High-molecular material 3D printing device applying nanosecond lasers to accurately control temperatures

A polymer material and 3D printing technology, applied in the field of 3D printing, can solve problems such as material melting, shrinkage cavity, and processing accuracy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art understand that the following content does not limit the protection scope of the present invention, and any improvements and changes made on the basis of the present invention are within the protection scope of the present invention.

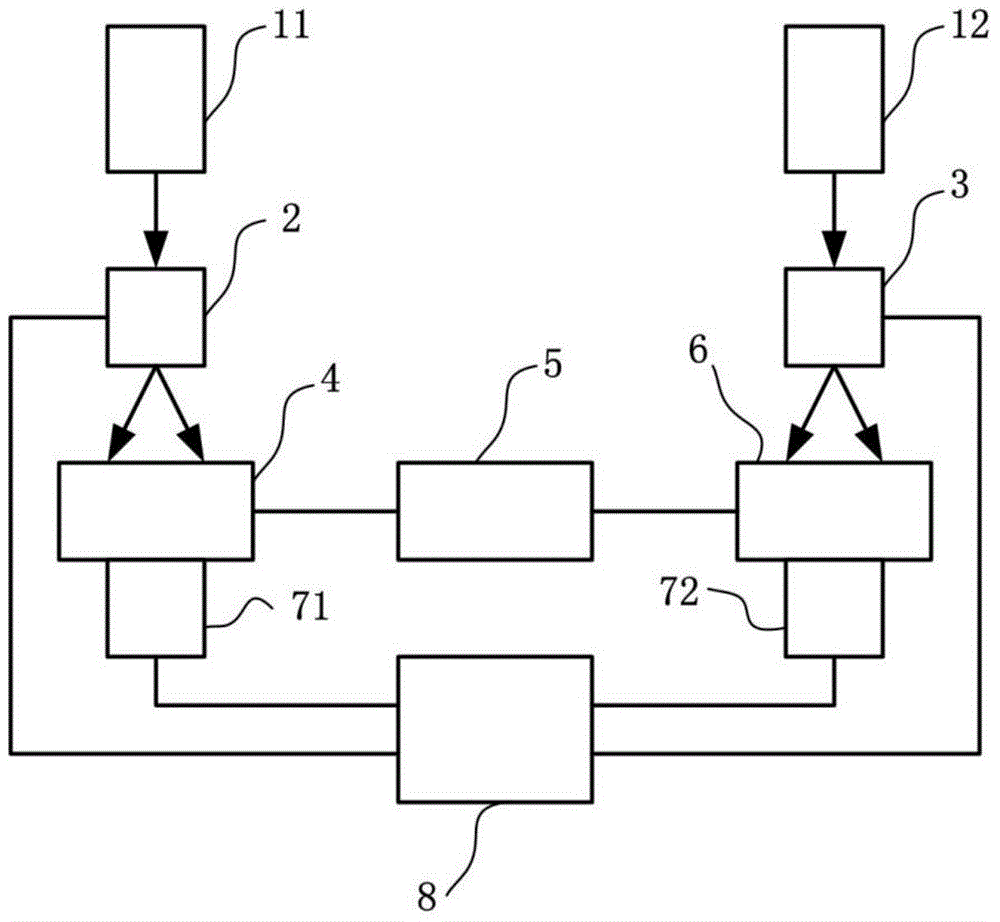

[0017] figure 1 It shows the structure of a device that uses nanosecond laser to precisely control the temperature of 3D printing polymer materials proposed by the present invention, as figure 1 As shown, the 3D printing device includes two nanoscale lasers 11 and 12, a preheating chamber 4, a powder feeder 5 and a working platform 6 arranged horizontally and sequentially, and a beam expander 2 and a beam expander 2 are arranged at a distance above the prehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com