System and method for preparing bionic super-hydrophobic metal surface through laser-electrochemical deposition

A metal surface and electrochemical technology, applied in the direction of electrochemical processing equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of poor thermal and mechanical stability, affecting the inherent properties of metal materials, and being vulnerable to damage, etc., to achieve Good thermal and mechanical stability, controllable shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Taking the copper substrate as an example below, that is, the material of the substrate 4 is copper, illustrating the implementation process of a system and method for preparing a bionic superhydrophobic metal surface by laser-electrochemical deposition of the present invention, including the following steps:

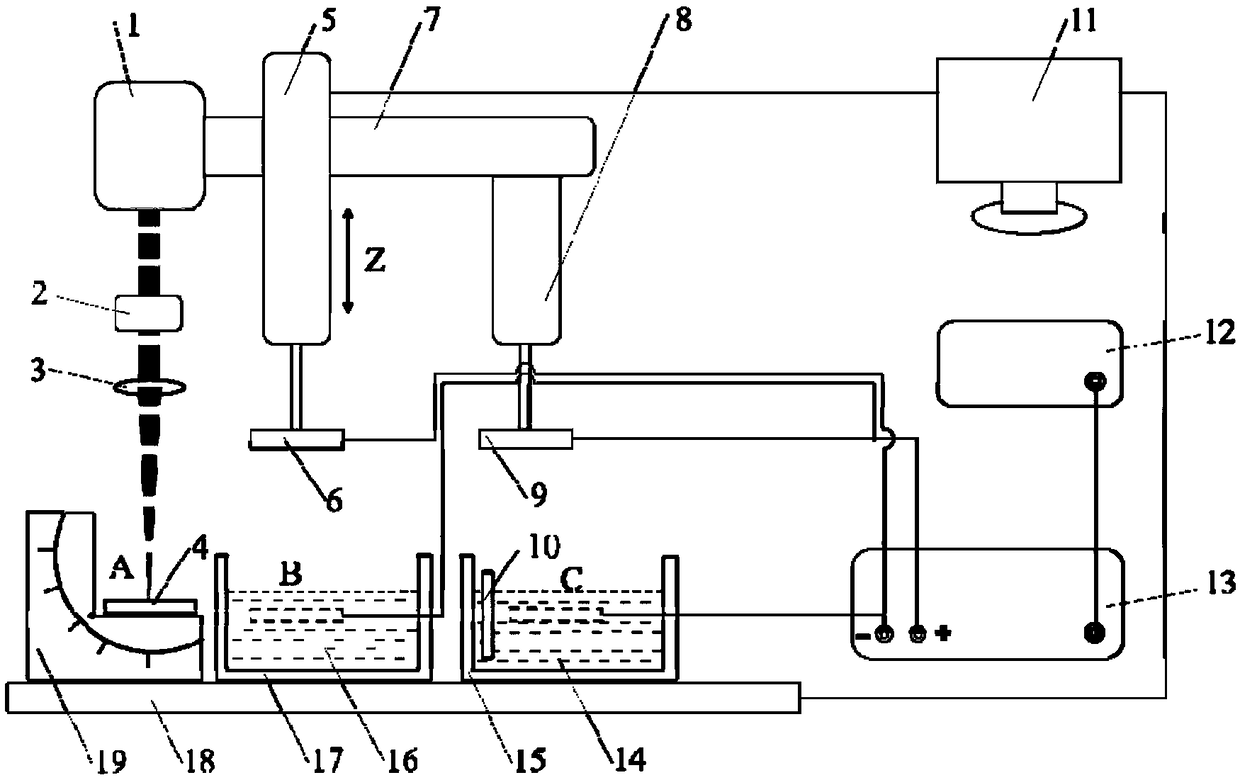

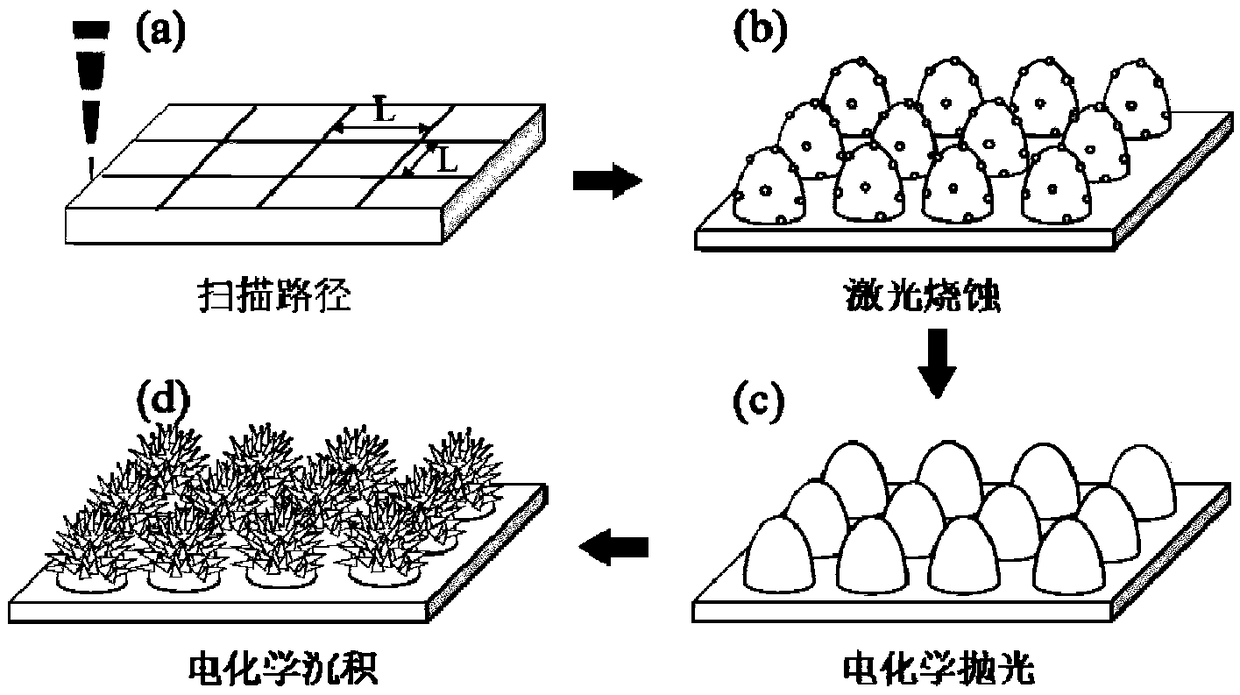

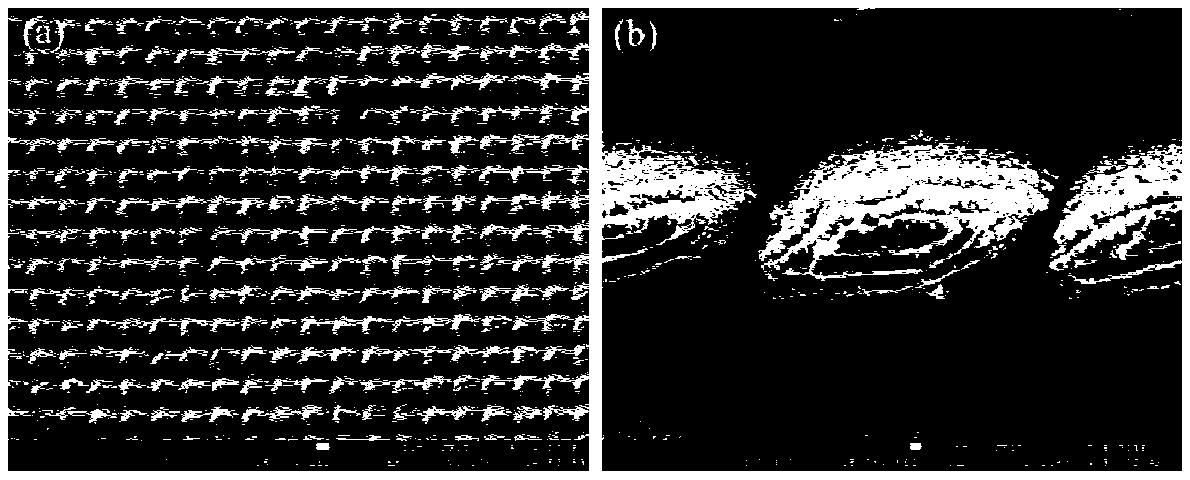

[0072] (1) build as figure 1The picosecond laser ablation, electrochemical polishing, and electrochemical deposition processing system shown; wherein, the picosecond laser ablation part includes a picosecond laser 1, x-y scanning galvanometer 2, F-θ focusing lens 3, substrate 4 and can Angle adjustment gauge 19; the base plate 4 is placed on the adjustable angle gauge 19, and the angle of the adjustable angle gauge 19 is adjusted to be 0°, namely figure 1 In the middle A position, the adjustable angle gauge 19 is placed on the x-y workbench 18. The pulsed laser with a wavelength of 1064nm, a pulse duration of 13ps, and a spot diameter of 20μm is generated by a p...

Embodiment 2

[0078] An implementation process of a system and method for preparing a biomimetic superhydrophobic metal surface by laser-electrochemical deposition, the steps are as follows:

[0079] (1) Build a picosecond laser ablation, electrochemical polishing, and electrochemical deposition processing system as shown in the figure; wherein, the picosecond laser ablation part includes picosecond laser 1, x-y scanning galvanometer 2, and F-θ focusing lens 3. The substrate 4 and the adjustable angle gauge 19; the substrate 4 is placed on the adjustable angle gauge 19, and the angle of the adjustable angle gauge 19 is adjusted to be 5°, namely figure 1 In the middle A position, the adjustable angle gauge 19 is placed on the x-y workbench 18. The pulsed laser with a wavelength of 1064nm, a pulse duration of 13ps, and a spot diameter of 20μm is generated by a picosecond laser 1, and the scanning path is determined by the x-y scanning galvanometer 2, and then focused by the F-θ focusing lens ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com