Multi-layer nano-film suitable for titanium alloy surface and preparation method thereof

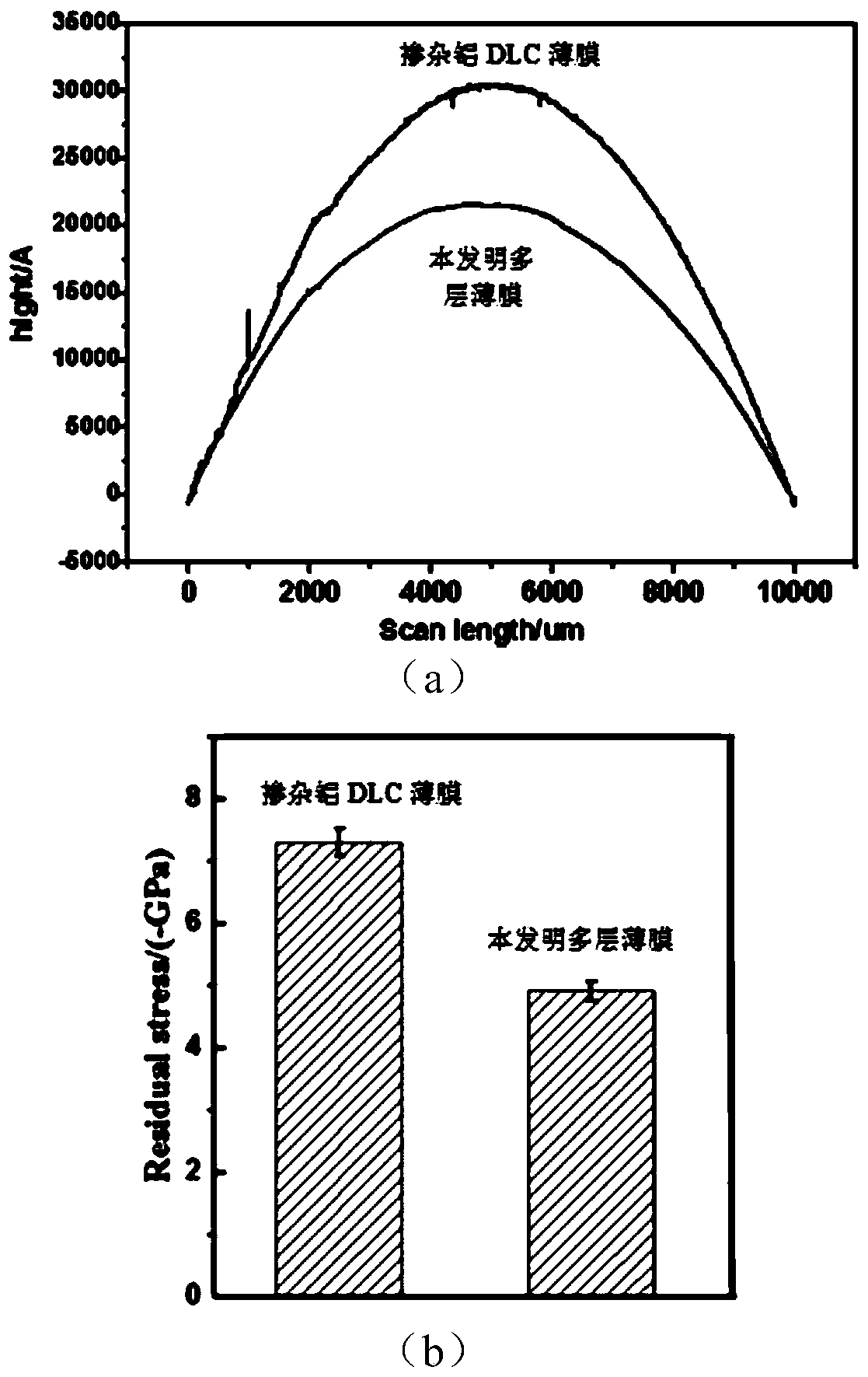

A nano-multi-layer, titanium alloy technology, applied in the direction of metal material coating process, coating, vacuum evaporation plating, etc., can solve the problems of unsatisfactory bonding force and internal stress, and achieve low internal stress and high resistance to friction and wear The effect of high performance and film hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of nanometer multi-layer thin film that is applicable to the surface of titanium alloy, it is characterized in that, it is made of five thin film layers; From the titanium alloy surface outwards successively is titanium nitride thin film layer, and its thickness is about 190nm; Titanium carbide thin film layer , its thickness is about 190nm; titanium nitride film layer, its thickness is about 190nm; titanium carbide film layer, its thickness is about 190nm; aluminum-doped diamond-like film layer, its thickness is about 240nm; The thickness is about 1000nm.

Embodiment 2

[0043] A kind of nanometer multi-layer thin film that is applicable to the surface of titanium alloy is characterized in that, it is made of five thin film layers; From the surface of titanium alloy outwards is the titanium nitride thin film layer successively, and its thickness is about 200nm; Titanium carbide thin film layer , its thickness is about 200nm; titanium nitride film layer, its thickness is about 200nm; titanium carbide film layer, its thickness is about 200nm; aluminum-doped diamond-like film layer, its thickness is about 250nm; The thickness is about 1050nm.

Embodiment 3

[0045] A kind of nanometer multi-layer thin film that is applicable to the surface of titanium alloy, it is characterized in that, it is made of five thin film layers; From the titanium alloy surface outwards successively is titanium nitride thin film layer, and its thickness is about 250nm; Titanium carbide thin film layer , its thickness is about 250nm; titanium nitride film layer, its thickness is about 250nm; titanium carbide film layer, its thickness is about 250nm; aluminum-doped diamond-like film layer, its thickness is about 250nm; The thickness is about 1250nm.

[0046] The nano-multilayer film suitable for the surface of titanium alloy obtained in the above-mentioned embodiments 1-3 is prepared by the following system and method:

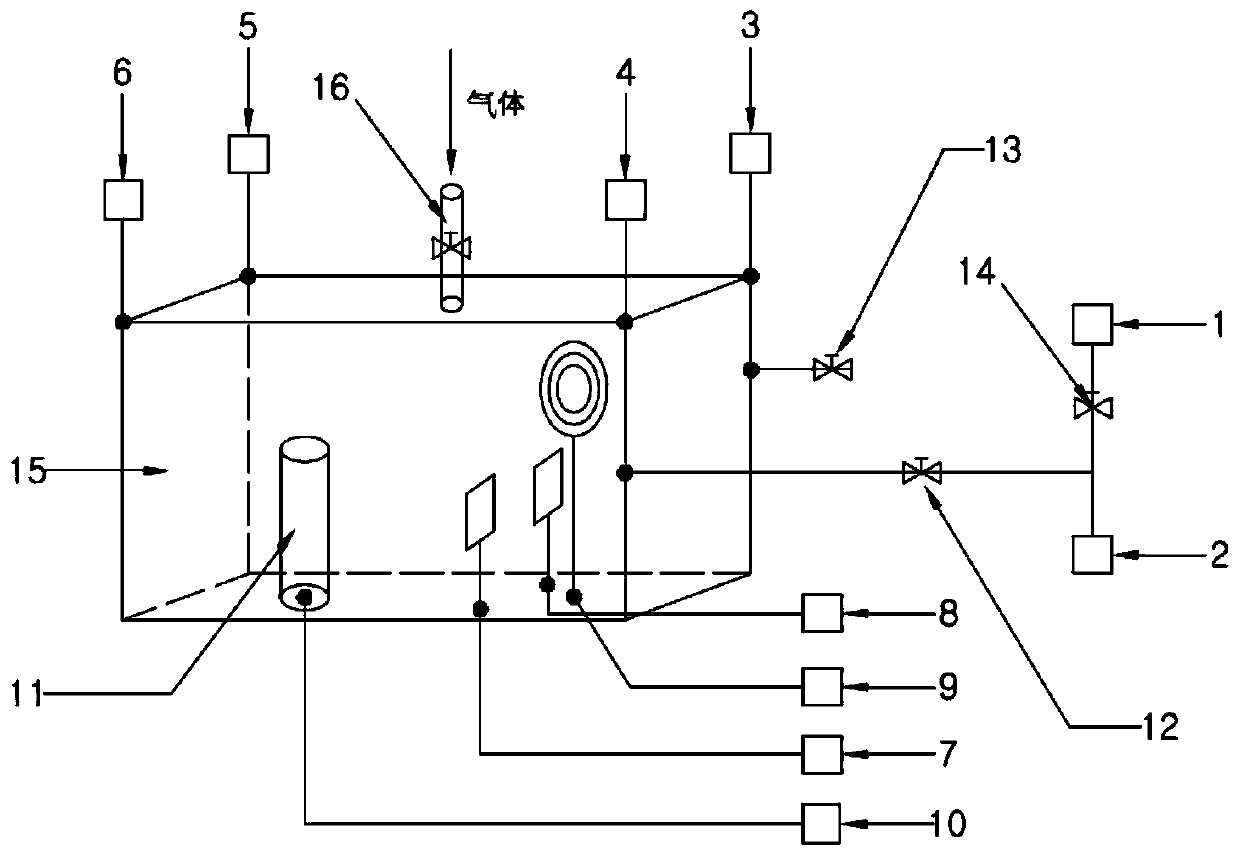

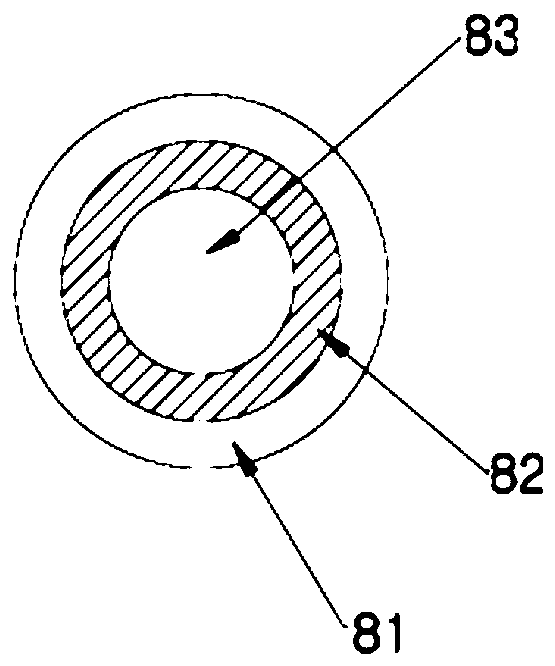

[0047] A preparation system for nano-multilayer films suitable for the surface of titanium alloys, using electron cyclotron resonance (ECR), two sets of target intermediate frequency magnetron sputtering devices, and a set of ring target D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com