A computer-controlled laser processing device and processing method thereof

A laser processing and computer technology, applied in the direction of manufacturing tools, metal processing equipment, laser welding equipment, etc., can solve the problems of unfavorable cutting speed and flexibility, and the failure of cut single pieces, so as to prevent improper operation and reduce cracks and debris, precisely controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

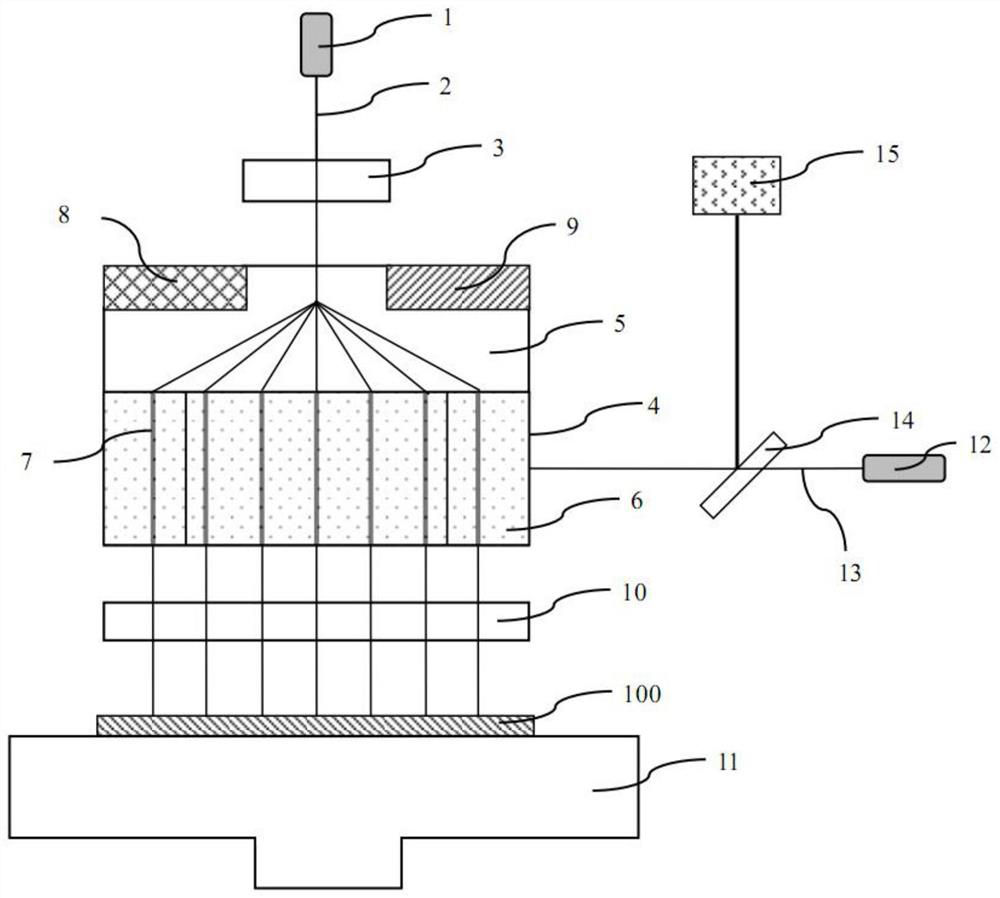

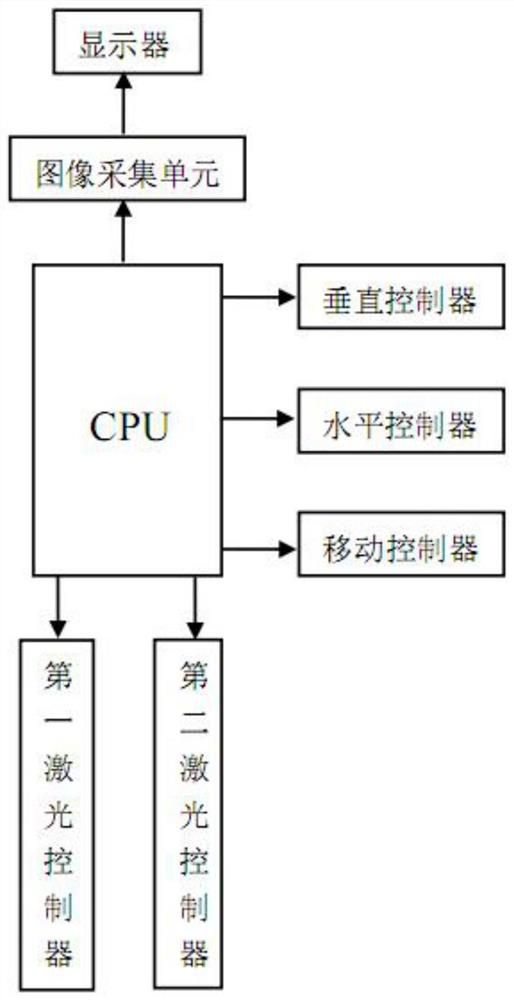

[0032] see figure 1 , the computer-controlled laser processing device of the present invention comprises:

[0033] a first laser 1 emitting a first laser beam 2 along a first optical axis;

[0034] A second laser 12, the second laser 12 emits a second laser beam 13 along a second optical axis, and the first optical axis and the second optical axis are perpendicular to each other;

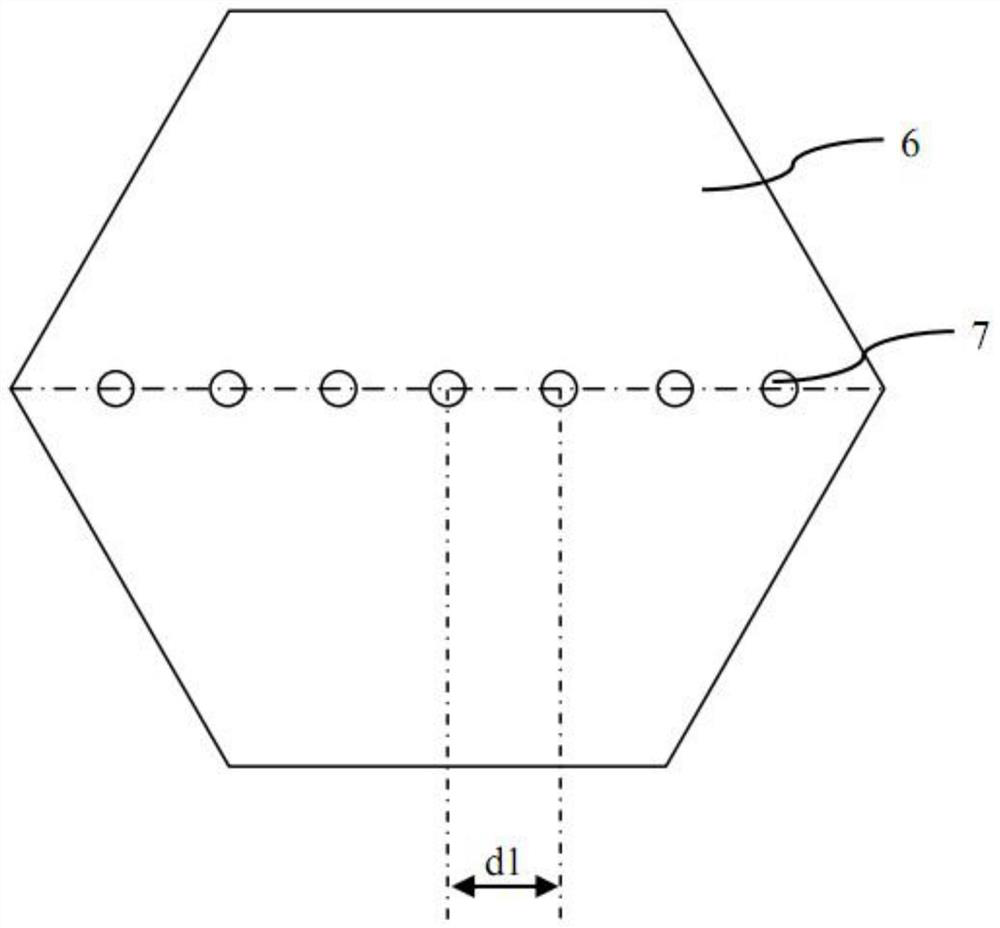

[0035] An optical system, which includes a first condenser lens 3, a fiber branch assembly 4, and a second condenser lens 10 arranged in sequence along the first optical axis direction; the fiber branch assembly 4 includes a beam splitter 5 and an optical fiber bundle assembly, The fiber bundle assembly is arranged in the extension direction of the first optical axis of the beam splitter 5; the fiber bundle assembly 4 includes a plurality of fiber bundles 7 and a hexagonal reflector 6, and the fiber bundles 7 are evenly distributed on the In the reflection cover 6, the reflection cover 6 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com