Propane dehydrogenation catalyst, preparation method thereof and method using propane dehydrogenation to prepare propylene

A propane dehydrogenation and catalyst technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of poor catalytic activity and unfavorable Storage, transportation, subsequent processing and application, poor fluidity and other issues, to achieve good structural stability, good mechanical strength, and appropriate pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] Preferably, in the step (a), the conditions of the contact include: the temperature is 10-60° C., the time is more than 25 minutes, and the pH is 1-6. In order to be more conducive to the uniform mixing of various substances, according to a preferred embodiment of the present invention, the mixing and contacting is carried out under stirring conditions.

[0040] In the present invention, the amount of the template agent and the silicon source can be changed within a wide range, for example, the molar ratio of the template agent and the amount of the silicon source can be 1:200-300; preferably 1: 225-275.

[0041] In the present invention, the silicon source can be various silicon sources conventionally used in the art, preferably the silicon source is ethyl orthosilicate, methyl orthosilicate, propyl orthosilicate, sodium orthosilicate and At least one of silica sol, more preferably tetraethyl orthosilicate.

[0042] According to the present invention, the conditions ...

Embodiment 1

[0055] This example is used to illustrate the propane dehydrogenation catalyst and its preparation method.

[0056] (1) Preparation of carrier

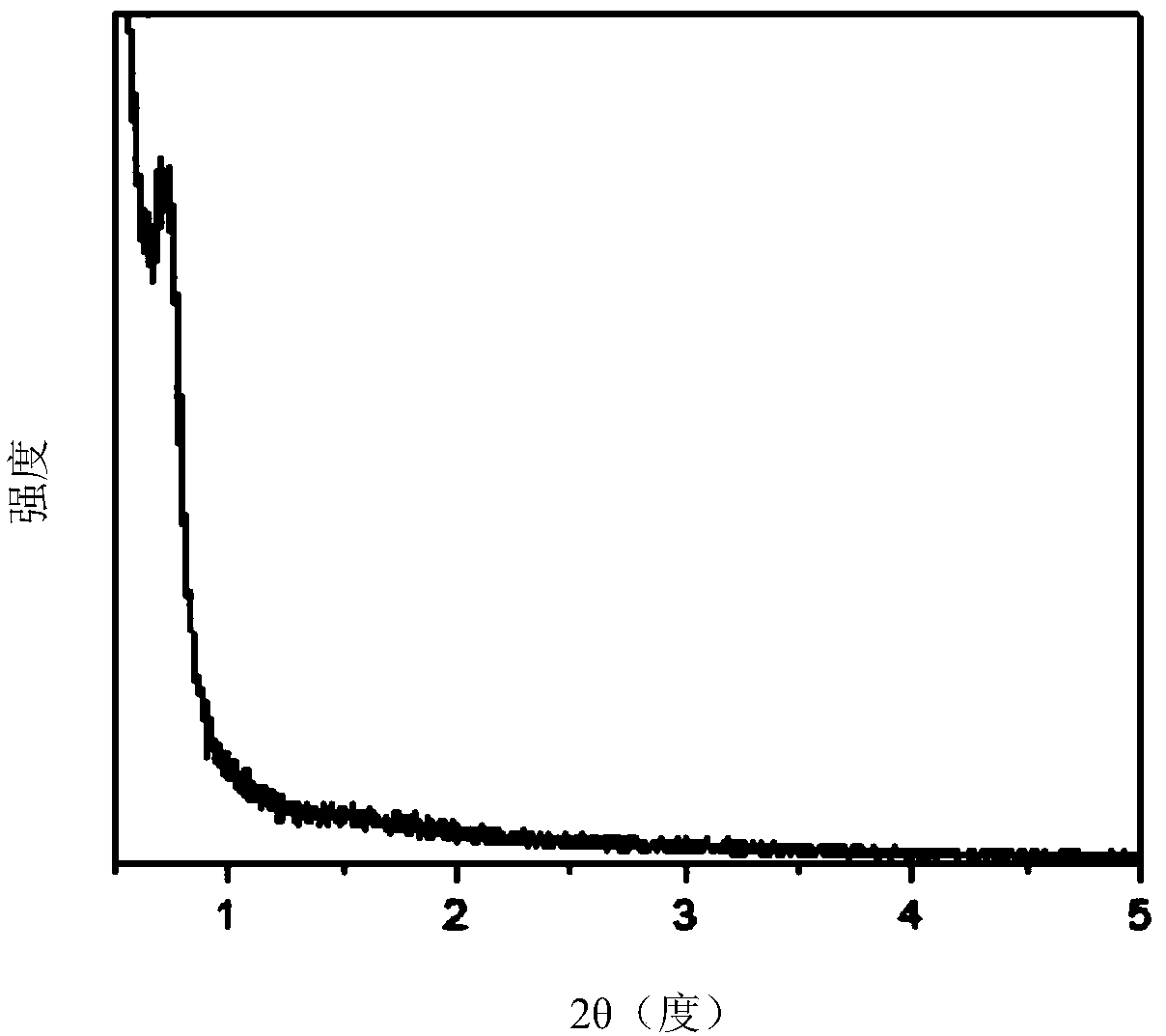

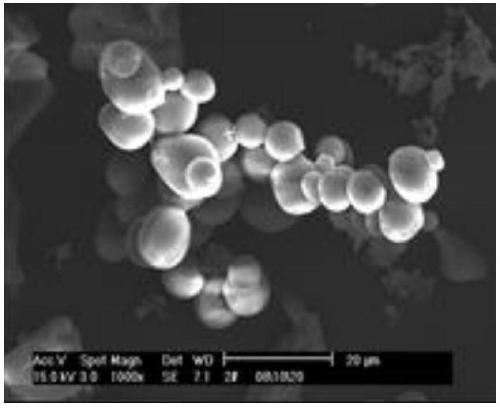

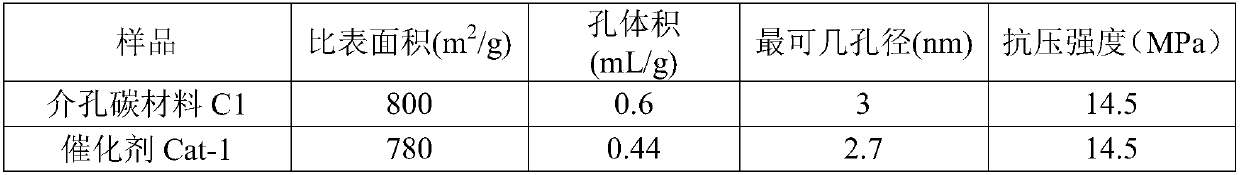

[0057] Add 2g of template agent F127 to a solution containing 37% by weight of hydrochloric acid (2.9g) and water (56g), stir at 40°C until F127 is completely dissolved; then add 8.2g (0.04mol) of tetraethyl orthosilicate into the above solution, stirred at 40°C for 45min, then transferred the resulting solution to a polytetrafluoroethylene-lined reactor, crystallized at 100°C for 24h, then filtered and washed 4 times with deionized water, Then carry out suction filtration and drying to obtain the raw powder of the mesoporous material; wash the raw powder of the mesoporous material with ethanol under reflux conditions for 24 hours, remove the template agent, and obtain spherical mesoporous silica C1.

[0058] (2) Preparation of propane dehydrogenation catalyst

[0059] 0.08g H 2 PtCl 6 ·6H 2 O, 0.207g SnCl 4 ·5H 2 O and 0.185g ...

Embodiment 2

[0076] This example is used to illustrate the propane dehydrogenation catalyst and its preparation method.

[0077] (1) Preparation of carrier

[0078] Add 2g of template agent F127 to a solution containing 37% by weight of hydrochloric acid (2.9g) and water (56g), stir at 40°C until F127 is completely dissolved; then add 9.09g (0.044mol) ethyl orthosilicate into the above solution, stirred at 60°C for 20h, then transferred the resulting solution to a polytetrafluoroethylene-lined reactor, crystallized at 120°C for 20h, then filtered and washed 4 times with deionized water, Then perform suction filtration and drying to obtain the raw powder of the mesoporous material; wash the raw powder of the mesoporous material with ethanol under reflux conditions for 24 hours, remove the template agent, and obtain spherical mesoporous silica C2.

[0079] (2) Preparation of propane dehydrogenation catalyst

[0080] 0.08g H 2 PtCl 6 ·6H 2 O, 0.207g SnCl 4 ·5H 2 O and 0.185g NaNO 3 Di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com