Double-mercury lamp spliced exposure system for lithography equipment

An exposure system and lithography equipment technology, which is applied in the field of double mercury lamp splicing exposure system, can solve the problems of difficult control and low lighting precision, and achieve the effect of improving illuminance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] The present invention expects to provide an optical system for splicing double mercury lamps, which can accurately monitor and control the energy of the double light sources while increasing the illuminance on the substrate, and can realize switching between the working modes of the double lamps and single lamp.

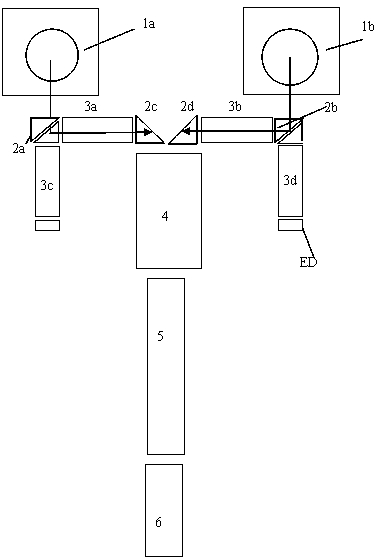

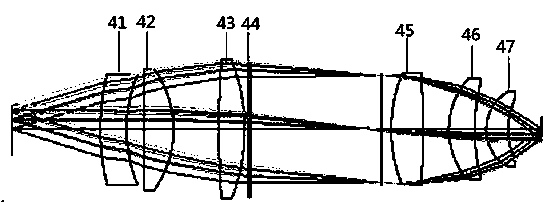

[0021] figure 1 It is a schematic diagram of the overall structure of the double mercury lamp splicing exposure system involved in the present invention. like figure 1 As shown in , the double mercury lamp splicing exposure system is mainly composed of the following modules: light source 1, rectangular prism 2, small quartz rod 3, coupling lens group 4, large quartz rod 5, and relay lens group 6. Here, the small quartz rod 3 and the large quartz rod 5 are defined according to the relative size of their volumes. like figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com