Device for testing gas/dust combustion and explosion performances with super-capacitor

A technology of supercapacitors and testing devices, applied in measuring devices, fuel testing, educational appliances, etc., can solve the problem of inability to control temperature sensors, pressure sensors, high-voltage solenoid valves and stop valves, failure to accurately control ignition source energy requirements, failure to Accurately control the temperature of the ignition source and other issues to achieve the effects of long-term use without maintenance, good explosion display effect, and fast charging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

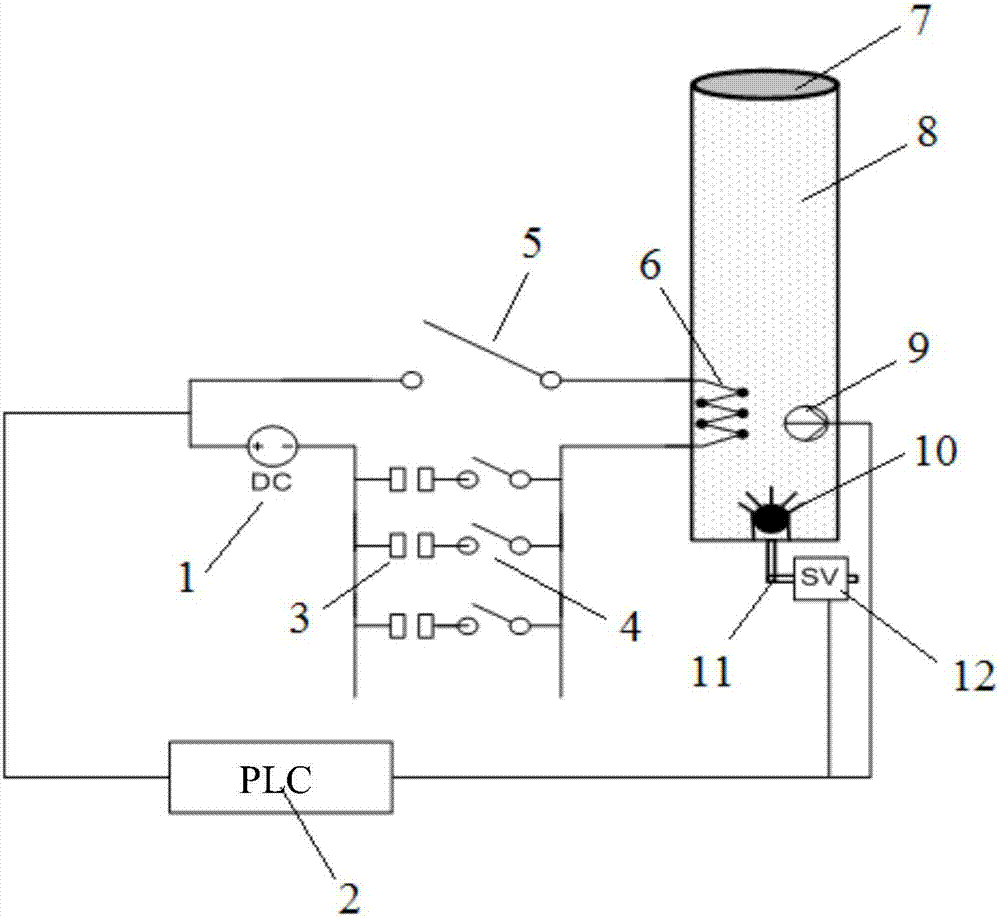

[0032] Gas or dust combustion and explosion performance test device using super capacitor, its structure is as follows figure 1 As shown, it includes a control terminal and a test terminal. The control terminal includes a series connection formed by a switching power supply 1, a supercapacitor 3, a unit control switch 4, and a total power supply control switch 5 connected in series, and a PLC control system 2 for general control. The test terminal It includes an explosion combustion reaction observation tube 8 and a pluggable heating wire 6 arranged in the observation tube, a powder spraying or air jet dispersing device 10, an infrared thermometer 9, and a discharge top cover arranged on the top of the explosion combustion reaction observation tube 8 7. The two ends of the pluggable heating wire 6 are respectively connected to the series components at the control end, and the powder spraying or air spraying dispersing device 10 is also connected to an external pipe 11, and an e...

Embodiment 2

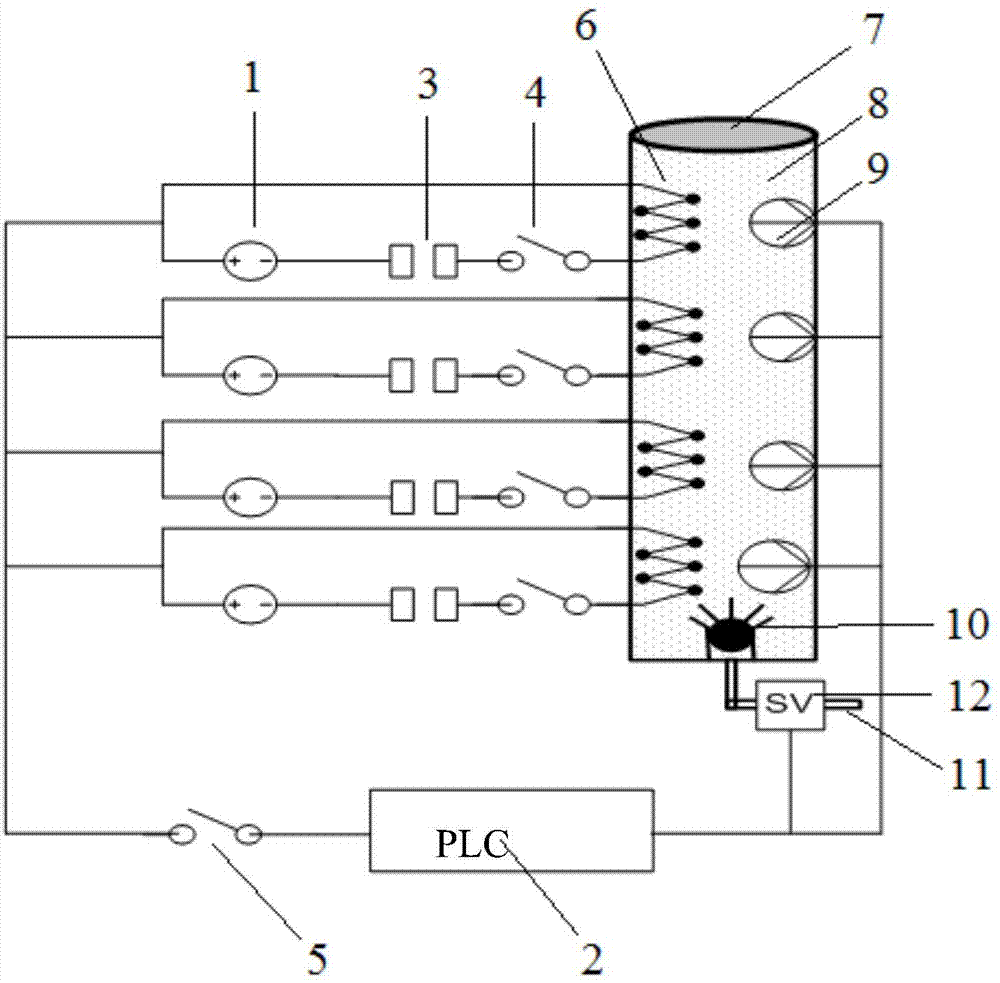

[0037] Gas or dust combustion and explosion performance test device using super capacitor, its structure is as follows figure 2 As shown, the structure is roughly the same as that of Embodiment 1, the difference is that there are multiple pluggable heating wires 6, and both ends of each pluggable heating wire 6 are connected to a group of series components, and each series connection They are connected in parallel with each other, and are controlled by the PLC control system 2 to heat the pluggable heating wire 6 . By setting multiple supercapacitors 3, unit control switch 4, pluggable heating wire 6 and infrared thermometer 9 on a set of explosion reaction observation tubes, it is possible to test samples at one time and achieve multi-temperature range testing and multi- Channel monitoring, to fully monitor the response of the entire explosion reaction observation tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com