Composite anodic bonding method

A composite anode and anodic bonding technology, used in precision positioning equipment, microstructure technology, microstructure devices, etc., can solve the problems that restrict the wide application of interface activation composite anode bonding process, strict wet chemical activation process conditions, and bonding efficiency. Low-temperature and other problems, to achieve the effect of low-temperature high-efficiency anodic bonding, good controllability of bonding performance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

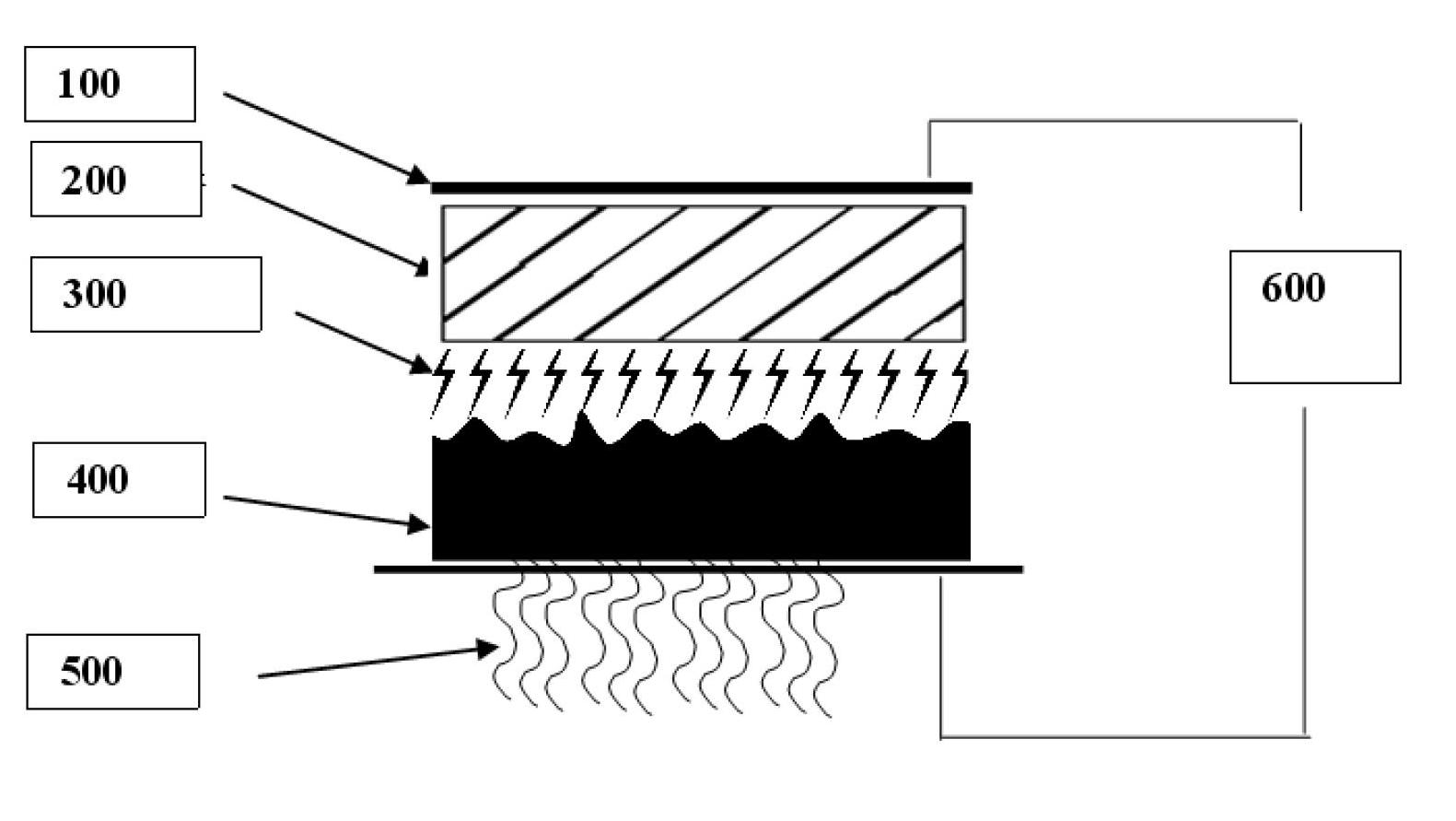

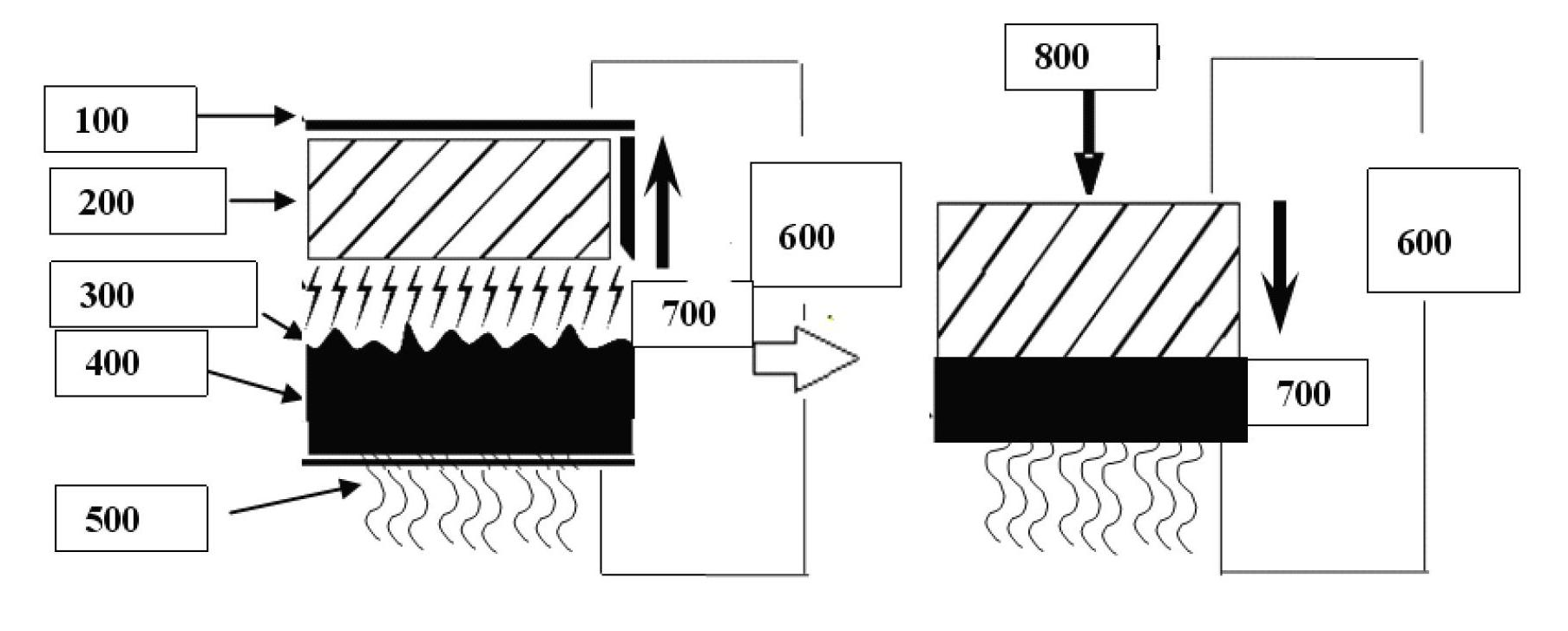

[0034] In the prior art, conventional anodic bonding has low bonding efficiency. In the silicon / glass bonding process, high temperature will cause the gas in the glass pores to expand, decompose, and overflow, forming a gas layer at the bonding interface, and poor gas drainage will form pore defects at the interface. In order to make the gas smooth At present, point electrodes and multi-point electrodes are widely used in wafer-level bonding. When this type of electrode is used, the distribution of the external electric field on the bonding interface is not uniform, and the bonding can only be gradually advanced from the electrode position to the edge. It takes a long time to complete the bonding of the whole piece, and the bonding efficiency is low.

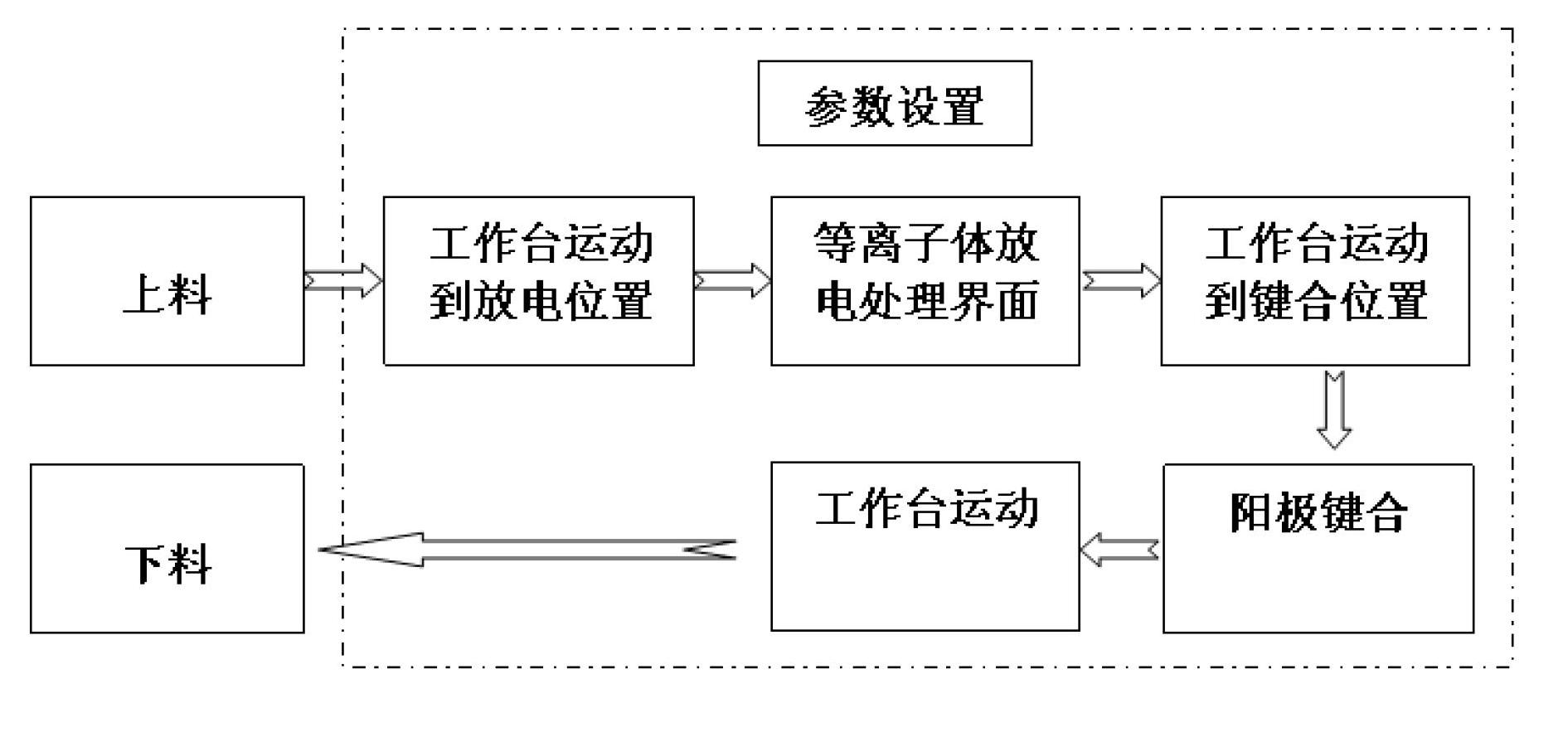

[0035] At present, the step-by-step pretreatment anodic bonding equipment used in the prior art is complicated, and the process is difficult to realize; moreover, the two processes of pretreatment and bonding are not in the same s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com