a small circuit breaker

A small circuit breaker, U-shaped technology, applied in the direction of circuit breaker components, etc., can solve the problems of small circuit breakers such as unfavorable arc extinguishing, potential safety hazards, and poor breaking capacity, so as to facilitate arc extinguishing, improve arc extinguishing ability, The effect of strong breaking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

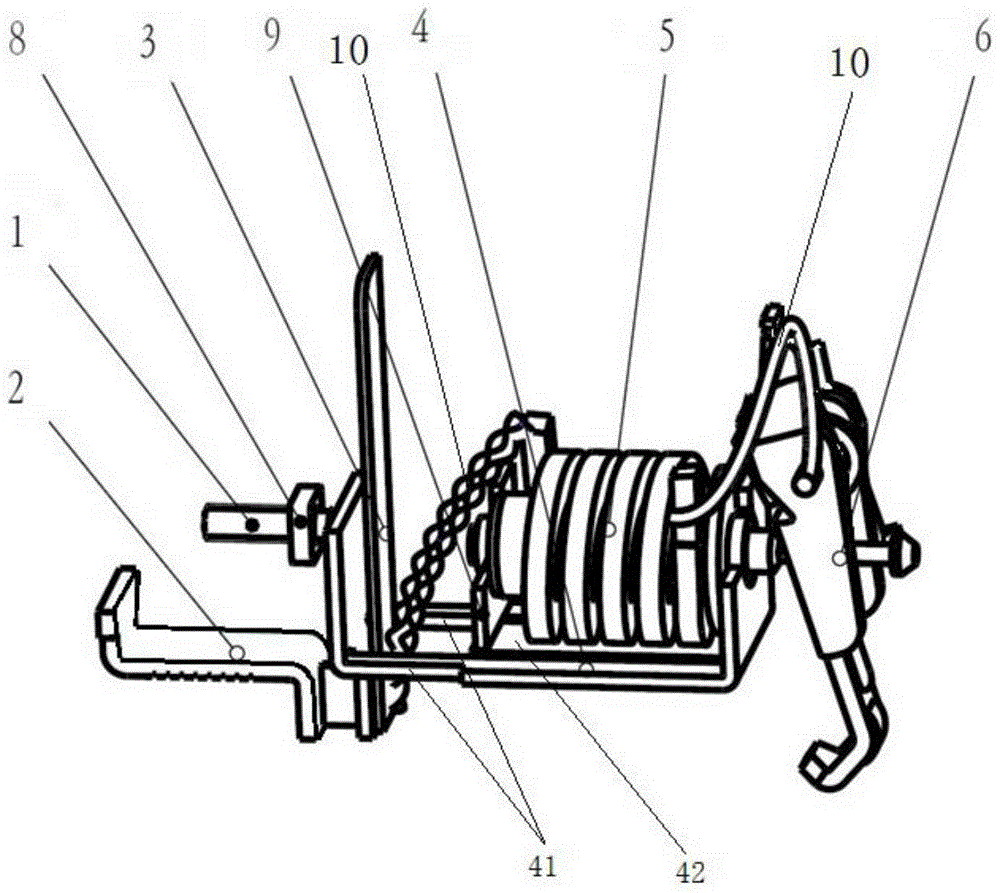

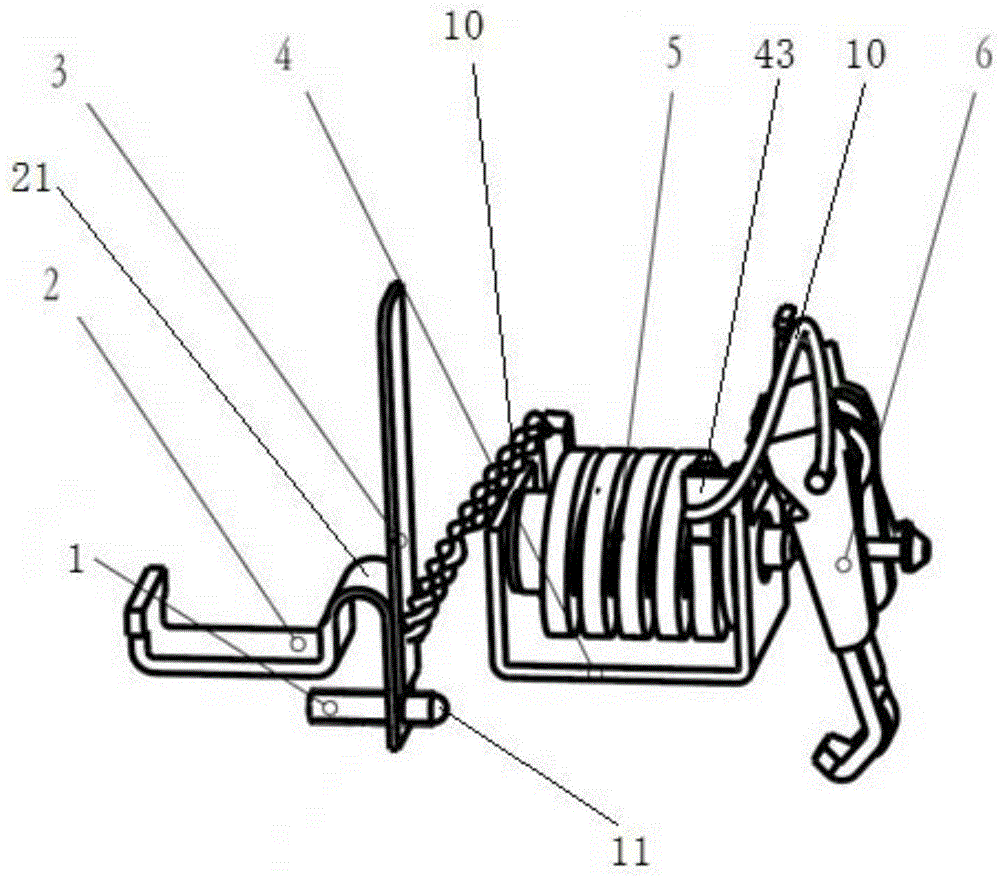

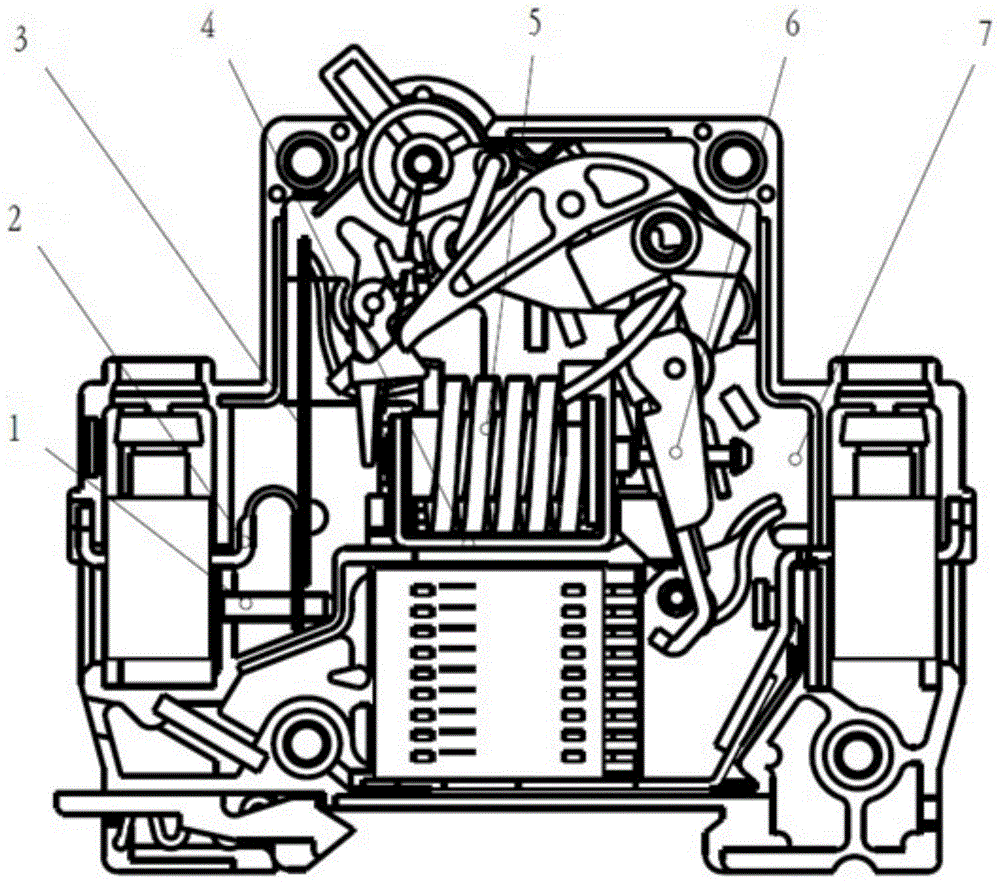

[0031] Such as figure 2 Shown is a preferred embodiment of a miniature circuit breaker of the present invention. The miniature circuit breaker includes a housing 7 and a yoke 4 disposed in the housing 7, a bimetallic strip 3, a moving contact 6, a static contact, a handle, an operating mechanism and other conventional miniature circuit breakers, such as image 3 shown.

[0032] The yoke 4 is U-shaped, and an iron core and a coil 5 sheathed outside the iron core are arranged between two side plates of the yoke 4 . The metal sheet 3 is electrically connected to one end of the coil 5; the movable contact 6 is electrically connected to the other end of the coil 5. In this embodiment, the bimetallic sheet 3 and the movable contact 6 are respectively electrically connected to both ends of the coil 5 through flexible connecting wires 10 . The coil 5 is fixedly connected to the yoke 4 at one end close to the movable contact 6 . The above connections are all realized by welding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com