In-vitro orthopedic device and manufacturing method thereof

A manufacturing method and orthopedic technology, applied in medical science and other fields, can solve problems such as time-consuming, ugly appearance, poor individual adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing, the usage mode and the method of inventive device are described further:

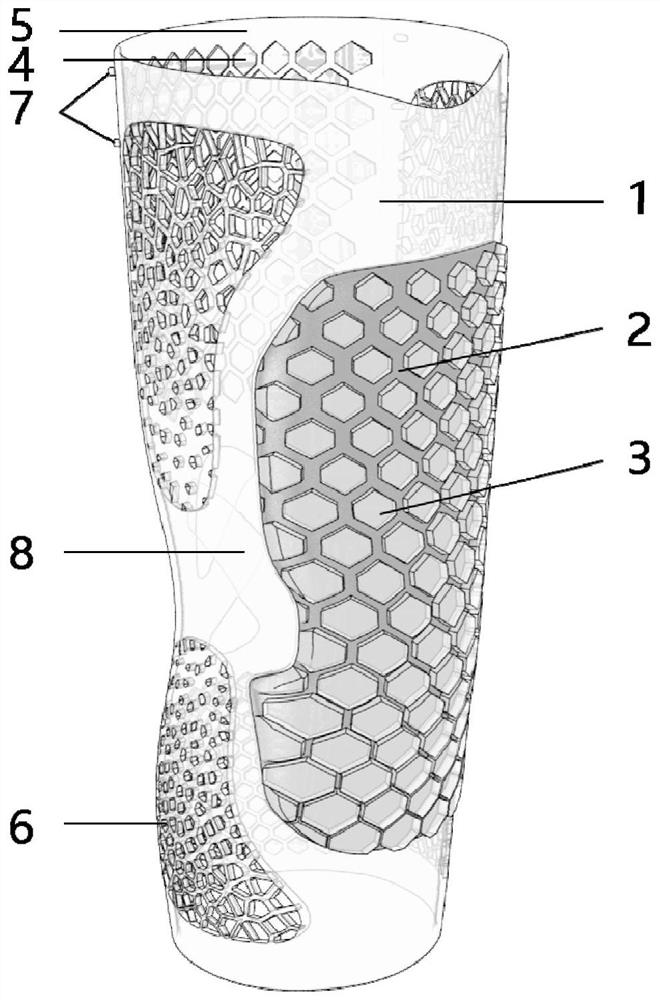

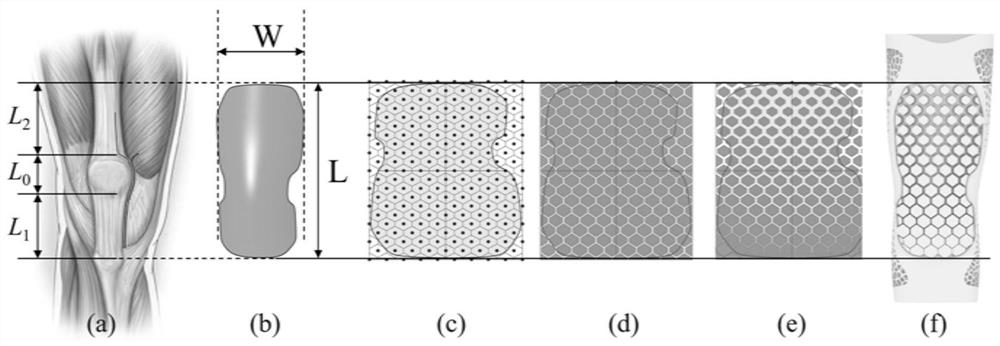

[0051]1 in the figure is the main body, the front block structure bottom surface 2 and the front outer unit block 3 form the front block structure area. Front outer unit block 3 is from top to bottom, the size is from small to large, and the gap is distributed from large to small hexagonal unit blocks, and its thickness is about 3mm. When the user's knee joint is stretched backward to about 5° and the knee joint is in a flexed state, the gap between part of the front outer unit blocks 3 will shrink and start to produce contact extrusion, which will produce a small deformation resistance; As the movement proceeds, the deformation of the bottom surface 2 of the front block structure continues to occur, and more front outer unit blocks 3 will be concentrated towards the center, and the force generated by the extrusion of the unit blocks against continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com