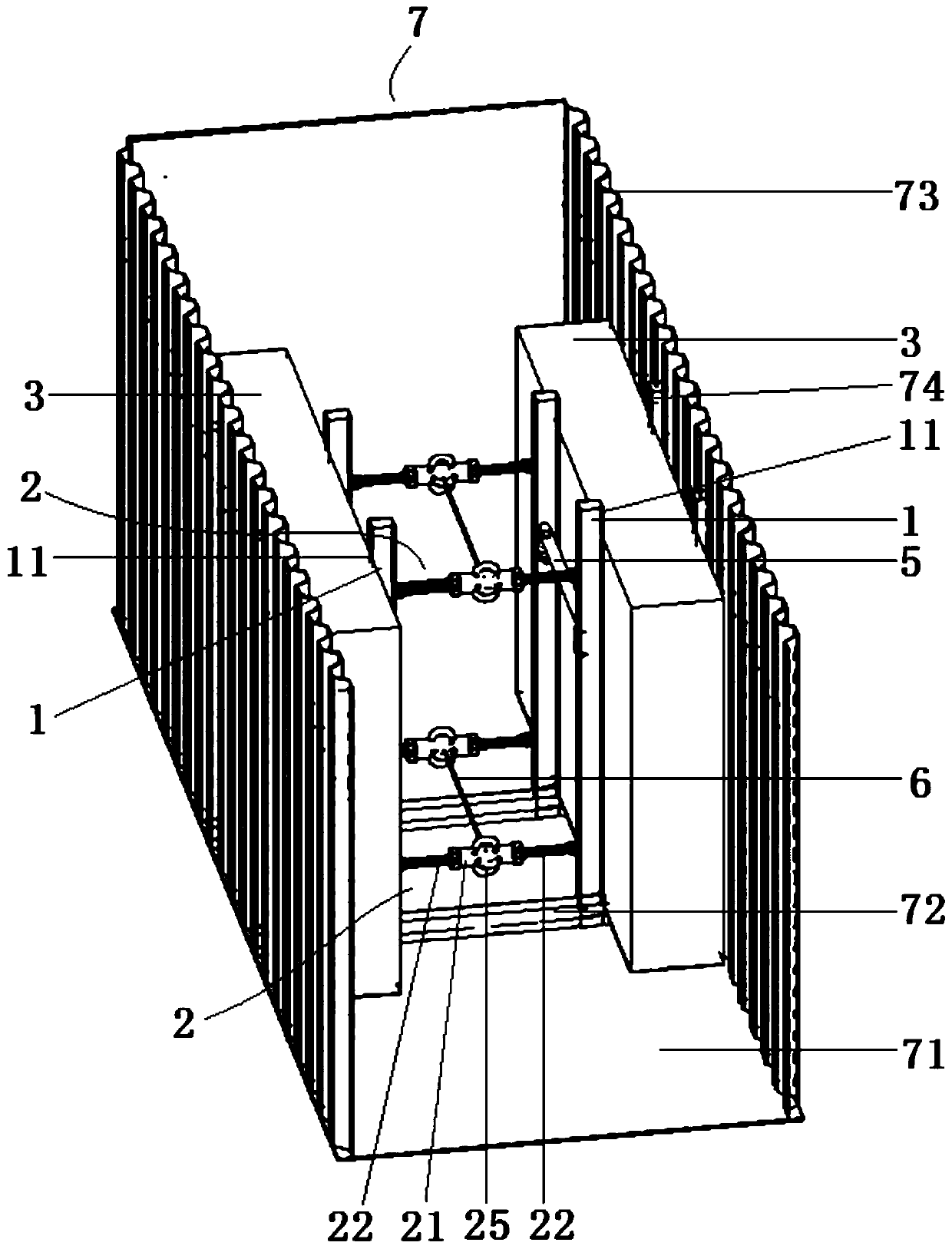

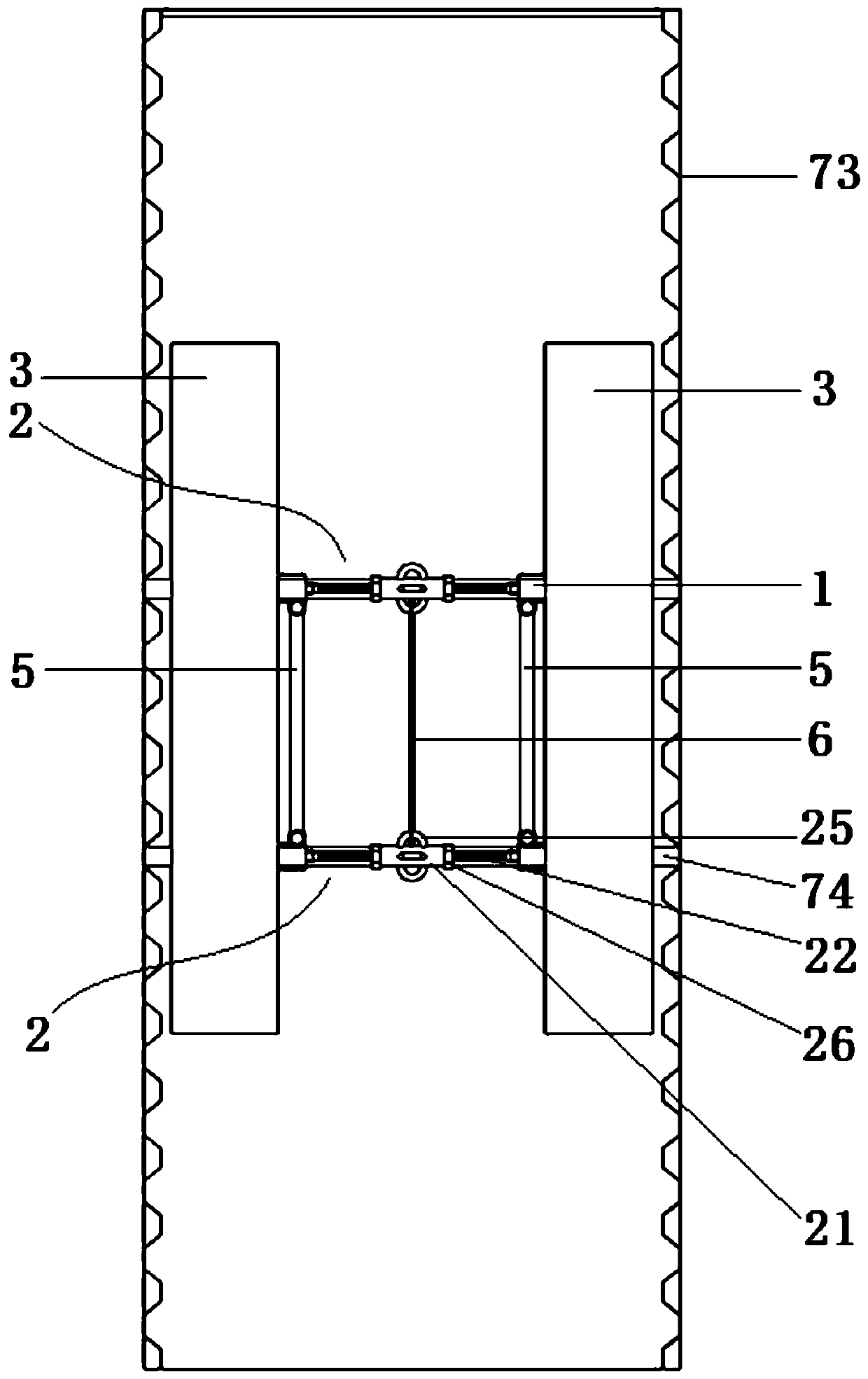

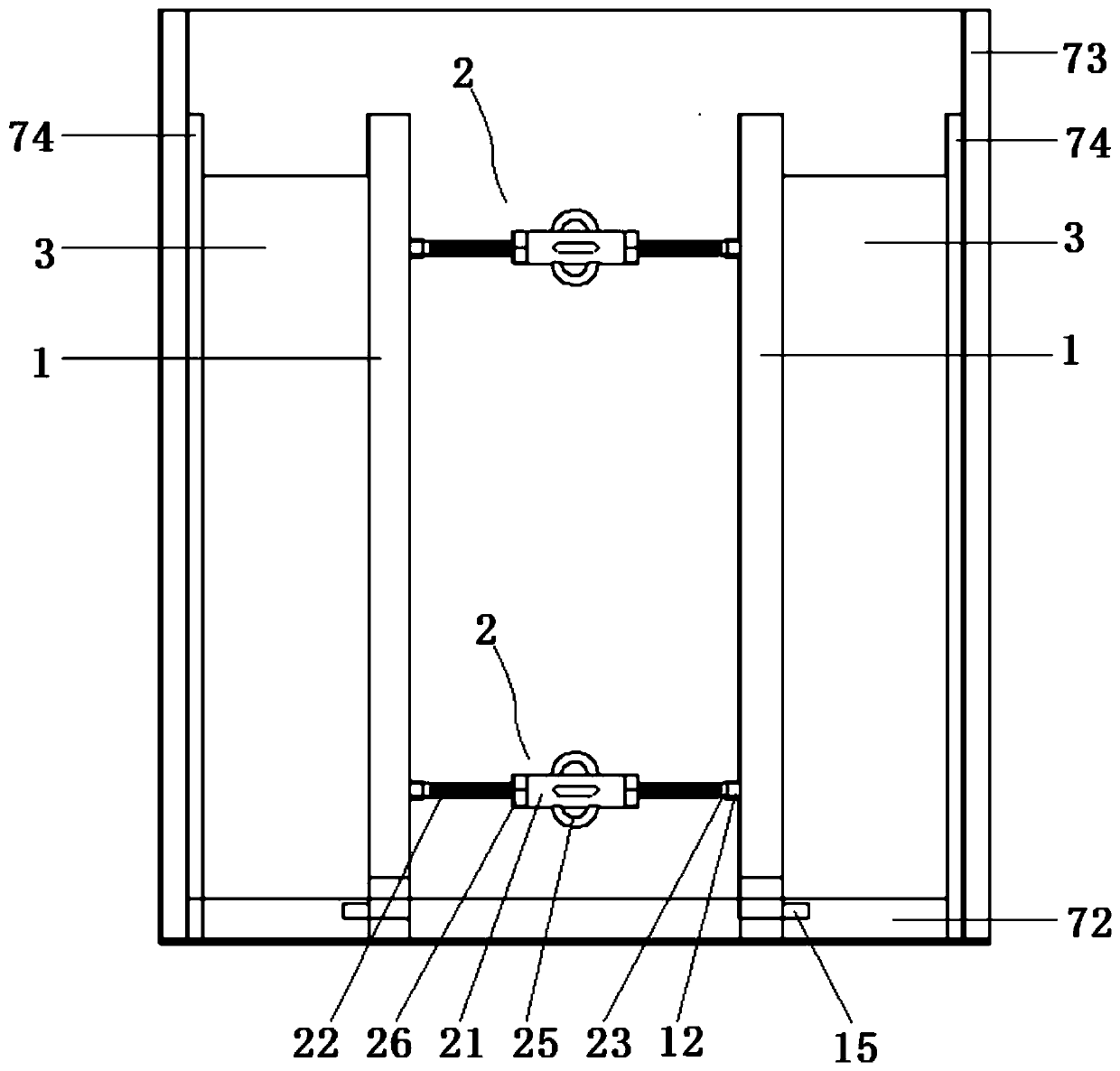

[0050] Reference Figure 1 to Figure 3 This embodiment provides a lateral support device for the cargo in the container, that is, the lateral support is provided to the cargo 3 from the inner side of the cargo 3, so that the cargo 3 abuts on the side wall 73 of the container 7 or supports it On the vertical beam 74 on the side wall 73 of the container 7.

[0051] In this embodiment, the lateral support device includes two sets of support components.

[0052] Each top support assembly includes two vertical support beams 1, which are supported on the inner floor 71 of the container 7, and the two vertical support beams 1 are used to be placed between two cargoes 3, that is, each vertical support beam 1 The supporting beam 1 is placed on the inner side of a corresponding cargo 3, and the outer side of the cargo 3 is the side wall 73 of the container 7. The vertical support beam 1 has a vertical support surface 11 that faces the cargo 3 and extends along the length of the vertical su...

Embodiment 2

[0098] See Figure 8 The difference between the lateral support device of this embodiment and the first embodiment is that there is no handle 25 on the sleeve 21, and accordingly, no locking member 6 is provided. In the same way, in the steps of the method for reinforcing the cargo in the container using the lateral support device, the steps of fixing with the locking member 6 and releasing the fixing of the locking member 6 are eliminated.

[0099] Preferably, if a self-locking structure is provided between the sleeve 21 and the lead screw 22, the handle 25 and the locking member 6 can be substituted for the locking function.

Embodiment 3

[0101] See Picture 9 The difference from the first embodiment is that the telescopic top brace 2 in the lateral bracing device of this embodiment includes a double-rod hydraulic cylinder, and the piston rod of the double-rod hydraulic cylinder is used to support the vertical support beam 1. The double-rod hydraulic cylinder can drive two piston rods to extend and contract simultaneously. Generally speaking, the double-rod hydraulic cylinder has a self-locking function, and there is no need to set handles and locking parts. Of course, for situations where the double-rod hydraulic cylinder needs to be locked, a handle and a locking piece can also be provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com