Bottle base conveying device

A conveying device and preform technology, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of affecting the heat conduction between the screw and the water channel, affecting the stability of the preform conveying, and falling of dust and other substances, so as to achieve the effect of heat dissipation Good, the effect of reduced interaction force and reduced climbing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention aims to solve the above-mentioned shortcomings of the prior art, and provides a preform conveying device for a plastic preform heater with good conveying stability, good durability and good heat dissipation effect.

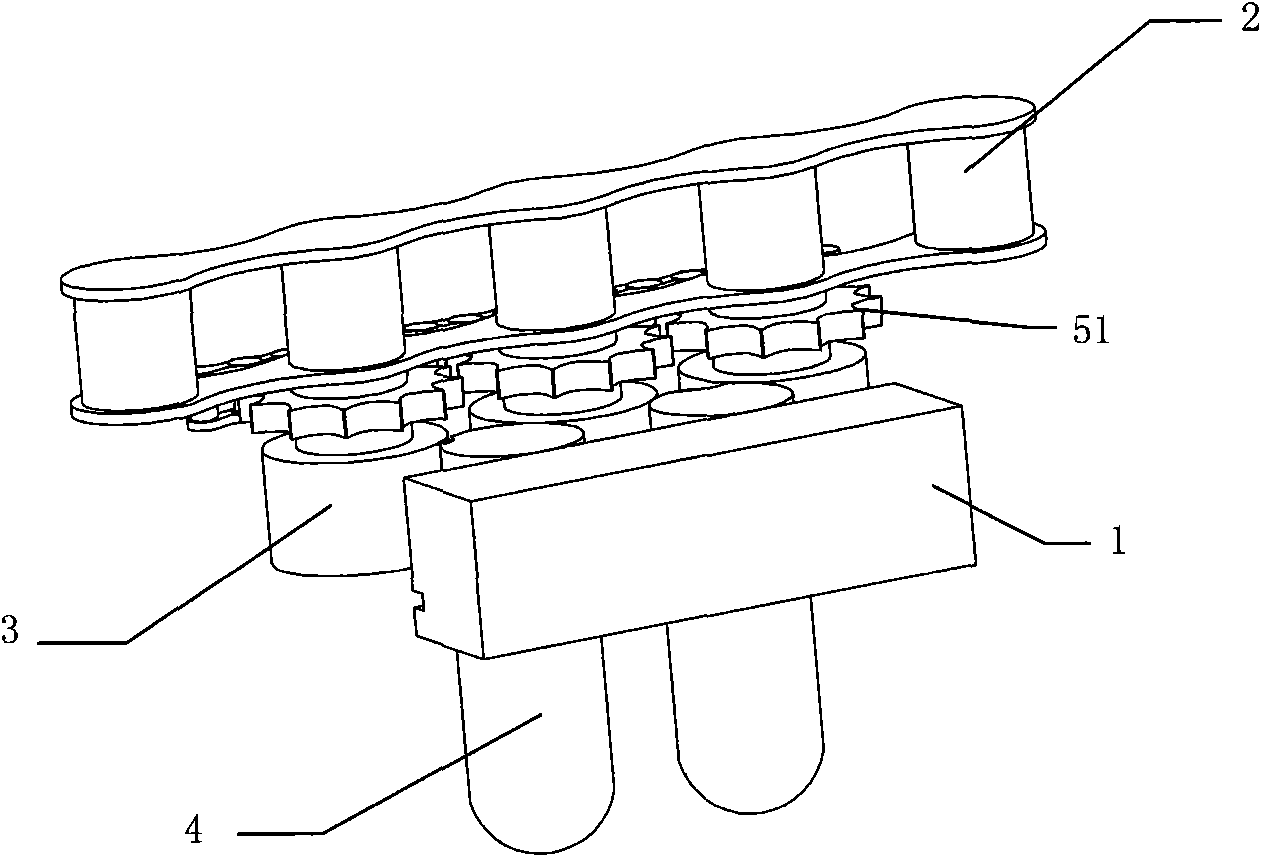

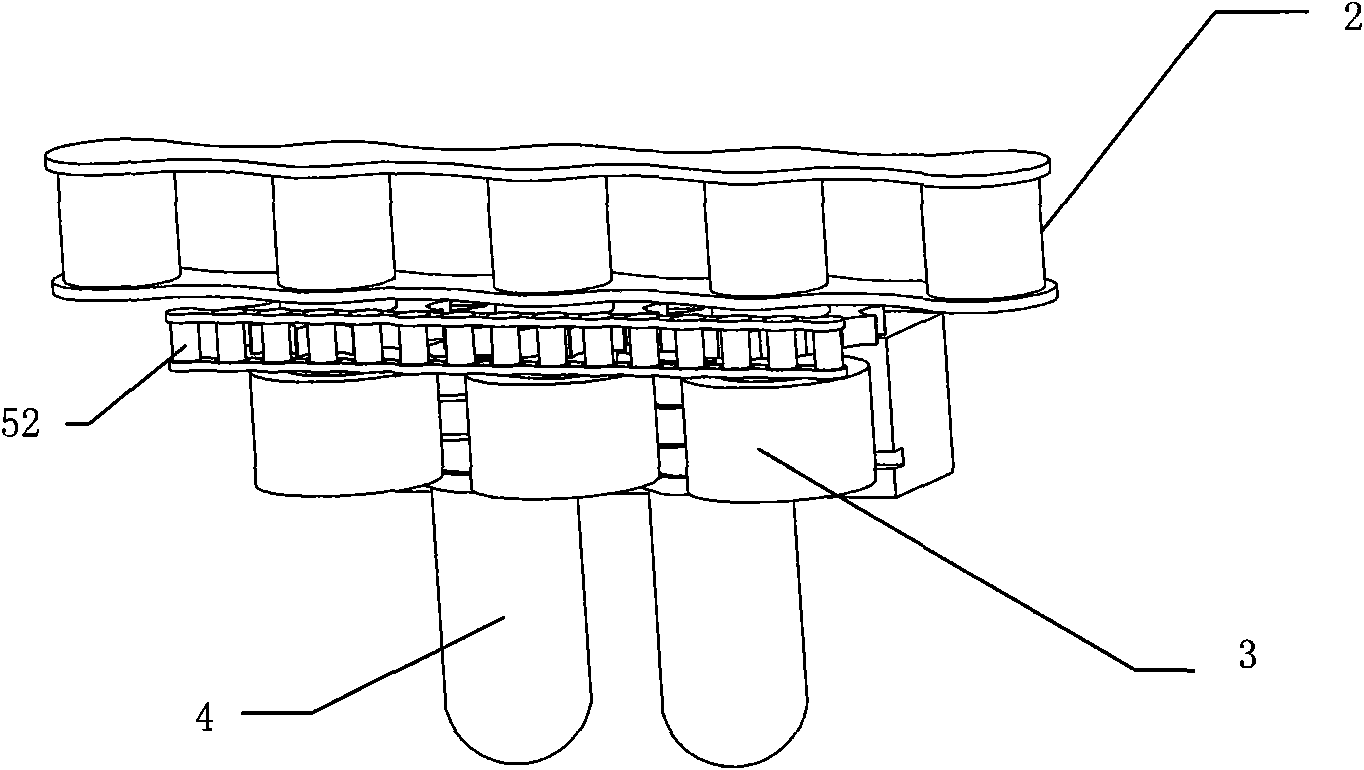

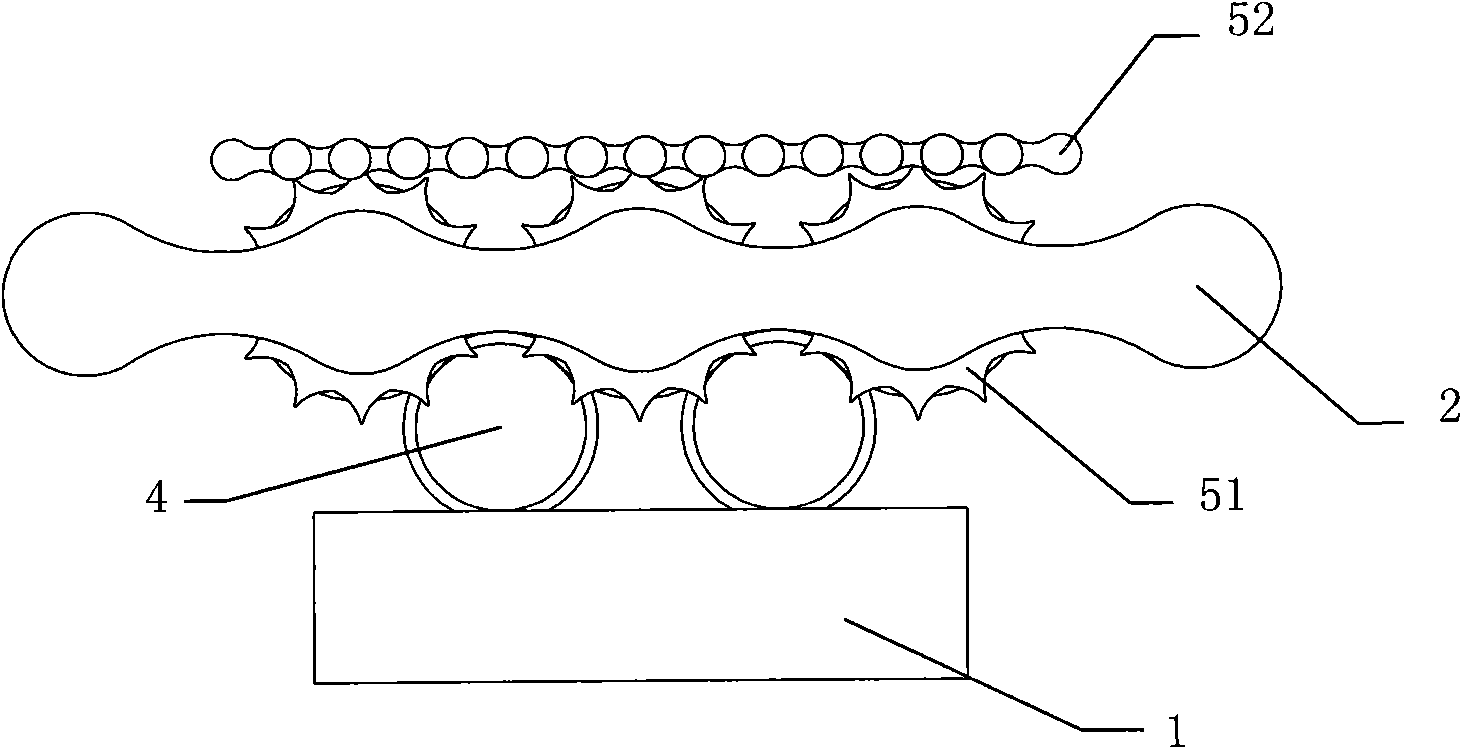

[0018] The preform conveying device of the present invention includes a cooling channel 1 and a chain support arranged on the heater, a transmission chain 2 is installed on the chain support, and a friction wheel 3 is installed on the transmission chain 2. The friction wheel 3 is inserted between the running plastic preforms 4, and the screw 42 of the plastic preform 4 is pressed against the wall of the cooling water channel 1; There is a groove 11 for inserting the convex ring 41 of the screw port 42 of the plastic bottle preform 4, and the height of the groove 11 is adapted to the height of the convex ring 41; the friction wheel 3 Connect the autobiographical drive mechanism.

[0019] The height of the groove 11 in the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com