Coarse aggregate void test equipment

A technology of testing and gap ratio, applied in the direction of material inspection products, measuring devices, permeability/surface area analysis, etc., can solve the problems of huge difference in compactness, unsatisfactory, and large influence of human factors on the results, so as to achieve repeatability and complexity. Reality improvement, avoiding the influence of human factors, and the effect of more objective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with preferred embodiments, and the following embodiments are only used to illustrate the present invention rather than limit the present invention.

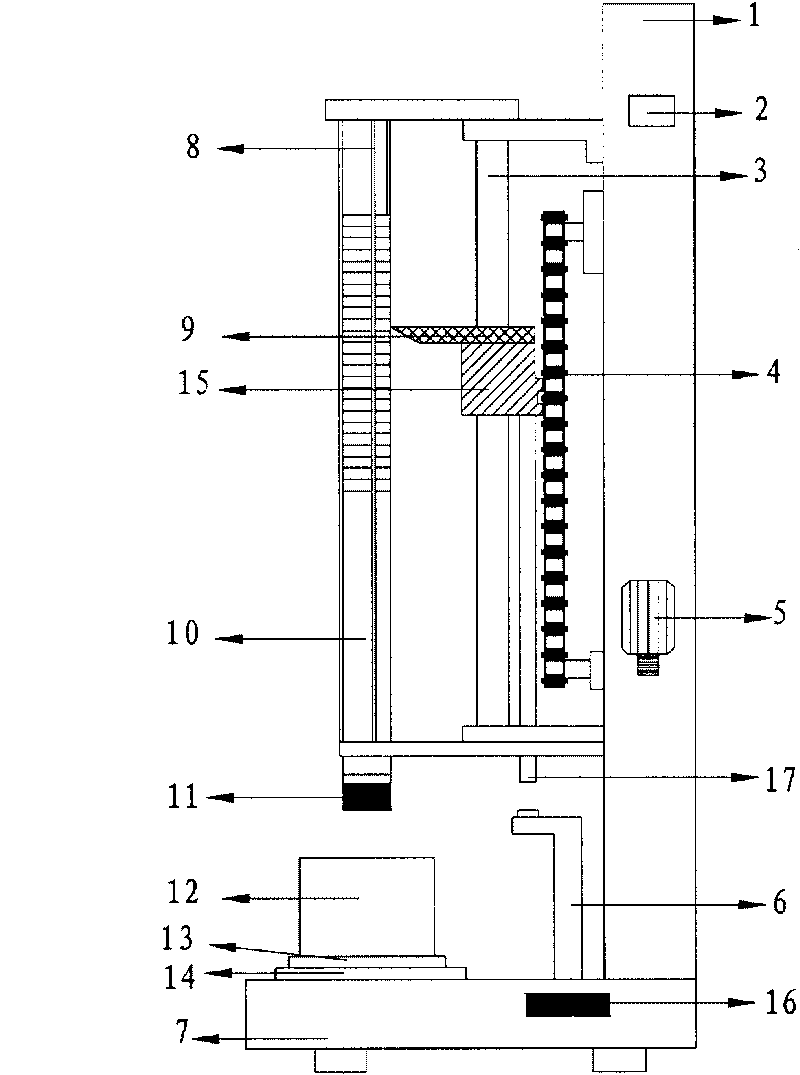

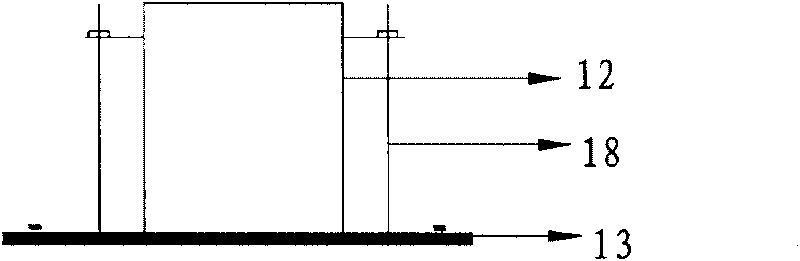

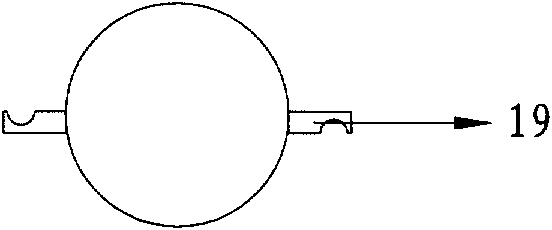

[0019] refer to figure 1 , the coarse aggregate ore gap rate test equipment of the present invention comprises frame part, base part and controller (not drawing in the latter figure), and controller links to each other with equipment through data line; In frame part, frame 1 is provided with a magnet 2, a motor and a reducer 5 are provided inside or next to the frame 1, and the front of the frame 1 is provided with a lifting hammer chain 4, a guide rail 3 and a drop hammer guide rod 8, and the lifting hammer chain 4 is controlled by the reducer. Driven, the slider 15 is sleeved on the guide rail 3 and can move up and down along the guide rail 3, and the slider 15 is connected to the lifting hammer chain 4 on the other side to fix the dowel 17, and the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com